Abstract

The effect of nanosized CoFe2O4 (60 nm) addition on the transport critical current density, J c, of (Bi1.6Pb0.4)Sr2Ca2Cu3O10(CoFe2O4) x (x = 0–0.05 wt%) superconductor prepared by the co-precipitation method was investigated. The optimal J c (measured using the four-point probe method) was observed in the x = 0.01 wt% pellets. Using this optimal wt%, Ag-sheathed (Bi1.6Pb0.4)Sr2Ca2Cu3O10(CoFe2O4)0.01 superconductor tapes were fabricated using the powder-in-tube method. The tapes were sintered for 50 and 100 h at 845 °C. The phase and microstructure of the samples were determined using the powder X-ray diffraction method and scanning electron microscopy, respectively. The temperature dependence of J c for the tapes in various applied magnetic fields was also measured. J c of (Bi1.6Pb0.4)Sr2Ca2Cu3O10(CoFe2O4)0.01/Ag tapes sintered for 100 h was 22,420 A/cm2 at 30 K. The non-added tapes sintered for 100 h showed a much lower J c (8280 A/cm2 at 30 K). This study showed that addition of CoFe2O4 nanoparticles enhanced the transport critical current density in the (Bi1.6Pb0.4)Sr2Ca2Cu3O10 superconductor tapes. This result is consistent with the previous calculations on frozen flux superconductor in a nanomagnet–superconductor hybrid system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Bi1.4Pb0.6Sr2Ca2Cu3O10+δ (Bi-2223) high-temperature superconductor has great potentials to be developed for energy applications. However, the flux pinning capability and intergrain connectivity need to be improved in order to overcome the rapid decrease in the transport critical current density, J c, at high temperatures and in magnetic fields [1, 2].

Nanoparticles have been added to Bi-2223 superconductor to act as pinning centers in order to improve flux pinning ability [3–6]. Nanosized Al2O3 (50 nm) improved J c of Bi-2223 pellets by 30 % with 0.2 wt% addition [4]. It also improved the J c in applied magnetic fields. Ag2CO3 addition increases the critical current density of Bi-2223 pellets by more than three times with 25 wt% addition [6].

Nanoparticles with size larger than the coherence length, ξ, and smaller than penetration depth, λ, have been suggested to increase J c [7]. However, other studies showed that the optimum size of pinning centers should be comparable to λ rather than ξ [8]. The coherence length of Bi-2223 is around 2.9 nm, and the penetration depth is between 60 and 1000 nm [9]. Stronger interaction between the nanoparticles and flux lines leading to higher J c can be expected for nanoparticles with size d, where ξ < d < λ [10].

The average size of CoFe2O4 nanoparticles employed in this study was 60 nm. CoFe2O4 was selected in this study because the average size is comparable with the penetration depth of Bi-2223 which is within the range required in the frozen flux model as discussed in [10] where enhanced flux pinning can be expected. The frozen flux model also requires magnetic nanoparticles as the pinning center; hence, CoFe2O4 was chosen to enhance J c in the Bi-2223 tapes. CoFe2O4 nanoparticles have spinel crystal structure, and the Néel temperature varies depending on the nanoparticle size ranging from 709 K (8 nm) to 809 K (92 nm) [11]. In this paper, we report the effect of CoFe2O4 on the transport critical current density, phase formation and microstructure of Ag-sheathed Bi-2223 tapes.

2 Experimental details

Bi1.4Pb0.6Sr2Ca2Cu3O10 (CoFe2O4) x (x = 0.00–0.05 wt%) pellets with nanosized CoFe2O4 addition (from Inframat Advanced Materials, 99.9 % purity) were prepared. The Bi-2223 powders were prepared using the acetate co-precipitation method [12]. The mixed powders were ground and pressed into pellets and sintered at 845 °C for 48 h. The sample with x = 0.01 wt% CoFe2O4 addition showed the highest J c at 77 K. This composition was chosen to fabricate Ag-sheathed Bi-2223 tapes by the powder-in-tube method. Tapes without the addition of CoFe2O4 were also prepared for comparison. (Bi1.6Pb0.4)Sr2Ca2Cu3O10 powders prepared by the co-precipitation method were added with 0.01 wt% nanosized CoFe2O4 before being packed into a 6.35-mm-outer diameter and 4.35-mm-inner diameter Ag tube (Alfa Aesar, 99.9 %). The tube was drawn to a 1-mm wire and then pressed into 0.12-mm-thick and 1.35-mm-wide tapes. The tapes were then cut into 2–3 cm sections and sintered for 50 and 100 h at 845 °C.

