Abstract

Water pollution by hydrocarbon derivatives is one of the significant problems and challenges globally and is one of the leading causes of disease and environmental catastrophes. Increasing oil effluents have become a primary global concern due to damage to living ecosystems and marine life. This oil should be removed from the water or the surface to protect the water and the environment. One of the most important remedies for oil spills is using sorbent materials. Conventional synthetic sorbents for oily water treatment are the most broadly applied materials, although they are not the optimal selection from environmental and economic points of view. However, the utilization of biobased sorbents derived from natural materials with environmentally friendly, low-cost, reusability, abundant, and biodegradability properties can be an ideal alternative for convectional synthetic sorbent, with a positive effect on sustainability and circular economy. These types of sorbents are used with various sizing from micro to nanoscale in different forms (membrane, aerogel, foam, and sponge). The objective of this paper is to review a report on the use of porous biobased sorbents in both natural and modified forms which are available in nature or our lives. Modification strategies for improving hydrophobicity of biobased sorbent were also broadly highlighted. Finally, the challenges and future research directions of this promising research field are briefly discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The treatment of oily water produced by many industries such as pharmaceutical, textiles, tanning, mining, petrochemical, metallurgical, shipping and maritime, food, and metal/steel industries has become a serious global environmental concern all over the world. Discharging oily wastewater without treatment results in different adverse effects on the environment by polluting soil, surface water, underground water, and an ecological system [1, 2]. The oil phase in wastewater can exist in three forms, dispersed oil (20 to 150 µm), free oil (> 150 µm), and emulsified oil (< 20 µm) [3].

The choice of and performance of oily water treatment methods depend on oil droplet sizes and other factors, like chemical composition, oil concentration, treatment efficiency, costs, and end- use of wastewater [4]. Numerous chemical and physical methods have been developed using different concepts for destabilizing oily wastewater treatment. They contain oil skimmers, coagulation, gravity separation, dissolved air floatation, photocatalytic, biological process, and membrane method [5,6,7,8,9].The adsorption process is one commonly, simply, and practical strategy for oil spills cleanup and removing organic dissolved in water, which has received much attention in recent years [10, 11]. The United State Environmental Protection Agency (USEPA) declared the best wastewater treatment method is adsorption, among others [12]. The adsorption process involves separating a substance from one phase accompanied by its accumulation or concentration at the surface of another [13].

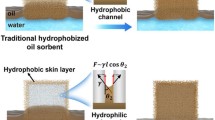

Various inorganic and organic materials have been applied as sorbents for oily water treatment. Generally, an ideal sorbent for oil cleanup has properties like high hydrophobicity, cost-effective, efficient uptake capacity, oleophilic, available, low density, non-toxic, high sorption capacity, porous enough with high surface area, and biodegradable [14].

Sorbents for oil spills cleanup can be classified into the groups' synthetic sorbents, natural organic, and natural inorganic sorbents [10, 15, 16]. Natural inorganic sorbents like alumina-phosphates, zeolite, silica, clay, and alumina are minor in spill cleanup. Their sorption capacity is about (4–20)g/g with little buoyancy properties [15, 17].

Common synthetic sorbents are polypropylene, polyester, and polystyrene foam. They have high oleophilic and hydrophobic features, and their sorption capacity is about 70 g/g; they can also recover and be used several times. These conventional sorbents are expensive, poorly biodegradable, unable to sorb adequately, and not environmentally friendly [18,19,20,21]. These have caused engineers, researchers, and scientists to consider the development of organic natural materials like agricultural waste and products, biodegradable polymer, and households waste as non-conventional materials that are available in our life or in nature and can be utilized as a novel part of oily wastewater remediation process [17, 22,23,24,25].

Agricultural waste and products-based sorbents are porous, cheap, biodegradable, efficient, and environmentally friendly. However, efficiency is related to density, sorption capacity, recyclability, and retention rate; examples are kapok fiber, rice husk, cotton, sawdust, luffa, and lignin. These materials are oleophilic due to their waxy nature [26,27,28].

Biodegradable polymeric materials (BPMs) are most commonly termed as biopolymers, and there are two classes of biodegradable polymers: natural and synthetic. Natural polymers from non-plant products like chitin and chitosan, as well as from plant products like cellulose, developed during a long course of evolution in nature, whereas the synthetic polymer is the outcome of just a century’s worth of research and development. In addition, both natural and synthetic are renewable, biocompatible, low-cost, non-toxic, and biodegradable [29,30,31]. In most home waste containers, eggshells, waste paper, fruit peel, and vegetable waste make up the highest proportion. Many vegetables and fruits are disposed of and fed to livestock or debris. They must be recycled or managed because of their harmful environmental effect. These materials are natural, green, and economical sources of sorbent for eliminating various types of waste contaminants and reducing pollution [32, 33].

This paper reports various types of modifications to natural sorbent materials for oily wastewater treatment that enhance properties like hydrophobicity and sorption capacity. The modification should, ideally, maintain the beneficial characteristics of the native material while strengthening its weaker properties [25, 34].

While there have been a few numbers of review papers on various kinds of porous biodegradable sorbent for oil spills cleanup, this article includes the activities conducted by numerous researchers in the recovery and removal of spilled oils using non-conventional sorbents that have been applied in oily wastewater treatment both in natural and modified form.

2 Types of porous biodegradable sorbents

Many different types of porous biodegradable sorbents such as agricultural wastes and products, natural polymers, and household waste are used for oily wastewater treatment.

Ideal biodegradable sorbents have some criteria like:

-

Be environmentally friendly.

-

Has a high sorption capacity for removing high pollutants

-

Low concentration in water / effluent; selectively.

-

Absorbed contaminants can be easily removed from the surface.

-

Be recyclable

The density values for the common various oils/solvents in wastewater are reported in the literature (see Table 1).

3 Agricultural waste and products

3.1 Luffa based sorbents

Luffa cylindrical is a lignocellulosic material composed primarily of cellulose, hemicellulose, and lignin with a continuous 3D macropore surface. Luffa sponge is extremely light, with a specific gravity of 0.92 g/cm3, low bulk of (30–04) g/cm, surface area of 850 m2/m3, and permeability of 79–93%. Additionally, luffa sponges can be found for a reasonable price in China, Japan, and other nations in Asia and South America. Due to its excellent mechanical qualities, renewable structure, high water sorption capacity, stable structure, and degradability, this sponge has many uses in daily life [35,36,37,38] see Fig. 1.

Hydrophobic bio-waxes, like Carnauba wax (CW) and rice bran wax, can become entirely non-toxic right away after being dissolved in polar solvents. These bio-based waxes produce rougher coatings with lower energy and textural levels. They can be used to create super-hydrophobic surfaces and have potential uses in the paper, wood, and food packaging industries. These waxes are among the low-energy natural materials with a variety of benefits, including affordability, abundance, commercial viability, ease of production, renewable resources, and environmental friendliness. However, their greatest benefit is the absence of organic solvents and chemicals, which makes them more suitable for industrial use [41]. The wax layer created the composite microstructure of the particle/film, which made the super-hydrophobic coating extremely stable when submerged in different oils and water and highly corrosion resistant. The ultra-hydrophobic and ultra-oil-friendly Luffa sponge was able to remove oil from the surface of water with great efficiency (91%), a high sorption capacity (9.5 g/g), and reusability (less than 10 Periods) [42] see Fig. 2.

