Abstract

Carboncoated maghemite (γ-Fe2 O 3) particles with nanoscale sizes were synthesized by an inexpensive and environmental friendly hydrothermal electrochemical method in a one-step process. Glucose and ferric citrate were used as the carbon and iron source, respectively. Transmission electron spectroscopy (TEM) analysis indicated that a carbon layer was coated on the surfaces of the individual γ-Fe2 O 3 nanoparticles prepared at 180 °C. The composition and phase structure of as-prepared materials were characterized by Raman and Fourier transform infrared spectroscopy (IR). Electromagnetic properties of the carbon/maghemite complex materials were measured using vibration sample magnetometer (VSM). The saturation of as prepared γ-Fe2 O 3/C nanocomposition was 31.2 emu/g.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nanoscale magnetic iron oxides offer a high potential application in several areas such as electronics, optoelectronics, medicine, magnetic storage, and biotechnologies [1–4]. Nanosized materials are known to take on peculiar properties compared to the bulk material. For instance, iron oxide magnetic nanoparticles have received considerable attention concerning the cleanup of environmental contaminants because of their small particle size, high surface area, catalytic activity, low cost, and ease of preparation [5]. However, iron nanoparticles are sometimes unstable, and their stabilization particularly in terms of aggregation and oxidation in air is a crucial point to be solved. These deficiencies could be avoided by coating ferromagnetic nanoparticles with different stable and nonmagnetic materials [6–10]. Among them, carbon materials have attracted more interest than other materials due to the high electrical conductivity, low cost, broad chemical, and physical stability [9, 10]. Various techniques have been developed for synthesis of such nanocomposite structures, including arc techniques [9], laser pyrolysis method [11], catalytic chemical vapor deposition (CVD) [12], and magnetron and ion-beam sputtering [13]. However, one-step method has not been reported for the synthesis of C/γ-Fe2 O 3 complex materials from solution so far.

In this paper, we reported the preparation of γ-Fe2 O 3 core carbon shell obtained by hydrothermal electrochemical method in one step. γ-Fe2 O 3/C materials were synthesized under mild aqueous conditions. The γ-Fe2 O 3/C obtained this way could be dispersed well in aqueous solution, and there were functional groups on its surface, which facilitated further modification in future applications.

2 Experimental

Ta substrates with 10 × 10 × 0.1 mm 3 dimensions of 99.9 % purity were mechanically polished and degreased with acetone using an ultrasonic cleaner. Ferric citrate and glucose were of reagent grade and were used without any further purification. To form a transparent ferric citrate solution, 1.22 g ferric citrate (FeC6 H 5 O 7, 0.005 mol) was dissolved in 100 mL distilled water Then, 1.0 g glucose (C6 H 12 O 6, 0.005 mol) was added into the solution and stirred.

The detailed description of the deposition facility and the growth method has been given elsewhere [14]. A typical preparation process was carried out under galvanostatic conditions with a constant current density 0.001 mA/cm 2 for 20 h. And the temperature of bath was maintained at 180° C or 170 °C. After each experiment, black powders were obtained. The powders were washed with water, ultrasonically in ethanol, and air-dried prior to characterization.

Raman (Labram HR 800, Jobin-Yvon) and IR spectroscopy (Nicolet Nexus 670) were employed to characterize the structure and bond parameters. The morphology of the samples was examined by TEM (JEM-1200EX). And the magnetic properties (M–H curve) were measured using VSM (HHZ15) at room temperature.

3 Results and Discussion

3.1 FTIR Spectroscopy

Figure 1a, b showed the FTIR spectra of as-prepared samples prepared at 180 °C (sample A) and 170 °C (sample B), respectively. FTIR spectra revealed the coexistence of γ-Fe2 O 3 and carbon, in which 580 and 630 cm −1 was assigned to maghemite [15], and 2927, 2854, 1627, 1562, 1387 and 1113 cm −1 to carbon [16–21]. The absorption bands at 2927, 2854, and 1387 cm −1 were corresponding to hydrogen bonded sp 3 carbon [16, 17], 1627 cm −1 to C =O bonds [18], 1562 cm −1 to C =C bonds [19], and 1113 cm −1 to C =C–H or C–O–C groups [20, 21]. Among them, the relative intensity of Fe–O, C =C–H, and CH3 bonds in sample A was stronger and the peak at 1562 cm −1 was only found in sample A, indicating that the hydrothermal electrochemical reaction was more exhaustive at 180 °C. Beside the main products, the peaks at 3435 and 2373 cm −1 implied the existence of residual hydroxyl groups [22] and byproduct of CO\(_{3}^{2-}\) [23].

3.2 Raman Spectroscopy

The Raman spectra were searched by exciting the sample with the visible light (488 nm) of an argon ion laser. Figure 2 showed the Raman spectra of samples A under different excitation energies. As shown in Fig. 2, the laser power has no clear effect on the sample, indicating no sample degradation by laser irradiation. The displayed spectrum revealed the presence of γ-Fe2 O 3 at 378, 524, and 678 cm −1 [24] and as an other phase carbon at 1361, 1589, and 1428 cm −1 [25, 26]. The peak around 1361, 1589 and 1428 cm −1 was assigned to D, G and sp 3-CH n , respectively [25, 26]. The Raman spectrum also showed a band at 1045 cm −1 owing to the presence of CO\(_{3}^{2-}\) [23].

