Abstract

The effects of nanoparticle additions, rolling, and sintering time on the transport critical current density, Jc, of Ag-sheathed Bi1.6Pb0.4Sr2Ca2Cu3O10 (Bi-2223) are reported. Nanosized PbO (20–30 nm) with 0.05 wt. % and MgO (20 nm) with 0.1 wt. % were added to Bi-2223 superconductor powders. The powders were packed into Ag tubes and deformed into tapes by drawing, sintering, and rolling steps. The Jc with two sintering time (100 h and 150 h) and two rolling processes was measured using the four-probe method between 30 and 77 K in self-field, and at 77 K in magnetic fields from 0 and 0.75 T. The effect of nanosized PbO and MgO and processing on the microstructure, phase, and Jc were examined. The effects of rolling versus no rolling on Jc were also compared. PbO-added tapes showed a higher Jc compared with MgO-added tapes which indicated that PbO enhanced the flux pinning capability more than MgO. Jc of PbO-added tapes obtained in the first rolling and sintered for 100 h was 28000 A/cm2 and 6000 A/cm2 at 30 K and 77 K, respectively. Jc of MgO-added tapes in the first rolling and sintered for 100 h was 17500 A/cm2 and 1500 A/cm2 at 30 K and 77 K, respectively. Intermediate rolling introduced more cracks than can be healed in the subsequent heat treatment. In the second rolling, the tapes developed more cracks, voids, and loose microstructure where the grains were not well connected. These results showed that further sintering time increased Jc, but further rolling decreased Jc of the PbO- and MgO-added Bi-2223 tapes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A high transport critical current density, Jc, in Bi1.6Pb0.4Sr2Ca2Cu3O10 (Bi-2223) superconductor is important for practical applications. The Bi-2223 sheathed Ag (Bi-2223/Ag tapes) prepared by the powder-in-tube method is the simplest technique for long wires and tapes fabrication. Magnetic fields and elevated temperatures strongly suppress Jc due to the motion of the vortex lattice and the weak links of grain boundaries. Many methods have been proposed to improve Jc in superconductor tapes such as chemical additions [1,2,3], heat treatment [4], rolling [5], hot and cold pressing [6, 7], and the magnetic grain alignment technique [8].

The mechanical deformation procedure in preparing the tapes has a large effect where the final Jc is higher in the pressed tape than that in rolled tape [9, 10]. Moreover, during the mechanical deformation process, many cracks were observed, and the grains are not well connected. The pressed tapes at lower pressures and repeated rolling showed a low Jc due to the formation of cracks and pores in the core of the Bi-2223/Ag superconductor tapes [7, 11]. Despite several studies, crack formation that suppresses Jc and mechanical deformation process still remain a problem. The influence of uniaxial pressing on Jc of Bi-2223/Ag tapes has been reported. However, very few studies have examined rolling effects on Jc of nanoparticle-added Bi-2223/Ag tapes. Further investigation on the effects of crack formation and densification is needed to enhance Jc.

Artificial flux pinning centers such as nanoparticles can be used to pin the vortex cores, heal the cracks, and increase Jc of the Bi-based superconductors [12,13,14]. The addition of nanoparticles may increase the strength of Bi-2223/Ag tapes and provides higher resistance to crack and helps to heal the crack. For example, a further rolling (2nd rolling) and sintering (150 h) increased Jc of nanosized Bi2O3 (150 nm)–added Bi-2223/Ag tapes [5]. The effect of PbO (20–30 nm) [15] and MgO (20 nm) [16] in addition to Bi-2223/Ag tapes has been reported in our earlier studies. The effects of sintering times for 50 h and 100 h without intermediate rolling on Jc between 30 and 77 K and in applied magnetic field at 77 K were investigated. Jc increased significantly especially for nanosized PbO as compared to the non-added and nanosized MgO-added tapes. Our initial studies on PbO- and MgO-added tapes suggested that a longer sintering time and other parameters are important to enhance Jc. The enhancement of flux pinning and improved microstructure due to two-step sintering (50 and 100 h) without intermediate rolling of PbO- and MgO-added tapes led to increase in Jc.

