Abstract

Polycrystalline FexPd1−x (x = 37–64 at.%) films with thicknesses of 47 ± 2 nm were prepared by dc magnetron sputtering on quartz glass substrates and subsequent annealing at 550 °C for 3 h. The evolution of crystal structure and magnetic properties with different Fe concentrations were investigated. For the Pd-rich FePd films, the A1 disordered phase and soft magnetic properties were found. The Fe-rich FePd films are more favorable to the formation of an ordered L10 phase. For Fe concentration of 51 at.%, the sample exhibits the highest coercivity, magnetic energy product and remanence ratio at room temperature, corresponding to 3.5 kOe, 17.6 MGOe and 0.94, respectively, and the coercivity increases to ~4.3 kOe at 120 K. The disorder-order transition temperature is evidently reduced to 550 °C and magnetic properties are improved in this work. These FePd films have shown promise for application as high-density magnetic recording medium.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

L10 ferromagnetic alloys, such as FePt, CoPt, and FePd, have been extensively investigated for the potential applications in the recording media, spintronic devices, microelectromechanical systems, owing to their excellent corrosion resistance and magnetically intrinsic properties, including strong uniaxial magnetocrystalline anisotropy (Ku = 1–7 × 107 erg/cm3), large saturation magnetization (4πMs = 12–14 kG), and high Curie temperature (Tc ~ 450–550 °C) [1–5]. For recording media applications, FePt was considered as the most promising candidate [6–8]. Nevertheless, the high coercivity in the range of 10–20 kOe of L10 FePt with nanogranular microstructure results in difficulty in magnetic writing. To solve this, heat assisted mechanism must be involved, which increases the complexity of the system. L10-FePd, having a much lower magnetic anisotropy field (Hk) of 37 kOe as compared to L10 FePt (120 kOe) but a comparable Ku, is therefore received considerable attention in recent years [9–12].

FePd thin films exhibit a disordered face centered cubic (fcc) structure at room temperature, which behave magnetically soft. In general, after annealed at 600–700 °C, the structure of samples could transform to an ordered face centered tetragonal (fct) structure [13]. Epitaxial L10-FePd films grown on MgO(001) single crystal substrates were reported to display a Hc below 1 kOe [14, 15]. Magntic energy product ((BH)max) of 8.1 MGOe with Hc = 3.0 kOe was obtained for L10-FePd nanoparticles with size in the range of 30-50 nm [16]. However, high cost of MgO (001) single crystal substrate and the inaccessible control on size distribution and compacted assembly make them not favorable for practical applications. Recently, Chang et al. [17] reported that sputter-prepared FePd films on glass substrates with W underlayer behaved well in magnetic properties after annealed at 650 °C, which manifested Hc and (BH)max about 3.0 kOe and 8.7 MGOe, respectively. For practical application, however, the temperature is still too high for realization of the disorder-order phase transformation of the FePd films.

In our previous work, we added successfully Si–N amorphous content to FePd films, and obtained a good magnetic property [18]. In this paper, pure FexPd1−x films with Fe concentration of 37–64 at.% were deposited on cheap quartz glass substrates, without any buffer layer and doped element. Interestingly, the films displayed also high degree of ordering and high coercivity at 550 °C, indicating a lower ordering transition temperature.

2 Experimental details

FexPd1−x (x = 37–64 at.%) thin films with thicknesses of 47 ± 2.0 nm were prepared on quartz glass substrates at room temperature, using dc magnetron sputtering. The pure Pd disk with Fe sectors was used as the sputter target and the purity of the Fe and Pd was better than 99.99%. The sputtering chamber was evacuated to a base pressure of 6.0 × 10−5 Pa. High-purity argon (99.99% purity) was used as the working gas. During sputtering, the ambient gas pressure, the gas flow rate and the dc power were maintained at 1.5 Pa, 24 SCCM (cubic centimeter per minute at STP) and 100 W, respectively. The distance between the cathodes and the substrate was set at 70 mm. After deposition, films were annealed at 550 °C under high vacuum (6.0 × 10−2 Pa) for 3 h. The crystal structure and magnetic properties of the films were investigated by X-ray diffraction (XRD, PANalytical Empyrean, U = 45 kV/I = 40 mA, X’celerator, Cu-Kα1: λ = 1.54056 Å, 0.0167°/step), physical properties measurement system (PPMS-9T, Quantum Design Co.), atomic force microscopy (AFM, BRUKER DIInnova) and scanning electron microscopy (SEM, FEI Quanta 450 FEG). The maximum magnetic field used was ±3 T. The atomic concentration for each element in the films was determined by energy dispersive X-ray spectrometer (EDS, Oxford instruments X-Max20).

