Abstract

In this study, poly(l-lactide) (PLA) films were fabricated by melt processing and the plasticizing effect of hexadecyl lactate (HL) (0, 5, 7.5, 10, and 12.5 wt% on PLA were investigated by scanning electron microscopy (SEM), differential scanning calorimetry, thermogravimetric analysis, tensile, transparency, and water vapor permeability tests. The SEM analysis revealed that PLA with 10 wt% HL appeared uniform with extra small bumps, confirmed the interaction between PLA and HL. The thermal analysis revealed a glass transition temperature of 57.4 °C for neat PLA film, but the addition of HL elicited a decrease in the temperature of the peak (43.8 °C). The incorporation of plasticizer into PLA resulted in the increase of elongation at break, as well as the decrease of tensile strength and tensile modulus. Even though a decrease in transparency was recorded, the PLA/HL blend films appeared transparent by visually observation. The water vapor permeability of PLA/HL blend films increased with the increase of HL. The PLA/HL blend films could effectively extend the shelf-life of fresh-cut pears as the commercial low density polyethylene films. The results indicated that the properties of PLA films can be modified with the addition of HL and PLA/HL blend films could serve as an alternative as food packaging materials to reduce environmental problems associated with synthetic packaging films.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Food packaging plays a decisive role in achieving protection and preservation of food from spoilage as well as dehydration and therefore extends the shelf life of food [1]. Plastics, by virtue of its low cost and easy availability, are widely used as food packaging materials [2]. However, the growing environmental concerns over the non-biodegradable nature complemented by serious waste disposal problems have increased interest in the use of biodegradable polymers from renewable sources [3].

Poly(l-lactide) (PLA) is one of the most promising materials for eco-friendly packaging, not only for its biodegrability and renewable source, but also for its processability, lightness, and transparency [4, 5]. PLA is currently commercialized and used in food packaging application for fresh products as containers, drinking cups, salad cups, overwrap and lamination films, and blister packages [6]. It is noteworthy that PLA is a relatively brittle and stiff polymer with a low deformation at break [7]. Thus, several modifications have been proposed to improve its processing and mechanical properties. One of the effective ways is the addition of plasticizer to PLA during processing. Plasticizer is a substance which changes certain properties of the materials by reducing the intermolecular forces among polymer matrix [6]. After plasticization, the crystallinity is in the range between 20 and 30 % [8]. Furthermore, the plasticizer should be compatible with the polymer and provides suitable thermal, mechanical, and barrier properties [4]. Several plasticizers have been studied as potential PLA plasticizers, such as poly(ethylene glycol), triacetin, oligomeric poly(1,3-butylene glycol adipate) (PBGA), tributyl citrate, and glycerol monostearate [9–12]. Ge et al. [12] studied the effect of glycerol monostearate on the mechanical properties of PLA films. They found that the adding of glycerol monostearate had enhanced the flexibility of PLA/glycerol monostearate blends as compared to neat PLA. A polyester plasticizer (Lapol 108) is derived from more than 50 % renewable resources and already in commercial development. Abdelwahab et al. [8] pointed out that the elongation at break of the PLA blends was greatly improved with the addition of this new plasticizer and the PLA blends were new type of eco-friendly blend materials suitable for single-use applications, such as fast-food packaging.

New and old plasticizers are continuously studied in the field of food-packaging materials [13]. Lactate esters are made from fatty alcohols and can be considered to be a chemical combination of lactic acid and fatty alcohols, like hexadecyl lactate (HL), and myristyl lactate. These lactate esters are readily biodegradable, suggesting little concern from an environmental point of view. Moreover, owing to their high safety and non-irritancy to skin, HL is widely used as food additives, perfume materials, medicine additives, and personal care products [14–16]. Tributyl citrate, a nontoxic citrate ester, has similar characteristics as HL and is effective in reducing the glass transition temperature and improving the elongation at break of PLA [17]. However, HL has been largely ignored as potential plasticizer, though it is readily available, inexpensive, and safe.

The objective of this work was to study the effect of various HL content on the thermal property, mechanical property, opacity, and water vapor permeability of PLA films that could be used for food packaging applications. Structural characterization was carried out using scanning electron microscopy (SEM). Differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) tests were performed to investigate the thermal behavior of the PLA/HL blends. In our previous work, we only studied the effect of N-octyl lactate on thermal and functional properties of extruded PLA-based films [13]. In this paper, we further studied the effect of the PLA/HL blend films on sensory quality of fresh-cut pears to create a new type of blend material suitable for postharvest preservations, such as fruit and vegetable packaging.

