Abstract

This paper reports the effect of film thickness (50, 200, 400 and 800 nm) on the structural and magnetic properties of amorphous Tb-Dy-Fe-Co alloy thin films. All the films are found to exhibit perpendicular magnetic anisotropy (PMA) irrespective of the film thickness. The PMA is found to decrease with increase in film thickness due to the decrease in the magnetic texture and anisotropy energy. While the coercivity deduced from the out-of-plane magnetization curve increases with increasing film thickness, the in-plane coercivity exhibits weak thickness dependence. The irreversibility point in the thermo-magnetic curves obtained from field-cooled and zero-field-cooled measurements along the out-of-plane direction is found to shift towards higher temperature compared to the measurements in in-plane directions, indicating the presence of strong PMA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Magnetic thin films with perpendicular magnetic anisotropy (PMA) have generated considerable interest in recent years for spin-based random-access memory devices [1, 2]. In contrast to the in-plane anisotropy materials, the PMA materials are found to operate at low switching currents, possess high thermal stability and aid larger data-storage capacity. PMA in magnetic thin films can be tuned by bi-layer ratio, annealing temperature, choice of under-layer material and under-layer material thickness, etc. [3–8]. PMA has been exhibited in multilayers of transition metals, Co- and Fe-based alloy thin films and rare earth-transition metal (R-TM)-based amorphous thin films [2, 9–11]. Of these, several R-TM-based thin films with PMA have been studied for magneto-optical-based memory device applications [11–15]. The high Curie temperature exhibited by these films makes them thermally more stable for Curie point writing. Further, these films are also studied for spin torque-based random-access memory applications because of their tunable magnetic properties such as saturation magnetization, Curie temperature and coercivity [12, 13]. It is observed from literature that highly anisotropic Tb-Fe-Co and very low anisotropic Gd-Fe-Co films are found to exhibit strong PMA [12, 15]. Therefore, it is of interest to examine whether such PMA behaviour is also exhibited in anisotropy-compensated systems based on mixed rare earths possessing the opposite sign of anisotropy (viz., Tb-Dy, Ho-Tb, Tb-Pr, etc.). In this context, the Tb-Dy-Fe-Co alloy system has been selected for the present study since it is a well-known anisotropy-compensated system (the anisotropy constant K 1 is negative for Tb and positive for Dy) and has been exploited for magnetostrictive device applications [17]. A detailed study has been carried out by depositing Tb-Dy-Fe-Co films with various thicknesses by electron beam evaporation and characterizing them for structural and magnetic properties.

2 Experimental Details

Tb-Dy-Fe-Co films were grown on Si <100 > substrate with different thicknesses (50, 200, 400 and 800 nm) by electron beam evaporation technique. During the deposition process, the rate of evaporation and substrate temperature were kept constant at 5 Å/s and 450 ∘C, respectively. Since the rare earth alloys are highly reactive, a thin layer of Al (∼ 4 nm) was deposited on the film as a capping layer in order to avoid oxidation of the films. The desired thickness of the film is obtained by adjusting the deposition time. The composition of the films was determined using energy-dispersive spectroscopy (EDS) technique. Structural studies were carried out employing X-ray diffraction (XRD) technique. Micro-structural investigations were carried out using a field emission gun scanning electron microscope (FEG-SEM). In-plane (x- or y-direction) and out-of-plane (z-direction) magnetization measurements were carried out employing a SQUID magnetometer up to a magnetic field of 5 T. Field-cooled (FC) and zero-field-cooled (ZFC) measurements were carried out in the temperature range 4–390 K with an applied magnetic field of 1 T.

3 Results and Discussions

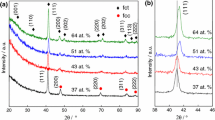

The X-ray diffraction spectra obtained from the Tb-Dy-Fe-Co films having different thicknesses, viz., 50, 200, 400 and 800 nm, show that all the films are amorphous in nature (Fig. 1). Efforts made to crystallize the film by depositing films at substrate temperatures greater than 450 ∘C resulted in debonding of the films from the substrate. This can be attributed to the residual stresses developed in the films due to mismatch in the thermal expansion between the film and the substrate.

The FEG-SEM micrographs for the films grown at different thicknesses are shown in Fig. 2. The surface morphology of the films exhibits the presence of uniformly distributed island-like features whose size increases with increasing film thickness (Fig. 2). Generally, in the thin-film deposition process, nucleation and growth are two important factors. With the deposition rate being constant, the rate of nucleation for island formation is expected to be constant in all the films. However, for films with higher thickness, the time available for growth is more which aids in readjustment of atoms. As a result, islands of lower free energy grow at the expense of others. Accordingly, the island size is found to be more for the films grown for longer duration. However, it is observed that films grown with thickness more than 800 nm are found to delaminate from the substrate due to large residual stress. The composition estimated using EDS analysis is found to be around Tb 10Dy 24Fe 60Co 6 which is nearly uniform for all the films.

