Abstract

In twenty first century, there is an increasing demand for packed food which requires packaging films. At present, these packaging films are processed from synthetic polymers such as polyethylene, polypropylene and many other synthetic polymers. But we need to start using soy protein as sustainable antimicrobial film that can be used for packaging purposes. There is abundance and high availability of soy protein isolate (SPI) as by-product from industries, such as food processing or biodiesel production. Soy based films from renewable resources can offer a more suitable alternative to films fabricated from synthetic materials. Soy based films in presence of additives such as acidic compounds, nanoparticles and natural compounds have good mechanical properties and are transparent in nature. In addition, soy based film in presence of 2,2-diphenyl-2-hydroxyethanoic acid and copper phosphate can give lotus-like structure as evidenced from morphological studies. Also the manufacturing process (solution casting and compression molding) of SPI film in the presence or absence of additives is very easy and commercially feasible. It is worth noting that SPI films can be produced at laboratory scale by both casting and compression molding methods. In this review paper, we have focused on the material properties as well as antimicrobial properties of SPI based films in the presence of natural and synthetic additives as reported in the last 20 years.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodegradable polymers obtained from renewable resources have received considerable attention due to inherent nature of degradation in natural environment. Soy protein isolate (SPI) are widely used to prepare bioplastics, biocomposites and films that can be used for edible purposes [1]. These films can also be used as antimicrobial films provided specific additives such as acidic, phenolic or bacteriocin based compounds are added [2,3,4,5].

It has been well stated that the soy protein is an impure protein with different globulins fractions such as 2S, 7S, 11S, and 15S and also it is a cheap renewable resource. For the formation of soy based film, it is necessary to have proteins of high molecular weight and this can be achieved by the polymerization. It has been reported long back that the polymerization of 11S and 7S protein by disulfide linkages is responsible for the film formation in soy protein [6]. Recently, several literatures have showed the formation of neat and additives incorporated SPI films with maximum tensile strength of 26.34 MPa [2,3,4,5, 7]. There are few literatures where the film forming ability and the flexible behavior of 7S-rich globulin (7S-RG) and 11S-rich globulins (11S-RG) have been reported [8]. 7S-RG or 11S-RG fractions are responsible for the smooth and uniform structure of SPI film. There are reports which stated that the 11S-RG fraction gives stronger soy film with tensile strength of 35 MPa and had lower water uptake property than those made from 7S-RG at 145 °C with tensile strength of 26 MPa. This is attributed to the presence of different sets of amino acids in 7S and 11S RG fractions.

The necessary aspects of film formation are its pH, temperature and the plasticizers to be added. The pH of the film-forming solution influences several properties of film as it increases the solubility of the proteins but high pH is generally avoided due to denaturation. Also the temperature of the SPI suspension during mixing for the formation of the SPI films should not exceed 65 °C so that denaturation can be avoided.

Plasticizers are necessary/must to produce soy protein based films. If the plasticizers are not added, then the resulting film will be brittle in nature [9]. Plasticizers are generally the low molecular weight compound with higher or lower hydrophilicity. The polyols based plasticizer with hydroxyl groups forms hydrogen bond with polymers hence they disturb the polymer–polymer interactions [2]. Plasticizers play very important role in the improvement of the processability and flexibility of soy proteins. Some of the most widely used plasticizers are glycerol, ethylene glycol, triethylene glycol, poly(ethylene glycol), butane diols [10, 11], urea [12], acetamide [13] and thiodiglycol [9]. Among polyols, most widely used plasticizer is glycerol so far, despite of the fact that the three hydroxyl groups of glycerol increases the water uptake property of plasticized soy protein films. Other plasticizers also show an increased moisture sensitivity and decreased mechanical strength upon addition in soy film [14, 15]. One of the major hurdle to get a widely acceptable film is to minimise the water absorption property of soy protein films, which can be overcome either by modifying soy protein by incorporating chemical compounds or by initiating crosslinking reactions. Scientists have reported that upon addition of suitable crosslinkers, such as furfural [16], formaldehyde [17] and dialdehyde starch [18], the hydrophobicity of plasticized soy film has been increased.

Soy protein is a polymer of eighteen amino acids and these amino acids retain different nature such as they can be hydrophobic or hydrophilic based on the functional group of their side chain. The functional group present in the side chains can alter the retention of chemical or antimicrobial compounds that have been incorporated in SPI [2,3,4,5]. The nature of the SPI films determines its mechanical strength, which can be influenced significantly by the incorporated additives and the method of film preparation [19]. The plastics prepared from 7S-RG and 11S-RG performs better because of intermolecular interactions among proteins in soy protein which is mainly due to the presence of amino acids which are hydrophobic in nature. These types of amino acids are present in side chain and that leads to the hydrophobic interaction and interactions of hydrogen bonds. The hydrophobic interactions and the degree of hydrogen bonding are further influenced by S–S bond [8, 20].

Edible films, particularly from SPI, which comes under the biological packaging materials, have drawn attention in recent years. Varieties of edible films and coatings have been developed, for example, the property of plant essential oils as a food protectant against pathogenic and deteriorating microorganisms has been reported by Rojas-Graü et al. [21]. Antimicrobial packaging systems from SPI with phenolics, acidic and bacteriocin based additives not only control the growth of microbes but also minimize recontamination of food borne pathogens that include Listeria monocytogenes, Escherichia coli O157:H7 and Salmonella typhimurium [22]. The mechanism involves the linking of soy protein molecules with phenolics, acid additives or bacteriocin through hydrogen bonding. The protein-additives interactions depend on the nature of additives being incorporated and their concentration [23], protein structure [24] and temperature [25]. The phenolics are the major group of antimicrobial compound and are present in most antimicrobial plant extracts [26]. The phenolic compounds accomplish their antimicrobial activities by various mechanisms and they are listed below [27].

-

(i)

Adhesion binding between pathogens and phenolic compounds.

-

(ii)

Protein and cell wall binding of pathogens with phenolic compounds resulting in enzyme inactivation.

-

(iii)

Intercalation into the cell wall and/or DNA during inactivation of pathogens.

The presence of phenolic compounds can also disturb the function of bacterial cell membranes which in turn retard the growth and multiplication of bacteria. Post-packaging hindrance plays a critical role in emergence of challenges of food borne pathogens because most of the contamination in the packed food occurs after processing. To minimize this problem, natural antimicrobial of edible films are also a good alternative. SPI as a biopackaging material is good but it needs some additional support in the form of some, chemical, natural or additives to increase their strength. In modern approach, nanoparticles are incorporated in SPI to get the packaging materials and if successful, nanotechnology can be a real big milestone in the field of packaging materials. The reinforcement effect by nanoparticles/nanomaterials at low loading of nanofiller results in the formation of bionanocomposites, or econanocomposites. They are the novel materials based on renewable resources combined with the nanoscale effects by in situ assembling nanophase or blending organic and inorganic nanoparticles.