3 Results and discussion

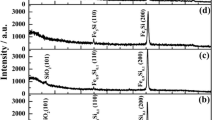

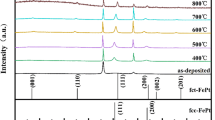

Figure 1a illustrates XRD patterns of the polycrystalline FexPd1−x films annealed at 550 °C with various Fe concentrations from 37 to 64 at.%. For the films with Fe ≤ 37 at.%, no superlattice peaks of the fct phase except the disorder-fcc fundamental peaks are observed, indicating that the films are solid solution with single disordered fcc structure. For the film with Fe = 43 at.%, the splitting of the (200) reflection of the fcc structure to the (200) peak and the weak (002) superlattice peak of the fct structure resulting from the break of lattice symmetry is observed, which indicates the film has begun to transform from fcc to fct structure. But at this time it is still dominated by the disordered fcc phase, indicating that Pd-rich FePd films have a poor degree of order. With increasing the Fe content further to 51 and 64 at.%, respectively, the (002) superlattice peak becomes well defined, a large number of L10 ordered fct structures were formed, indicating that the Fe-rich FePd films are more favorable to the formation of an ordered L10 phase. In addition, the (111) diffraction peak shifts to high angle as the Fe concentration increases as shown in Fig. 1b. This is because that the atomic radius of Fe is smaller than that of Pd, resulting in the shrinking of the lattice plane after more Fe atoms substituting for the Pd atoms.

The in-plane hysteresis loops of the FexPd1-x films with different chemical composition are illustrated in Fig. 2a. For the film with Fe content of 37 at.%, the loop reaches the saturation easily with a low Hc of ~0.1 kOe, showing a typical magnetically soft behavior, due to the presence of the disordered FePd phase that exhibits low Ku. With increasing Fe content to 43 at.%, the Hc increases rapidly to 1.2 kOe, indicating the occurrence of L10 ordering at 550 °C. The Hc reaches a maximum value of 3.5 kOe at the nearly equiatomic composition, and at the same time the loop of Fe51Pd49 film also shows a good squareness, which indicates the degree of ordering of the sample has been very high, up to 0.95. In Ref. [19], the Hc of FePd films deposited on glass substrate is ~3.4 kOe after being annealed at 700 °C. In contrast, the temperature of fcc–fct phase transition is set to 550 °C in present work, which is the 150 °C lower than that in Ref. [19], whereas the coercivity is improved to 3.5 kOe. With higher Fe content up to 64 at.%, the Hc decreased to 2.3 kOe. In addition, the saturation magnetization (Ms) varies nonlinearly with increasing Fe content, suggesting that the maximum magnetization does not simply rely on the concentration of magnetic atoms based on the assumption that the magnetic moment of Fe remains constant while Pd does not contribute any magnetic moment. Nevertheless, the magnetic moment of Fe was found to depend on the chemical composition of FePd alloys based on in situ neutron diffraction experiments [20]. Besides, the magnetic structure may also be altered by the crystal structure of FePd alloys, i.e., as the crystal structure changes between A1 and L10 in FePd alloys, its magnetic structure will also be altered.

Figure 2b shows remanence ratio (Mr/Ms) and (BH)max versus Fe content. The Fe content dependence of Mr/Ms and (BH)max show a strong consistent trend with that of the Hc. For the films with Fe content of 37 at.%, the Mr/Ms is only 0.44 and (BH)max is almost zero due to low coercivity. As the Fe content is increased to 43 at.%, the sample undergoes the fcc–fct transition, Mr/Ms increases rapidly to 0.75, and (BH)max to 6.8 MGOe. At the nearly equiatomic composition, the degree of the ordering in the film is so high that Mr/Ms is close to 1 and Hc also reaches a maximum value of 3.5 kOe, which leads (BH)max to 17.6 MGOe. The Hc, Mr/Ms and (BH)max obtained in our work are also better than those of the FePd films with W as underlying [17], which makes the preparation process simplified. As the Fe content is increased further to 64 at.%, the Mr/Ms and (BH)max decrease slightly to 0.89 and 14.8 MGOe, respectively, which indicates the Fe-rich FePd films were more favorable for the formation of the ordered L10 phase. The results were consistent with the results of XRD analysis.