The Raman spectra of sample B are shown in Fig. 3. The spectrum recorded with 1 mW showed the same behavior as sample A, but when the laser power was raised to 5 mW, new bands showed up. The new bands at 179, 218, and 282 cm −1 were characteristic of hematite [27]. Moreover, the intensity of the D and G peak strongly decreased with increasing laser power. It indicated that unstable carbon prepared at 170 ∘C gradation by laser irradiation, the carbon could not afford effective protection, and maghemite was assumed to transform into hematite during high-power laser radiation.

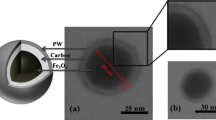

3.3 TEM Analysis

Figures 4 and 5 showed the TEM images of sample A and sample B, respectively. According to Fig. 4, dispersible carbon-stabilized γ-Fe2 O 3 nanoparticles with average particle size of 10 nm could be obtained at 180 °C. However, coarse aggregates consisting of tens of γ-Fe2 O 3 particles were observed in Fig. 5.

3.4 VSM Analysis

Figure 6 showed the magnetization curves of the sample A and sample B at room temperature. The corresponding saturation magnetizations strengths (M s) were 31.2 and 13.6 emu/g, respectively. These values were much lower than 76 emu/g of the corresponding bulk magnetite [28], which could be attributed to the nanosize of the γ-Fe2 O 3 particles and the presence of carbon [29, 30].

The saturation magnetization for sample B was lower than that of sample A. This might be attributed to high proportion of non-crystal form of carbon, OH − and nonmagnetic iron oxide.

4 Conclusion

The C/ γ-Fe2 O 3 powders with high magnetization (31.2 emu/g) was obtained by a hydrothermal electrochemical technique at 180 ∘C one step. The dispersible γ-Fe2 O 3 nanoparticles with average particle size of 10 nm were stabilized by carbon. The carbon could afford an effective protection against maghemite transforming into nonmagnetic hematite.

References

Yamauchi, S., Hibino, M., Yao, T.: Structure change analysis in γ-Fe2 O 3/carbon composite in the process of electrochemical lithium insertion. Solid State Ionics 191, 45–48 (2011)

Ma, Y., Jia, G., Lee, J.Y.: Synthesis of mixed-conducting carbon coated porous γ-Fe2 O 3 microparticles and their properties for reversible lithium ion storage. J. Mater. Chem. 21, 13009–13014 (2011)

Ou, C.R., Shen, C.I., Ou, C.M.: Biocompatibility of Fe2 O 3 nanoparticles for the activation of glia cell migration. J. Supercond. Nov. Magn. (2013). doi:10.1007/s10948-010-0692-1

Prucek, R., Tucek, J., Kilianova, M., Panacek, A., Kvitek, L., Filip, J., Kolar, M., Tomankova, K., Zboril, R.: Preparation and antibacterial properties of magnetic nanocomposite of iron oxide and silver nanoparticles. Biomater 32, 4704–4713 (2011)

Baikousi, M., Bourlinos, A.B., Douvalis, A., Bakas, T., Anagnostopoulos, D.F., Tucek, J., Safarova, K., Zboril, R., Karakassides, M.A.: Synthesis and characterization of γ-Fe2 O 3/carbon hybrids and their application in removal of hexavalent chromium ions from aqueous solutions. Langmuir 28, 3918–3930 (2012)

Jafari, A., Boustani, K., Shayesteh, S. Farjami: Effect of carbon shell on the structural and magnetic properties of Fe3 O 4 superparamagnetic nanoparticles. J. Supercond. Nov. Magn. (2013). doi:10.1007/s10948-013-2239-8

Keng, P.Y., Shim, I., Korth, B.D., Douglas, J.F., Pyun, J.: Synthesis and self-assembly of polymer-coated ferromagnetic nanoparticles. ACS Nano. 1, 279–292 (2007)

Guskos, N., Likodimos, V., Glenis, S.: Magnetic properties of γ-Fe2O3/poly(ether- ester) nanocomposites. J. Nanosci. Nanotechno. 8, 2127–2134 (2008)

Brunsman, E.M., Sutton, R., Bortz, E., Kirkpatrick, S., Midelfort, K., Williams, J., Smith, P., McHenry, M.E., Majetich, S.A., Artman, J.O., Graef, M.D., Staley, S.W.: Magnetic properties of carbon-coated ferromagnetic nanoparticles produced by a carbon arc method. J. Appl. Phys. 75, 5582–5584 (1994)

Hayashi, K., Kamigaki, M., Morii, H.: Novel method for coating magnetic iron oxide particles with carbon black. J. Am. Ceram. Soc. 83, 2901–2906 (2000)