Materials and Methods

Materials

The Poly(l-lactide) (PLA) (NatureWorks Co. LLC, Nebraska, USA) had an average molecular weight of 280 kDa and a polydispersity (Mw/Mn) of 1.98. It was dried in a vacuum oven at 85 °C for 24 h, resulting in a moisture level of <0.2 wt%, in order to avoid polymer degradation during processing. HL (Mw = 314.5) was obtained from Sigma-Aldrich (St. Louis, MO, USA).

Preparation of the PLA/HL Blends

PLA was swollen with different amount (0, 5, 7.5, 10, and 12.5 wt%) of the HL plasticizer and the blends were processed using a single-screw extruder (LSJ-20, Kechuang Rubber Plastics Machinery Set, Shanghai, China) at a screw rotating speed of 80 rpm. The screw diameter was 20 mm with a screw ratio (L/D) of 25. The temperature was 160 °C in the feeding zone and reached a maximum of 170 °C. The die temperature was 165 °C.

The obtained blends were compression molded on a hot press (LSY-80, Kechuang Rubber Plastics Machinery Set, Shanghai, China) to obtain films of 300–500 μm. The molding conditions were set at the temperature of 180 °C for 30 s under a mold pressure of 1 MPa. Specimens of PLLA/s-PCLA blends for mechanical properties and water vapor permeability measurements were prepared by a film blowing machine (LSC-120, Kechuang Rubber Plastics Machinery Set, Shanghai, China) to obtain films of around 50 μm. The temperature of blowing head was 160 °C and the temperature of cooling air was 25 °C. The blow up ratio was 2:1 and the draw down ratio was held at 7:1 [18].

Scanning Electron Microscopy (SEM)

The cross-section morphology of plasticized PLA films was observed using SEM. Before the SEM examination, the films were submerged in liquid nitrogen and fractured. The fracture surfaces were coated with a thin conductive gold layer in 20 nm thick. Specimens were viewed in a scanning electron microscope (Quanta 200, Chicago, USA) under an acceleration voltage of 15 kV.

Thermal Properties

Differential scanning calorimetry was performed under nitrogen atmosphere in a TA Instrument (STA 449, Netzsch, Germany). Approximately 10 mg of samples were weighed in a stainless pan and an empty pan was used as a reference. Measurements were carried out according to the following protocol: the sample was heated from room temperature to 200 °C at a heating rate of 10 °C/min, and then held for 5 min. The first heating scan was used to eliminate any prior thermal history of the sample. Then, the sample was cooled to room temperature at a cooling rate of 10 °C/min. DSC analyses were followed by quenching to room temperature and further heating to 200 °C at 10 °C/min. The second heating scan was used to evaluate melting temperature (T m ) and crystallinity (X c ) of all the samples. The degree of crystallinity X c was evaluated according to the Eq. (1).

where ΔH m is the melting enthalpy (J/g) that was calculated from the fusion peak in the DSC curve, ΔH c is the cold crystallization enthalpy (J/g) of sample, ΔH° m is the heat of fusion for completely crystalline PLA (93.7 J/g), and w is the weight fraction of PLA in the blends [19].

Thermal gravimetric analysis (TGA) was conducted under nitrogen atmosphere in a TA Instrument (STA 449, Netzsch, Germany). The samples were heated from 40 °C to 700 °C at a rate of 10 °C/min.

Mechanical Properties

Tensile strength (TS), tensile modules (TM), and elongation at break (EB) of the films were measured according to ASTM Method D 882-88 on an Universal tensile machine (WDW-10, Shanghai Jadaronson M&C System Co., ltd., Shanghai, China). The measurements were conducted at a cross-head speed of 100 mm/min at room temperature [20]. In each case, eight specimens were measured and the average values were reported.

Transparency

The transparency of the film was determined using the method reported by Rodríguez-Núñez et al. with some modifications [3]. Samples were cut into a rectangle section (0.7 cm × 1.5 cm) and directly placed on the internal side of a spectrophotometer test cell. The transparency of the film was determined by measuring the absorbance at 600 nm using a UV–Vis spectrophotometer (T90, Beijing Purkinje general instrument Co., Ltd. Beijing, China) [21]. An empty test cell was used as the Ref. [22]. The opacity of the film was calculated using Eq. (2), which was derived by Han and Floros [23].

where A 600 is the value of absorbance at 600 nm and T is the thickness of the film (mm). The higher opacity value indicated that the film was less transparent. The measurements were repeated three times for each sample and the average values were reported.