It will be interesting to investigate the combined effect of artificial flux pinning centers by adding PbO and MgO nanoparticles and deformation method through intermediate rolling on crack formation and Jc of Bi-2223 sheathed Ag tapes. This study aims to investigate and compare the influence of two-step rolling and sintering at 100 and 150 h on phase formation, microstructure, crack, and Jc of PbO and MgO nanoparticle–added tapes. X-ray diffraction method was used to confirm the phase and scanning electron microscope was used to determine the microstructure. The transport critical current density was measured using the four-probe method by employing the 1 µV/cm criterion.

2 Experimental Details

Our initial work on nanosized PbO (20–30) and MgO (20 nm)–added Bi1.6Pb0.4Sr2Ca2Cu3O10(MO)x (M = Pb or Mg) pellets showed the highest Jc for the x = 0.05 and 0.10 wt. % samples, respectively. These amounts were selected to prepare nanosized PbO- and MgO-added Bi-2223/Ag tapes (nano-T) by the powder-in-tube method [15, 18]. The co-precipitation method was used to prepare ultrafine Bi1.6Pb0.4Sr2Ca2Cu3O10 superconductor powders as described elsewhere [17]. Nanosized PbO or MgO were added to the Bi-2223 powders which were then packed into Ag tubes with 99.9% purity (from Alfa Aesar). The inner diameter of the tube was 4.35 mm and outer diameter was 6.35 mm. The Ag tube filled with the superconductor powders was drawn to produce a l-mm diameter wire. The wire was rolled to produce tapes with 1.5-mm width and 0.30-mm thickness which were then cut into 2- to 3-cm sections. The PbO- and MgO-added tapes were sintered for 100 h (T100) and 150 h (T150) at 845 °C, followed by two-step intermediate rolling (R1 and R2) as follows: the tapes were sintered at 845 °C for 50 h (T50) and then rolled (T50R1). The T50R1 tape was subjected to further heating at 845 °C for another 50 h to produce tapes sintered for 100 h with the first roll (PbO-T100R1 and MgO-T100R1). Part of the T100R1 tapes was subjected to further rolling (R2) and then sintering at 845 °C for another 50 h to produce tapes sintered for a total of 150 h with the second rolling (PbO-T150R2 and MgO-T150R2).

The Jc of the added tapes was measured by using the four-probe method with the 1 μV/cm criterion between 30 and 77 K in self-field, and at 77 K in 0 to 0.75 T magnetic fields. A Zeiss VPSEM (Leo 1450) was used to examine the microstructural change and measure the superconductor core cross-section of the tapes. A Siemens D5000 diffractometer with CuKα source ( λ= 1.54 Å) was used to determine the resultant crystalline phases.

3 Results and Discussion

In a previous study, the nanoparticle-added tapes were sintered for 50 h (nano-T50) and 100 h (nano-T100) at 845 °C without intermediate rolling. The results showed that Jc of the added tapes improved significantly compared with the pellets and non-added tapes. Also, nano-T100 tapes showed a higher Jc as a function of temperature and magnetic fields compared to nano-T50 tapes. Moreover, PbO-T100 tapes showed the highest Jc (26,800 A/cm2 at 40 K and 10,700 A/cm2 at 77 K) compared with MgO-T100 tapes (18,380 A/cm2 at 30 K and 3676 A/cm2 at 77 K). Herein, nanosized PbO and MgO were added to Bi-2223/Ag tapes. The influence of intermediate rolling (R1 and R2) with two sintering times 100 h and 150 h on crack formation and transport critical current density of the tapes was investigated and compared.