Soy protein film alone has no antimicrobial effects, so different kind of antimicrobial compounds are used as additive to enhance its antimicrobial activity in order to increase the shelf-life of food items. In this review paper, we have discussed about several additives that had been incorporated in SPI film to get antimicrobial SPI films. It has been also been reported in the literatures that the presence of cross-linking agent or antimicrobial agent or acids as an antimicrobial agents can effect SPI films strength and/or toughness, water resistance and other physical properties [28]. Hence, we have discussed the fabricated antimicrobial SPI films on the basis of the above material properties.

Preparation of Soy Protein Film

Soy protein films can be prepared by several methods such as compression molding and solution casting. The details of each of the process are given below.

Compression Molding

Generally soy protein based films are prepared by this method. Different amounts of plasticizers such as glycerol (~ 30% w/w with respect to SPI) are mixed with SPI powder separately in an electronic mixer for about 15 min. The resulting mixtures are subjected to hot pressing at 140 °C for 20 min under 15 MPa of pressure [9]. Thus the plasticized SPI films are prepared. In one report, Kumar et al. dipped compression molded SPI film in acid catalyzed furfuryl alcohol to get polyfurfuryl alcohol reinforced SPI biofilms [29]. This can be another method to incorporate additives in the prepared SPI films provided the additives bind with the SPI. For incorporating solid additives in SPI, it is important to mix the additives with SPI in an electronic mixer. The resulting additives can be incorporated in SPI powder to fabricate compression molded SPI biofilms.

Solution Casting

About 5–8 g of SPI is mixed with water under constant stirring to form film forming solution and glycerol at 30% (w/w) of SPI is added [2]. The pH of the solution is maintained at ~ 10 with 1 N sodium hydroxide. Liquid additives in desired amount can be added in this step depending on the nature of the additives. The SPI solutions are then heated in a water bath at 65–70 °C for 60 min, and cast on leveled Teflon-coated glass plates or simple glass plate coated with silicone oil. After drying the solution casted SPI film at ambient conditions (50–60 °C) for about 24 h, the films are peeled off from the plates. Carvacrol and cinnamaldehyde at different concentrations (10, 30 and 60% (w/w of SPI)) had been added in SPI solution to get antimicrobial SPI film with a coating of carvacrol and cinnamaldehyde [30].

Recently, Garrido et al. compared the properties of film formed by above two methods [31]. The manufacturing process can significantly affect the material properties of the SPI film. Particularly, the thermal, barrier, optical, and mechanical properties are different for SPI films prepared by both the methods. The films prepared by solution casting exhibit low hydrophobicity and low water resistance. On the other hand, films prepared by compression molding, show a smoother surface, higher tensile strength, higher elongation at break and high transmittance than that prepared from solution casting.

Additives

Chemical Compounds

Among the chemical compounds, organic acids are best candidates to be used as additives they are end products of amino acid catabolism and are naturally present in plant products or as an end product of fermentation process. Major organic acids that naturally occur in fruits and vegetables are acetic, citric, succinic, malic, tartaric, benzoic and sorbic acids [32]. These organic acids also exhibits antimicrobial activities, their antimicrobial activity is accomplished by several mechanisms, such as

-

(i)

Reduction in internal pH, as they are smaller in size and can enter in cytoplasm,

-

(ii)

Organic acid ionizes the undissociated acid molecules and that results in decreased pH of microbial cell,

-

(iii)

Organic acid disturbs the membrane transport by altering its permeability thus causing a disrupted substrate transport [32],

-

(iv)

Alteration in ion potential that results in reduction of proton motive force [33].

Antimicrobial activity of the SPI film is increased by incorporating these organic acids. When these organic acids are incorporated in film with other natural antimicrobial compounds such as nisin the antimicrobial activity of film get enhanced. Neat nisin also exhibit antimicrobial activity after incorporation in SPI film as they form pores in membrane thus the ionic potential of bacterial cell get disrupted. The additives enhanced the capacity of both the antimicrobial compounds as they complement to each other and their synergistic affect enhanced the antimicrobial capacity of nisin. It has been stated that the smaller molecular weight compounds have higher antimicrobial activity.

EDTA is a metal chelator which sequesters divalent cations (notably Ca2+ and Mg2+). The presence of EDTA interacts with protein and lipopolysaccharides electrostatically which ultimately leads to a stable outer membrane of gram negative bacteria. In addition, the EDTA also release an enormous amount of gram negative lipo-polysaccharides from the external membrane and uncovering hydrophobic phospholipids that amplifies the vulnerability of the cell to hydrophobic and cell wall degrading agents [34].

Hydrophobic SPI film have been prepared by using 2,2-diphenyl-2-hydroxyethanoic acid (DPHEAc) or benzilic acid [7, 35]. DPHEAc falls in the category of amphiphilic compounds and the water-resistant soy protein plastic could be prepared by incorporating DPHEAc [35]. The mechanism for the interaction of soy protein with benzilic acid is presented in Fig. 1. In this Figure, Kumar et al. stated that carboxylic groups of benzilic acid interacted with amino groups of soy protein to give arylated soy protein (I). Once the arylated soy protein films having structure (I) was immersed in water there was a release of CO2. The dominance of exposed aryl groups led to the high hydrophobicity of the benzilic acid incorporated SPI films and that led to the formation of nanospheres [7] similar to the structure of lotus and rice plant leaves [36].

[Reproduced with permission from American Chemical Society (Ref. [7]; Copyright 2019)]

Mechanism of interaction of SPI with benzilic acid

Mandelic acid and salicylic acid have also been incorporated in SPI to fabricate acid incorporated SPI films [4, 37]. Mandelic acid has the ability to repair skin damage from prolonged sun exposure and as an acne treatment. Salicylic acid has been used in medicine since ancient times. Both the acids showed good compatibility with SPI and this resulted in increased material properties of SPI films as discussed in the later sections.

Effect of physical and chemical treatments by adding acid additives on cross-linking properties has been discovered by numerous scientists as a possible method to increase the material properties of protein films [38, 39]. Ferulic acid is an abundant phenolic acid in plants and it acts as a cross-linking agent in cell walls [40]. Ferulic acid could act as suitable crosslinking agent in preparation of SPI, gelatin, starch-chitosan and sodium caseinate based edible films [41,42,43,44]. Hence, crosslinking of ferulic acid with proteins and polysaccharides can be accomplished by three main mechanisms. In case of proteins, firstly ferulic acid can cross-link with tyrosine and other amino acids through a free radical mechanism. In second case, it can oxidize to quinine which further reacts with amines on the protein. A third possibility is its esterification with amino acids having hydroxyl functional group. It has been stated by Alves et al. that optimum concentration of ferulic acid incorporated in the SPI film can also increase the antioxidant property of films for maintenance of fresh lard [45]. Ferulic acid also protects against coronary disease, lowers cholesterol and increases sperm viability so if it incorporated in edible film it will increase the uses of protein based edible films [5].

Tannic acid (TA) is “generally recognized as safe” (GRAS) as a food additive and is low cost and readily available [46]. Due to presence of polyphenol groups in TA, it acts as a natural antioxidant having antimicrobial activity [47]. Due to versatile and potential surface functionalization modification it can be used as a coating material [48, 49]. Due to the surface coating ability of TA–Fe(III) complexes, it can adhere to a variety of substrates such as metal oxide, metal, and polymers and this is attributed to polyphenol ligand (TA)–metal coordination [50, 51]. There are several factors on which the formation of TA–Fe(III) complexes depends [50, 52] and they are

-

(i)

the level of Fe(III),

-

(ii)

adsorption of the polyphenol,

-

(iii)

its pH.

