Abstract

Various artificial multilayers consisting of YDy0.2 Ba2Cu3O7−ε /RE2O3/YDy0.2Ba2Cu3O7−ε films (RE = Y, Gd, Eu, etc.) about 1 μm in a sandwich-type structure are fabricated on oxide-buffered Hastelloy substrates using low-fluorine metalorganic deposition (MOD) method. Superconducting and microscopic performances are studied on composite YDyBaCuO multilayer films with and without intercalated Y2O3, Gd2O3, and Eu2O3 ultrathin films. X-ray diffraction (XRD) and field emission scanning electron microscopy (FE-SEM) are used to investigate growth orientation and surface morphology, revealing that multiple superconducting YDyBaCuO thin films separated by an ultrathin RE2O3 interlayer have better c-axis orientation, better in-plane and out-plane textures, as well as superior surface morphology. Using this interlayer technology, a significant enhancement of critical current density (J c) both in self-field and under applied magnetic field is obtained.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The development of second-generation (2G) REBa2Cu3 O7−δ (RE = Y, Gd, or other rare-earth elements) high-temperature superconducting (HTS)-coated conductors has achieved great progress, for their potential applications in generators, motors, and transformers [1, 2]. High critical current (I c) is a crucial issue for wide applications of 2G high-temperature superconducting wires. Fabrication of thick films with high critical current density (J c) is necessary in order to obtain high I c. However, the critical current density (J c) of YBCO films decreases with increasing film thickness [3, 4]. Several possible reasons for the so-called “thickness effect” of J c have been proposed, including the accumulation of various defects in HTS films, the increase of roughness and porosity, a-axis-oriented growth, the degradation of texture, and oxygen deficiency [5]. In order to overcome the thickness effect, strong artificial modification appears necessary and significant [6].

Many methods have been developed to overcome the thickness effect, including substrate decoration [7], doping with secondary phases [8], and multilayers with ultrathin interlayers [9]. At present, investigation of the current carrying ability of separate HTS layers and related ultrathin interlayer architectures of this type is topical. The most suitable interlayers are SrTiO3 [10], CeO2 [9], REBCO [11], and Y2O3 [12]. The incorporation of Y2O3 intermediate layer by pulsed laser deposition (PLD) gives rise to significant effects on superconductive and microstructural properties of YBCO HTS films [13, 14]. However, the research on RE2O3 interlayer effects on metalorganic deposition (MOD)-YBCO films is still limited. The present work is devoted to various artificial multilayers of YDyBaCuO with and without inserted RE2O3 layers, on buffered Hastelloy substrates (Hastelloy/Al2O3/Y2O3/IBAD-MgO/epi-Mg O/LaMnO3) by the low-fluorine MOD method.

2 Experimental

The RE2O3 coating solution was prepared by dissolving RE propionate in methanol. The RE cation concentration was 0.1 mol/L. To get the YDyBaCuO precursor solution, stoichiometric quantities of Y, Dy, and Cu acetates were dissolved in propionic acid and water; Ba acetate (Y/Dy/Ba/Cu = 1:0.2:2:3.3) was dissolved in trifluoroacetic acid and water. The next step in solution preparation was refining the solution by drying and redissolving in methanol several times. This process removed the excess acetic acid, water, and other impurities from the solution. Finally, the Y, Dy, Ba, and Cu solutions were mixed, evaporated, and diluted in methanol to control the viscosity. The YDyBaCuO precursor solution’s total cation concentration was 2.0 mol/L.

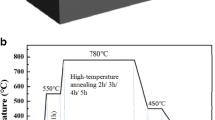

Then, the YDyBaCuO precursor films were deposited on LaMnO3/MgO/Y2O3/Al2O3/Hastelloy substrates by dip coating. The coated gel films were heated from room temperature to 550 ∘C in the presence of moist oxygen to get the amorphous decomposed films. The decomposed films were then coated with RE2O3 solution. The coated films are decomposed below 400 ∘C in humid oxygen atmosphere. The decomposed films were then coated again with YDyBaCuO solution as mentioned above. Coated films were decomposed again as mentioned earlier. The crystallization was performed at 780 ∘C for 120 min in a humid mixed N2/O2 atmosphere. The oxygen partial pressure was 150 ppm. Finally, the films were annealed at 450 ∘C for 1 h in a dry oxygen atmosphere. For reference, pure YDyBaCuO bilayers without ultrathin RE2O3 interlayer are prepared under the same processing conditions as well. The coated YDyBaCuO bilayers with and without the inserted ultrathin RE2O3 layer are illustrated in Fig. 1. The film thickness was measured by a Bruker Dektak XT stylus. The thickness for all present films was ∼ 1 μm. The bilayer YDyBaCuO film with RE2O3 was about several nanometers thicker than the pure YDyBaCuO film. The phase and texture analysis of YDyBaCuO films was investigated by X-ray diffraction (XRD). The surface morphology of YDyBaCuO films was observed by field emission scanning electron microscopy (FE-SEM). The self-field critical current densities of the films were inductively measured by a Cryoscan system at 77 K. The superconductive properties under applied magnetic field were determined by magnetic property measurement and the extended Bean’s critical state model.

