Abstract

In this present work, we have focused on the effect of cobalt substitution in the nickel aluminate system. The aluminate samples were synthesized by the chemical precipitation method. The structural and optical properties of the NiAl2O4, CoAl2O4, and Ni0.5Co0.5Al2O4 samples were studied through X-ray diffraction and UV-DRS absorbance spectral analysis. The XRD pattern confirms the cubic phase with the space group of Fd-3 m through its analysis of the diffraction peaks. The UV absorption peaks around at 360, 480, 551, 580, and 621 nm extend the formation of NiAl2O4, CoAl2O4, and Ni0.5Co0.5Al2O4 system. The surface morphological images of the samples were scanned by using the scanning electron microscope. The room temperature magnetic nature of the aluminate samples was carried out using VSM, and the observed result reveals a weak ferromagnetic and super-paramagnetic nature for NiAl2O4 and Ni0.5Co0.5Al2O4, respectively. The temperature dependence impedance spectra and AC conductivity were measured using an impedance analyzer at selected temperatures, and that reveals the bulk resistance of the grain and the grain boundary region of the sample. The observed results were analyzed and discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The oxides of spinel aluminate systems were extensively studied due to their promising and fascinating physical and chemical properties. In comparison with other spinel aluminates, the Nickel aluminate (NiAl2O4) semiconductor materials have unique properties and play a crucial role for particular applications like a sensor, electronic, ceramic pigments, refractory materials, photocatalytic, etc. [1,2,3,4]. The physical and chemical properties of spinel aluminate depend on the synthesis technique as well as on the morphology [6]. The substitution or doping of transition metal ions in spinel aluminate systems such as NiAl2O4 and CoAl2O4 has shown an enhancement of optical properties, and these properties are utilized for variation dyes or color pigments of ceramic and pottery glazes. However, the Ni/Co aluminate system was synthesized by various methods such as mechanical activation (MA) of thermodynamically stable decagonal quasicrystalline alloy [7], microwave combustion method [8], sol-gel auto combustion method [9], and Al2O3-based Co-Ni alloy by a thermal explosion, etc. [10]. In addition, the review of the literature shows that a few researchers synthesized the Ni/Co-aluminate system by different routes and in comparison with other methods the chemical co-precipitation provides a unique nature of the samples.

There are numerous reports available on NiAl2O4 with substitution or doping with various types of transition metal ions like Cr, Zn, Mg, and Ca develop the properties of photocatalytic and transparent conducting oxides [10,11,13]. Among these, Co2+ substitution on nickel aluminate enhances the electrical properties, and it can be predictable as most suitable for optoelectronic device applications. However, only very few literature reports realizing the mechanism of electrical properties of temperature dependence like complex impedance and conductivity of NiAl2O4 [14] and Ni0.5Co0.5Al2O4 [7] samples.

In this manuscript, we report the nickel aluminate with substitution of Co2+ ions in it, which was synthesized by the chemical precipitation method. We have studied the structural and optical properties of samples at room temperature. Also, we measured and analyzed the complex impedance spectra at different temperatures, and the dispersive nature of AC conductivity at different temperatures for the Ni-Co aluminate system were analyzed and discussed.

2 Experimental

The raw materials with nitrate form of nickel (Ni (NO3)2.6H2O), cobalt (Co (NO3)2.6H2O), and aluminum (Al (NO3)3.9H2O) were used for synthesizing of the NiAl2O4, Ni0.5Co0.5Al2O4, and CoAl2O4 systems through chemical precipitation method [15]. The final products of dried samples were sintered at 900 °C in an open-air atmosphere for 3 h. Henceforth, the sintered samples were labeled as Ni-aluminate (NiAl2O4), Co-aluminate (CoAl2O4), and Ni-Co aluminate (Ni0.5Co0.5Al2O4), respectively.

The structural properties of samples were studied by using Bruker D2 Phaser X-ray diffractometer with Cu Kα line. The grain size and surface morphological properties of the sample were analyzed using high-resolution scanning electron microscopy (HR-SEM) images. The UV-visible absorbance spectra of the samples were recorded using a diffuse reflectance spectroscopy technique (Varian 5000). The room temperature magnetization (M-H curve) of the samples was measured using (Lakeshore 7410) vibrating sample magnetometer. The electrical properties of the samples were measured using an impedance analyzer (PSM1735 NumetriQ) in the frequency range between 10 Hz and 1 MHz over a selected temperature range from 473 K to 573 K with an excitation voltage of ∼ 1 V.