AFM and SEM images of the Fe51Pd49 films as-deposited (a, b) and annealed (c, d) at 550 °C are shown in Fig. 3. For the as-deposited films, it shows that the surface of the film is flat, loose, and homogeneous. A smooth surface with surface roughness Ra = 0.377 nm was demonstrated. After annealing at 550 °C, the sample surface morphology becomes compact, agglomerate and island-like state, surface Ra increases to 2.70 nm. Besides, holes were clearly observed, as shown in Fig. 3d. Because there are large differences in the thermal expansion coefficient between FePd layer and quartz glass substrate, holes form in the films after post-annealing at 550 °C due to stress release and the characteristic of thin film, which gives rise to magnetoelastic effects. The result is consistent with the conclusion of Carbucicchio et al. [21]. It suggests that the interface effects may play an important role on L10 ordering of FePd films.

Figure 4 exhibits the in-plane hysteresis loops at 300 and 120 K for Fe51Pd49 films annealing at 550 °C, respectively. By contrast, loop of 120 K shows a higher Hc and (BH)max, about 4.3 kOe and 24.2 MGOe respectively. The magnetic properties are composition dependent and are affected by Fe–Pd interactions within the particles [22]. The relatively large Hc of Fe51Pd49 may results from the large anisotropic field and optimized microstructure. These FePd films show a promise for application as high-density magnetic recording medium.

4 Conclusions

FexPd1−x (x = 37–64 at.%) films of 47 nm in thickness with different Fe concentrations were prepared on quartz glass substrates by dc magnetron sputtering. The crystal structure and magnetic properties of the films were characterized. The results show that the FexPd1−x films with Fe concentration x ≤ 37 at.% has disordered structure and soft magnetic properties. For the Fe43Pd57 films, the fcc–fct phase transition begins to occur in the sample after a heat treatment at ~550 °C. When the Fe content is close to equiatomic composition, the performance of the Fe51Pd49 film is optimal, the Hc, Mr/Ms and (BH)max reach to 3.5 kOe, 0.94 and 17.6 MGOe at 300 K, respectively, and the Hc increases to ~4.3 kOe at 120 K. In this work the preparation process of FePd films is simplified, the temperature of fcc–fct phase transition is lowered to 550 °C and better magnetic properties are achieved. The correlation between the structure and magnetic properties provides basic insights and useful information for further development of FePd-based application.

References

M. Weisheit, S. Fähler, A. Marty, Y. Souche, C. Poinsignon, D. Givord, Electric field-induced modification of magnetism in thin-film ferromagnets. Science 315(26), 349–351 (2007)

C.Y. Shen, H.W. Chang, F.T. Yuan, M.C. Lin, C.C. Su, H.H. Yeh, M.F. Huang, C.R. Wang, C.W. Shih, W.C. Chang, Energy product enhancement of FePt films by underlayering with Ti, Zr, and Hf. Appl. Surf. Sci. 313, 755–761 (2014)

J.C. Chiu, W.C. Wen, L.W. Wang, D.S. Wang, C.H. Lai, Effects of B additions in FePt and FePt: c films. J. Appl. Phys. 115(17), 17B713 (2014)

L. Ma, Z.W. Liu, H.Y. Yu, X.C. Zhong, Y.P. Zeng, D.C. Zeng, X.P. Zhong, High coercivity FePtSiN films with L10–FePt nanoparticles embedded in a si-rich matrix. IEEE Trans. Magn. 47(10), 3505–3508 (2011)

O.D. Oniku, B. Qi, D.P. Arnold, Electroplated L10 CoPt thick-film permanent magnets. J. Appl. Phys. 115(17), 17E521 (2014)

T. Ichitsubo, S. Takashima, E. Matsubara, S. Tsukimoto, Y. Tamada, T. Ono, Control of c-axis orientation of L10-FePd in dual-phase-equilibrium FePd/Fe thin films. J. Appl. Phys. 109, 033513 (2011)

Y.C. Chang, S.N. Hsiao, S.H. Liu, S.K. Chen, Y.T. Liu, H.Y. Lee, A.C. Sun, J.G. Dhu, Influence of stoichiometry and growth temperature on the crystal structure and magnetic properties of epitaxial L10 Fe–Pd (001) films. J. Appl. Phys. 115(17), 17A740 (2014)

M. Kohda, S. Iimori, R. Ohsugi, H. Naganuma, T. Miyazaki, Y. Ando, J. Nitta, Structural and magnetic properties of L10-FePd/MgO films on GaAs and InP lattice mismatched substrates. Appl. Phys. Lett. 102(10), 102411 (2013)

M. Perzanowski, Y. Zabila, M. Krupinski, A. Zarzycki, A. Polit, M. Marszalek, Chemical order and crystallographic texture of FePd: Cu thin alloy films. J. Appl. Phys. 111(7), 074301 (2012)