It has been reported that TA has a high gallolyl group and that allows it to be used to assemble multilayer capsules or films with neutral polyamides and proteins through the hydrogen bonding and hydrophobic interactions [46, 53].

Natural Compounds

The grape seed extract (GSE) is a natural compound which is abundant in phenolics and possesses effective antimicrobial and antioxidant activities [54]. Depending on the variety, grape seeds contain different contents of lipid, protein, carbohydrates, and 5–8% polyphenols. Grape seed polyphenols contain flavan-3-ols as monomers (catechin, epicatechin, gallocatechin, epigallocatechin and epicatechin 3-O-gallate), procyanidin as dimers, trimers, and highly polymerized procyanidins, apart from phenolic acid precursors (gallic acid) [55]. It has been reported that pathogen inhibitions by natural extracts are due to the presence of reactive groups in form of hydroxyl groups and conjugated double bonds [56]. Though, these natural extracts strongly interact with food constituents, thus their activity decreases as compared to laboratory system [57].

Rababa et al. have confirmed the possible use of GSE and green tea extracts (GTE) as a stabilizing agent in meat systems [58]. Natural extracts act as antioxidants as well as they improve the shelf-life of meat products [54]. Nisin, GSE, and GTE inhibit the growth of pathogenic microbes individually, but their synergistic effect is more prominent. The major phenolic constituents (mg/100 g extract) in the GSE are epicatechin (1158.5), catechin (887.4), gentistic acid (472.8), and syringic acid (253.4), whereas in the GTE the phenolic constituents in mg/100 g extract are epicatechin (1087.0), caffeic acid (830.1), benzoic acid (319.8), and syringic acid (75.91) [58].

Another natural product is nisin which is recognized as a safe preservative for certain food products. Lactococcuslactis is responsible for producing nisin which is actually bacteriocin. Nisin is a wide range inhibitor of gram positive bacteria, including L. monocytogenes [59]. Nisin generates the proton motive force due to which target cell membrane gets deformed, which ultimately result in misbalance of membrane potential. Consequently there is efflux of amino acids, potassium ions etc. Reports have been suggested that nisin is less effective against gram-negative bacteria as compared to gram-positive bacteria [33].

GSE, nisin, and nisin with EDTA show inhibitory activity against food borne microbes individually. However, on separate applications, these compounds may show insufficient protection against food borne pathogenic microbes. Researchers have investigated the GSE, nisin, EDTA and their combinations as additives in SPI film. Also the effect of these additives on the physical properties of the SPI film and activity of these additive incorporated films against major food borne pathogens including L. monocytogenes, E. coli O157:H7 and S. typhimurium have been investigated [60].

Thyme essential oil and oregano essential oils are well known preservatives/protectant in meat applications because they possess a good inhibitory potential against microbes. Thymol and carvacrol are rich in phenolics, and are the most effective essential oils [61,62,63,64,65,66].

Curcumin obtained from the curcuma longa rhizomes is a hydrophobic polyphenol with a strong yellowish color and it is a well-known anti- inflammatory agent, anticancer agent, anti-microbial agent and neuroprotectant [67]. Recently, Chen et al. showed that the formulation of SPI and curcumin at low pH (pH 3.0 and 7.0) result in low surface hydrophobicity of SPI [68]. The complexation process of SPI with curcumin changes the mixing properties of SPI to some extent at both the mentioned pH values and indirectly enhances the lipid oxidation in the resulting emulsions.

Figure 2 shows that SPI compatibly forms nanocomplexes with curcumin [69]. And this capacity to form nanocomplex can be enhanced by exposure of high energy ultrasonic wave. It has been reported that the nano complexation considerably enhanced the physicochemical properties of the proteins, and even the stability of curcumin under storing conditions. Hydrophobic nature of hydrophobic sites determined the capacity of SPI at which curcumin can be loaded. As stated by the authors that both the hydrophobic interactions and disulfide bonds are important for binding curcumin molecules with SPI and also SPI can act as effective nanocarriers for water-insoluble curcumin.

[Reproduced with permission from Elsevier (Ref. [69]; Copyright 2019)]

Schematic mechanism for the formation of curcumin-SPI nanocomplexes at low or high LA, and influence of ultrasonication on the formed nanocomplexes

Nanoparticles

Inorganic nanoparticles due to nanoscale size exhibit significantly novel and improved, chemical, physical and biological properties [70]. In nanoparticles, materials shape, integrity, and their size play a major role in its functionality. It has been stated that small size sometimes leads to an entirely new and novel phenomenon due to changed physical and chemical properties. Nanosized antimicrobial formulations could be used as effective bactericidal material [71]. It has been proved that many highly reactive metal oxides such as zinc oxide nanoparticles retains an excellent biocidal action against a large spectrum of gram positive and gram negative bacteria [72,73,74,75]. In recent years, montmorillonite (MMT), carbon nanotubes (CNTs) and carbon nanoparticles have attracted great industrial and academic interests because of its high aspect ratio, high surface area and quite interesting morphology. However, CNTs exhibit extraordinary mechanical strength as well as high electrical and thermal conductivity. Carbon nanoparticles obtained from kitchen soot or from hydrothermal reactions have also shown to have antimicrobial activity [76, 77].

The antimicrobial properties of silver ions are known since ancient times. Now-a-day this property of silver ion is harvested in various medical applications such as healing of burn wounds and dental work [78, 79]. Advance technologies utilized the nanoparticles made up of silver in variety of purposes such as lining of washing machines, refrigerators, dishwashers, and toilet seats because of inhibitory activity towards many kinds of microbes [79, 80]. Several methods involving chemical, reducing or stabilizing agents have been developed to synthesize silver nanoparticles [81, 82]. Shrivastava et al. has reported the preparation of silver nanoparticles in the range of 10–15 nm with enhanced stability and increased resistance towards bacterial growth [83].

The basic mechanism behind the antimicrobial property of silver ions against microbes is somewhat meticulously associated with their interaction with thiol (sulfhydryl) groups) present in most of the biomolecules. Basically silver ion interacts with the thiol group of enzymes and proteins, and these types of interactions are major reason behind their antimicrobial action. It has been proposed that silver ions cause the release of potassium ions from bacteria and that causes biochemical imbalances. Hence, the enzymes and protein containing sites of microbes are major targets of silver ion, thus bacterial plasma or cytoplasmic membrane become vulnerable because of high content of protein and enzymes. A silver ion not only affects the enzymes of microbes, but it also initiates noticeable deterioration of bacterial growth by damaging the cell envelope and thereby inhibits cell division of bacteria [84]. It has been reported that silver ions can also interact with the bases of nucleic acids in DNA.

It has also been proposed that in case of E. coli, silver reportedly inhibit the uptake of phosphate, mannitol, succinate, proline and glutamine from E. coli cells which lead to the changes in morphology and structure of bacterial cell [85].