3 Results and Discussion

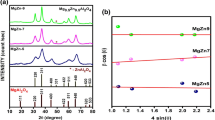

The powder X-ray diffraction pattern of NiAl2O4, CoAl2O4, and Ni0.5Co0.5Al2O4 samples were shown in Fig. 1(a). From the diffraction data, we confirm the formation of the single-crystalline phase of the spinel cubic system. All the diffracted peaks were indexed and compared with JCPDS # 65–3102 and JCPDS # 38–0814, and there were no other foreign impurity phases present. In addition, a finite diffraction peak shift was observed for (311) plane in Ni-Co aluminate at due to Co2+ occupation at the tetrahedral site as shown in the inset of Fig. 1(a). Also, the volume of the unit cell of Ni-Co aluminate was increased due to the Co2+ions occupation. From the W-H plot of Ni0.5Co0.5Al2O4 sample as shown in Fig. 1(b), the parameters such as the average crystallite size and the extent of micro-strain induced in lattice were calculated using

where D is the crystallite size of a particular sample, λ is the wavelength and is 1.540 Å, k = 0.94 is a constant, and β1/2 is the full width at half-maximum of the particular intensity of the peak. The peaks are fitted by using a Voigt function to get FWHM of peak position 2θ. The lattice parameters of the samples were calculated from their XRD data by using Nelson and Riley [16] equation.

From the above equations, the calculated values were tabulated in Table 1. From Table 1, we observed that the average crystalline size, micro-strain, and the lattice parameters of the Ni0.5Co0.5Al2O4 sample are lesser than that of NiAl2O4 and CoAl2O4 samples, which may be due to the ionic radii of exchanging cation reordering with spinel cubic phase (i.e., tetrahedral and octahedral sites).

The optical energy band gap values of the NiAl2O4, CoAl2O4, and Ni0.5Co0.5Al2O4 samples were calculated from the UV-Vis absorbance spectra which are recorded by utilizing UV-DRS technique, and the measured UV-Vis spectra were presented in Fig. 2(a). The strong absorption edge was observed around the UV-region for all the samples. The band gap energies were calculated by Tauc plot relation

where “α” is the absorption coefficient, “hv” is incident photon energy, “A” is constant and depends upon possible transition, and “n” is power coefficient of allowed transitions. Insignificance, if n = ½ then direct band gap transition is allowed and n = 2 an indirect band gap transition is allowed. The calculated value of direct band gap energies for nickel aluminate, cobalt aluminate, and Ni-Co aluminate are 3.27 eV, 3.02 eV, and 3.37 eV, respectively. Fig. 2(b) depicts the Tauc plot of Ni0.5Co0.5Al2O4 sample for the determination of optical band gap. The optical band gap of Ni0.5Co0.5Al2O4 sample is higher when compared with the values of the optical band gap of the other two spinel aluminate samples and which may be due to the combination of Ni-Co ions radii of aluminate system. In order to ascertain the observed result, the presence of both Ni2+ and Co2+ ions in the spectra and the other side absorbance peaks were fitted by Gaussian function. The fitted data discloses that the values of full width half maximum (FWHM) interrelated to peak intensity and peak position of the absorbance spectra.

From Fig. 2(c), the spectra have three shoulder peaks related to the tetrahedral site and were observed to be between 550 and 630 nm, and the first two peaks represent the Co2+ ions, and the third peak corresponds to Ni2+ ions at A-site coordinate positions [17]. Moreover, the additional peaks of Ni and Co are evidence of the Ni-Co aluminate system of absorbance spectra and the slight hump peak represent the Ni2+ ions in the region around ~ 350 nm, and Co2+ peaks were present at around ~ 480 nm. The peaks corresponding to Al3+ ions coordinate were existent at around between 200 and 300 nm and that represent sites of tetrahedral and octahedral coordinates of samples. The absorption band around at 580–630 nm is corresponding to Ni2+ at the tetrahedral site with the electronic transition of 3 T1 (F) → 3 T1 (p) and the Co2+ ion in the tetrahedral site only at triplet band process [9]. The triplet band ascribed to Jahn-Teller distortion of tetrahedral coordinate in the spinel structure.