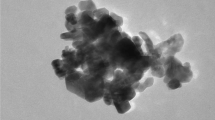

The phase of the samples was examined by X-ray powder diffraction (XRD) using a Bruker D8 Advance diffractometer with CuKα radiation. The microstructure of the tapes was examined using a Philips XL 30 scanning electron microscope (SEM). The distribution of CoFe2O4 in the tapes was determined using the energy-dispersive X-ray spectroscopy (EDX). A transmission electron microscope (TEM) using Philips model CM12 was used to confirm the average size of CoFe2O4 nanoparticles. The four-point probe method using the 1 V/cm criterion was used to determine J c. The measurements were taken from 30 to 77 K in zero magnetic fields, and at 77 K under magnetic fields applied from 0 to 0.75 T.

3 Results and discussion

Figure 1 shows the J c of Bi1.4Pb0.6Sr2Ca2Cu3O10 (CoFe2O4) x (x = 0.00–0.05 wt%) pellet between 30 and 77 K. The sample with x = 0.01 wt% of nanosized CoFe2O4 showed the highest J c which was 2.85 A/cm2 at 30 K and 1.15 A/cm2 at 77 K. Therefore, this wt% of CoFe2O4 was used to prepare Bi1.4Pb0.6Sr2Ca2Cu3O10 (CoFe2O4)0.01/Ag tape.

The onset transition temperature T c onset of the tapes with and without CoFe2O4 is around 110 K, and the zero resistance temperature T c zero is 78 K. Figure 2 shows the temperature dependence of resistance for CoFe2O4-added tape sintered for 100 h. The presence of Bi-2212 phase has resulted in a lower T c zero in the samples. The I–V curve for the same tape at 30 K is shown in Fig. 3.

The XRD pattern of the non-added tape is shown in Fig. 4a. Figure 4b shows the patterns for x = 0.01 wt% CoFe2O4-added tapes heated for 50 h, and Fig. 4c shows the pattern for x = 0.01 wt% CoFe2O4-added tapes heated for 100 h. Majority of the peaks in both non-added and nanosized CoFe2O4-added tapes correspond to the high-T c Bi-2223 phase (H). A small number of peaks correspond to the low-T c Bi-2212 phase (L) were also observed. The volume fraction of Bi-2223 phase was determined by

where \(\sum I_{2223}\) and \(\sum I_{2212}\) are the sum of intensities of Bi-2223 and Bi-2212 phases, respectively [13, 14]. The tape sintered at 100 h showed the highest volume fraction of Bi-2223 (Table 1). No Bi-2201 peaks were observed.

TEM micrograph showed that the average grain size of CoFe2O4 nanoparticles used in this study was about 60 nm (Fig. 5a). This size is larger than the coherence length, ξ, and comparable to the penetration depth, λ, of Bi-2223. SEM micrographs of the non-added and CoFe2O4-added tape surface exhibited plate-like layered microstructure, which is the typical microstructure of Bi-2223 system (Figs. 5b–d). The tapes added with CoFe2O4 sintered for 100 h showed a slightly longer plate compared with the tape sintered for 50 h.

Figure 6 and Table 1 show the temperature dependence of J c in zero magnetic fields for non-added and CoFe2O4-added tapes sintered for 50 and 100 h. The tapes with CoFe2O4 sintered for 50 and 100 h showed much higher J c compared with the non-added tapes. A slight increase in J c was also observed in tapes sintered for 100 h compared with tapes sintered for 50 h. This could be due to improvement in grains connectivity with longer sintering times as seen from the longer plates in the CoFe2O4-added tapes sintered for 100 h. A higher J c (22,420 A/cm2 at 30 K and 4520 A/cm2 at 77 K) was observed for tape sintered for 100 h. This value is lower compared with previous report on Ag-sheathed Bi-2223 tapes with addition of nanosized PbO sintered for 100 h (26,800 A/cm2 and 10,700 A/cm2 at 30 and 77 K, respectively) [15]. The higher J c in the nanosized PbO-added sample may be due to the combined effect of enhanced flux pinning and improved microstructure that led to the significant enhancement as discussed in Ref. [15]. The improvement in microstructure is due to the relatively lower melting point of PbO.

J c increased with a decrease in the volume fraction of the Bi-2212 phase. The presence of the Bi-2212 phase as an impurity in the Bi-2223 tapes resulted in the lowering of the zero resistance transition temperature and hence the suppression of the critical current density (Table 1).

Many applications of superconductor operate at very low fields [16]. In this work, we also studied the effect of low fields on the J c of the tapes. Figure 7 shows J c of the non-added and CoFe2O4-added tapes at 77 K under magnetic field applied parallel and perpendicular to the surface of the tape. J c of CoFe2O4-added tapes sintered for 50 and 100 h was higher than the non-added tapes under applied magnetic fields. A decrease in J c was observed under higher magnetic field strength due to the destruction of weak links in higher magnetic fields [11].

A comparison with other nanosized particle addition is shown in Table 2. A lower optimal amount (wt%) to optimize J c was observed when the tapes are added with magnetic nanoparticles. The optimal amount of CoFe2O4 addition in this study (0.01 wt%) is similar to that of the γ-Fe2O3-, Fe3O4-, NiFe2O4- and NiO-added tapes [17–20]. For PbO- [15] and MgO [21]-added tapes, the optimal amount is x = 0.1 wt%. This indicated different pinning mechanisms for enhancing J c in tapes added with magnetic and non-magnetic nanoparticles.