Figure 3 shows the variation of room temperature magnetization with the magnetic field along the in-plane and out-of-plane directions for Tb-Dy-Fe-Co films grown at different thicknesses. The magnetization curves clearly indicate that all the films exhibit a strong anisotropy along the out-of-plane direction (perpendicular magnetic anisotropy). The PMA is found to decrease with increasing film thickness. However, the magnetization behaviour with the magnetic field parallel to the x− or y-direction (in plane) is found to be similar (a schematic representation of the film plane is given in Fig. 3b). To understand the degree of perpendicular anisotropy for different film thicknesses, magnetic texture and anisotropy energies were calculated after incorporating the demagnetization field corrections to the magnetization curves. The magnetic texture (MT) is derived from the quantity (\(M_{\mathrm {r}}^{\bot }-M_{\mathrm {r}}^{\|}) / M_{\mathrm {r}}^{\bot }\), and this quantity can vary in the range 0–1 (\(M_{\mathrm {r}}^{\mathrm {\bot } }\)—remnant magnetization along the out-of-plane direction, \(M_{\mathrm {r}}^{\|}\)—remnant magnetization along the in-plane direction) [17]. While MT values close to 1 indicate a high degree of perpendicular magnetic anisotropy, MT values close to 0 indicate random domain orientation. From the variation of magnetic texture with film thickness shown in Fig. 4, it is observed that the magnetic texture of about 0.92 has been realized for the 50-nm-thick film and it is found to decrease with increasing film thickness. These calculations clearly indicate that perpendicular anisotropy is strong at lower thickness.

The anisotropy energy is calculated by finding the difference in area between the in-plane and out-of-plane initial magnetization curves. The anisotropy energy is also found to decrease with increasing film thickness, indicating a decrease in the degree of PMA. The anisotropy energy for Tb-Dy-Fe-Co films are found to be higher compared to that of Gd-Fe-Co films (anisotropy energy = 3.8 × 105 erg/cc) but lower than that of Tb-Fe-Co (anisotropy energy = 1.1 × 107 erg/cc) [12, 16] for the same thickness values. Since Tb-Dy-Fe-Co is an anisotropy-compensated system, the anisotropy energy is found to be less when compared with that of Tb-Fe-Co. However, when compared with that of Gd-Fe-Co which does not possess any rare earth anisotropy, the value is found to be larger.

The variation of coercivity with film thickness evaluated for the in-plane and out-of-plane magnetization curves is shown in Fig. 5. The out-of-plane coercivity is found to increase with increase in film thickness, while the in-plane coercivity exhibits weak thickness dependence. The increase in out-of-plane coercivity with thickness is corroborated by the large PMA exhibited by the films. It is also consistent with the fact that residual stresses in the films increase with increase in film thickness resulting in enhanced pinning of the domains. The weak dependence of in-plane coercivity with thickness is attributed to the presence of some minor in-plane anisotropy component along the plane of the film. The origin of the in-plane anisotropy component with thickness could be due to the decline of PMA with thickness resulting in a magnetization component along the in-plane direction.

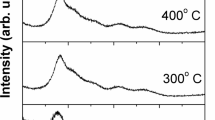

To understand the effect of anisotropy further, detailed thermo-magnetic measurements were carried out under field-cooled (FC) and zero-field-cooled conditions (ZFC) with the magnetic field applied perpendicular to the plane of the film. The large irreversibility observed in the FC and ZFC thermo-magnetic curves indicates the presence of large magnetic anisotropy at low temperatures (Fig. 6a). From these curves, it is observed that the temperature at which the irreversibility starts is nearly the same for all the films. It is also worth noting that the ZFC curve for the 50-nm-thick film shows a sharp decrease in magnetization with temperature below the irreversibility point when compared with the films grown at other thicknesses. This indicates the presence of strong perpendicular anisotropy for the 50-nm-thick film which is in concurrence with the magnetic texture calculations. The in-plane FC and ZFC thermo-magnetic curves are shown in Fig. 6b. The FC and ZFC thermo-magnetic curves corresponding to the 50-nm film do not show any sharp irreversibility points, indicating the absence of strong in-plane anisotropy. However, FC and ZFC curves corresponding to the higher thickness films exhibit irreversibility due to the presence of some minor in-plane components. This is in concurrence with the in-plane coercivity variation with thickness which also exhibits the presence of some in-plane component. One more interesting feature is that the temperature at which the irreversibility in magnetization (FC and ZFC curves) occurs is found to shift towards lower temperatures as compared to out-of-plane thermo-magnetic measurements, indicating a lower magnetic anisotropy along the in-plane direction.