The magnetizations (M-H curve) of Ni-Co aluminate samples were shown in Fig. 3. In the literature for the spinel aluminate system, the nature of magnetic properties for NiAl2O4 and CoAl2O4 shows a weak ferromagnetic in nature [18, 19]. However, the (Ni, Co) Al2O4 system is the weak ferromagnetic of nano-decagonal [20], super-paramagnetic of nanoparticles [8]. The inserted image in the M-H curve implies that magnetic interaction refers to the paramagnetic behavior of the sample. We observed that the narrow hysteresis loop of the M-H curve of Ni-Co aluminate sample indicates as super-paramagnetic nature and at ± 15 KOe with a saturation magnetization of 3.357 × 10−3 emu/g.

Room temperature M−H hysteresis curve of Ni0.5Co0.5Al2O4 sample

The surface morphological image of Ni0.5Co0.5Al2O4 sample was scanned by using a scanning electron microscope (SEM) at room temperature at different resolutions and were shown in Fig. 4. The SEM images show slight self-agglomerated, at 2 μm and irregular shapes of the sample with the resolution image of 500 nm, and it reveals the grain and grain boundary region of the sample. For the sintered Ni0.5Co0.5Al2O4 sample, from the XRD pattern and SEM image analyses, the crystallized sizes were found to be different and may be due to the fact that the XRD pattern relates to the average crystallite size of the sample (i.e., A collection of information from the whole part of the sample), and SEM image reveals grain and grain boundary of the sintered sample (i.e., by selection of image information from the particular area/size of the sample.)

The impedance spectra of the Ni0.5Co0.5Al2O4 sample was shown in Fig. 5(a)–5(d) at different temperatures. The impedance plot in the temperature region (473–513 K) as shown in Fig. 5(a) contributes an incomplete semicircular arc, and in the 533-573 K, a complete semicircular arc was seen. The sample bulk resistance depends upon the diameter of the semicircular arc. The diameter of the semicircle decreases as the temperature increases, which suggests that the samples are semiconductor in nature. [21]. While increasing the temperature of samples, the diameter of the semicircle arc decreases, and this variation of resistance with temperature depicts as a negative thermal coefficient of resistance (NTCR) [22].

The complex impedance form (Z*) has to be rewritten as a series and parallel combination of RC circuit as given below:

here, Re is the electrode resistance, (Rg) and (Rgb) is the grain and grain boundary resistances with the respective capacitance as (Cg) and (Cgb) of the sample. However, in the present case, CPE (constant phase element) is used instead of capacitance in the circuit. Figure 5(b)–5(d) represents the depressed semicircle arc which refers to a parallel R-CPE element that reveals the grain and grain boundary of the sample which was fitted by Z-view software. Figure 5(b)–5(d) shows that fitted data of impedance spectra at low-temperature part (473–513 K) contributes by the grain effect of the mid-frequency region, and the electrode effect or electrode interface effect contributes in the low-frequency region. The impedance spectra in the 533 K–573 K range reveal that the contribution of grain and grain boundary effect through semicircular arcs at the high-frequency and low-frequency regions, respectively. The presence of two semicircular arcs overlapped, and it exhibits the distinction in conduction mechanism. The results of the fitted parameters are tabulated in Table 2. The resistance values of grain and grain boundary of the samples were decreased with a gradual increase in the temperature, and it confirms the NTCR and a signature of the semiconducting behavior. The value of power factor (n) of CPE is less than unity, which indicates a non-Debye relaxation behavior of the sample [22].

The dispersion in the AC conductivity of Ni0.5Co0.5Al2O4 sample was shown in Fig. 6a. In all the measured temperature region within the applied frequency range, the frequency-dependent conductivity exhibit a power-law behavior. At the observed frequency-independent conductivity (σdc) at the low-frequency region, the conduction mechanism is elucidated by the jump relaxation model [23, 24]. The dispersion in AC conductivity spectra increases with increasing temperature. Furthermore, the temperature and frequency dependence is closely related to universal dielectric response and follows Jonscher’s power law.