Water Vapor Permeability (WVP)

The gravimetric modified cup method based on ASTM E96-95 was used to determine the WVP of the film. Ahead of testing, the thickness of the film was measured and the average thickness was used to calculate the WVP of the film. The film was mounted on the top of the test acrylic cup filled with silica gel and sealed with paraffin waxes. The test acrylic cup was 40 mm in diameter and 25 mm in depth. The sealed cup was placed in a relative humidity chamber at 25 °C and relative humidity (RH) of 50 %. After steady-state conditions were reached, the weight of the cup was measured every 12 h over 3 days. The weight loss of the cup was recorded to the nearest 0.0001 g as a function of time [24]. The WVP was calculated according to Eq. (3) [5, 25].

where WVTR is the measured water vapor transmission rate through the film (g/m2 s), T is the average film thickness (m), and ΔP is the partial pressure difference across the film (Pa).

Effect of HL-Containing PLA Film on the Sensory Attributes of Fresh-Cut Pears

Pears were dipped into a 7,500 ppm HClO solution for 5 min, washed with sterilized distilled water, and dried prior to cutting operations. Pears were peeled, the core tissue was completely removed, the remaining tissue was cut into wedges, and fruit pieces were dipped in an aqueous solution of N-acetylcysteine at 0.75 % (w/v) for 2 min. The pears were randomly assigned to one of three treatments: no packaging (Control group), pears were packaged with low density polyethylene (LDPE) film (LDPE group), and pears were packaged with PLA film containing 10 wt% of HL (PLA–HL10 group). The films were cut in the same dimensions (150 mm × 300 mm) and submitted to UV light. Then, the fresh-cut pears weighing about 200 g were packed with the tested films, sealed, and stored at 4 ± 1 °C for 15 days. The sensory attributes evaluated were visual appearance, flavor, firmness, and overall acceptability of the product, using a 10-point numerical scale, where 10 corresponded to components characteristic of the highest quality. A score of 6 or higher in any of the attributes was considered acceptable for sale or consumption. The sensory assessment panel was consisted of ten trained members from Department of Food Science and Technology, Kunming University of Science and Technology, on days 10 and 15 of storage.

Statistical Analysis

Statistics on a completely randomized design were performed with the analysis of variance (ANOVA) (p < 0.05) using statistical computer software package (SPSS version 13.0).

Results and Discussion

Scanning Electron Microscopy (SEM)

The effect of plasticizer level on films was investigated by SEM analysis. The morphology of the blends fractured in liquid nitrogen was shown in Fig. 1a–e. All the films obtained were very clear and uniform in thickness. Surface of the neat PLA film (Fig. 1a) revealed only features typical of brittle fracture of polymer, without any evidences of heterogeneities. The SEM micrographs (Fig. 1b, c) plasticized with lower amounts of HL (5–7.5 wt%) showed surfaces morphology with little plastic deformation and a few long threads of a deformed material occasionally discernible [12, 26]. Furthermore, a large amount of plastically deformed material was visible on the surface of PLA with 10 wt% HL (Fig. 1d). By further increasing the HL content to 12.5 wt% (Fig. 1e), coarseness was observed on the fracture surface of film where HL had been accumulated. This suggested incomplete mixing of the plasticizers at the 12.5 wt% level in the bulk of the sample [21].

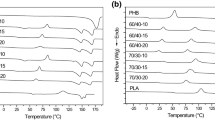

DSC

The glass transition and crystallization/melting phenomena of PLA and PLA/HL blends were investigated by DSC analysis. DSC traces recorded during the second heating cycle of the polymer samples were presented in Fig. 2. The curves revealed similar thermal events for the neat PLA and PLA/HL blends samples as follows: the glass transition temperature (T g ), peak crystallization temperature (T c ), and melting temperatures (T m ). The T g was taken as an inflection point in the jump of the heat capacity in the second heating scan [27]. The thermal characteristics were summarized in Table 1.