Like MMT, carbon nanotubes (CNTs) are considered ideal reinforcing fillers for polymer matrices to achieve high performance and special functions [86]. The blending of nanofillers such as chitin [87], industrial lignin [88], layered silicate [89, 90], carbon nanoparticles [91] and carbon nanotube [92] showed obvious reinforcing effects in soy protein polymers. The nanocomposites fabricated by incorporating MMT into SPI polymers can be divided into intercalated and exfoliated nanocomposites. Highly exfoliated polymer/clay nanocomposites constituted fundamental and application research [93]. Solution intercalation, melt intercalation, and in situ intercalative polymerization resulted in exfoliated nanocomposites [94].

Chen et al. constructed flower-like CuO and Cu(OH)2 nanorod arrays through surface oxidation with an assistance of strong alkali [95]. Similarly, Hao and co-workers fabricated CuO hierarchical flower-like structures [96]. For the fabrication of SPI nanoflower films, neat soy was immersed into a CuSO4 solution with glycerol for 10 h followed by addition of phosphate buffered solution (100 mM) with pH being maintained at 7.4 and incubation at room temperature [97]. After this treatment, the film was washed with deionized water followed by immersion with octadecylamine/ethanol (5 wt%) solution at 40 °C for 5 h for improved hydrophobicity.

Four step mechanism were proposed for the formation of Cu3(PO4)2·3H2O nanoflowers on the surface of the SPI film [97] (Fig. 3).

-

(1)

Cu2+ was absorbed by SPI via the coordination interaction.

-

(2)

In the presence of phosphate, primary Cu3(PO4)2·3H2O nanocrystals were formed at the nucleation location where SPI interacted with Cu2+.

-

(3)

Appearance of lamellar networks as the crystal size became larger.

-

(4)

The formation of nanoflowers due to repulsion between the lamellas induced the crimple of the lamella tip.

[Reproduced with permission from American Chemical Society (Ref. [97]; Copyright 2019)]

Mechanism of soy film surface fabrication with Cu3(PO4)2·3H2O nanoflowers

Tian and Xu prepared citric acid-modified starch nanoparticles (CSN) having an average size of 82 nm and incorporated them in soy film [98]. The crosslinking of CSN with protein took place by hydrogen bonding.

Fermented SPI

There are very less studies related to the preparation of fermented SPI films. Kim et al. and Kumar et al. have reported that SPI films can be prepared by adding in situ via fermentation process [99, 100]. Kim et al. conducted experiments to economically develop an antimicrobial edible film from defatted soybean meal by inoculating with bacteriocin-like substance (BLS)-producing bacteria. They tried to verify whether the fermented SPI film could be used as a packaging material. Recently, Kumar et al. fermented SPI by Bacillus subtilis and then prepared SPI film by solution casting. They reported that during fermentation, there are chances of formation of low molecular mass SPI by microorganisms which may affect film forming ability of SPI and also the physical properties of the prepared fermented films [99].

Material Properties

Molecular Mass

SPI showed mixture of high and low molecular mass proteins shown in the form of a continuous band in the gel. However, two distinct molecular mass fractions of 34–38 and 68 kDa were resolved in several studies, which signified that the protein fractions of these molecular masses are predominant in soy protein (Fig. 4, all lanes). The band of very high intensity at 34–38 kDa represented the acidic subunit (AS) of 11S-RG protein. α, α′ and β subunit of 7S-RG are denoted by 80, 68 and 48 kDa molecular mass bands, respectively. Kumar et al. has stated that there was no difference in the molecular mass band of mandelic acid incorporated SPI and neat SPI [100]. On the other hand, fermented SPI showed the absence of all the major bands that indicated the significant reduction in the molecular mass of SPI. The reduction in the molecular mass of SPI prevented the formation of fermented SPI film.

[Reproduced with permission from Tech Science Press (Ref. [100]; Copyright 2019)]

SDS-PAGE of mandelic acid incorporated SPI films. (Showing lane 1,10 µl of S-0 M; lane 2,10 µl of S-1 M; lane 3, blank; lane 4,10 µl of S-2 M; lane 5,10 µl of S-3 M; lane 6,10 µl of S-4 M; lane 7,10 µl of S-5 M)

Chen et al. isolated SPI at two pH i.e., pH 3.0 or 7.0 and conducted the SDS-PAGE profile [68]. At both the mentioned pH, the solubility of SPI increased considerably (about 90–92%) due to surface charge. The authors have not found any noticeable difference in polypeptide composition and their relative ratios at different pH values and between the soluble (S) and insoluble (P) fractions. SDS-PAGE was carried out to monitor crosslinking of soy protein with 1.5% unoxidized or oxidized phenolic acids i.e., ferulic acid (FA), caffeic acid (CA), gallic acid (GA) (Fig. 5). As shown in Fig. 5, incorporation of phenolic acids, especially oxidized caffeic acid and oxidized gallic acid resulted in a noticeable decrease in intensity of the bands representing lower molecular weight protein and that implied extensive cross-linking in the samples [101].

[Reproduced with permission from American Chemical Society (Ref. [101]; Copyright 2019)]

SDS-PAGE profile of SPI fraction obtained at different pH

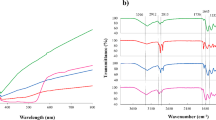

FT-IR

SPI film with and without additive can be subjected to FT-IR spectroscopy in the film form. This technique can give us the information about the level of interactions between SPI and the incorporated additives. In native SPI films, a broad N–H stretching and O–H stretching band between 3200 and 3400 cm−1 were assigned to amide A of soy protein films [102]. The peaks at 1538 and 1260 cm−1 were assigned to the amide II and amide III bands of protein, respectively [91]. Carbonyl bond (–C=O) band in SPI films is generally represented between 1630 and 1640 cm−1. It has been reported that with the introduction of mandelic acid or any aromatic acid, the intensity of the prominent peak at 699 cm−1 increased [4].

Wang et al. examined the tannic acid (TA)–Fe(III) complex coating on (montmorillonite) MMT nanosheets by FT-IR. They reported the appearance of absorption bands at 3614, 1634 and 1017 cm−1 which were attributed to Al–OH stretching vibration, H–O–H bending vibration, and Si–O–Si asymmetric stretching vibration, respectively [103, 104]. After the deposition of TA, other peaks appeared and the broad peak in the region of 3100–3600 cm−1 is attributed to the phenol groups present abundantly in TA [105].

Puncture Strength

Puncture strength is the defined as the capacity of film to retain integrity of the product and to resist external stress when film is used as viable product. It can be measured using a texture analyzer. Prior to measurement, film samples are needed to be preconditioned at room temperature with about 50% relative humidity for at least 48 h. The film can be mounted on a 30-mm film piece on a 10-mm film testing rig and then it can be punctured with a 2-mm probe. The force exerted to rupture can be recorded as puncture strength.

It has been reported that the puncture strength of the soy protein film can be increased by upon incorporation of certain additives. In one of the report, the addition of nisin, increased the puncture strength from 5.55 to 7.22 N [2, 106]. pH also plays a crucial role in increase or decrease of puncture strength, as it decreased the puncture strength from 0.66 to 0.42 N after addition of nisin at normal pH. Deprotonation of histidine residue at high pH reduced the net positive charges of nisin and that may weaken the electrostatic bond between nisin and protein molecules.