N.I. Vlasova, N.M. Kleinerman, V.V. Serikov, A.G. Popov, Mössbauer study of fine structure features of equiatomic FePd alloy after severe plastic deformation and ordering annealing. J. Alloy. Compd. 583, 191–197 (2014)

S.N. Hsiao, S.H. Liu, C.C. Chen, C.L. Chou, S.K. Chen, S.H. Su, K.F. Chiu, C.K. Sung, A comparison of rapid-annealed FePt and FePd thin films: internal stress, L10 ordering, and texture. Vacuum 125, 1–5 (2016)

A.C. Sun, K.A. Hsu, C.F. Huang, Heat treatment methods on magnetic properties and microstructure of FePd alloy thin films. IEEE Trans. Magn. 50(1), 2300804 (2014)

D. Halley, A. Marty, P. Bayle-Guillemaud, B. Gilles, J.P. Attane, Y. Samaon, Chemical order and selection of the mechanism for strain relaxation in epitaxial FePd(Pt) thin layers. Phys. Rev. B 70(17), 174438 (2004)

C. Clavero, J.M. Garcí, Martí-a, n, J. L. Costa Krä, mer, G. Armelles, A. Cebollada, Y. Huttel, R. A. Lukaszew, A. J. Kellock. Temperature and thickness dependence at the onset of perpendicular magnetic anisotropy in FePd thin films sputtered on MgO(001). Phys. Rev. B 73(17), 174405 (2006)

D.H. Wei, Y.D. Yao, Controlling microstructure and magnetization process of FePd (001) films by staged thermal modification. Appl. Phys. Lett. 95(17), 172503 (2009)

N. Sakuma, T. Ohshima, T. Shoji, Y. Suzuki, R. Sato, A. Wachi, A. Kato, Y. Kawai, A. Manabe, T. Teranishi, Exchange coupling interaction in L10-FePd/α-Fe nanocomposite magnets with large maximum energy products. ACS Nano 5(4), 2806–2814 (2011)

H.W. Chang, F.T. Yuan, W.C. Chen, D.H. Wei, M.C. Lin, C.C. Su, C.R. Wang, C.W. Shih, W.C. Chang, Y.D. Yao, Hard magnetic property improvement of sputter-prepared FePd films on glass substrates by underlayering with refractory Nb, Mo, and W elements. IEEE Trans. Magn. 51(11), 2102904 (2015)

L. Ma, L. Zhou, T. Liu, S.Q. Zhao, L. Li, X.F. Wu, Y.L. Zhang, G. Cheng, Microstructure and magnetic properties of self-assembled FePd–SiN films. J. Mater. Sci.: Mater. Electron. 27(7), 7420–7424 (2016)

S.H. Liu, C.C. Chen, S.N. Hsian, S.K. Chen, Y.C. Chang, S.H. Su, K.F. Chiu, Crystallographic structure and magnetic properties of polycrystalline FePd thin films on glass substrate. Appl. Phys. A 119, 623–627 (2015)

J. Lyubina, O. Gutfleisch, O. Isnard, Phase transformations and magnetic structure of nanocrystalline Fe–Pd and Co–Pt alloys studied by in situ neutron powder diffraction. J. Appl. Phys. 105(7), 07A717 (2009)

M. Carbucicchio, A. Valenti, G. Battaglin, P. Mazzoldi, R. Dal Maschio, Mössbauer and adhesion study of H+ implanted iron films on insulators. Radiat. Eff. Defect S 98(1–4), 21–26 (1986)

H.G. Boyen, K. Fauth, B. Stahl, P. Ziemann, G. Kastle, F. Weigl, F. Banhart, M. Hessler, G. Schutz, N.S. Gajbhiye, J. Ellrich, H. Hahn, M. Buttner, M.G. Garnier, P. Oelhafen, Electronic and magnetic properties of ligand-free FePt nanoparticles. Adv. Mater. 17(5), 574–578 (2005)

Acknowledgements

This work is supported by the Guangxi Natural Science Foundation (2016GXNSFAA380030, 2013GXNSFBA019242), Innovation Project of GUET Graduate Education (YJCXS201564) and the National Natural Science Foundation of China (51461012, 51261004).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, T., Ma, L., Zhao, S.Q. et al. Crystal structure and magnetic properties of FexPd1−x thin films annealed at 550 °C. J Mater Sci: Mater Electron 28, 3616–3620 (2017). https://doi.org/10.1007/s10854-016-5963-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5963-6