The neat PLA sample showed a T g at 57.4 °C, an exothermic crystallization peak at 105.7 °C, and a melting peak at 167.9 °C. The T g values of the PLA/HL blends clearly depended on the sample composition and the T g values of these samples decreased gradually from 57.4 °C (neat PLA) to 43.8 °C (PLA with 12.5 wt% HL), with increasing HL content. The addition of HL markedly caused changes in the phase transition behavior of the polymer matrix. The trends in T g values were in good agreement with those reported in previous investigations of the effects of plasticizing PLA [4, 9–11]. This marked decrease could be related to the interaction between PLA and HL, exerting a plasticizer effect which typically increased free volume of the polymer network and segmental mobility of the polymer chains [7, 28]. From Table 1, it could be noticed that with increasing HL content, the T c decreased from 105.7 to 91.9 °C, and the T m decreased from 167.9 to 162.1 °C. Moreover, the melting peaks became much wider and larger with the increase of plasticizer content. Considering that all blends were prepared under the same processing conditions, the T m changes of components might be a result of interactions between components. It is also known that the T m of a crystalline polymer is depressed by low molecular weight plasticizers because of the increase of chain end [10]. Similar observations had been presented in studies concerning PLA blends with plasticizer [9–11].

The degree of crystallinity (X c ) of the PLA/HL blends was calculated and listed in Table 1. It was found that the degree of crystallinity in the films was higher in the more plasticized materials. This might be because that a low T g allowed an additional crystallization to occur during cooling of the extruded film, as compared with the situation for neat PLA [11]. In the present case of PLA, within the content limits studied, all of the plasticizers enhanced the crystallinity to some extent due to higher chain mobility and a better packing of segments [8]. The enhancement of the crystallizability had already been reported for PLA plasticized with PEG, adipates, citrate esters, and malonate oligomers [9–12].

Thermal Stability

Processability and applicability of polymer systems depends greatly on their thermal stability. The TGA thermogram of the PLA/HL blend films produced by extrusion was shown in Fig. 3. Neat PLA decomposed in a single step process with a maximum degradation rate at 325 °C, in agreement with values reported by Abdelwahab et al. [8]. The addition of plasticizers had no significant effect on the thermal stability of the PLA/HL blends with 5–12.5 % HL. As a consequence, it could be concluded that the plasticized PLA/HL blend films could be processed by usual thermoplastic technologies (extrusion or compression molding) under the same conditions than neat PLA without risking thermal degradation [11, 29, 30].

Mechanical Properties

The mechanical properties of PLA-based blend films were presented in Table 2. In general, from the results can be seen that addition of plasticizer lowered TS and TM of the films and improved E of the films in comparison to neat PLA.

The TM values of PLA blend films decreased about 15.5, 19.4, 67.3, and 47.5 %, when the HL content was 5, 7.5, 10, and 12.5 %, respectively. The incorporation of HL caused significant (p < 0.05) reduction in TM values. The TS of PLA blend films decreased significantly (p < 0.05) when HL content increased from 5 wt% (48.3 MPa) to 12.5 wt% (31.1 MPa). Ge et al. [12] reported that the use of plasticizer decreased the interactions between PLA chains and enhanced the mobility of PLA chains, thereby decreasing TS values of PLA-based films.

The films intended for food packaging applications are subjected to elongation during the packaging procedure, being important their elongation characteristics [31]. The EB values of all of the blends increased with the plasticizer content. The PLA films with 5 and 7.5 wt% HL exhibited rather small elongation at break. On the contrary, the PLA films with 10 and 12.5 wt% HL fractured at elongation of 228 and 189 %, respectively. Similar trends were reported elsewhere in the literature. Kulinski et al. [26] reported that the elongation at break exceeded that of neat PLA beginning with the plasticizer content of 7.5 wt% and reached 500 % for the plasticizer content of 10 wt%. This behavior might be because plasticizers reduced the intermolecular forces between PLA molecules, thereby improving flexibility and extensibility of the films [32].

The main effects were found in the presence of 10 wt% HL: The TM decreased from 2,357 to 870 MPa, the TS decreased from 60.2 to 32.9 MPa, and EB increased from 5.4 to 228 %. By further increasing the HL content to 12.5 wt%, TM increased from 870 to 1237 MPa, while EB decreased from 228 to 189 %. This was probably due to the possible occurrence of phase separation at this blend ratio. The changes in mechanical properties of the PLA/HL blends were verified by the SEM analysis. It may be noted that higher tensile strength as well as elongation at break will be preferable for food packaging films [1]. So, the PLA-based blend film containing 10 wt% HL was a good compromise from application point of view.