Decreasing the acid level from 0.9 to 2.6% resulted in the decreased puncture strength of the film. Incorporation of lower-molecular-weight acids i.e., lactic acid (90.08 Dalton) and malic acid (134.09 Dalton), increased the puncture strength (0.55 and 0.50 N, respectively) of SPI film up to a 1.8% concentration. Tartaric acid lowered the puncture strength (0.16–0.33 N) of the film compared with control film (0.32–0.62 N) with HCl.

Transmittance

Generally, SPI film is yellow in colour and transmittance of SPI in visible range increases with increasing wavelength. Incorporation of MMT and TA decreased the transmittance of the additives incorporated SPI because the film became darker [103]. This indicated the good UV resistance of the SPI film. In case of mandelic acid incorporated SPI films, the transmittance of mandelic acid incorporated SPI films almost showed similar values except that of 3% mandelic acid incorporated SPI which showed higher transmittance. This may be attributed to better interaction of mandelic acid with SPI [100]. Generally the transmittance of SPI incorporated with nanoparticles is low because of particle nature of nanoparticles in SPI film.

Water Uptake

The water uptake and thickness swelling of the SPI films are usually calculated according to ASTM D570-81. For the water uptake test, films are cut into a suitable dimension and placed at 50 °C for 24 h in order to precondition it and weigh. After preconditioning the films are transferred in distilled water for 24 h and then dried out with help of paper towels to remove the extra water from the surface and weighed. The total mass gain of the films after immersing it in water are used to evaluate the water uptake capacity of film.

The SPI film containing TA and MMT were conditioned for a period of 48 h in a desiccator containing K2SO4 saturated solution at 25 °C to provide 98% relative humidity. The water uptake capacity of SPI film decreased significantly from 46.86 to 28.81% after addition of MMT and TA [103].

The water uptake up to equilibrium for SPI/MWNT nanocomposite sheets at 98% relative humidity is presented in Fig. 6 [107]. Two well separated zones below and above 75 h were observed. First zone represented for rapidly increasing water uptake and the second zone showed the water uptake tending towards equilibrium. The decrease in water uptake of the nanocomposites was attributed to the restriction of the relatively rigid MWNTs and their aggregates to SPI motion associated with the wrapping of SPI chains on MWNTs.

[Reproduced with permission from John Wiley and Sons (Ref. [107]; Copyright 2019)]

Water uptake of carbon nanotubes incorporated SPI

The water uptake of soy protein films decreased from 131.6 to 23.2% after incorporation of mandelic acid [4]. Water resistance of the neat SPI and arylated SPI in presence of different plasticizers were studied. The SPI films showed water uptake of 68 ± 4%. The arylated SPI films showed lower water uptake (25 ± 2%) than unarylated SPI films [7, 35]. A superhydrophobic film can be formed by controlling growth time, content of copper sulfate, and pH value of the solution (Fig. 7) [97]. The superhydrophobic film also exhibited a self-cleaning function.

[Reproduced with permission from American Chemical Society (Ref. [97]; Copyright 2019)]

Superhydrophobic property of soy film surface fabricated with Cu3(PO4)2·3H2O nanoflowers

Tensile Strength

Additives may vary and also there is variation in the tensile properties of the neat SPI film. The tensile strength of SPI film as prepared by solution casting is reported as 8.8 MPa [59]. Tensile strength increased from 8.8 to 10.7 MPa and 9.2 MPa in presence of grape seed extract and EDTA, respectively in comparison to the neat SPI film. On the other hand, tensile strength of SPI film decreased up to 5.11 MPa after incorporation of nisin in the SPI film. It was also observed that the presence of nisin decreased the tensile strength of SPI film even in the presence of other additives.

Figure 8 shows the mechanical properties of SPI/MMT plastic sheets [89]. The elongation at break decreased with the increase in the addition of MMT. The values of the Young’s modulus (E) increased from 180.2 to 587.6 MPa with an increase of the MMT content from 0 to 20 wt% [89]. At higher content (20 wt%) of MMT, the value of tensile strength decreased to 14.48 MPa. This study stated that the enhancement of the modulus and tensile properties of the SPI film was due to the fact that soy protein interacts with dispersed MMT layers by the means of hydrogen bonds and strong electrostatic interactions. This interaction behavior limited the segmental motion of the soy protein that led to improved modulus and tensile strength of the soy protein plastics.

[Reproduced with permission from American Chemical Society (Ref. [89]; Copyright 2019)]

Mechanical properties of MWCNT incorporated SPI

Zheng et al. showed the effect of MWNT with different diameter (< 10, 10–15, 20–40, 40–60, and > 60 nm) on the mechanical properties of the resulting SPI based nanocomposites [107]. The tensile strength and Young’s modulus increased with the increase in the diameter of MWNT and it reached maximum values of 11.7 MPa and 258.6 MPa, respectively till 10–15 nm. However, at increasing MWNT diameter (40–60 nm) the mechanical properties decreased.

The effects of nano-SiO2 contents on the mechanical properties of nano silica incorporated soy protein nanocomposite sheet (S–nSi) have also been reported [108]. The effects of nano-SiO2 content on tensile strength and modulus are similar at 4 wt% nano-SiO2 followed by a sharp decrease at 8 wt% nano-SiO2. Except for estimated strength increase, the elongation was enhanced for the sheets with nano-SiO2 content lower than 8 wt%. It was reported from this study of nano-SiO2 that incorporation of 4 wt% nano-SiO2 increased the tensile strength of the nanonocomposite sheet to its maximum of 11.3 MPa, while addition of 8 wt% nano-SiO2 gave the optimum elongation as well as a reinforcing effect. Citric acid–starch nanoparticles (CSN) increased the tensile properties of CSN/SPI nanocomposites. Both tensile strength and Young’s modulus were enhanced from 3.7 to 60 MPa at 3 and 4% CSN loading and reached maximum value of 5.6 MPa and 130 MPa, respectively.

Figure 9 dictates about the increased mechanical properties of the arylated SPI films compared to the SPI films. The researchers also reported the increase in tensile strength and modulus factor in glycerol plasticized arylated SPI film (SGy-B) as compared to other plasticizer plasticized arylated SPI film. Tensile strength was slightly decreased and the modulus factor was slightly increased in 1,2-propane diol plasticized arylated SPI film (SPd-B) films. This may be attributed to the non-linear and rigid three-dimensional structure of Pd as a plasticizer. It was reported that the SPd film showed the modulus of 359 MPa, in comparison to modulus of all other SPI samples which was < 100 MPa [35].

[Reproduced with permission from Elsevier (Ref. [35]; Copyright 2019)]

Mechanical properties of neat and arylated SPI

XRD

SPI is amorphous in nature and hence we get broad peaks for SPI. But the incorporation of nanoparticles like MMT increased the crystallinity of SPI. From the XRD patterns, the SPI film containing MMT showed two basal reflection diffraction peaks at 2θ = 8.96° and 19.97° corresponding to the α-helix and β-sheet structures of the SPI secondary conformation, respectively [102]. These peaks became weaker with the incorporation of tannic acid (TA) in SPI [103].