A Schematic diagram of the preparation of modified luffa sponge using rice bran and carnauba wax [42]

The surface of the luffa sponge was modified with NaOH (0.5 N) for 2 h in order to cleanup impurities and make the surface ready to react with the substance. Then, a milky white colloidal suspension was created by mixing water-based polyurea adhesive and SiO2 nanoparticles in an organic ethanol solvent. After that, luffa sponges were dipped in the solution and dried. A high degree of chemical and mechanical resistance, hydrophobicity, and oil friendliness were all displayed by the modified luffa sponge [43]. In another study, modified luffa sponges using graphene were suggested. They removed the impurities on the surface of the sponge by alkalizing it. By immersion and drying, modified graphene was then applied to the sponge's surface. The sponge was converted from being hydrophilic to hydrophobic. The outcomes demonstrated the modified luffa sponge's excellent oil sorption stability [44]. Additionally, a novel technique used F-SiO2-NPs (fluorine silica) nanoparticles made by the sol–gel technique to coat the surface of a hydrophilic luffa sponge. According to the results, the modified luffa sponge had a high WCA of 156° and high hydrophobicity [45]. Another study found that a simple coating of Polyhedral Oligomeric Silsesquioxane (POSS) on the surface of the luffa sponge increased the amount of sorbent by 8 to 12 times its weight for a range of oils. It could be recycled for different times in use. Furthermore, the modified luffa sponge has a WCA ~ 155°. The result displayed that sorption capacity decreased with increased oil viscosity and pore size [46]. Similarly, another study created a biodegradable superhydrophobic, super-oleophilic, eco-friendly, and cost-effective luffa/graphene/carnauba and beeswax sponge with a sorption capacity of about 11.92 g/g and a sorption efficiency of more than 91.32% after 10 cycles, and the as-synthesized modified luffa sponge-maintained oil recovery of about 91.32% after 10 cycles [47].

3.2 Wood based sorbents

The fabrication process of superhydrophobic wood sponge modified by reduced graphene oxide fluoralkylene silane (F-Rgo@WS) is shown in Fig. 3. In this research, balsa wood was selected as a cheap and biodegradable material. A two-step chemical treatment was performed to obtain longitudinal channels and eliminate hemicellulose and lignin compounds from the natural wood cell wall to synthesize a highly porous wood sponge. First, the pieces of balsa wood were dignified in 2Wt% NaClO2 solution for 12 h at 105 °C. Then, wood samples were transferred for the second step of chemical treatment with 8wt% of NaOH solution for 12 h at 80 °C, followed by freezing drying for 6 h at − 15 °C. Finally, the treated wood sample was immersed in a graphene oxide (GO) solution. The obtained wood sponge modified by graphene oxide was chemically reduced by ascorbic acid. This sorbent with a contact angle of about 145° exhibited excellent sorption capacity of about 10 g/g and sorption efficiency of about 99% [48].

A Schematic diagram of the preparation of modified wood sponge a the cross-linking system of the as-synthesized hydrogel, b sponges' hydrophobic modification [48]

In another study, Wood sponges were prepared from natural balsa-derived wood; this sponge is applied for cleanup oil spills and organic pollutants. This study selectively removed lignin and hemicellulose using chemical treatment during two stages. It became a porous cellulose-layered structure with enough compression and mechanical traction. Then, a hydrophilic cellulose sponge with a silylating agent to produce. A hydrophobic and oil-friendly coating with chemical vapor deposition (CVD) results showed high selective removal of oily substances at about 41 g/g. In addition, the absorbed oils can be quickly recovered with simple mechanical pressure. Due to their low cost, scalability, and flexibility, these sorbents can be used as a good option for removing oily substances from water sources [49] see Fig. 4.

A Schematic diagram of the preparation of balsa-sensitized wooden sponge [49]

One complex organic polymer with antimicrobial qualities is rich in polyphenols and found in almost dry plants like the woody bark of trees and crop residues. After cellulose, this polymer which has a three-dimensionally branched architecture is the most common compound in the structure of woody and non-woody plants. However, hardwoods have less lignin content than softwood. This substance can be employed as a good alternative in the area of oil sorption from water due to its advantageous properties, which include environmental friendliness, low toxicity, biocompatibility, lipophilicity, and sensitivity to enzyme breakdown. Every year, an abundant amount of lignin is produced as post-harvest agro-biomass in the pulp and paper industries, which is actually wasted [50,51,52]. Lignin-modified melamine sponge (UHS) is used as a biodegradable sorbent with high hydrophobic and super-oleophilic properties with very low density, high porosity, high selectivity, oil friendliness, and recyclability. Moreover, other biomass such as tannins can be used as a modification agent to make an ideal sponge for cleaning up an oil spill. Oil sorption capacities of the UHS sponge were up to 217 g/g [53] see Fig. 5.

A Schematic of lignin location and structure in plants [54]

Lignin-based carbon aerogels are modified with graphene oxide nanoparticles (LCAGO) to separate the oil/water mixture. Graphene oxide is a well-known substance used to increase hydrophobicity and mechanical properties. Also, GO nanosheets contain functional groups such as carboxylic acid, epoxy, and hydroxyl, which can react vigorously with active sites, especially amine groups. In this synthesized aerogel, due to the strong bands created between the amine groups of lignin derivatives and the carboxylic groups of GO and acrylic acid (AA), it has more compactness and strength than the unmodified aerogel/lignin. The synthesized aerogel has a contact angle of 150° and a sorption capacity of about (32–34) g/g. Oluwasola Oribayo et al. reported a super-hydrophobic and super oleophilic lignin polyurethane foam modified by octadecyl amine (ODA) and reduced graphene oxide (rGO). LPU-rGO-ODA porous foam showed a high capacity for crude oil, chloroform, kerosene, and engine oil, with a sorption capacity of (26–68) g/g. Modified sponge showed excellent reusability over repeated sorption-squeezing and high selectivity for oil sorption capacity. After squeezing the oil-laden sponge, the absorbed oils in the sorbent could be eliminated and aggregated. The foam sorbent was now ready to be used again in the following sorption cycle [55] see Fig. 6.

A Schematic of the construction of LPU-rGO-ODA foam sorbent [55]

Lignin and cellulose are modified by carbon nanotube (CNT) in different conditions by using (CNT-COCl) in the presence of sodium hydroxide. The material can be immobilized with Fe3O4 nanoparticles, which causes easier separation. This study showed that the sorption capacity of CNT-g-Lignin/Fe3O4 and CNT-g-Cellulose/Fe3O4 is calculated as (15–25) g/g and (10–23) g/g, respectively, for several oil/organic solvents [56]. Super-hydrophobic and super oleophilic bio-based porous martial was prepared by cotton modified with lignin and bio-oil wax. The lignin and beeswax provide micro/nanoscale structures and low surface energy. This sponge's contact angle exceeds 150°, and it has good sorption properties for heavy oils with densities greater than or equal to 17 g/g, such as methylbenzene, ethyl acetate, trichloroethane, and soybean oil. Moreover, the advantages of porous materials are easy reactivation and recyclability. They found that by the increasing amount of lignin and temperature treatment, the rate of the biomass-based porous gradually increases and decreases, respectively [57].

Carbon foam was synthesized from polyurethane (PU) polymer as the template and lignin-phenol–formaldehyde (LPF) resin as the source of carbon. The lignin was extracted from sedge grass, and 25 wt.% phenol was replaced to create an LPF resin in an alkaline medium with as-synthesized carbon foams with exceptional, distinctive properties like low bulk density, effective oil sorption, open macrospores, and good water repellency. The capacities sorption of the carbon foams is (12 to 41) g/g for different kinds of organic solvents. Foam sorption efficiency maintenance remains more than 83% after 10 sorption tests. Additionally, carbon foams can be recycled by combusting the oil contained within their pores directly [58].

3.3 Cotton based sorbent

Cotton is a famous and common crop; this fiber is cheap, and products are often made from multiple fabrics. This sorption is an ideal oil-sorbent substrate because of its loose internal and small density[59, 60]. Calcagnile et al. created super oleophilic and super-hydrophobic cotton using a sol–gel method and subsequent octadecyl trichlorosilane (OTS) modification to add hydrophobicity to the material with a WCA of 156°. This martial difference and reusability for 10 times and almost constant sorption capacity [61]. Super-hydrophobic cotton fabric by dip-coating Cellulose nanocrystal (CNC) was obtained in order to sorption oil from oily water and separate different oil/water blends with high separation proficiency (> 98%). CNC nanocrystal with biodegradability, renewability, and nanoscale size was used as the rough structure component for modified cotton in place of inorganic nanoparticles was obtained. Moreover, this super-hydrophobic cotton exhibited high constancy, making it recyclable for different times without decreasing separation proficiency. This sorbent could be degraded hydrolytically for 10 weeks at 37 °C in a phosphate buffer solution with a 14.4% weight loss [62]. The biodegradable fabric was prepared from cotton fabric modified by natural acid–alkali-salt resistant urushiol @ TiO2. The as-synthesized U@TiO2-covered cotton has not only exceptional constancy toward high temperatures but also showed good resistance to acid–base solutions with different pH values and mechanical abrasion [63]. Graphene oxide-coated cotton displays the practical separation of oil /water mixture. Cotton was dipped into a dispersal of 30 ml GO aqueous solution. This nanoparticle-covered cotton also owned great mechanical features; the result showed that the graphene oxide-covered cotton's oil sorption capacity decreased slightly after ten cycles of oil–water separation. Moreover, the time which is necessary for oil sorbent was shortened. Furthermore, cotton/graphene oxide's oil-sorption capacity is up to 30 g/g [64].