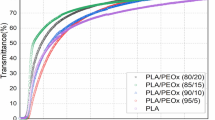

Transparency

Nowadays, transparent packaging materials have been widely used in many food industries. This is because that the aspect of packaging could influence the decision of consumers [33]. The samples were physically characterized, determining the transparency of each film. The opacity of the PLA/HL blend films with different HL contents was shown in Fig. 4. As could be seen from Fig. 4, the transparency of the PLA/HL blend films decreased with the content of HL. It is well known that PLA forms transparent films [29]. The opacity values of the PLA/HL blend films with 5, 7.5, and 10 wt% HL contents were only 6.3, 10.6, and 12.2 % higher than that of neat PLA film, respectively. This represented the notable transparency of the PLA/HL blend films. Furthermore, the low opacity of PLA/HL blend films conveyed a sense of great stability achieved between the two phases [34].

The visual appearance of neat PLA and PLA/HL blend films was shown in Fig. 5. The PLA/HL blend films presented a decrease on the transmittance value compared with neat PLA film, but the PLA/HL blend films appeared transparent by visually observation.

Water Vapor Permeability (WVP)

WVP is one of the most important properties in food packaging applications, mainly because of the noticeable role of water in deteriorative reactions and microbial growth [35]. It is well known that plasticizers increase the free volume in PLA matrix and result in a reduction in the barrier properties of PLA films [31]. The water vapor permeability of the PLA/HL blend films was studied and the obtained results were shown in Fig. 6. The WVP of neat PLA film was 1.85 × 10−14 kg m/m2 s Pa. The WVP of the PLA/HL blend films increased significantly (p < 0.05) with the increase of HL content from 5 to 12.5 %. Similarly, Laboulfie et al. [36] reported that the highest grades of polyethylene glycol (PEG) provided a better plasticizing effect for the film but increases the WVP of the film. On the other hand, Arrieta et al. [33] showed that barrier properties of the PLA films were reduced due to the increase of the chain mobility produced by limonene. This behavior might be because of the changes in crystallinity of PLA. A lower degree of crystallinity is usually related with reduction in barrier properties of the films because water diffusion mainly occurs through amorphous regions [37].

Effect of HL-Containing PLA Film on the Sensory Attributes of Fresh-Cut Pears

Quality evaluations were done using human subjects, because it is important that not just quantifiable physical and chemical measurements be used to determine if a shelf-life extending treatment has merit [38, 39]. Changes in sensory attributes including visual appearance, flavor, firmness, and overall acceptability of fresh-cut pears during storage were shown in Fig. 7a, b. The pear wedges without packaging deteriorated very quickly as the time increased. The PLA–HL10 packaged pears scored similar to the samples packaged with the LDPE films for sensory attributes during the whole storage period. The results indicated that consumer panelists had no strong preference to the pear wedges of LDPE and PLA–HL10 groups they were asked to evaluate. It could be concluded that use of PLA–HL10 film to extend the shelf-life of fresh-cut pears was a viable option.

Conclusions

From the datas obtained by the different techniques, it can be concluded that PLA can be effectively plasticized by HL. The significant decrease in glass transition temperature observed with increasing HL content was well correlated with the increase in the blends ductility. The thermal and SEM analysis provided evidence for the presence of interaction between PLA and HL as well as to offer a more detailed insight into the structure and morphology of the blends. Large improvements of the elongation at break values were noted for blends containing HL as compared to neat PLA. Although the PLA/HL blend films presented a decrease on the transmittance value compared with neat PLA film, the PLA/HL blend films appeared transparent by visually observation. The WVP values increased with the addition of HL. The PLA–HL10 packaged pears scored similar to the samples packaged with the commercial LDPE films for sensory attributes during the whole storage period. As a consequence, blending PLA with 10 wt% HL could obtain flexible films with appropriate optical and barrier properties. This suggests a great potential of the PLA/HL blend films in the application of food packaging.