SEM and TEM

Kumar et al. stated from SEM studies that surface structure of soy protein is smooth while on the surface of arylated SPI film there is formation of nanosphere with a diameter of 30–40 nm (Fig. 10) [7].

[Reproduced with permission from American Chemical Society (Ref. [7]; Copyright 2019)]

Surface morphology of neat (left) and arylated SPI (right)

The formation of Cu3(PO4)2·3H2O nanoflowers as nanospheres on the surface of the SPI film was observed by SEM (Fig. 11) [97]. The nanospheres are similar to that has been reported earlier for arylated SPI film.

[Reproduced with permission from American Chemical Society (Ref. [97]; Copyright 2019)]

SEM image of the nanoflower incorporated SPI film (b–f) and control (a)

Zheng et al. reported the SEM images of the cross sections for the nanocomposite sheets and neat SPI. The neat SPI sheet showed morphology of fractured lamellae and after introduction of MWNTs, that lamellar morphology was transformed into the surface with raised blob-like and donut-like objects. It has been reported that with the increase in the content of MWNT the number of those ring shaped objects increased [107].

The SEM images of the cross sections for nanocomposite sheets incorporated with and without nano-SiO2 have been reported [108]. The morphology of SPI film incorporated with the nano-SiO2was heterogeneous. The change in fractured morphology was not observed after adding 4 wt% nano silica unlike 8 wt% nano silica.

Chen et al. reported the microstructure of SPI/MMT plastics by using TEM, and the images are shown in Fig. 12 [89]. At lower content of MMT, the dimensions of the silicate layers were reduced to about 30 nm in length and 1 nm in thickness and that indicated the highly exfoliated layered structure of MMT the soy protein molecules (Fig. 12a). On the other hand, intercalated tactoids with a d-spacing of about 6 nm were observed at higher contents of MMT in SPI (Fig. 12b).

[Reproduced with permission from American Chemical Society (Ref. [89]; Copyright 2019)]

TEM images of SPI/MMT plastics, a MS-8 and b MS-16

Antimicrobial Properties

Antimicrobial activity of SPI film is actually the capacity of film to inhibit or reduce the microbial load. This property of SPI film is defined by the inhibition zone formed on a rich culture of microbes and log number of survivors after encounter with film. Sivarooban et al. evaluated the antimicrobial activity of soy protein films incorporated with GSE, nisin and EDTA alone and in combinations [55]. Initially the counts of L. monocytogenes, E. coli O157:H7 and S. typhimurium after inoculation onto 1 cm diameter film disk and incubation at room temperature (25 °C) for 1 h were noted. It was observed that, the colony forming units of L. monocytogenes decreased from 6.4 to 5.6 log CFU/ml when inoculated on SPI film incorporated with GSE, 4.9 log CFU/ml when inoculated on SPI film incorporated with nisin, 5.9 log CFU/ml on SPI film incorporated with EDTA, 3.7 log CFU/ml on SPI film incorporated with GSE + nisin, 4.3 log CFU/ml on SPI film incorporated with GSE + EDTA, 4.7 log CFU/ml on SPI film incorporated with nisin + EDTA, 3.5 log CFU/ml on SPI film incorporated with GSE + nisin + EDTA. E.coli followed a slight different pattern as it decreased from 6.3 log CFU/ml (control) to 4.5 log CFU/ml in SPI film incorporated with mixtures of GSE, nisin, EDTA. In case of S. typhimurium, the minimum no. of CFU was 5.9 log CFU/ml found on SPI film incorporated with the mixture of GSE, nisin and EDTA, while initial inoculum was same as 6.3 log CFU/ml. It was concluded by the authors that L. monocytogenes was more susceptible to different combinations of nisin, GSE and EDTA, but the other two pathogens showed less sensitivity against these drugs. Various combinations of GSE, nisin and EDTA successfully inhibited L. monocytogenes unlike E. coli and S. typhimurium.

Three pathogenic bacteria L.monocytogenes, Salmonella, E. coli were tested for antibacterial activity of SPI films prepared by incorporatingorganic acids including citric, lactic, malic, or tartaric acids [2]. Authors observed that SPI film incorporated with nisin showed very less inhibition (< 0.1 mm) of L. monocytogenes. However, when L. monocytogenes was treated with nisin (205 IU/g protein) in combination of citric acid, load of bacteria decreased significantly, similar effects were observed with the treatment of lactic acid, malic acid, or tartaric acid as compared with neat SPI film. Salmonella was inhibited only by the incorporation of citric acid, malic acid and tartaric acid. SPI films with 2.6% organic acids in absence of nisin exhibited less inhibition against salmonella activity. Addition of citric acid, malic acid, and tartaric acid inhibited the growth of E. coli O157:H7. Lactic acid exhibited very less anti-Salmonella activity (0.1 mm) or anti-E. coli O157:H7 (0.1 mm).

Figure 13 dictates the diameters of inhibition zone of soy protein based edible film disks with 1% and 5% concentrations of oregano (OR) and thyme (TH) essential oils against some selected microorganisms [60]. The graph shows that the neat SPI film without any additive was unable to resist any microbial growth thus there was no zone of inhibition. SPI film incorporated with OR and TH essential oils exhibited excellent inhibitory property against all test microbes even at a concentration of 1% of total film formulation. It was also reported that the antimicrobial activity of TH and OR embedded SPI film increased significantly against S. aureus with respect to the increasing concentration of these essential oils and that resulted in significantly higher antimicrobial activity. Antimicrobial activities of S. aureus for SPI and whey protein isolate-based films incorporated with essential oils from oregano and thyme essential were also determined by several authors [109,110,111,112,113]. SPI film disks with TH essential oils shows strong antibacterial activity against E. coli and E. coli O157:H7 as well as P. aeruginosa and L. plantarum.

Sun et al. prepared bactericidal films from SPI based film-forming dispersions (FFDs), which were aimed to be further used in pharmaceuticals and food industries [114]. To prepare the FED and films, the authors used different concentration of AgNO3 as a bactericidal additive. The authors also reported that the addition of AgNO3 decreased the opacity of FED. The minimum inhibitory concentration of AgNO3 had been found to be 336 μg/ml FFD for both E. coli (ATCC 25923) and S. aureus (ATCC 25922).

Zhao et al. prepared SPI films with antimicrobial silver nanoparticles (AgNPs) as an additive [115]. AgNPs were in situ synthesized from SPI/AgNO3 solution in a process which is highly energy-efficient and eco-friendly. The SPI/AgNPs films can be also prepared by blending in situ synthesized AgNPs in SPI solution. The resulting antimicrobial SPI films showed inhibitory effect against both gram negative and gram positive bateria.

One of the significant work was contributed by Zhang et al. in which the authors prepared soy protein containing nanofibers by solution blowing and decorated them with silver nanoparticles [116]. The prepared nanofibers exibited significant inhibitory activity against E. coli colonies without treatment of UV light.