3.4 Rice husk

Rice husk is an essential by-product in rice milling and constitutes a significant agricultural industry waste, including more than 70% hemicellulose, calluses, lignin, and 20% hydrated silica and ash content. Because the structure of rice husk is woody, tough, and insoluble in water, it can be a significant pollution problem for the environment. According to Food and Agriculture Organization in the United States (FAO), the annual rice paddy production is approximately 582 million tons annually [65].

In order to study the sorption capacities of diesel fuel and crude oil, black rice husk ash (BRHA) and white rice husk ash (WRHA) were produced through the thermal decomposition of raw rice in a fluidized bed pilot reactor under various sorbent conditions. The results showed that BRHA had been higher sorption capacity than WRHA in these operating conditions [66]. Obtained porous carbon composite modified with silica nanoparticles (C/SiO2) using pyrolysis of rice husk at 480 °C. The results showed that pyrolysis increases the hydrophobicity, buoyancy, and oil sorption capacity of foam sorbent [67]. Another study fabricated bio-waste sorption from rice husk to remove oils and petroleum products by alkaline treatment of rice husk at low temperature. Alkaline treatment by NaOH aims to remove silica. As a result, it produces a lignocellulose sorbent. Some factors like duration, temperature, and sodium hydroxide concentration were investigated. The result showed oil capacity of the modified rice husk was about 20 times its own weight [68].

3.5 Kapok fiber

Kapok fiber is a kind of natural fiber that has high oil sorption capacity because of its porous nature and waxy coating on the structure and has many hydroxyl groups in its structure. The oil spills sorption capacity is increased and improved using several surface modifications.

Kapok fibers that have been hydrophobically modified with SiO2 nanoparticles and polymerized butyl methacrylate (PBMA) were studied for oil sorption. The surface modified by a mix of PBMA and SiO2 improved the oil sorption capacity because of the low energy of PBMA and improved micro and nanoscale roughness on the fiber with hydrophobic silica nanoparticles. This sorbent can reuse at least 6 times via vacuum filtration. After 6 cycles of sorption and desorption, the decrease of oil sorption capacity does not exceed (6.1–10.2) %. In the oil–water mixture, the sorption capacity for different oil types such as soybean, diesel, crude, 20cst, and 150SNwas about (65–90 g/g) [69]. In another study, kapok fibers were modified by SiO2 nanoparticles via the sol–gel method and hydrophobic modification by hydrolyzed dodecyltrimethoxysilane (DTMS). Oil sorption capacity for soybean and diesel oil was about 58.8 g/g and 46.9 g/g, respectively. More than 90% of absorbed oil can be removed by vacuumed filtration, and after 8 cycles of sorption desorption, the loss of sorption capacity of fiber is no more than 20% [70]. The surface of kapok fibers and cotton was modified by dip coating of P-SiO2 nanoparticles. For prepared P-SiO2, polydimethylsiloxane (PDMS) was deposited on hydrophobic SiO2 nanoparticles. The dip-coated kapok fibers and cotton exhibited high repellency towards the water with WCA ~ 150 º, and modified cotton and kapok fibers showed a high oil sorption capacity of about (20–60 g/g) depending on the oil type. Moreover, oil absorbed can be mechanically extracted, and the sorbent can be reused easily [71].

3.6 Straw

Agricultural waste products include lignocellulosic straws, flax, barley, wheat, and oat. These straws are primarily composed of lignocellulose, cellulose, and hemicellulose, which contain carbon (C), nitrogen (N), hydrogen (H), and oxygen (O) [72].

Investigated the potential of a sorbent for oil removal, which was prepared from organic waste martial (barley straw). Two forms of barely straw were investigated: carbonized raw and commercial straw. Natural straw was pyrolyzed at (200–500 °C). The result showed that carbonized straw in pad form has the highest oil sorption capacity compared to commercial and raw straw; due to the thermal treatment of straw, the amount of water sorption was reduced [73].

In another study, the oil sorption capacity of three models of straw (oat, wheat, and barley) were investigated. The result showed that barely straw with an average particle size of about (150–1000) mm has a maximum oil sorption capacity of about 6.07 g/g. Oat and wheat, with an average size of about (425–600) mm, had an oil sorption capacity of about 5 g/g and 5.49 g/g, respectively. In addition, the result showed that oat straw could be used for many cycles and only an 18.45% absorbency value reduction after 6 cycles [74].

4 Biodegradble polymer

4.1 Natural polymer

4.1.1 Chitin & chitosan

Chitin is a long-acting polymer of n-acetylglucosamine, a glucose derivative found in various organisms such as crustaceans (shrimp and crabs) and aquatic animals (fish and coral) [75]. All these substances are impurities and must be removed to achieve the desired purity. In order to remove impurities, the crushed material (crustacean skin) is first treated with acid to attain the complete dissolution of the protein. Then the material to alkaline extracts is sent to dissolve the proteins. Finally, after a decolorization step, colorless materials are produced. It is extensively used in various fields such as agriculture, pharmacy, water purification, environment, and biotechnology. Chitin is used as an effective coagulant for water treatment [76, 77] see Fig. 7.

A Schematic diagram of preparation of chitin and chitosan by two different methods [78]

A super-hydrophobic chitin sponge was synthesized for the first time by freezing dried and using a thermal chemical vapor deposition of methyl trichlorosilane (MTCS) at diverse relative humidity. The average pore size was about (20 to 50) µm because the modified sponge, coated with MTCS on the surface of chitin, had an interconnected structure. In addition, MTCS nanofilaments are immobilized on the surface of the chitin matrix, which results in high hydrophobicity. So, this sponge showed excellent high mechanical durability and elasticity. The sponges could efficiently collect organic material from the water’s surface and bottom with more than 58 g/g. Microorganisms can biodegrade this sponge in the soil in less than 32 days [79].

The chitin/halloysite nanotube sponge (C/HNTs) was prepared for oil–water separation. The C/HNTs porous sponge was crosslinked by freeze-drying and epichlorohydrin and modified by 1-bromohexadecane ethanol solution to be a hydrophobic sponge. The mechanical properties, oil sorption capacity, efficiency, surface structure, and microstructure of the as-synthesized sponge were investigated. The absorption capacity of different types of oil and grease were investigated, like n-hexane, seed oil, chloroform, methylbenzene, acetone, and sunflower seed oil. The result showed that oil sorption capacity for hexane was 3.94 g/g, chloroform was 11.23 g/g, and oil sorption efficiency was about 98.7% [80] see Fig. 8.

A Schematic diagram of a process of modified sponges, b the cross-linking mechanism of hydrogel, and c the hydrophobic modification of sponges [80]

In another research, YDT Trang et al. synthesized an oleophilic and super-hydrophobic chitin-modified polyurethane foam sorbent. The elastic sorbent contained 10% chitin with a sorption capacity of 13.3 g/g. This sorbent had the highest sorption rate in the first (15–20) min but gradually decreased after 60 min. Due to the saturation of the porosity of the sorbent, the amount of sorption capacity reached its minimum value. The amount of sorption by this sorbent with chitin particles with a size of (1–3) mm is much higher than chitin particles with a size of (5–10) mm [81].