3 Results and Discussion

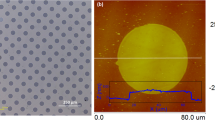

The surface morphologies of pyrolyzed YDyBaCuO monolayer films with and without RE2O3 observed by optical microscopy are shown in Fig. 2. The surface of all present films is crack-free without bucklings or pores. But, the surface of pure YDyBaCuO is rough with several pencil-like shapes. In comparison with pure YDyBaCuO, the YDyBaCuO films with RE2O3 modification are smooth as shown. Furthermore, the number of pencil-like shapes seems to be reduced by RE2O3 modification, suggesting that RE2O3 modification may result in a high-quality subsequent YDyBaCuO layer. In order to further observe the surface morphologies, AFM images of pyrolyzed YDyBaCuO monolayer films with and without RE2O3 have been obtained. The pyrolyzed YDyBaCuO monolayer films with Gd2O3 film tend to be more smooth and regular than the pyrolyzed YDyBaCuO monolayer films without RE2O3 film as shown in Fig. 3.

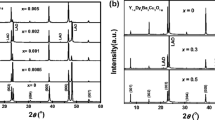

X-ray diffraction analysis is performed to determine the orientation and texture of YDyBaCuO films. As shown in Fig. 4a, no peaks other than YDyBaCuO and buffer reflections were detected for these films. All the derived films have sharp and strong (00 l) peaks without undesirable phases, but RE2O3 was hardly detected. The XRD 2 𝜃 patterns of YDyBaCuO films with and without RE2O3 make little difference, except that the (00 l) peaks of YDyBaCuO with RE2O3 are stronger, suggesting that YDyBaCuO films with RE2O3 have better crystallization. To further examine the texture of YDyBaCuO films, phi-scans and omega-scans are documented in Fig. 4b, c. Four symmetric peaks with high intensity can be observed in their phi-scanning and omega-scanning patterns, indicating their good in-plane and out-plane textures. The full width at half maximum (FWHM) values of YDyBaCuO are reduced by RE2O3 modification, revealing that RE2O3 modification leads to higher texture.

The surface morphology of crystallized YDyBaCuO bilayer film is also changed by RE2O3, as shown in Fig. 5. All the films are crack-free without any a-axis-oriented grains. Compared with the dense surface of RE2O3-modified YDyBaCuO films, bigger grains and more pores are observed on the surface of pure YDyBaCuO film, which may lead to poor current carrying properties.

The critical current density in self-field at 77 K improves by RE2O3 modification, as shown in Fig. 6. The Gd2O3-interlayered YDyBaCuO shows the highest performance, which may be attributed to the improved texture, crystallization, as well as microstructure. The dependence of the J c on magnetic field at 77 K, B//c is shown in Fig. 7. J c decreases in an external field. Compared to the pure YDyBaCuO sample, the J c values of the RE2O3-modified samples decrease slowly with increasing magnetic field, especially that of the Gd2O3-modified sample, indicating that the incorporation of RE2O3 interlayer may introduce more pinning defects. Yet, there are some other reasons contributing to flux pinning, such as voids, dislocations, and boundaries [15]. The relationship between flux pinning and J c is complex, and more work will be done in our future studies.

4 Conclusion

In summary, bilayer 1- μm-thick YDyBaCuO films are successfully fabricated by low-fluorine MOD method. A significant increase in the current carrying ability both in self-field and under applied magnetic field is achieved by adopting the ultrathin RE2O3 interlayer architecture, which might be beneficial to prevent degradation of microstructure and texture of YDyBaCuO films with increasing film thickness.

