Abstract

Wastewater treatment is designed to eradicate toxic pollutants emanating from the industrial effluent to the surface and underground water. The efficiency and limitations of most of the existing water treatment techniques such as coagulation/flocculation, photocatalysis, membrane technologies and adsorption in the remediation of toxic pollutants have been established. However, the success reported for each of these techniques is usually associated with the efficiency and environmental friendliness of water treatment products applied. MOFs-based products are one of the materials serving as an alternative to chemically synthesized products, and their application as water treatment products has been reported extensively but not systematically documented. In this review, authors endeavoured to comprehensively provide insights into the recent MOFs-based product synthesis for different applications, especially in water treatment. The key factors influencing the synthesis of MOFs, including choice of metal ions, organic linkers, and synthesis conditions, along with the latest developments in scalable and cost-effective fabrication techniques are discussed. The synthesis routes, their limitation and their performances as an adsorbent, photocatalyst and additives in membrane fabrication in the removal of toxic pollutants from water are elaborated. The prospects in the large-scale production of MOFs-based water treatment products for real industrial applications are critically reviewed in this study. Overall, a well-curated synthesis and application of MOFs in water treatment is hereby generated from the best resources accessible through the literature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Water pollution by anthropogenic sources and the rapid development of industries pose an adverse threat of water scarcity due to the growing water demand worldwide. Pollutants such as pharmaceutical and personal care products, dyes, pesticides and heavy metals are discharged into water sources before any treatment leading to severe health threats and environmental issues [1]. The availability of potable water is pivotal for the growth of any economy. Therefore, there is an urgent need to develop effective methods for the removal of these pollutants from water to preserve lives, the environment and economic sustainability [2, 3].

Techniques such as ion exchange, advanced oxidation, adsorption, ozonation, and coagulation/flocculation have been discussed in the literature with their respective benefits and drawbacks [4,5,6,7,8,9,10,11]. Despite the efficiency of these techniques, the use of chemically synthesized water treatment materials during the operation could be responsible for additional hazardous chemicals found in process waters via leaching [12]. Thus, this causes more harm than good to the water bodies, hence, more investigations or ideas are required to develop highly efficient and environmentally friendly water treatment products. Metal-organic frameworks (MOFs) could be a good candidate for such replacements [4,5,6,7,8,9,10,11].

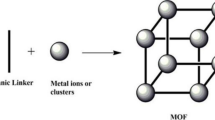

Metal-organic frameworks are emerging multifunctional materials which are extensively being explored for various applications including and not limited to drug delivery, catalysis, gas storage and sensing. Their wide range of applications is due to their adjustable structures, large surface area, unique optical characteristics, and suitability [4,5,6,7,8,9,10,11]. The utilization of MOFs in water treatment has been instigated by many researchers, and this might be due to their outstanding properties which includes high porous structure, high specific surface area, adjustable surface structure, well-defined pore sizes, diverse architectural and layout. Metal-organic frameworks are made of diverse metal clusters that are coordinated to multifunctional organic linkers [13,14,15]. They can be synthesized in different shapes and sizes by controlling the raw materials depending on the intended application. One of the important benefit of MOFs is the fact that, they possess adjustable structure that can be modified with other appropriate materials to produce more efficient MOFs composites with enhanced properties or even new added properties [16, 17].

Numerous uses have been developed since the discovery of this innovative class of nanoporous materials and the idea of “reticular design.” Several gas separation, purification, and storage processes have found success with the use of MOFs in the catalysis and gas processing domains [18]. Amongst the applications of MOFs, water treatment is prominent and an area that is receiving more interest. Metal-organic frameworks are applied in the removal of various pollutants from water using either adsorption [19], membrane separation [20, 21] and/or photocatalytic degradation [22,23,24]. Understanding how MOFs and the pollutants interact is important in order to develop an efficient and appropriate MOFs to be used in a particular water treatment technique. For example, the adsorptive and photocatalytic performances of MOFs depend on their charged surface, active sites, surface area, and pore sizes.

As a result, the aim of this review is to provide an update on the latest developments on the synthesis and application of different MOFs in already-existing water treatment technologies for the removal of various pollutants from water. Additionally, the advantages, limitations and the future prospect of MOFs utilization in water treatment is analysed. Therefore, large-scale production and industrial applications of MOFs-based water treatment products are outlined and thoroughly discussed.