Chitosan (CS) is a natural, low-cost polymer used in different studies for oily wastewater treatment. Chitosan is poly [2-amino-2-deoxy-(1–4)-β-D-glucopyranose] and derived from chitin which is poly [β-(1 → 4)-2-acetamido-deoxy-2-D-glucopyranose] and produced by alkaline deacetylation of chitin. Chitosan is an appealing material for wastewater treatment because of its biodegradability, non-toxicity, hydrophilicity, biocompatibility, and presence of highly reactive amino (-NH2) and hydroxyl (-OH) groups [82]. Using chitosan in its flake or powder form is challenging due to its low surface area, high crystallinity, resistance to mass transfer, and low porosity. Chemical and structural modification of chitosan is a reason to improve chitosan sorption capacity. This modification contains cross-linking, grafting, combining chitosan with other sorbent materials, and using the ion-imprinting technique to improve the selectivity of chitosan sorbent's metal ions [83, 84] see Fig. 9.

A Schematic of Protonation and deprotonation equilibrium of chitosan [78]

Electrostatic interactions between chitosan polymer and (cs, itaconic acid, Fe3O4) and coating immersed in an ethanol solution of candelilla wax were used to create a biodegradable magnetic chitosan-based hydrophobic aerogel. Because of the hydrophobicity of magnetic nanoparticles (Fe3O4) and candelilla wax, the properties of synthesized aerosols for spill cleanup have improved. The as-synthesized aerogel has a high sorption capacity (17.7 to 43.8) g/g to a variety of organic liquids and oil-in-water emulsions as a filter. It is also water repellent with a contact angle of 147.9 °C, and the absorbed organic fluids are recovered as soon as they are exposed to ethanoic acid at 75 °C [83]. Another low-cost sorbent was obtained from oxidized chitosan aerogel with cellulose using cross-linking, freeze-drying, cold plasma, and cellulose oxidation modification. The as-synthesized aerogel displayed a high sorption capacity (13.77–28.20) g/g for several oils and organic solvents. This sorbent can be used for up to 50 cycles by squeezing the sorbent sponge [85] see Fig. 10.

A Schematic of absorption process of synthesized aerogel A oily substances, B and organic solvent [85]

A simple freeze-drying procedure synthesized porous three-dimensional chitosan aerogel (CSA). The as-synthesized aerogel was highly porous (porosity > 98.16%) and ultralight with a density ranging from 10.19 to 36.05 mg/cm3, and it had a density range of 10.19 to 36.05 mg/cm3 as well. Modify aerogel properties by coating hydrogel on the aerogel surface with a simple spray method. The result showed super hydrophilicity (θwater∼0°) in oil and superoleophobicity (θoil ∼162°) underwater. The as-synthesized aerogel has a sorption capacity as high as 147 times its own weight [86, 87]. Chitosan aerogel from waste industry seafood and prawn shells is found as a suitable sorbent for oil separation from oil–water solution. Some factors like the effect of initial concentration, contact time, pH, and mass sorption were investigated on efficiency value. They understood that the maximum sorption of oil by chitosan happened after 6 min of contact time. Moreover, the maximum oil sorption capacity from the acquis solution was 17.96 g/g [88]. Similarly, in another study, zirconium-chitosan composite (Zr–Cs–HS) was synthesized for sorption oil from oil/water pollution. The contact time's effect on eliminating oil from the water solution was investigated. Their study showed maximum oil removal was 79% when revealing 400 mg of sorbent to 25 ml of diluted solution after 4 h of contact time. The (Zr–Cs–HC) has had higher elimination efficiency than chitosan without any modification [89].

Prepared biodegradable microporous aerosol membrane and modified with chitosan biosynthesis to separate crude vegetable oil/water emulsion, bio-diesel/water emulsion, and oil spills wastewater from the water source. Aerogel membrane attracted much attention in recent years because of some advantages like disposal biodegradability, stability in different conditions, ease of the process, and less toxicity. The result showed that the permeate water purity of the synthesized aerogel membrane was > 99% at high water flux > 600 L.m− 2.h− 1 [90]. Also, in another research, super-hydrophobic and super-oleophilic chitosan sponges were produced by freeze-drying. The procedure is schemed for getting three dimensions porous with large pore volume and great compressive features. This sponge can adsorb oil from the water up to 99% and claims adsorptive capacity up to 60 times its own weight. After being reused for different cycles, it maintains a high adsorptive capacity [91]. The amphiphilic sodium salt of oleoyl carboxymethyl chitosan (NaO–CMCS) was available to remove floatable oil from the aqueous solution. For the emulsion study, oil diesel was selected as the oil phase. In this research, both (o/w) emulsion (1:1 v/v). For the prepared creamy emulsion, different content of NaO-CMCS (0.5–5 g/lit) and a calcium chloride dehydrate solution (0.1%) were poured into this solution. They reported about 75–85% and 19–49% from polluted aqueous seawater and deionized water, respectively. They could recover 20% oil from seawater with a 2 g/L concentration of NaO-CMCS, and 20% of oil from seawater, with a 2 g/L concentration of NaO-CMCS [92]. In another study, a novel and straightforward approach were made up of the Super-hydrophobic cellulose and chitosan composite aerogel (SCECS). With the help of electrostatic interaction and ion exchange, sodium stearate modifies the aerogel's surface. The hydrophobic and oil-friendly super-aerogel composite was selectively and with desirable properties such as sorption capacity above 10 g/g, WCA∼156°, and many cycles to adsorb oil emulsions stabilized with surfactants in water [93, 94] see figs. 11, 12.

A Schematic of SEM micrographs of aerogels surface a CE, b CECS and c SCECS. The cross-sectional SEM image of aerogels d CE, e CECS, and f SCECS [93]

A Schematic of A sorption capacity of SCECS aerogel for toluene water mixtures and the contact angle of SCECS aerogel after different separation cycles. B sorption capacities of SCECS aerogel for various oils and organic solvents [93]

4.1.2 Cellulose based sorbent

Cellulose is a natural liner polymer (polysaccharide) composed of glucose units with the formula (C6H10O5) X [95]. Generally, this biopolymer is synthesized by plants and found more in stalks and leaves. Due to excellent properties such as mechanical strength and hardness, lightweight, high porosity, resistance to hydrolysis, and biodegradability, it has the potential for the sorption of oily substances from water sources [96].

The super-hydrophobic cellulose aerogel was synthesized using the plasma treatment, physical–chemical foaming technique, and subsequent silane modification process to absorb and store oil. These aerogels have a three-dimensional skeletal structure and interconnected pores like a beehive with a low density of about 0.034 g/cm3 and high mechanical strength and contact angle of more than 156°. In addition, these aerogels have a high oil sorption efficiency of about 99%. These aerogels showed excellent mechanical resistance to abrasion and corrosion in strong acids, alkaline solutions, and marine salt environments. These sponges can be used for up to 30 cycles while maintaining and regenerating efficiency by immersing in ethanol [97] see Fig. 13.

A Schematic of a oil sorption steps by cellulose aerogel and b sorption of organic solvents by cellulose aerogel [97]

Using the freeze-drying and sol–gel methods to create cellulose aerogel, its hydrophobic properties were changed by adding trimethylchlorosilane (TMCS) or hexamethyldisilane (HMDS) to it while it was heated. Finally, the synthesized aerogel has high hydrophobic properties. It had a contact angle of about 100–150°, quickly removing many oil and grease stains [98] see Fig. 14.

A Schematic of a cellulose aerogel, b modified cellulose aerogel using TMCS, and c modified aerogel using HDMS [98]

Similarly, another study synthesized a three-dimensional hierarchical nano cellular aerogel foam with excellent oil sorption capacity. The effect of nano-cellulose and sodium dodecyl sulfate (SDS) concentration on fabricating a nano-cellulose aerogel foam (NAF) was investigated. The results show that the optimal concentrations of nano-cellulose and SDS for preparing this NAF/SDS three-dimensional aerogel are 0.4% and 0.2%, respectively. Moreover, the sorption capacity of aerogel sorbent for cyclohexane, ethyl acetate, and vacuum pump oil was 206.79 g /g, 194.75 g/g, and 145.2 g/g, respectively [99].