Bi, X.X., Ganguly, B., Huffman, G.P., Huggins, F.E., Endo, M., Eklund, P.C.: Nanocrystalline α–Fe, Fe3C, and Fe7 C 3 produced by CO2 laser pyrolysis. J. Mater. Res. 8, 1666–1674 (1993)

Sano, N., Akazawa, H., Kikuchi, T., Kanki, T.: Separated synthesis of iron-included carbon nanocapsules and nanotubes by pyrolysis of ferrocene in pure hydrogen. Carbon 41, 21592179 (2003)

Delaunay, J.J., Hayashi, T., Tomita, M., Hirono, S., Umemura, S.: CoPtC nanogranular magnetic thin films. Appl. Phys. Lett. 71, 3427–3429 (1997)

Tao, Y., Chen, Z.H., Zhu, B.J., Huang, W.Z.: Preparation of preferred oriented LiCoO2 thin films by soft solution processing. Solid State Ionics 161, 187–192 (2003)

Anand, N., Reddy, K.H.P., Satyanarayana, T., Rao, K.S.R., Burri, D.R.: A magnetically recoverable γ-Fe2 O 3 nanocatalyst for the synthesis of 2-phenylquinazolines under solvent-free conditions. Catal. Sci. Technol. 2, 570–574 (2012)

Pozefsky, A., Coggeshall, N.D.: Infrared absorption studies of carbon-hydrogen stretching frequencies in sulfurized and oxygenated materials. Anal. Chem. 23, 1611–1619 (1951)

Heitz, T., Drevillon, B., Godet, C., Bouree, J.E.: Quantitative study of C-H bonding in polymerlike amorphous carbon films using in situ infrared ellipsometry. Phys. Rev. B 58, 13957–13961 (1998)

Titirici, M.M., Thomas, A., Antonietti, M.: Aminated hydrophilic ordered mesoporous carbons. J. Mater. Chem. 17, 3412–3418 (2007)

Santos, C.M.B., Silva, S.W.D., Guilherme, L.R., Morais, P.C.: SERRS study of molecular arrangement of amphotericin B adsorbed onto iron oxide nanoparticles precoated with a bilayer of lauric acid. J. Phys. Chem. C 115, 20442–20448 (2011)

Cao, F.Y., Chen, C., Wang, Q., Chen, Q.W.: Synthesis of carbon–Fe3 O 4 coaxial nanofibres by pyrolysis of ferrocene in supercritical carbon dioxide. Carbon 45, 727–731 (2007)

Wang, H., Shen, M.R., Ning, Z.Y., Ye, C., Dang, H.Y., Cao, C.B., Zhu, H.S.: Deposition of underhydrogenated diamond-like amorphous carbon films by electrolysis of organic solutions. Thin Solid Films 293, 87–90 (1997)

Simons, W.W.: Editor, The Sadtler handbook of infrared spectra. Sadtler research laboratories Inc., Philadelphia (1978)

Kloprogge, J.T., Wharton, D., Hickey, L., Frost, R.L.: Infrared and Raman study of interlayer anions CO\(_{3}^{\mathrm {2-}}\), NO\(_{3}^{\mathrm {-}}\), SO\(_{4}^{\mathrm {2-}}\) and ClO\(_{4}^{\mathrm {-}}\) in Mg/Alhydrotalcite. Am. Mineral 87, 623–629 (2002)

Sousa, M.H., Tourinho, F.A., Rubim, J.C.: Use of Raman micro-spectroscopy in the characterization of MIIFe2 O 4 (M = Fe, Zn) electric double layer ferrofluids. J. Raman Spectrosc. 31, 185–191 (2000)

Ferrari, A.C., Robertson, J.: Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 61, 14095–14107 (2000)

Ristein, J., Stief, R.T., Ley, L., Beyer, W.: A comparative analysis of a-C:H by infrared spectroscopy and mass selected thermal effusion. J Appl. Phys. 84, 3836–3847 (1998)

Mazzetti, L., Thistlethwaite, P.J.: Raman spectra and thermal transformations of ferrihydrite and schwertmannite. J. Raman Spectrosc. 33, 104–111 (2002)

Montagne, F., Mondain, M.O., Pichot, C., Mozzanega, H., Elaissari, A.: Preparation and characterization of narrow sized (o/w) magnetic emulsion. J. Magn. Magn. Mater. 250, 302–312 (2002)

Martinez, B., Obradors, X., Balcells, L., Rouanet, A., Monty, C.: Low temperature surface spin-glass transition in γ- Fe2 O 3 nanoparticles. Phys. Rev. Lett. 80, 181–184 (1998)

Dong, X.P., Chen, H.R., Zhao, W.R., Li, X., Shi, J.L.: Synthesis and magnetic properties of mesostructured γ- Fe2 O 3 /carbon composites by a co-casting method. Chem. Mater. 19, 3484–3490 (2007)

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 50602051).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, Y., Yi, D., Zhu, B. et al. One-Step Hydrothermal-Electrochemical Route to Carbon-Stabilized γ-Fe2O3 Powders. J Supercond Nov Magn 28, 169–172 (2015). https://doi.org/10.1007/s10948-014-2831-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-014-2831-6