1.1 Advantages and Disadvantages of Existing Water Treatment Methods

Water treatment is designed to prevent the environment and human health from the negative impact of toxic substances emanated from industrial or household activities [25]. Water treatment techniques such as chemical precipitation, adsorption, coagulation/flocculation have been in existence and utilized extensively [22,23,24]. Although, membrane technology and photocatalysis innovations were discovered afterwards; they have also been utilized in the past two decades. The use of any of these techniques depends on the water matrix to be treated [22,23,24]. Additionally, the methods could also be integrated together as they often complement each other to achieve highly efficient results in water treatment [26]. Despite their effectiveness and efficiency, each of the method is associated with some limitations that needed to be considered before utilization [22,23,24]. Table 1 presents a summary of some of the common methods used with their advantages and disadvantages.

2 Common Synthesis Routes for MOFs for Different Applications

Various methods are used in the synthesis of MOFs which includes solvothermal [49, 50], mechanochemical [51, 52], sonochemical [53, 54], sol gel [55,56,57], hydrothermal [58, 59] and ultrasound-assisted method [60,61,62]. The commonly synthesized MOFs are ZIFs-type MOFs (ZIF stands for zeolitic imidazolate frameworks), MIL-type MOFs (MIL stands for Material Institute Lavoisier) and UiO-66 MOFs (UiO refers to University of Oslo). These aforementioned MOFs types have been thoroughly studied for water treatment application due to their stability in water and their affinities for removal of various pollutants from water [63, 64]. Metal-organic frameworks are highly porous and quite beneficial in volume specific applications which includes adsorption, photocatalysis and some other purification purposes. Metal-organic frameworks could be synthesized under different temperature, however, well-known four MOFs such as MOF-5, MOF-74, MOF-177, and MOF-199 are synthesized at room temperature. New MOFs such as IRMOF, and IRMOF-0 are synthesized from acetylene dicarboxylic acid which possess the same cubic topology as MOF-5. This synthesis route ensures that the thermal sensitivity of the linkers are accommodated [65]. Other synthesis methods to produce and enhance the performance of MOFs are presented in Fig. 1.

Enhanced synthetic methods of metal-organic frameworks for different application [66]

Recent advances in MOFs synthesis are aimed on the development of new strategies for surface modification to enhance the performance of MOFs-based materials. The addition of more functional groups is usually based on the intended application. The new and improved properties make the materials highly attractive for more applications [67]. For example, MOFs are extensively used in gas adsorption [68], and separation [69], and recently developed for photocatalysis [70], and drug carrier [71]. However, water instability is one of the drawbacks that prevents MOFs from being utilised to their fullest potential.

Recent advances in the development and the plausible applications of MOFs-based long afterglow materials is briefly presented in Fig. 2. Additionally, some of the challenges in the development and applications and future perspective of MOFs-based long afterglow have been outlined in the literature [23, 72]. Specifically, the common synthesis routes for MOFs that could be applied solely in water treatment is the major target of this study.

Figure 2b presents unique MOFs which are regarded as long afterglow MOFs. It is a hybrid material made of inorganic and organic components that have a high interior surface area, movable structures and distinctive optical properties. The behaviour of MOFs with lengthy afterglow has garnered increased attention lately. The literature provides a detailed summary of the potential mechanism of long afterglow materials as well as the most current developments in the synthesis and use of MOFs-based long afterglow materials. While there are a few obstacles and a limited time frame for the creation and use of successful MOFs-based extended afterglow materials, they can be avoided with more study. In addition, long afterglow can be utilized in different applications like every other types of MOFs.

Over the last twenty years, MOFs-based materials have found extensive use in a variety of fields, such as food packaging, gas separation and storage, supercapacitor sensing, catalysis, biomedical and water purification. It is said that the efficiency and environmental friendliness of the product has increased with the incorporation of MOF-based products [73]. For instance, food packaging based on MOFs prevents adverse effects on human health while preserving product safety throughout the processing to an appropriate consumption level (Fig. 2a).