4.2 Synthetic polymer

In recent years, there has been a significant increase in interest in biodegradable materials such as polyglycolic acid (PGA), polyethylene adipate (PEA), polycaprolactone (PCL), polybutylene succinate (PBA), poly p-dioxanone (PDS), and poly lactic acid (PLA) for use in drug delivery, medicine, agriculture, packaging, wastewater treatment, and other areas. Many researchers are trying to modify traditional polymers to design novel polymer composites out of bio-based material and change their structure to be user-friendly. On the other hand, the synthetic biodegradable polymer has a positive economically and environmentally effect. It helps to reduce the need for synthetic polymer production [29, 100,101,102].

Fabrication of superhydrophobic and magnetic polylactic acid (SMPLA) nonwoven fabric for oil–water separation with the cost-effective, simple, and scalable method. First, polydopamine (PDA) was created on the surface of the biodegradable polylactic acid by polymerizing PDA to create a strong adhesion force. The PDA layer was then immobilized with iron oxide (Fe3O4) particles to give the magnetic fabric its characteristics and produce surface roughness. To reduce surface energy, poly (vinylidene fluoride-co-hexafluoropropylene) was applied to the fabric after it had been synthesized. The result showed the fabric exhibition great water repellency with WCA ~ 151.7°, oil sorption capacity for different oil−water mixtures was about 36 g/g, and oil sorption efficiency reached up to 99.5% [103].

An eco-friendly sorbent made from the biopolymer Polylactic acid (PLA) with honeycomb-like structures was prepared using a water-assisted thermally induced phase separation plan for effective oil spills cleanup. This sorbent could adsorb 27.3 g/g because of excellent properties like the large surface area of PLA and super-hydrophilicity features [104].

Using the Supercritical carbon dioxide (sCO2) process, are created cost-effective and biodegradable polylactic acid/poly (butylene succinate) (PLA/ PBS) foams with excellent oil sorption performance. PLA/PBS foam displays a lattice-like open-cell structure with 98.2% open-cell content. In the meantime, PLA/PBS open-cell foam has a porosity of 97.7% and an increased ratio of 43.6, which is about 315% higher than the former study. (PLA/PBS) foam can selectively adsorb oil from water to separate oil and water efficiently. PLA/PBS foam has a sorption capacity of (7.9–21.9) g/g for several organic solvents and oils [105].

5 House hold wastes

House hold waste like waste of paper, vegetable and fruit peels,and eggshells which more than 50% of their structure contains carbon or cellulose, are evaluated for oil separate from water [106]. Different peels like orange and banana are rich in cellulosic content and can eliminate oil more efficiently than lighter oils [107]. Prepared a sorbent from the usefulness of potato peel for separation lubricating oil /water aqueous solution. This sorbent exhibited an excellent potential for keeping in oil for a long time, and also oil sorption capacity of this sorbent was 2.15 g/g [108]. Similarly, natural pomelo peels powder fibers coated on the mesh by a facile spry method. The sorption efficiency of natural sorbent was more than 98% for a heavy and light oil mix after 50 cycles of the separation process [109]. The bio-waste banana peel was investigated for oil separate from water. They reported that different factors directly affect sorbent's oil capacity depending on factors like oil film thickness, temperature, oil type, and sorption time. This sponge can be reused more than 10 times until it reaches 50% of the first sorption efficiency [110]. Three different varieties of material, such as Garlic and Onion peels and sludge which contains calcium aluminum silicate, were formed in different steps of units in petroleum-like dissolved air floatation clarification and filtration. In this work, they examined the oil capacity of sludge sorption in two ways: thermal treatment and chemical treatment, and the result showed 1.388 and 0.8 g/g, respectively. In contrast, onion peel and garlic have sorption capacities of 0.455 g/g and 0.385 g/g, respectively [111]. One of the most common biomaterials in nature is eggshells; 11% of the egg's total weight is eggshell. An. important component of eggshells is MgCO3 (1%), calcite CaCO3 (94%), organic matter (4%), and Ca3 (PO4)2 (1%). Eggshell has a great combination of stiffness, impact resistance, strength, and toughness. Both modification and non-modification form of the eggshell has the potential for wastewater treatment. Calcination at a high temperature changes the eggshell structure due to the development of pores by the emission of carbon dioxide gas. The modified surface of eggshells by hexadecyl-trimethyl-ammonium-bromide surfactant solution (HDTMA-Br) was used as the treating agent. The surface-modified eggshell (SMES) was used to eliminate crude oil from water. The result showed that SMES could absorb oil from water in less than 10 min with 91.2% sorption efficiency [112]. Fabricated hybrid aerogel from banana peel/waste paper (BPWP) by combining different steps like pyrolysis, freeze-drying, and freezing-cast method. The result showed BPWP aerogels displayed a high-hydrophobicity WCA ~ 149.3°/under air superoleophobicity (OCA of 0°), high porosity, and compression strain of 75%, which can adsorb free oil, and high oil sorption capacity was about (35–115) g/g. Additionally, these aerogels efficiently separate different surfactant-stabilized water in oil emulsions driven solely via gravity. Also, it exhibited higher fluxes of up to 8550 L. m− 2.h− 1 and efficiency above 99.6% [113].

6 Benefits and limitations of porous biodegradable sorbents

Biodegradable biomass has been used in recent years as a raw material with many good properties for water treatment. For oil/water separation, bio-sorbent materials like lignin, cellulose, kapok, wood, cotton, luffa, paper, chitin, chitosan, polylactic acid, and fruit peels are used. These materials are excellent for cleaning up oil spills because they have some advantages over other types of sorbents, such as low cost, non-toxic, abundant, environmentally friendly, degradability, composability, low density, and mechanical and chemical stability. In addition, various modifications can improve the properties of materials, like sorption capacity and hydrophilicity. Ideally, the modification should enhance weaker properties and keep good features; for example, alkaline treatment of rice husk produced lignocellulose by removing silica on the surface. The limitations of bio-based sorbents are chemical modifications of sorbents which may increase the cost of treatment; these sorbents may leach out color into solutions on contact with water, and the collection of bio-based sorbents along with transportation to a processing area, create an extra cost. For clarity, there are different kinds of oil recovery methods reported in the literature (see Table 2).

7 Outlook and challenges with porous biodegradable sorbents

In the text above, various materials are used as biodegradable sorbents for oily water treatment. In this review, we discussed different sorts of biodegradable products that can be used as low-cost sorbents and used for oily wastewater treatment. Without a doubt, biodegradable material will increase shortly due to the leakage of oil resources in the environment applied for oily water treatment. One of the biggest challenges with sorbents is their efficiency which decreases when the viscosity of oil and emulsion increases due to emulsification and evaporation over a period of time.

In general, biodegradable sorbents have many advantages due to their biological origin and abundance. Also, the possibility of reusing the sorbent and recovering the oil is a desirable property of sorbent from an economical and environmental view. However, the low hydrophilicity of these materials can lead to low oil buoyancy properties and sorbent capacity. These materials can be modified to improve these properties, but doing so may reduce this sorbent's biocompatibility. To enhance the ability of sorbent materials to separate oil from water, they must undergo effective and environmentally friendly modification.

The emulsion can be stabilized by using hydrophilic and hydrophobic nanoparticles when the wettability of particles is partial with WCA (20–120°) or modified by a chemical-surfactant or bio-surfactant. The microsphere's porosity and surface area rule over nanosized particles in the oily water treatment. For stable emulsion, nanoparticles' dispersion rate must be higher. Moreover, emulsions stabilized through particles are more stable against coalescence than the chemical-surfactant or bio-surfactant stabilized emulsions, but sprayed or coated surface materials show a lack of long-time reusability and stability. Furthermore, the wetting properties of the separators are switchable between hydrophobic and hydrophilic states by surface modification with hydrophobic and hydrophilic materials. Moreover, hydrophilic and superoleophobic materials are superior to oleophobic and hydrophilic materials because of the reduction in water barrier capacity and external fouling.