where σ (ω) is the total conductivity, σdc is DC conductivity and temperature dependence, ω is the angular frequency, A is a coefficient, and “n” is that its magnitude of the frequency exponent is dependent on temperature. The power factor of “n” is playing a vital role in the hopping mechanisms’ process between the ions at A and B sites of the sample. The “n” is above unity that describes the translation motion with a sudden hopping the sites and the ‘n’ is below unity that describes the hopping process between the nearby sites. The fitted parameters of the AC conductivity of the sample are tabulated in Table 2. From the conductivity plot, we observed that there are two types of power-law function that was fitted (i) at the high-frequency region (n1) and (ii) at the low-frequency region (n2). From the fitted data, variation of “n” with frequency region and temperatures quite different were shown in Fig. 6(b). The variation of power factor “n” with different temperatures can be explained by the various type’s conduction hopping phenomena [7]. In the present case, within the measurement temperature range, a decreasing trend of “n” can be attributed to correlated barrier hopping (CBH). In the present work, the conductivity spectra of the samples were fitted in two regions. With increasing the frequency and temperature of the sample, the value of conductivity decreases. This type of behavior of the hopping process is explained by correlated barrier hopping (CBH) model. The potential barrier (the neighbor sites between charge carrier hopping) concludes the nature of the AC conductivity of the sample. It’s related to site spacing between the Al2+ and Al3+ ions and barrier height. The “n” and maximum barrier height Wm was n = 1-\( \frac{6{k}_BT}{W_m} \). The maximum potential barrier of Wm for the sample value is obtained to be 0.16 eV from the intercept of the slope of T vs. “n” [22]. From the temperature dependence AC and DC conductivity at a different frequency, the activation energy of the sample was calculated from the Arrhenius equation is σa.c.

where, σo is the pre-exponential factor, and E is the activation energy of the sample, Boltzmann’s constant with temperature (KBT). The plot of loge(σac) vs. 1000/T, as shown in Fig. 6(c), from the slope, the activation energy of NiCoAl2O4 is found to decrease with the increase in various frequencies ranging from 0.89 to 0.20 eV at frequency 1 kHz to 1 MHz.

4 Conclusion

The spinel aluminates NiAl2O4, NiCoAl2O4, and CoAl2O4 semiconductors were synthesized by using the co-precipitation technique. The structural and optical properties of the sample were studied through XRD and UV-DRS techniques. The single crystalline phase with cubic structure and the optical band gap energy was founded to be 3.37 eV, and it has significant enhancement in the absorbance behavior. The surface morphological images of the samples show the grain and the grain boundary nature of the particles. The nature of magnetization of the sample is found to be super-paramagnetic at RT for NiCoAl2O4. The temperature dependence impedance spectra reveal that there is a combination of the grain and grain boundary region at all measured temperature regions. Then, the conductivity spectra results were analyzed based on the correlated barrier hopping and reported.

References

Abaide, E.R., Anchieta, C.G., Foletto, V.S., Reinehr, B., Nunes, L.F., Kuhn, R.C., Mazutti, M.A., Foletto, E.L.: Production of copper and cobalt aluminate spinels and their application as supports for inulinase immobilization mater. Res. 18, 1062–1069 (2015)

Farhadi, S., Panahandehjoo, S.: Spinel-type zinc aluminate (ZnAl2O4) nanoparticles prepared by the co-precipitation method: A novel, green and recyclable heterogeneous catalyst for the acetylation of amines, alcohols and phenols under solvent-free conditions. Appl. Catal. A Gen. 382, 293–302 (2010)

Mazza, D., Delmastro, A., Ronchetti, S.: Co, Ni, cu aluminates supported on mullite precursors via a solid state reaction. J. Eur. Ceram. Soc. 20, 699–706 (2000)

Maddahfar, M., Ramezani, M., Sadeghi, M., Sobhani-Nasab, A.: NiAl2O4 nanoparticles synthesis and characterization through modify sol–gel method and its photo-catalyst application. J. Mater. Sci. Mater. Electron. 26, 7745–7750 (2015)

Koonsaeng, N., Laobuthee, A., Hasin, P.: Controllable synthesis of metallo-alkoxide precursor-derived nickel aluminate spinels using TEA-gel process and morphology-dependent reducibility. Mater. Chem. Phys. 182, 287–297 (2016)

Harshit, A., Yadav, T.P., Srivastava, O.N., M.A.: Shaz: Cation distribution in nanocrystalline (co, Ni) Al2O4 spinel. Ceram. Int. 43, 16986–16992 (2017)

Suguna, S., Shankar, S., Jaganathan, S.K., Manikandan, A.: Novel Synthesis and Characterization Studies of Spinel NixCo1−xAl2O4 (x=0.0 to 1.0) Nano-Catalysts for the Catalytic Oxidation of Benzyl Alcohol. J. Nanosci. Nanotechnol. 18, 1019–1026 (2018)