Samples in the pellet form also showed improvement in J c as the samples were added with Al2O3 [4], Ag2CO3 [6], Nb2O5 [22] and CoFe2O4 (Table 2). Some differences in the J c values reported by different groups may be due to the different preparation method that resulted in varied microstructure and other properties that affect the transport current. These results showed that suitable particles can be used to enhance the current density in the samples. However, J c in the tape samples was much higher than the pellet samples as a result of the thermomechanical pressing of the tapes. Tapes added with smaller nanosized PbO (10–30 nm) and Fe3O4 (40 nm) showed higher J c than the larger CoFe2O4 (60 nm)-added sample.

4 Conclusion

J c of CoFe2O4-added Ag-sheathed Bi-2223 tapes sintered for 50 and 100 h improved significantly compared with non-added tapes. This showed that nanosized CoFe2O4 can act as effective pinning centers and enhanced the flux pinning capability of the tapes. Tapes sintered for 100 h showed a higher J c in comparison with tapes sintered for 50 h due to improvement in grains connectivity. Therefore, a much longer sintering time is suggested to improve the transport critical current density even further. A judicious amount of magnetic nanoparticles enhanced the transport critical current density in the Bi-2223 superconductor tapes. In addition to the condensation energy associated with their core, the full vortex magnetic energy due to magnetic nanosized CoFe2O4 can contribute to J c enhancement in Bi-2223 tapes.

References

D. Larbalestier, Science 274, 736 (1996)

D.J. Bishop, P.L. Gammel, D.A. Huse, C.A. Murray, Science 255, 165 (1992)

A. Ghattas, M. Annabi, M. Zouaoui, F.B. Azzouz, M.B. Salem, Physica C 468, 31 (1998)

A. Annabi, M. M’chirgui, F.B. Azzouz, M.B. Salem, Physica C 405, 25 (2004)

Z.Y. Jia, H. Tang, Z.Q. Yang, Y.T. Xing, Y.Z. Wang, G.W. Qiao, Physica C 337, 130 (2000)

I.H. Gul, F. Amin, A.Z. Abbasi, M. Anis-ur-Rehman, A. Maqsood, Physica C 449, 139 (2006)

U. Al-Khawaja, M. Benkraouda, I.M. Obaidat, S. Alneaimi, Physica C 442, 1 (2006)

N. Takezawa, K. Fukushima, Physica C 290, 31 (1997)

H.L. Anderson (ed.), A physicist’s desk reference, 2nd edn. (American Institute of Physics, New York, 1989), p. 118

I.F. Lyuksyutov, D.G. Naugle, Mod. Phys. Lett. B 1(13), 491 (1999)

N. Sivakumar, A. Narayanasamy, K. Shinoda, C.N. Chinnasamy, B. Jeyavedan, J.M. Greneche, J. Appl. Phys. 102, 013916 (2007)

M. Ismail, R. Abd-Shukor, I. Hamadneh, S.A. Halim, J. Mater. Sci. 39, 3517 (2004)

Q.Y. Yu, H.K. Liu, S.X. Dou, Physica C 250, 7 (1995)

R.K. Nkum, W.R. Datars, Supercond. Sci. Technol. 8, 822 (1995)

N.A.A. Yahya, R. Abd-Shukor, Ceram Int. 40, 5197 (2014)

E. Pardo, M. Vojenčiak, F. Gömöry, J. Šouc, Supercond. Sci. Technol 24, 065007 (2011)

K.T. Lau, S.Y. Yahya, R. Abd-Shukor, J. Appl. Phys. 99, 123904 (2006)

R. Abd-Shukor, W. Kong, J. Appl. Phys. 105, 07E311 (2009)

W. Kong, R. Abd-Shukor, J. Supercond. Nov. Magn. 23, 25 (2010)

A. Agail, R. Abd-Shukor, J. Supercond. Nov. Magn. 27, 1273 (2014)

N.A.A. Yahya, R. Abd-Shukor, Adv. Condens. Matter Phys. 82, 2013 (1073)

N. Ghazanfari, A. Kılıc, A. Gencer, H. Ozkan, Solid State Commun. 144, 210 (2007)

Acknowledgments

This research was supported by the Malaysian Ministry of Education under Grant No. FRGS/2/2013/SG02/UKM/01/1 and Universiti Kebangsaan Malaysia under Grant No. UKM-DPP-2014-055.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hafiz, M., Abd-Shukor, R. Transport critical current density of (Bi1.6Pb0.4)Sr2Ca2Cu3O10/Ag superconductor tapes with addition of nanosized CoFe2O4 . Appl. Phys. A 120, 1573–1578 (2015). https://doi.org/10.1007/s00339-015-9357-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-015-9357-z