8 Conclusion

Hydrocarbon contamination is of serious worry due to its widespread effect on all aspects of life. Oil contamination can occur during operational oil discharge from tankers, and spill oil from offshore platforms, ships, and pipelines, so treating oily wastewater before discharging to seas and oceans is necessary. In recent years biodegradable sorbent due to some features such as cost-effective, non-toxic, recovery of oil and reutilization of waste, available, easily regenerated, a significant decrease in the amount of oil in the water, and most economical methods for wastewater treatment received much attention in recent years. The challenge and opportunity for the future is to create efficient sorbents with the least amount of environmentally-friendly modification while retaining the beneficial characteristics of native bio-based materials, such as non-toxicity and biodegradability. Therefore, using renewable sorbent opens a new opportunity to solve the problem of oil containment and, as a result, the lack of water resources in the world. In this review paper, the most used sorbents for eliminating oil contamination from water resources have been investigated.

References

D. Li, J. Huang, L. Huang, S. Tan, T. Liu, Langmuir 37(4), 1521–1530 (2021)

C. Zhao, J. Zhou, Y. Yan, L. Yang, G. Xing, H. Li, P. Wu, M. Wang, H. Zheng, Sci. Total Environ. 765, 142795 (2021)

Q. Zhong, G. Shi, Q. Sun, P. Mu, J. Li, J. Memb. Sci. 640, 119836 (2021)

S. Putatunda, S. Bhattacharya, D. Sen, C. Bhattacharjee, Int. J. Environ. Sci. Technol. 16(5), 2525 (2019)

A. Abidli, Y. Huang, P. Cherukupally, A.M. Bilton, C.B. Park, Environ. Technol. Innov. 18, 100598 (2020)

A.D.L.M.D. Medeiros, C.J.G.D. Silva Junior, J.D.P.D. Amorim, I.J.B. Durval, A.F.D.S. Costa, L.A. Sarubbo, Processes 10(4), 743 (2022)

L. Yu, M. Han, F. He, Arab. J. Chem. 10, S1913 (2017)

W. Dong, F. Liu, X. Zhou, L. Wang, Z. Zhao, Y. Zhou, H. Li, Q. Liu, B. Deng, D. Li, Sep. Purif. Technol. 12, 2022 (1903)

A. Xie, J. Cui, Y. Liu, C. Xue, Y. Wang, J. Dai, J. Memb. Sci. 627, 119242 (2021)

S. Sabir, Crit. Rev. Environ. Sci. Technol. 45(17), 1916–1945 (2015)

M. Nasrollahzadeh, M. Sajjadi, S. Iravani, R.S. Varma, Carbohydr. Polym. 251, 116986 (2021)

R. Chakraborty, A. Asthana, A.K. Singh, B. Jain, A.B.H. Susan, Int. J. Environ. Anal. Chem. 102(2), 342–379 (2022)

F.E. Titchou, H. Zazou, H. Afanga, J. El Gaayda, R.A. Akbour, M. Hamdani, Groundw Sustain. Dev. 13, 100575 (2021)

O. Cheremisina, T. Litvinova, V. Sergeev, M. Ponomareva, J. Mashukova, Water (Switzerland) 13(21), 3101 (2021)

A.O. Ifelebuegu, A. Johnson, Crit. Rev. Environ. Sci. Technol. 47, 964 (2017)

A. Kayan, Adv. Compos. Hybrid Mater. 2(1), 34–45 (2019)

M. Zamparas, D. Tzivras, V. Dracopoulos, T. Ioannides, Molecules 25(19), 4522 (2020)

J. Saleem, M. Adil Riaz, M. Gordon, J Hazard Mater. 341, 424–437 (2018)

A.H. Hamidian, E.J. Ozumchelouei, F. Feizi, C. Wu, Y. Zhang, M. Yang, J. Clean. Prod. 295, 126480 (2021)

T. Dong, G. Xu, F. Wang, Ind. Crops Prod. 76, 25–33 (2015)

A. Alassod, M. Gibril, S.R. Islam, W. Huang, G. Xu, Heliyon 6(9), e04591 (2020)

M.M. Cheng, L.J. Huang, Y.X. Wang, Y.C. Zhao, J.G. Tang, Y. Wang, Y. Zhang, M. Hedayati, M.J. Kipper, S.R. Wickramasinghe, J. Mater. Sci. 54(1), 252–264 (2019)

V. Romanovski, Agricultural waste based-nanomaterials: green technology for water purification, in Aquananotechnology. ed. by V. Romanovski (Elsevier, 2021), pp. 577–595

R. Wahi, L.A. Chuah, T.S.Y. Choong, Z. Ngaini, M.M. Nourouzi, Sep. Purif. Technol. 113, 51 (2013)

B. Doshi, M. Sillanpää, S. Kalliola, Water Res. 135, 262 (2018)

Y. Dai, Q. Sun, W. Wang, L. Lu, M. Liu, J. Li, S. Yang, Y. Sun, K. Zhang, J. Xu, W. Zheng, Z. Hu, Y. Yang, Y. Gao, Y. Chen, X. Zhang, F. Gao, Y. Zhang, Chemosphere 211, 235–253 (2018)

N. Karić, A.S. Maia, A. Teodorović, N. Atanasova, G. Langergraber, G. Crini, A.R.L. Ribeiro, M. Đolić, Chem. Eng. J. Adv. 9, 100239 (2022)

X. Tan, H.M.D. Wang, D. Zang, L. Wu, F. Liu, G. Cao, Y. Xu, S.H. Ho, Clean Technol. Environ. Policy 23(1), 145–152 (2021)

S.S. Panchal, D.V. Vasava, ACS Omega 5(9), 4370–4379 (2020)

N.H. Ismail, W.N.W. Salleh, A.F. Ismail, H. Hasbullah, N. Yusof, F. Aziz, J. Jaafar, Sep. Purif. Technol. 233, 116007 (2020)

K. Abuhasel, M. Kchaou, M. Alquraish, Y. Munusamy, Y.T. Jeng, Water (Switzerland) 13(7), 980 (2021)

H.S. Alhasan, N. Alahmadi, S.A. Yasin, M.Y. Khalaf, G.A.M. Ali, Separations 9(1), 10 (2022)

N.H. Solangi, J. Kumar, S.A. Mazari, S. Ahmed, N. Fatima, N.M. Mubarak, Development of fruit waste derived bio-adsorbents for wastewater treatment: a review. J. Hazard. Mater. 416, 125848 (2021)

J. Cui, A. Xie, Z. Yan, Y. Yan, Purif. Technol. 265, 118528 (2021)

J. Shen, Y.M. Xie, X. Huang, S. Zhou, D. Ruan, J. Mech. Behav. Biomed. Mater. 15, 141–152 (2012)

H. Liu, S. Zhao, Y. Jin, X. Yue, L. Deng, F. Wang, T. Tan, Bioresour. Technol. 244, 929–933 (2017)

I. Anastopoulos, I. Pashalidis, Environmental applications of Luffa cylindrica-based adsorbents. J. Mol. Liq. 319, 114127 (2020)

R. da R. Schio, K. da Boit Martinello, M.S. Netto, L.F.O. Silva, E.S. Mallmann, G.L. Dotto, J. Mol. Liq. 118144 (2021). https://doi.org/10.1016/j.molliq.2021.118144

Y. Chen, N. Su, K. Zhang, S. Zhu, L. Zhao, F. Fang, L. Ren, Y. Guo, Materials (Basel) 10(5), 479 (2017)

A. Saeed, M. Iqbal, Biotechnol. Prog. 29(3), 573–600 (2013)

J. Chen, Y. Wang, J. Cao, W. Wang, Forests 11(3), 271 (2020)

F. Wang, T. Xie, W. Zhong, J. Ou, M. Xue, W. Li, Surf. Coatings Technol. 372, 84–92 (2019)

M. Yu, B. Lin, S. Chen, Q. Deng, G. Liu, Q. Wang, RSC Adv. 8(43), 24297–24304 (2018)

S. Diwakar, K. Rajkumar, Preparation of super hydrophobic loofah sponge for fast and efficient separation of oil from seawater. Mater. Today: Proc. 5(6), 14367–14374 (2018)