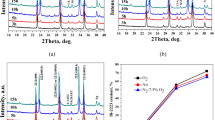

The XRD patterns of MgO-added tapes sintered for 100 h with the first roll (MgO-T100R1) and PbO-added tapes sintered for 150 h with the second roll (PbO-T150R2) are shown in Fig. 1. Both nano-T100R1 and nano-T150R2 tapes showed the Bi-2223 (high-Tc) as the major phase and a few peaks belonging to the (Bi,Pb)2Sr2CaCu2O8 (Bi-2212) phase (low-Tc). The Bi-2223 peaks are indicated by H and the Bi-2212 peaks are indicated by L in Fig. 1. A high intensity peak belonging to silver sheath was observed. A minor Ca2PbO4 peak was also observed.

The volume fraction of Bi-2223 \({(V}_{2223 })\) and Bi-2212 \({(V}_{2212})\) phase was obtained from XRD intensities of the phases, i.e., the Bi-2223 phase (I2223) and Bi-2212 (I2212) phase, using the relation \({V}_{2223\; or\; 2212}=\frac{\sum ({I}_{2223}{\; or\; I}_{2212})}{(\sum {I}_{2223}{+ \sum I}_{2212})}\times 100\) [19]. The volume fraction for the two-step rolling showed a dominant Bi-2223 phase (Table 1). In the first roll, PbO-added tape showed the highest volume fraction of the Bi-2223 phase (76%) and 24% for the low-Tc phase. However, MgO-added tapes showed a decrease in V2223 and an increase in V2212.

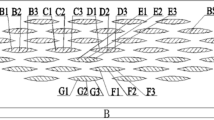

The cross-section SEM images of nanoparticle-added tapes with two sintering and two rolling are shown in Fig. 2. Figure 2a and b show the cross-section SEM of the PbO-added tapes heated for 100 h with the first roll (PbO-T100R1) and 150 h with the second roll (PbO-T150R2), respectively. MgO-added tapes sintered for 100 h with the first roll (MgO-T100R1) and 150 h with the second roll (MgO-T150R2) are shown in Fig. 2c and d, respectively. In both added tapes, rolling reduced the tape thickness. The cross-sectional area of the nanoparticle-added Bi-2223 superconducting core in the tapes rolled twice decreased by around 25% compared to that of the first roll tapes. Figure 3 shows SEM micrographs of the nanoparticle-added Bi-2223 superconducting core. Figure 3a shows SEM of PbO-T100R1 and Fig. 3b shows SEM of PbO-T150R2 tapes. Surface SEM micrographs of MgO-T100R1 and MgO-T150R2 core are shown in Fig. 3c and d, respectively. The plate-like microstructure (typical of the Bi-2223 phase) was observed in all tapes. The core of nanoparticle-added Bi-2223 tapes exhibited loose microstructure, cracks, and voids. The cracks were more clearly seen in the second roll compared with the first roll. A larger plate-like structure was observed in both nanoparticle-added tapes sintered for 150 h (nano-T150R2). The microstructure destruction due the cold deformation led to the decrease in Jc [11].

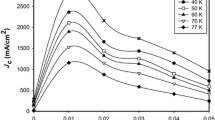

Figure 4 and Table 1 show Jc versus temperature of the nano-T100R1 and nano-T150R2 tapes. Jc of non-added tape (pure-T50) is included in Fig. 4 for comparison. In both rolling, Jc decreased as the temperature was increased from 30 to 77 K. Jc of the second roll tapes (nano-T150R2) was lower than that of the first roll tapes (nano-T100R1). Both PbO-added tapes with the first and second roll resulted in a higher Jc compared with the MgO-added tapes. The highest Jc of 28,000 Acm−2 and 6000 Acm−2 at 30 and 77 K, respectively, was observed for the PbO-T100R1 tapes. Nanosized PbO is a more effective flux pinning center compared with MgO. A second rolling and sintering (150 h) decreased Jc of PbO-T150R2 tapes to 25,000 Acm−2 and 1600 Acm−2 at 30 and 77 K, respectively. Similar behavior was observed for Jc of MgO-added tapes. Jc of MgO-T100R1 was 17,500 Acm−2 and 1500 Acm−2 at 30 and 77 K, respectively. The lower Jc in nanosized PbO-T150R2 and MgO-T150R2 tapes was probably due to the extra rolling which caused increase in cracks [20, 21] as seen from Fig. 2.