Conclusions

Table 1 shows the tensile strength and other properties of the neat and additives incorporated SPI films prepared by solution casting or compression molding method. In general, the SPI films are processed by compression molding and solution casting methods. The compression molded specimens are thermally and mechanically more stable and possessed higher tensile strength and elongation at break values compared to solution casting method. Also, the compression molded films are more transparent and possessed smoother surface and this method could be considered a more appropriate process for industrial applications due to the use of shorter processing time. SPI films in presence of acid additives, natural compounds and nanoparticles have been fabricated either by solution casting or compression molding films. All the acid additives incorporated SPI films showed increase in tensile strength and antimicrobial properties but water uptake showed less increase. Incorporation of DPHEAc and copper phosphate showed formation of nanospheres on the surface of the SPI film resulting in hydrophobic SPI films. There is increase in tensile strength of nanoparticles incorporated SPI film unlike fermented SPI film. Also the water uptake properties of SPI films showed decrease in the properties. It is evident from the literature review of the last 20 year that SPI in presence of several additives can be successfully explored as packaging film because of good tensile strength (from 5 to 18 MPa) and low water uptake. However, there are very few reports on the antimicrobial properties of nanoparticle incorporated SPI films and fermented films. Hence, more studies on the antimicrobial properties of nanoparticles incorporated SPI films are needed so as to use it successfully in packaging films. Also the work is needed to prepare SPI film with maximum of ~ 5% water uptake when completely immersed in water.

References

Song F, Dang TL, Wang XL, Wang YZ (2011) Biomacromol 12:3369–3380

Eswaranandam S, Hettiarachchy NS, Johnson MG (2004) J Food Sci 69:79–84

Friesen K, Chang C, Nickerson M (2015) Food Chem 172:18–23

Kumar R, Anandjiwala RD, Kumar A (2016) J Therm Anal Calorim 123:1273–1279

Ou S, Kwok KC (2004) J Sci Food Agric 84:1261–1269

Briggs DR, Wolf WJ (1957) Arch Biochem Biophys 72:127–144

Kumar R, Zhang L (2008) Biomacromol 9:2430–2437

Sun XS, Kim HR, Mo X (1999) J Am Oil Chem Soc 76:117–123

Kumar R, Wang L, Zhang L (2009) J Appl Polym Sci 111:970–977

Wang S, Zhang S, Jane JL, Sue H (1995) J Polym Mater Sci Eng 72:88–89

Wang S, Sue HJ, Jane JL (1996) J Macromol Sci Pure Appl Chem 33:557–569

Mo X, Sun X (2001) J Am Oil Chem Soc 78:867–872

Liu D, Zhang L (2006) Macromol Mater Eng 291:820–828

Chen P, Zhang L (2005) Macromol Biosci 5:237–245

Chen P, Zhang L, Cao F (2005) Macromol Biosci 5:872–880

Swain SN, Rao KK, Nayak PL (2004) J Appl Polym Sci 93:2590–2596

Swain SN, Rao KK, Nayak PL (2005) Polym Int 54:739–743

Rhim JW, Gennadios A, Weller CL, Cezeirat C, Hanna MA (1998) Ind Crop Prod 8:195–203

Dawson PL, Hirt DE, Rieck JR, Acton JC, Sotthibandhu A (2003) Food Res Int 36:959–968

Rhim JW, Gennadios A, Handa A, Weller CL, Hanna MA (2000) J Agric Food Chem 48:4937–4941

Rojas-Graü MA, Avena-Bustillos RJ, Olsen C, Friedman M, Henika PR, Martín-Belloso O, McHugh TH (2007) J Food Eng 81:634–641

Cagri A, Ustunol Z, Ryser ET (2004) J Food Prot 67:833–848

Kroll J, Rawel HM (2001) J Food Sci 66:48–58

Nice DJ, Robinson DS, Holden MA (1995) Food Chem 52:393–397

Sastry MS, Rao MN (1990) J Agric Food Chem 38:2103–2110

Lin YT, Labbe RG, Shetty K (2004) Appl Environ Microbiol 70:5672–5678

Davidson PM (2001) Chemical preservatives and natural antimicrobial compounds. In: Doyle MP, Beuchat LR, Montville TJ (eds) Food microbiology, 2nd edn. ASM Press, Washington, DC, pp 611–616

Xia C, Wang L, Dong Y, Zhang S, Shi SQ, Cai L, Li J (2015) RSC Adv 5:82765–82771

Kumar R (2012) J Therm Anal Calorim 107:1287–1292

Suppakul P, Miltz J, Sonneveld K, Bigger SW (2003) J Food Sci 68:408–420

Garrido T, Leceta I, Cabezudo S, Guerrero P, de la Koro C (2016) Eur Polym J 85:499–507

Beuchat LR (1998) Surface decontamination of fruits and vegetables eaten raw: a review. Food safety issues. Food Safety Unit/World Health Organization, Geneva, p 42

Jay JM (2000) Modern food microbiology, 6th edn. Chapman and Hall, New York, p 257

Walsh SE, Maillard JY, Russell AD, Catrenich CE, Charbonneau DL, Bartolo RG (2003) J Appl Microbiol 94:240–247

Kumar R, Zhang L (2009) Ind Crops Prod 29:485–494

Guo Z, Liu W (2007) Plant Sci 172:1103–1112

Bai H, Kumar R, Yang C, Liu X, Zhang L (2010) Polym Compos 18:197–203

Azeredo HM, Waldron KW (2016) Trends Food Sci Technol 52:109–122

Wihodo M, Moraru CI (2013) J Food Eng 114:292–302

Liyama K, Lam TB, Stone B (1984) Plant Physiol 104:315–320

Cao N, Fu Y, He J (2007) Food Hydrocoll 21:575–584

Fabra MJ, Hambleton A, Talens P, Debeaufort F, Chiralt A (2011) Food Hydrocoll 25:1441–1447

Mathew S, Abraham TE (2008) Food Hydrocoll 22:826–835

Ou S, Wang Y, Tang S, Huang C, Jackson MG (2005) J Food Eng 70:205–210

Alves MM, Gonçalves MP, Rocha CM (2017) LWT-Food Sci Technol 80:409–415

Luo J, Lai J, Zhang N, Liu Y, Liu R, Liu X (2016) ACS Sustain Chem Eng 4:1404–1413

Peng L, Guo R, Lan J, Jiang S, Lin S (2016) Appl Surf Sci 386:151–159

Barrett DG, Sileika TS, Messersmith PB (2014) Chem Commun 50:7265–7268

Guo J, Ping Y, Ejima H, Alt K, Meissner M, Richardson JJ, Caruso F (2014) Angew Chemi Int Ed 53:5546–5551

Ejima H, Richardson JJ, Liang K, Best JP, van Koeverden MP, Such GK, Caruso F (2013) Science 341:154–157

Hou C, Wang Y, Zhu H, Wei H (2016) Chem Eng J 283:397–403

Rahim MA, Ejima H, Cho KL, Kempe K, Müllner M, Best JP, Caruso F (2014) Chem Mater 26:1645–1653

Zhao J, Pan F, Li P, Zhao C, Jiang Z, Zhang P, Cao X (2013) ACS Appl Mater Interfaces 5:13275–13283