Gouda, M.E., Bayoumy, W.A.A.: Structural, optical and magnetic properties of Ni-aluminates with co substitution Int. J. Sci. Eng. Res. 6, 328–333 (2015)

Lu, T., Pan, Y.: Analysis of thermal explosion process for preparing ferromagnetic Al2O3-based Cermets. Mater. Manuf. Process. 27, 914–918 (2012)

He, G., Liu, J., Jiang, X., Li, J.: Infrared emission properties of Cr3+ doped NiAl2O4 spinel ceramics. Adv. Funct. Mater. 617–624 (2018)

Merikhi, J., Jungk, H.-O., Feldman, C.: Sub-micrometer CoAl2O4 pigment particles synthesis and preparation of coatings. J. Mater. Chem. 10, 1311–1314 (2000)

Yan, J., Huang, J., Zhang, T., Tian, H., Yu, J., Zhang, L., Zhang, Y.: Investigation of the microstructure, Cation distribution and optical properties of nanoscale NixMg1-xAl2O4 spinel pigments. Ceram. Int. 45, 14073–14083 (2019)

Kurien, S., Mathew, J., Sebastian, S., Potty, S.N., George, K.C.: Dielectric behavior and ac electrical conductivity of nano-crystalline nickel aluminate. Mater. Chem. Phys. 98, 470–476 (2006)

Jagadeeshwaran, C., Madhan, K., Murugaraj, R.: Size effect and order–disorder phase transition in MgAl2O

4: synthesized by co-precipitation method. J. Mater. Sci. Mater. Electron. 29, 18923–18934 (2018)Nelson, J.B., Riley, D.P.: An experimental investigation of extrapolation methods in the derivation of accurate unit-cell dimensions of crystals. Proc. Phys. Soc. 57, 160–171 (1945)

Gaudonn, M., Robertson, L.C., Lataste, E., Duttine, M., Menetrier, M., Demourgues, A.: Cobalt and nickel aluminate spinels: blue and cyan pigments Ceram. Int. 40, 5201–5207 (2014)

Karmakar, S., Behera, D.: Non-overlapping small polaron tunneling conduction coupled dielectric relaxation in weak ferromagnetic NiAl2O4. J. Phys. Condens. Matter. 31, 245701 (2018)

Jayasree, S., Manikandan, A., Mohideen, A.M.U., Barathiraja, C., Antony, S.A.: Comparative Study of Combustion Methods, Opto-Magneticand Catalytic Properties of Spinel CoAl2O4 Nano and Microstructures. Adv. Sci. Eng. Med. 7, 1–11 (2015)

Yadav, T.P., Tiwari, R.S., Srivastava, O.N., Mukhopadhyay, N.K.: Evolution of a nanocrystalline (co, Ni) Al2O4 spinel phase from quasicrystalline precursor. Int. J. Appl. Ceram. Technol. 5, 449–457 (2008)

Nandana, K.R., Ruban Kumar, A.: Structural and electrical properties of Ca0.9Dy0.1MnO3 prepared by sol-gel technique. J. Mater. Res. Technol. 8(3), 2996–3003 (2019)

Joseph, D., Kaliyaperumal, C., Mumoorthy, S., Paramasivam, T.: Dependence on temperature of the electrical properties of nanocrystalline Y2Ti2O7 ceramics. Ceram. Int. 44, 5426–5432 (2018)

Joshi, J.H., Kanchan, D.K., Joshi, M.J., Jethva, H.O., Parikh, K.D.: Dielectric relaxation, complex impedance and modulus spectroscopic studies of mix phase rod like cobalt sulfide nanoparticles. Mater. Res. Bull. 93, 63–73 (2017)

Bouzidi, S., Hassen, A.B., Dhahri, J., Khirouni, K.: Structural and dielectric properties of BaTi0.5 (Co0.33 Mo0.17) O3 perovskite ceramic. J. Alloys Compd. 781, 936–944 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jagadeeshwaran, C., Murugaraj, R. Structural, Optical, Magnetic, and Electrical Properties of Ni0.5Co0.5Al2O4 System. J Supercond Nov Magn 33, 1765–1772 (2020). https://doi.org/10.1007/s10948-020-05427-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-020-05427-z