Figures 4 and 5 and Table 2 show Jc of nanosized PbO-T100R1 and MgO-T100R1 tapes versus temperature from 30 to 77 K, and their comparison with our previous studies of non-added and MgO- and PbO-added tapes sintered for 50 and 100 h without intermediate rolling. A small amount of nanosized PbO (0.05 wt.%) and a higher amount of MgO (0.1 wt.%) optimized Jc of Bi-2223 pellets and tapes in comparison with the non-added samples. Nanosized PbO-added tapes showed a larger enhancement compared with MgO-added tapes. This can be due to better flux pinning in PbO-added tapes. A longer sintering time from 100 to 150 h together with second rolling decreased Jc due to the increase in the pores and cracks although the cross-section area was reduced by 25%. However, a longer sintering time from 50 to 100 h without intermediate rolling increased Jc of tapes due to better grain connectivity. In general, the Jc of nano-T100R1 and nano-T150R2 tapes was lower than that of nano-T100 tapes. A further intermediate rolling increased crack formation in the tapes’ superconductor core.

Figure 6 shows the Jc versus magnetic fields of nanosized PbO-T100R1, PbO-T150R2, MgO-T100R1, and MgO-T150R2 tapes at 77 K. The magnetic fields from 0 and 0.75 T were applied parallel to the tapes’ surface. Jc of added tapes decreased with increasing magnetic fields. For both PbO and MgO addition, the first roll tapes showed a higher Jc in magnetic fields compared with the second roll tapes. The second rolling increased the cracks in the superconducting core. Jc of tapes deteriorates in the rolling direction due to the poor Bi-2223 microstructure [21]. Similar to Fig. 3, it can be observed from Fig. 6 that PbO-added tapes with the first roll and sintering for 100 h showed the highest Jc in magnetic fields. This showed that addition of nanosized PbO resulted in better flux pining than MgO-added tapes. Nanosized PbO can also heal the cracks formed during rolling which enhanced grain coupling. The interface debonding between Ag and Bi-2223 superconducting core and cracks in the superconducting tapes cause weak links and thus reduce Jc [20]. A recent work showed that the current density, Io, of non-added Bi-2223/Ag tapes is dependent on the angle of the applied field with respect to the tapes’ surface. Io was found highest when the field was parallel and lowest when the field was perpendicular to the tapes’ surface [22]. Hence, further works on angle dependent of current density to applied magnetic field are suggested for further investigation.

4 Conclusions

Nanosized PbO- and MgO-added Bi-2223/Ag tapes were subjected to heat treatment for 100 and 150 h at 845 °C with two intermediate rolling. The combined effects of artificial flux pinning centers by adding nanoparticles (PbO and MgO) and the deformation procedure by intermediate rolling on the crack formation and Jc of Bi-2223 tapes were investigated. Jc of nanosized PbO-added tapes was higher than the non-added and nanosized MgO-added tapes. Although longer sintering time is generally beneficial in increasing the Jc, the effect of further rolling and sintering time led to a decrease in Jc. This decrease may be due to formation of cracks which affected the supercurrent flow path. Nanoparticle addition, number of rolling, and sintering time are important variables to optimize the transport critical current density. The effects of different intermediate pressing and sintering processes on cracks and Jc of other nanoparticle in Bi-2223/Ag tape are suggested for future works.