Ahn J, Grun IU, Mustapha A (2004) J Food Prot 67:148–155

Sivarooban T, Hettiarachchy NS, Johnson MG (2008) Food Res Int 41:781–785

Ultee A, Bennik MHJ, Moezelaar R (2002) Appl Environ Microbiol 68:1561–1568

Kim S, Ruengwilysup C, Fung DYC (2004) J Food Prot 67:2608–2612

Rababah TM, Hettiarachchy NS, Horax R (2004) J Agric Food Chem 52:5183–5186

Sivarooban T, Hettiarachchy NS, Johnson MG (2006) J Food Sci 71:39–44

Emiroğlu ZK, Yemiş GP, Coşkun BK, Candoğan K (2010) Meat Sci 86:283–288

Burt S (2004) Int J Food Microbiol 94:223–253

Oussalah M, Caillet S, Salmieri S, Saucier L, Lacroix M (2004) J Agric Food Chem 52:5598–5605

López P, Sánchez C, Batlle R, Nerín C (2005) J Agric Food Chem 53:6939–6946

Oussalah M, Caillet S, Salmieri S, Saucier L, Lacroix M (2006) J Food Prot 69:2364–2369

López P, Sánchez C, Batlle R, Nerín C (2007) J Agric Food Chem 55:4348–4356

Solomakos N, Govaris A, Koidis P, Botsoglou N (2008) Meat Sci 80:159–166

Brito-Oliveira TC, Bispo M, Moraes ICF, Campanella OH, Pinho SC (2017) Food Res Int 102:759–767

Chen S, Zhang N, Tang CH (2016) Food Hydrocoll 61:102–112

Chen FP, Li BS, Tang CH (2015) Food Res Int 75:157–165

Brigger I, Dubernet C, Couvreur P (2002) Adv Drug Deliv Rev 54:631–651

Sondi I, Salopek-Sondi B (2004) J Colloid Interface Sci 275:177–182

Stoimenov PK, Klinger RL, Marchin GL, Klabunde KJ (2002) Langmuir 18:6679–6686

Espitia PJP, Soares NDFF, dos Reis Coimbra JS, de Andrade NJ, Cruz RS, Medeiros EAA (2012) Food Bioprocess Tech 5:1447–1464

Padmavathy N, Vijayaraghavan R (2008) Sci Technol Adv Mater 9:035004

Sirelkhatim A, Mahmud S, Seeni A, Kaus NHM, Ann LC, Bakhori SKM, Hasan H, Mohamad D (2015) Nano-Micro Lett 7:219–242

Varghese S, Kuriakose S, Jose S (2013) J Nanosci. https://doi.org/10.1155/2013/457865

Kempiński W, Łoś S, Kempiński M, Markowski D (2014) Beilstein J Nanotechnol 5:1760–1766

Klasen HJ (2000) Burns 26:117–130

Rai M, Yadav A, Gade A (2009) Biotechnol Adv 27:76–83

Kim JS, Kuk E, Yu KN, Kim JH, Park SJ, Lee HJ, Kim YK (2007) Nanomedicine NBM 3:95–101

Sondi I, Goia DV, Matijević E (2003) J Colloid Interface Sci 260:75–81

Ramesh GV, Porel S, Radhakrishnan TP (2009) Chem Soc Rev 38:2646–2656

Shrivastava S, Bera T, Roy A, Singh G, Ramachandrarao P, Dash D (2007) Nanotechnology 18:225103

Jung WK, Koo HC, Kim KW, Shin S, Kim SH, Park YH (2008) Appl Environ Microbiol 74:2171–2178

Yamanaka M, Hara K, Kudo J (2005) Appl Environ Microbiol 71:7589–7593

Moniruzzaman M, Winey KI (2006) Macromolecules 39:5194–5205

Zheng H, Tan Z, Zhan Y, Huang J (2003) J Appl Polym Sci 90:3676–3682

Huang J, Zhang L, Chen P (2003) J Appl Polym Sci 88:3291–3297

Chen P, Zhang L (2006) Biomacromol 7:1700–1706

Tian H (2012) J Compos Mater 46:427–435

Li Y, Chen H, Dong Y, Li K, Li L, Li J (2016) Ind Crops Prod 82:133–140

Zhang J, Jiang L, Zhu L, Jane J, Mungara P (2006) Biomacromol 7:1551–1561

Plummer CJG, Garamszegi L, Leterrier Y, Rodlert M, Månson JE (2002) Chem Mater 14:486–488

Ray SS, Okamoto M (2003) Prog Polym Sci 28:1539–1641

Chen X, Kong L, Dong D, Yang G, Yu L, Chen J, Zhang P (2009) J Phys Chem C 113:5396–5401

Li H, Yu S, Han X (2016) Chem Eng J 83:1443–1454

Xie WY, Song F, Wang XL, Wang YZ (2017) ACS Sustain Chem Eng 5:869–875

Tian H, Xu G (2011) J Polym Environ 19:582–588

Kim HW, Kim KM, Ko EJ, Lee SK, Ha SD, Song KB, Park SK, Kwon KS, Bae DH (2004) J Microbiol Biotechnol 14:1303–1309

Kumar R, Rani P, Kumar KD (2019) J Renew Mater 7:103–115

Insaward A, Duangmal K, Mahawanich T (2015) J Agric Food Chem 63:9421–9426

Xu F, Dong Y, Zhang W, Zhang S, Li L, Li J (2015) Ind Crops Prod 67:373–380

Wang Z, Kang H, Zhang W, Zhang S, Li J (2017) Appl Surf Sci 401:271–282

Chen GG, Qi XM, Guan Y, Peng F, Yao CL, Sun RC (2016) ACS Sustain Chem Eng 4:1985–1993

Rubentheren V, Ward TA, Chee CY, Nair P (2015) Cellulose 22:2529–2541

Ko S, Janes ME, Hettiarachchy NS, Johnson MG (2001) J Food Sci 66:1006–1111

Zheng H, Ai F, Wei M, Huang J, Chang PR (2007) Macromol Mater Eng 292:780–788

Ai F, Zheng H, Wei M, Huang J, Chang PR (2007) J Appl Polym Sci 105:1597–1604

Sağdıç O (2003) LWT—Food Sci Tech 36:467–473

Dadalioglu I, Evrendilek G (2004) J Agri Food Chem 52:8255–8260

Donaldson JR, Warner SL, Cates RG, Young DG (2005) Pharm Biol 43:687–695

Nedorostova L, Kloucek P, Kokoska L, Stolcova M, Pulkrabek J (2009) Food Control 20:157–160

Seydim AC, Sarikus G (2006) Food Res Int 39:639–644

Sun Q, Li X, Wang P, Du Y, Han D, Wang F, Liu X, Li P, Fu H (2011) J Food Sci 76:E438–E443

Zhao S, Yao J, Fei X, Shao Z, Chen X (2013) Mater Lett 95:142–144

Zhang Y, Lee MW, An S, Ray SS, Khansari S, Joshi B, Hong S, Hong JH, Kim JJ, Pourdeyhim B, Yoon SS, Yarin AL (2013) Catal Commun 34:35–40

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rani, S., Kumar, R. A Review on Material and Antimicrobial Properties of Soy Protein Isolate Film. J Polym Environ 27, 1613–1628 (2019). https://doi.org/10.1007/s10924-019-01456-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01456-5