References

Joseph CS, Prashanth KH, Rastogi NK, Indiramma AR, Reddy SY, Raghavarao KSMS (2011) Optimum blend of chitosan and poly-(ε-caprolactone) for fabrication of films for food packaging applications. Food Bioprocess Tech 4(7):1179–1185

Voon HC, Bhat R, Easa AM, Liong MT, Karim AA (2012) Effect of addition of halloysite nanoclay and SiO2 nanoparticles on barrier and mechanical properties of bovine gelatin films. Food Bioprocess Tech 5(5):1766–1774

Rodríguez-Núñez JR, Madera-Santana TJ, Sánchez-Machado DI, López-Cervantes J, Valdez HS (2014) Chitosan/hydrophilic plasticizer-based films: preparation, physicochemical and antimicrobial properties. J Polym Environ 22(1):41–51

Burgos N, Martino VP, Jiménez A (2013) Characterization and ageing study of poly(lactic acid) films plasticized with oligomeric lactic acid. Polym Degrad Stab 98(2):651–658

Rhim JW, Hong SI, Ha CS (2009) Tensile, water vapor barrier and antimicrobial properties of PLA/nanoclay composite films. LWT Food Sci Technol 42(2):612–617

Fortunati E, Peltzer M, Armentano I, Torre L, Jiménez A, Kenny JM (2012) Effects of modified cellulose nanocrystals on the barrier and migration properties of PLA nano-biocomposites. Carbohydr Polym 90(2):948–956

Rodríguez-Llamazares S, Rivas BL, Pérez M, Perrin-Sarazin F (2012) Poly(ethylene glycol) as a compatibilizer and plasticizer of poly(lactic acid)/clay nanocomposites. High Perform Polym 24(4):254–261

Abdelwahab MA, Flynn A, Chiou BS, Imam S, Orts W, Chiellini E (2012) Thermal, mechanical and morphological characterization of plasticized PLA–PHB blends. Polym Degrad Stab 97(9):1822–1828

Tanoue S, Hasook A, Iemoto Y, Unryu T (2006) Preparation of poly(lactic acid)/poly(ethylene glycol)/organoclay nanocomposites by melt compounding. Polym Compos 27(3):256–263

Ren Z, Dong L, Yang Y (2006) Dynamic mechanical and thermal properties of plasticized poly(lactic acid). J Appl Polym Sci 101(3):1583–1590

Ljungberg N, Andersson T, Wesslén B (2003) Film extrusion and film weldability of poly(lactic acid) plasticized with triacetine and tributyl citrate. J Appl Polym Sci 88(14):3239–3247

Ge H, Yang F, Hao Y, Wu G, Zhang H, Dong L (2013) Thermal, mechanical, and rheological properties of plasticized poly(L-lactic acid). J Appl Polym Sci 127(4):2832–2839

Wang Y, Qin Y, Zhang Y, Yuan M, Li H, Yuan M (2014) Effects of N-octyl lactate as plasticizer on the thermal and functional properties of extruded PLA-based films. Int J Biol Macromol 67:58–63

Clary JJ, Feron VJ, Van Velthuijsen JA (1998) Safety assessment of lactate esters. Regul Toxicol Pharm 27(2):88–97

Zhang J, Liu M, Jin H, Deng L, Xing J, Dong A (2010) In vitro enhancement of lactate esters on the percutaneous penetration of drugs with different lipophilicity. Aaps Pharmscitech 11(2):894–903

Crisologo NM, Taskovich LT, Yum SI (1997) Monoglyceride/lactate ester permeation enhancer for codelivery of steroids. U.S. Patent 5,686,097[P]. 11 Nov 1997

Labrecque LV, Kumar RA, Dave V, Gross RA, McCarthy SP (1997) Citrate esters as plasticizers for poly(lactic acid). J Appl Polym Sci 66(8):1507–1513

Qin Y, Liu S, Zhang Y, Yuan M, Li H, Yuan M (2014) Effect of poly(ɛ-caprolactone-co-L-lactide) on thermal and functional properties of poly(L-lactide). Int J Biol Macromol 70:327–333

Yang SL, Wu ZH, Meng B, Yang W (2009) The effects of dioctyl phthalate plasticization on the morphology and thermal, mechanical, and rheological properties of chemical crosslinked polylactide. J Polym Sci Polym Phys 47(12):1136–1145

Zhai CP, Liu XJ, Yuan JF, Gao QY (2013) Synthesis, characterization, and drug delivery research of an amphiphilic biodegradable star-shaped block copolymer. Polym Bull 70(2):419–429