References

Skov-Hansen, P., Koblischka, M.R., Vase, P., Kovac, P., Marti, F.: IEEE Trans. Appl. Supercond. 11, 3740 (2001)

Siregar, D.R.D., Yudanto, S.D., Chandra, S.A., Lubis, E.F.R., Humaidi, S., Darsono, N.: Mater. Minerals. 31, 76 (2021)

Lu, X.Y., Yi, D., Nagata, A.: J. Phys. Conf. Ser. 1590, 012028 (2020)

Zhang, P.X., Zhou, L., Li, C., Liu, F., Jiang, B., Zheng, H.L., Yu, Y., Feng, Z.M.: Physica C. 412, 1120 (2004)

Yahya, N.A.A., Al-Sharabi, A., Suib, N.R.M., Chiu, W.: R. Abd-Shukor. Ceram. Int. 42, 18347 (2016)

Togano, K., Gao, Z., Matsumoto, A., Kumakura, H.: Supercond. Sci. Technol. 26, 115007 (2013)

Balachandran, U., Iyer, A., Youngdahl, C., Motowidlo, L., Hoehn, J., Haldar, P.: In Adv. Cryogenic Eng. Mater. Springer. 289, (1994)

Takeda, Y., Iwami, T., Saito, Y., Motoki, T., Shimoyama, J.I.: Physica C. 584, 1353873 (2021)

Grasso, G., Jeremie, A., Flukiger, R.: Supercond. Sci. Technol. 8, 827 (1995)

Parrell, J.A., Polyanskii, A.A., Pashitski, A.E., Larbalestier, D.C.: Supercond. Sci. Technol. 9, 393 (1996)

Lee, M.H., Park, H.S., Lee, H.G., Hong, G.W.: In Adv. Supercond. Springer, X. 803, (1998)

Masnita, M.J., Awang, R., Abd-Shukor, R.: Sains Malaysiana. 51, 315 (2022)

Nurbaisyatul, E.S., Azhan, H., Ibrahim, N. Saipuddin, S.F.: Cryogenics. 119, 103353 (2021)

Fallah-Arani, H., Sedghi, A., Baghshahi, S., Tehrani, F.S., Moakhar, R.S., Riahi-Noori, N., Nodoushana, N.J.: J. Alloys Compd. 900, 163201 (2022)

Yahya, N.A.A., Abd-Shukor, R.: Ceram. Int. 40, 5197 (2014)

Yahya, N.A.A., Abd-Shukor, R.: Adv. Condens. Matter Phys. 2013, 821073 (2013)

Yahya, N.A.A., Abd-Shukor, R.: Int. J. Electrochem. Sci. 14, 11509 (2019)

Yahya, N.A.A., Abd-Shukor, R.: J. Supercond. Novel Magn. 27, 329 (2014)

Masnita, M.J., Abd-Shukor, R.: Results Phys. 17, 103177 (2020)

Singh, J.P., Joo, J., Vasanthamohan, N., Poeppel, R.B.: J. Mater. Res. 8, 2458 (1993)

Lee, H.G., Kim, W.J., Hong, G.W., Lee, M.H., Park, H.S.: Physica C. 297, 124 (1998)

Yang, T., Li, W., Xin, Y., Chen, X., Yang, C., Tang, C., Lu, J.: Physica C. 1582, 1353825 (2021)

Acknowledgements

Nabil A. A. Yahya and Ahmed Abdulrab Ali Ebrahim wish to thank the Scholar Rescue Fund, Institute of International Education (IIE-SRF), New York, USA, for the support.

Funding

This work was also supported by Thamar University, Thamar, Yemen; The Ministry of Higher Education, Malaysia (FRGS/1/2020/STG07/UKM/01/1); and American University in Cairo, Egypt.

Author information

Authors and Affiliations

Contributions

Nabil A. A. Yahya prepared the superconductor tapes, performed the characterizations, and analyzed the data. Ahmed Abdulrab Ali Ebrahim and Mohamad A. Swillam performed the characterizations and initial data analysis. R. Abd-Shukor designed the experiment, analyzed the data, and wrote the paper.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yahya, N.A.A., Ebrahim, A.A.A., Swillam, M.A. et al. Effects of Nanosized PbO and MgO, Rolling, and Sintering Time on Crack and Current Density of Bi1.6Pb0.4Sr2Ca2Cu3O10/Ag Superconductor Tapes. J Supercond Nov Magn 35, 2293–2300 (2022). https://doi.org/10.1007/s10948-022-06231-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-022-06231-7