References

Rupich, M. W., Li, X., Sathyamurthy, S., Thieme, C., Fleshler, S.: Advanced development of TFA-MOD coated conductors. Phys. C: Supercond. 471, 919–923 (2011)

Kitazawa, K.: Superconductivity: 100th anniversary of its discovery and its future. Jpn. J. Appl. Phys. 51, 010001 (2012)

Foltyn, S., Civale, L., MacManus-Driscoll, J., Jia, Q., Maiorov, B., Wang, H., et al.: Materials science challenges for high-temperature superconducting wire. Nat. Mater. 6, 631–642 (2007)

Foltyn, S., Arendt, P., Jia, Q., Wang, H., MacManus-Driscoll, J., Kreiskott, S., et al.: Strongly coupled critical current density values achieved in Y1Ba2Cu3O7-delta coated conductors with near-single-crystal texture. Appl. Phys. Lett. 82, 4519 (2003)

Watanabe, T., Iwai, H., Ibi, A., Muroga, T., Miyata, S., Yamada, Y., et al.: Investigation of multi-deposition for high I c YBCO coated conductors prepared by PLD on self-epitaxial CeO2 buffers. IEEE Trans. Appl. Supercond. 15, 2620–2623 (2005)

Zhou, H., Maiorov, B., Baily, S., Dowden, P., Kennison, J., Stan, L., et al.: Thickness dependence of critical current density in YBa2Cu3O7- δ films with BaZrO3 and Y2O3 addition. Supercond. Sci. Technol. 22, 085013 (2009)

Sarkar, A., Mikheenko, P., Dang, V., Abell, J., Crisan, A.: Enhancing critical current in YBCO thick films: substrate decoration and quasi-superlattice approach. Phys. C: Supercond. 469, 1550–1553 (2009)

Fa-Zhu, D., Hong-Wei, G., Hong-Yan, W., Hui-Liang, Z., Teng, Z., Fei, Q., et al.: Effects of thickness on superconducting properties and structures of Y2O3/BZO-doped MOD-YBCO films. Project supported by the National Natural Science Foundation of China (Grant No. 51272250), the National Basic Research Program of China (Grant No. 2011CBA00105), the National High Technology Research and Development Program of China (Grant No. 2014AA032702), and the Beijing Natural Science Foundation, China (Grant No. 2152035), Chinese Physics B, vol. 24, p. 057401 (2015)

Foltyn, S., Wang, H., Civale, L., Jia, Q., Arendt, P., Maiorov, B., et al.: Overcoming the barrier to 1000 A/cm width superconducting coatings. Appl. Phys. Lett. 87, 2505 (2005)

Garaeva, M. Y., Chernykh, I. A., Krylova, T. S., Shainurov, R. I., Krasnoperov, E. P., Zanaveskin, M. L.: Developing an approach based on the formation of YBa2Cu3Ox-interlayer-YBa2Cu3Ox epitaxial structures with high current-carrying ability. Tech. Phys. Lett. 40, 905–908 (2014)

Lin, J., Yang, W., Gu, Z., Shu, G., Li, M., Sang, L., et al.: Improved epitaxial texture of thick YBa2Cu3O7- δ/GdBa2Cu3O7- δ films with periodic stress releasing. Supercond. Sci. Technol. 28, 045001 (2015)

Feldmann, D., Holesinger, T., Maiorov, B., Zhou, H., Foltyn, S., Coulter, J., et al.: 1000 A cm-1 in a 2 μm thick YBa2Cu3O7-x film with BaZrO3 and Y2O3 additions. Supercond. Sci. Technol. 23, 115016 (2010)

Gapud, A. A., Kumar, D., Viswanathan, S. K., Cantoni, C., Varela, M., Abiade, J., et al.: Enhancement of flux pinning in YBa2Cu3O7- δ thin films embedded with epitaxially grown Y2O3 nanostructures using a multi-layering process. Supercond. Sci. Technol. 18, 1502 (2005)

Mele, P., Matsumoto, K., Horide, T., Ichinose, A., Mukaida, M., Yoshida, Y., et al.: Insertion of nanoparticulate artificial pinning centres in YBa2Cu3O7-x films by laser ablation of a Y2O3-surface modified target. Supercond. Sci. Technol. 20, 616 (2007)

Holesinger, T. G., Civale, L., Maiorov, B., Feldmann, D. M., Coulter, J. Y., Miller, D. J., et al.: Progress in nanoengineered microstructures for tunable high-current, high-temperature superconducting wires. Adv. Mater. 20, 391–407 (2008)

Acknowledgments

This work was supported in part by the Shanghai Key Laboratory of High Temperature Superconductors (14DZ2260700), the Science and Technology Commission of Shanghai Municipality (16521108400, 16DZ0504300, and 14521102800), and the National Natural Science Foundation of China (51572165, 11174193, and 51202141).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, Q., Li, M.Y., Sun, M.J. et al. Improvement of Surface Morphology and Critical Current Density of YDy 0 . 2 Ba2Cu 3 . 3 O7−δ Thick Films by Inserted RE2O3 Thin Films. J Supercond Nov Magn 30, 1713–1717 (2017). https://doi.org/10.1007/s10948-016-3952-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-016-3952-x