Park PJ, Je JY, Kim SK (2004) Free radical scavenging activities of differently deacetylated chitosan using an ESR spectrometer. Carbohydr Polym 55(1):17–22

Wang L, Dong Y, Men H, Tong J, Zhou J (2013) Preparation and characterization of active films based on chitosan incorporated tea polyphenols. Food Hydrocoll 32(1):35–41

Han JH, Floros JD (1997) Casting antimicrobial packaging films and measuring their physical properties and antimicrobial activity. J Plast Films Sheet 13(4):287–298

Vásconez MB, Flores SK, Campos CA, Alvarado J, Gerschenson LN (2009) Antimicrobial activity and physical properties of chitosan-tapioca starch based edible films and coatings. Food Res Int 42(7):762–769

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll 27(1):220–227

Kulinski Z, Piorkowska E, Gadzinowska K, Stasiak M (2006) Plasticization of poly(L-lactide) with poly(propylene glycol). Biomacromolecules 7(7):2128–2135

Yu F, Prashantha K, Soulestin J, Lacrampe MF, Krawczak P (2013) Plasticized-starch/poly(ethylene oxide) blends prepared by extrusion. Carbohydr Polym 91(1):253–261

Jagadeesh D, Kumar BP, Sudhakara P, Prasad CV, Rajulu AV, Song JI (2013) Preparation and properties of propylene glycol plasticized wheat protein isolate novel green films. J Polym Environ 21(4):930–936

Martino VP, Jiménez A, Ruseckaite RA (2009) Processing and characterization of poly(lactic acid) films plasticized with commercial adipates. J Appl Polym Sci 112(4):2010–2018

Gao C, Ma H, Liu X, Yu L, Chen L, Liu H, Li X, Simon GP (2013) Effects of thermal treatment on the microstructure and thermal and mechanical properties of poly(lactic acid) fibers. Polym Eng Sci 53(5):976–981

Arrieta MP, López J, Hernández A, Rayón E (2014) Ternary PLA–PHB-Limonene blends intended for biodegradable food packaging applications. Eur Polym J 50:255–270

Nur Hanani ZA, McNamara J, Roos YH, Kerry JP (2013) Effect of plasticizer content on the functional properties of extruded gelatin-based composite films. Food Hydrocoll 31(2):264–269

Arrieta MP, López J, Ferrándiz S, Peltzer MA (2013) Characterization of PLA-limonene blends for food packaging applications. Polym Test 32(4):760–768

González A, Alvarez Igarzabal CI (2013) Soy protein-poly(lactic acid) bilayer films as biodegradable material for active food packaging. Food Hydrocoll 33(2):289–296

Jamshidian M, Tehrany EA, Imran M, Akhtar MJ, Cleymand F, Desobry S (2012) Structural, mechanical and barrier properties of active PLA-antioxidant films. J Food Eng 110(3):380–389

Laboulfie F, Hémati M, Lamure A, Diguet S (2013) Effect of the plasticizer on permeability, mechanical resistance and thermal behaviour of composite coating films. Powder Technol 238:14–19

Fabra MJ, Lopez-Rubio A, Lagaron JM (2013) High barrier polyhydroxyalcanoate food packaging film by means of nanostructured electrospun interlayers of zein. Food Hydrocoll 32(1):106–114

Oms-Oliu G, Soliva-Fortuny R, Martín-Belloso O (2008) Edible coatings with antibrowning agents to maintain sensory quality and antioxidant properties of fresh-cut pears. Postharvest Biol Technol 50(1):87–94

Gorny JR, Hess-Pierce B, Cifuentes RA, Kader AA (2002) Quality changes in fresh-cut pear slices as affected by controlled atmospheres and chemical preservatives. Postharvest Biol Technol 24(3):271–278

Acknowledgments

This work was supported by the National Natural Science Foundation of China (31160198, 31360417), the Applied Basic Research Key Project of Yunnan (2013FA039), the Applied Basic Research Project of Yunnan (2011FB084), and the High-End Technology Professionals Introduction Plan in Yunnan province (2010CI119).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, Y., Wang, Y., Wu, Y. et al. Effect of Hexadecyl Lactate as Plasticizer on the Properties of Poly(l-lactide) Films for Food Packaging Applications. J Polym Environ 23, 374–382 (2015). https://doi.org/10.1007/s10924-014-0702-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-014-0702-7