Y. Lin, P. Yi, M. Yu, G. Li, Mater. Lett. 230, 219–223 (2018)

Z. Wang, H. Ma, B. Chu, B.S. Hsiao, Polymer (Guildf). 126, 470–476 (2017)

M.K. Heidari, M. Fouladi, H.A. Sooreh, O. Tavakoli, J. Water Process Eng. 48, 102783 (2022)

W. Huang, L. Zhang, X. Lai, H. Li, X. Zeng, Chem. Eng. J. 386, 123994 (2020)

H. Guan, Z. Cheng, X. Wang, ACS Nano (2018). https://doi.org/10.1021/acsnano.8b05763

K. Wang, X. Liu, Y. Tan, W. Zhang, S. Zhang, J. Li, Chem. Eng. J. 371, 769–780 (2019)

H. Negi, R.K. Singh, A review on lignin utilization in petroleum exploration, petroleum products formulation, bio-fuel production, and oil spill clean-up. Biomass Convers. Biorefinery 1, 12 (2020). https://doi.org/10.1007/s13399-020-01126-w

Y. Liu, C. Jin, Z. Yang, G. Wu, G. Liu, Z. Kong, Recent advances in lignin-based porous materials for pollutants removal from wastewater. Int. J. of Biol. Macromol. 187, 880–891 (2021)

Y. Yang, H. Yi, C. Wang, ACS Sustain. Chem. Eng. 3(12), 3012–3018 (2015)

M.S. Ganewatta, H.N. Lokupitiya, C. Tang, Lignin biopolymers in the age of controlled polymerization. Polymers 11(7), 1176 (2019)

O. Oribayo, X. Feng, G.L. Rempel, Q. Pan, Chem. Eng. J. 323, 191–202 (2017)

H. Neelamegan, D.K. Yang, G.J. Lee, S. Anandan, J.J. Wu, Mater. Today Commun. 22, 100746 (2020)

Y. Zhang, Y. Zhang, Q. Cao, C. Wang, C. Yang, Y. Li, J. Zhou, Sci. Total Environ. 706, 135807 (2020)

J.Y. Qu, Q. Han, F. Gao, J.S. Qiu, Xinxing Tan Cailiao/New Carbon Mater. 32, 86–91 (2017)

X. Zhou, Z. Zhang, X. Xu, F. Guo, X. Zhu, X. Men, B. Ge, ACS Appl. Mater. Interfaces. 5, 7208–7214 (2013)

S. Lei, Z. Shi, J. Ou, F. Wang, M. Xue, W. Li, G. Qiao, X. Guan, J. Zhang, Colloids Surfaces A Physicochem. Eng. Asp. 533, 249–254 (2017)

P. Calcagnile, I. Caputo, D. Cannoletta, S. Bettini, L. Valli, C. Demitri, Mater. Des. 134, 374–382 (2017)

Q.Y. Cheng, C.S. Guan, M. Wang, Y.D. Li, J.B. Zeng, Carbohydr. Polym. 199, 390–396 (2018)

W. Bai, K. Chen, J. Chen, J. Xu, H. Lin, Y. Lin, Y. Xu, J. Lin, Sep. Purif. Technol. 253, 117545 (2020)

Y. Li, Q. Yu, X. Yin, J. Xu, Y. Cai, L. Han, H. Huang, Y. Zhou, Y. Tan, L. Wang, H. Wang, Cellulose 25, 6691–6704 (2018)

Y. Zou, T. Yang, Rice husk, rice husk ash and their applications, in Rice bran and rice bran oil (Elsevier, 2019), pp. 207–246

L. Vlaev, P. Petkov, A. Dimitrov, S. Genieva, J. Taiwan Inst. Chem. Eng. 42, 957–964 (2011)

D. Angelova, I. Uzunov, S. Uzunova, A. Gigova, L. Minchev, Chem. Eng. J. 172, 306–311 (2011)

A. Bazargan, J. Tan, C.W. Hui, G. McKay, Cellulose 21, 1679–1688 (2014)

J. Wang, Y. Zheng, Y. Kang, A. Wang, Chem. Eng. J. 223, 1–7 (2013)

J. Wang, Y. Zheng, A. Wang, Chem. Eng. J. 213, 1–7 (2012)

J.H. Lee, D.H. Kim, S.W. Han, B.R. Kim, E.J. Park, M.G. Jeong, J.H. Kim, Y.D. Kim, Chem. Eng. J. 289, 1–6 (2016)

E. Witka-Jezewska, J. Hupka, P. Pienia̧zek, Spill Sci. Technol. Bull. 8, 561–564 (2003)

M. Husseien, A.A. Amer, A. El-Maghraby, N.A. Taha, J. Appl. Sci. Res 4, 652–657 (2008)

M.M. Tijani, A. Aqsha, N. Mahinpey, J. Environ. Manage. 171, 166–176 (2016)

M. Khajavian, V. Vatanpour, R. Castro-Muñoz, G. Boczkaj, Carbohydr. Polym. 275, 118702 (2022)

F.C.F. de Barros, L. Vasconcellos, C. Grombone, T.V. Carvalho, R.F. do Nascimento, Orbital Electron. J. Chem. 6, 70–74 (2014)

S.S.D. Elanchezhiyan, S. Meenakshi, J. Clean. Prod. 139, 1339 (2016)

C. Escudero-Oñate, E. Martínez-Francés, A review of chitosan-based materials for the removal of organic pollution from water and bioaugmentation. Chitin-Chitosan - Myriad Functionalities Sci Technol (2018). https://doi.org/10.5772/intechopen.76540

B. Duan, H. Gao, M. He, L. Zhang, ACS Appl. Mater. Interfaces 6, 19933–19942 (2014)

X. Zhao, Y. Luo, P. Tan, M. Liu, C. Zhou, Int. J. Biol. Macromol. 132, 406–415 (2019)

Y.D.T. Trang, L.A. Zenitova, Study on the sorption capacity of the adsorbent based on polyurethane and chitin to remove oil spills, in IOP Conference Series: Earth and Environmental Science, vol. 337 (2019)

R.A. Ilyas, H.A. Aisyah, A.H. Nordin, N. Ngadi, M.Y.M. Zuhri, M.R.M. Asyraf, S.M. Sapuan, E.S. Zainudin, S. Sharma, H. Abral, M. Asrofi, E. Syafri, N.H. Sari, M. Rafidah, S.Z.S. Zakaria, M.R. Razman, N.A. Majid, Z. Ramli, A. Azmi, S.P. Bangar, R. Ibrahim, Natural-fiber-reinforced chitosan chitosan blends and their nanocomposites for various advanced applications. Polymers 14, 874 (2022)

Z. Yin, X. Sun, M. Bao, Y. Li, Int. J. Biol. Macromol. 165, 1869–1880 (2020)

E. Wolok, J. Barafi, N. Joshi, R. Girimonte, S. Chakraborty, Study of bio-materials for removal of the oil spill. Arabian J Geosci 13, 1–11 (2020)

Z. Li, L. Shao, W. Hu, T. Zheng, L. Lu, Y. Cao, Y. Chen, Carbohydr. Polym. 191, 183–190 (2018)

L. Zhang, Y. Dong, N. Zhang, J. Shi, X. Zhang, C. Qi, A.C. Midgley, S. Wang, Mater. Sci. Eng. C 109, 110618 (2020)

I.C. Da Silva Grem, B.N.B. Lima, W.F. Carneiro, Y.G. De Carvalho Queirós, C.R.E. Mansur, Polimeros 23(6) (2013)

A. Ummadisingu, S. Gupta, Desalin. Water Treat. 44, 44–51 (2012)

S.S. Elanchezhiyan, N. Sivasurian, S. Meenakshi, Carbohydr. Polym. (2016). https://doi.org/10.1007/s13762-018-2061-8

J.P. Chaudhary, N. Vadodariya, S.K. Nataraj, R. Meena, ACS Appl. Mater. Interfaces 7, 24957–24962 (2015)