4 Summary

Tb-Dy-Fe-Co films with different thicknesses (50, 200, 400 and 800 nm) were deposited on Si <100 > substrate using the electron beam evaporation technique and characterized for structural and magnetic properties. Structural analysis using XRD shows that all the films are amorphous in nature. The micro-structural analysis using FEG-SEM shows smooth and continuous films with uniform distribution of fine island features. The size of the islands is found to increase with increasing film thickness. All the films are found to exhibit perpendicular magnetic anisotropy. The anisotropy energy and magnetic texture calculated from the out-of plane and in-plane magnetization curves decrease with increasing film thickness. While the coercivity obtained from the out-of-plane magnetization measurement is found to increase considerably with increase in film thickness, the in-plane coercivity exhibits weak dependence on it which is correlated with the strong PMA displayed by the films. The FC and ZFC thermo-magnetic plots display the presence of large PMA at lower thickness.

References

Meng, H., Wang, J.P.: Appl. Phys. Lett. 88, 172506 (2006)

Ikeda, S., Miura, K., Yamamoto, H., Mizunuma, K., Gan, H.D., Endo, M., Kanai, S., Hayakawa, J., Matsukura, F., Ohno, H.: Nat. Mater. 9, 721 (2010)

Wang, W.G., Jordan-sweet, J., Miao, G.X., Ni, C., Rumaiz, A.K., Shah, L.R., Fan, X., Parsons, P., Stearrett, R., Nowak, E.R., Moodera, J.S., Xiao, J.Q.: Appl. Phys. Lett. 95, 242501 (2009)

Worledge, D.C., Hu, G., Abraham, D.W., Sun, J.Z., Trouilloud, P.L., Nowak, J., Brown, S., Gaidis, M.C., O’Sullivan, E.J., Robertazzi, R.P.: Appl. Phys. Lett. 98, 022501 (2011)

Li, Z.G., Smith, D.J., Marinero, E.E., Willett, J.A.: J. Appl. Phys. 69, 6590 (1991)

Dirks, A.G., Leamy, H.J.: Thin Solid Films 4, 219 (1977)

Ko, J., Sun, J., Lee, S., Kim, S., Hong, J.: Thin solid films 519, 8252 (2011)

Fang, Y.H., Kuo, P.C., Chou, C.Y., Chen, S.C., Cheng, N.W., Lin, P.L.: J. Magn. Magn. Mater. 310, 930 (2007)

Kim, G., Sakuraba, Y., Oogane, M., Ando, Y., Miyazaki, T.: Appl. Phys. Lett. 92, 172502 (2008)

Shima, T., Takanashi, K., Shima, T., Takanashi, K.: Appl. Phys. Lett. 81(6), 1050 (2002)

Tsunashima, S.: J. Phys. D: Appl. Phys. 34(17), R87—R102 (2001)

Brown, S., Harrell, J.W., Fujiwara, H., Takeuchi, T.: J. Appl. Phys. 91, 8243 (2002)

Nakayama, Kai, T., Shimomura, N., Amano, M., Kitagawa, E., Nagase, T., Yoshikawa, M., Kishi, T., Ikegawa, S., Yoda, H.: J. Appl. Phys. 103(7), 07A710 (2008)

Abo, S., Neveu, N., Kim, S.G., Choi, C.J., Lee, J.G.: J. Appl. Phys. 107(9), 09A731 (2010)

Ding, M., Poon, S.J.: J. Magn. Magn. Mater. 339, 51 (2013)

Palit, M., Pandian, S., Chattopadhyay, K.: J. Alloys Compd. 541, 297 (2012)

Rama Rao, N.V., Gabay, A.M., Hadjipanayis, G.C.: J. Phys. D: Appl. Phys. 46, 062001 (2013)

Acknowledgments

The authors thank the Director, DMRL, Hyderabad for his constant support and encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Basumatary, H., Jeyaramane, A.C., Kamat, S.V. et al. Structural and Magnetic Properties of Amorphous Tb-Dy-Fe-Co Thin Films. J Supercond Nov Magn 29, 863–867 (2016). https://doi.org/10.1007/s10948-015-3360-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-015-3360-7