C. Su, H. Yang, H. Zhao, Y. Liu, R. Chen, Chem. Eng. J. 330, 423–432 (2017)

B. Doshi, E. Repo, J.P. Heiskanen, J.A. Sirviö, M. Sillanpää, J. Clean. Prod. 170, 339–350 (2018)

G. Meng, H. Peng, J. Wu, Y. Wang, H. Wang, Z. Liu, X. Guo, Fibers Polym. 18, 340–349 (2017)

C. Antonini, T. Wu, T. Zimmermann, A. Kherbeche, M.J. Thoraval, G. Nyström, T. Geiger, Nanomaterials 9, 1142 (2019)

F.L. Cavender, Synthetic polymers-cellulosics, other polysaccharides, polyamides, and polyimides. Patty’s Toxicol (2012). https://doi.org/10.1002/0471435139.tox091.pub2

B. Peng, Z. Yao, X. Wang, M. Crombeen, D.G. Sweeney, K.C. Tam, Cellulose-based materials in wastewater treatment of petroleum industry 5, 37–49 (2020)

H. Zhang, Y. Li, Y. Xu, Z. Lu, L. Chen, L. Huang, M. Fan, Phys. Chem. Chem. Phys. 18, 28297–28306 (2016)

M. Fauziyah, W. Widiyastuti, and H. Setyawan, A hydrophobic cellulose aerogel from coir fibers waste for oil spill application, (2020).

H. Zhang, S. Lyu, X. Zhou, H. Gu, C. Ma, C. Wang, T. Ding, Q. Shao, H. Liu, Z. Guo, J. Colloid Interface Sci. 536, 245–251 (2019)

D. Dionisi, G. Carucci, M. Petrangeli Papini, C. Riccardi, M. Majone, F. Carrasco, Water Res. 39, 2076–2084 (2005)

S.H. Choi, T.G. Park, Int. J. Pharm. 311, 223–228 (2006)

L. Yu, K. Dean, L. Li, Prog. Polym. Sci. 31, 576–602 (2006)

Q. Zeng, P. Ma, X. Su, D. Lai, X. Lai, X. Zeng, H. Li, Ind. Eng. Chem. Res. 59, 9127–9135 (2020)

X. Wang, Y. Pan, H. Yuan, M. Su, C. Shao, C. Liu, Z. Guo, C. Shen, X. Liu, Chinese Chem. Lett. 31, 365–368 (2020)

B. Li, G. Zhao, G. Wang, L. Zhang, J. Gong, Z. Shi, Sep. Purif. Technol. 257, 117949 (2021)

N. Zhang, Y. Qi, Y. Zhang, J. Luo, P. Cui, W. Jiang, A review on oil/water mixture separation material. Indus. Eng. Chem. Res. 59(33), 14546–14568 (2020)

M. Abdullah, S.H.A. Muhamad, S.N. Sanusi, S.I.S. Jamaludin, N.F. Mohamad, M.A.H. Rusli, J. Appl. Environ. Biol. Sci. 6, 59–63 (2016)

P. Tontiwachwuthikul, I. Al Zubaidi, E. Rennie, S. Schubert, M. Seitz, C. Selinger-Silva, Remediation of water from waste lubricating oil spill using potato peels, in Proceedings of the 3rd International Conference on Fluid Flow, Heat and Mass Transfer (FFHMT’16), Paper No. 163 (2016). https://doi.org/10.11159/ffhmt16.163

Y. Fan, H. Liu, B. Xia, K. Guo, J. Nat. Fibers 16, 1177–1188 (2019)

G. Alaa El-Din, A.A. Amer, G. Malsh, M. Hussein, Alex. Eng. J. 57, 2061–2068 (2018)

S.A. Sayed, A.M. Zayed, Desalination 194, 90–100 (2006)

I. Muhammad, U. El-Nafaty, A. Surajudeen, Y.I. Makarfi, Energy Biotechnol. 85, 84–92 (2015)

X. Yue, T. Zhang, D. Yang, F. Qiu, Z. Li, J. Clean. Prod. 199, 411–419 (2018)

Z. Xue, Z. Sun, Y. Cao, Y. Chen, L. Tao, K. Li, L. Feng, Q. Fu, Y. Wei, RSC Adv. 3, 23432–23437 (2013)

Z. Xiong, H. Lin, Y. Zhong, Y. Qin, T. Li, F. Liu, J. Mater. Chem. A 5, 6538–6545 (2017)

B. Ye, C. Jia, Z. Li, L. Li, Q. Zhao, J. Wang, H. Wu, J. Appl. Polym. Sci. 137, 49103 (2020)

Q. Zeng, P. Ma, D. Lai, X. Lai, X. Zeng, H. Li, J. Mater. Sci. 56, 11266–11277 (2021)

X. Zhang, J. Zhao, L. Ma, X. Shi, L. Li, J. Mater. Chem. A 7, 24532–24542 (2019)

L. Yan, P. Li, W. Zhou, Z. Wang, X. Fan, M. Chen, Y. Fang, H. Liu, ACS Sustain. Chem. Eng. 7, 15463–15470 (2019)

H. Peng, H. Wang, J. Wu, G. Meng, Y. Wang, Y. Shi, Z. Liu, X. Guo, Ind. Eng. Chem. Res. 55, 832–838 (2016)

H. Peng, J. Wu, Y. Wang, H. Wang, Z. Liu, Y. Shi, X. Guo, Appl. Phys. A Mater. Sci. Process. 122, 516 (2016)

H. Zhang, Y. Li, Z. Lu, L. Chen, L. Huang, M. Fan, Sci. Rep. 7, 1–8 (2017)

Z. Luo, C. Duan, Y. Li, Y. Wang, B. Wang, RSC Adv. 8, 29570–29577 (2018)

F. Jiang, Y.L. Hsieh, J. Mater. Chem. A. 2, 6337–6342 (2014)

Y.R. Zhang, J.T. Chen, B. Hao, R. Wang, P.C. Ma, Carbohydr. Polym. 240, 116318 (2020)

K. Rohrbach, Y. Li, H. Zhu, Z. Liu, J. Dai, J. Andreasen, L. Hu, Chem. Commun. 50, 13296–13299 (2014)

H. Sai, R. Fu, L. Xing, J. Xiang, Z. Li, F. Li, T. Zhang, ACS Appl. Mater. Interfaces 7, 7373–7381 (2015)

S. Han, Q. Sun, H. Zheng, J. Li, C. Jin, Carbohydr. Polym. 136, 95–100 (2016)

Z. Wang, P. Jin, M. Wang, G. Wu, C. Dong, A. Wu, ACS Appl. Mater. Interfaces 8, 32862–32868 (2016)

W. Yuan, X. Zhang, J. Zhao, Q. Li, C. Ao, T. Xia, W. Zhang, C. Lu, Results Phys. 7, 2919–2924 (2017)

Y.Q. Li, Y.A. Samad, K. Polychronopoulou, S.M. Alhassan, K. Liao, ACS Sustain. Chem. Eng. 2, 1492–1497 (2014)

B. Zhao, L. Ren, Y. Du, J. Wang, J. Clean. Prod. 255, 120184 (2020)

N. Li, Q. Yue, B. Gao, X. Xu, R. Su, B. Yu, J. Clean. Prod. 207, 764–771 (2019)

Y. Song, H. Li, Y. Gao, Q. Yue, B. Gao, W. Kong, Y. Zang, W. Jiang, Process Saf. Environ. Prot. 129, 119–129 (2019)

Acknowledgements

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

MF: Conceptualization, Investigation, Literature collection and arrangement, writing the original draft, writing—review & editing; MKH: Literature collection and arrangement, and edit of the original draft; OT: Supervision and revision. All authors participated and approved the final manuscript to be published.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest related to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fouladi, M., Kavousi Heidari, M. & Tavakoli, O. Development of porous biodegradable sorbents for oil/water separation: a critical review. J Porous Mater 30, 1037–1053 (2023). https://doi.org/10.1007/s10934-022-01385-0

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-022-01385-0