Due to their high surface area and porous structure, MOFs in food packaging materials offer a means of ensuring product safety because they are a class of functional materials with distinct chemical and physical properties that greatly promise food safety. With the goal of introducing cutting-edge solutions into the food supply chain, the integration of MOFs into packaging materials in many forms guided the advancement in the field of food packaging to assure product safety. Some of the issues with conventional food packaging are antimicrobial qualities, active molecule removal, and dishonestly labeled food products; therefore, the development of novel materials like MOFs may offer a solution. Base on its excellent biocompatibility and host-indifferent behavior, MOFs are becoming a crucial component of food packaging [74].

3 Common Synthesis Routes and Application of MOFs in Water Treatment

The intend mode of MOFs application in any water treatment technique governs the synthesis route to be adopted in order to achieve the desired goal. For example, MOFs used as a media in photocatalysis or adsorption can only be developed in powder or pellet form with a nano surface to allow total penetration of wastewater, and all the necessary functional groups will be embedded during synthesis. This section critically reviewed the different water treatment methods with their different MOFs synthesis routes. The application of MOFs-based adsorbents is still largely based on batch experiments phase. However, with continuous progress in the field, MOFs are considered to be promising adsorbents for water treatment in the removal of various pollutants including dyes, emerging contaminants available in trace quantities, and heavy metals. This is because of the flexible functional groups, large specific surface area, adjustable pore sizes and diverse structural characteristics. Additionally, due to the functional properties of organic linkers, MOFs are highly selective in the adsorption of organic molecules. Their stability, adsorption selectivity, adsorption capacity and regeneration of spent adsorbent is also attractive and of high interest [76, 77]. The mechanism in which pollutants interact with MOFs includes hydrophobic interactions, Lewis acid-base interactions, ion exchange, hydrogen bonding, physical adsorption, electrostatic interactions, surface complexation and π − π stacking interactions [77]. It is possible to have more than one adsorption mechanism in which the pollutants interact with MOFs-based adsorbents. The mechanism in which the pollutants are removed is depended on the type of pollutants either anionic or cationic, the surface charge and the properties of the MOFs-based adsorbents.

3.1 Synthesis Methods of MOFs-Based Adsorbents in Water Treatment

Metal-organic frameworks-based adsorbents could either be in form of powder or pellet with nano surfaces and their unique properties are selective in the removal of targeted pollutants in the presence of competitive ions or even other pollutants, although with other pollutants the adsorption capacity could be hindered [77]. The commonly used synthesis approach in MOFs-based water treatment products is hydrothermal, solvothermal, microwave, diffusion, sono-chemical, and electrochemical synthesis techniques. The simple and progressive introduction of different species into solvent-liquid diffusion interaction is the typical diffusion method. As a result, there are two layers with different densities: the precipitant solvent layer and the solvent layer that covers the product [78]. Crystal growth occurs at the interface following the precipitant solvent’s slow diffusion into the distinct layer. The microwave synthesis route can be used to create metal nanosized crystals by increasing the temperature of the solution which comprises small metal and oxide particles.

To manufacture MOFs on an industrial scale level, electrochemical techniques are usually adopted due to some associated benefits such as avoiding anions such as nitrates from metal salts, slight temperatures of reaction and extremely quick synthesis, as compared to other synthesis routes [79]. Chemical reactions and a number of physical phenomena that could be produced by mechanical force are both involved in the mechanochemical technique. In mechanochemical synthesis, a chemical transformation occurs before certain mechanical breaks of intramolecular connections.

The sonochemistry method involves applying high-energy ultrasound to a reaction mixture to initiate chemical reactions. One simple synthesis method for creating MOFs is the hydrothermal approach [80]. In this procedure, reactions between the metal salts, ligand, and organic solvent take place in a glass container at a specific pressure and temperature. The metal ions and organic ligands can complete the self-assembly process, thereby obtaining the required MOFs. Overall, the choice of synthesis method depends on the kind of intended application of MOFs-based materials, and most of the routes are cost-effective, efficient and environmentally friendly.

3.1.1 Adsorptive Performance of MOFs in Heavy Metals Removal from Water

The rapid development and advancement of manufacturing industries increases the pollution of surface water by inappropriate discharge of effluent-laden toxic metals into the environment. The presence of higher concentration or even trace quantities of these heavy metals have detrimental effects on aquatic life, humans and the environment due to the potential toxicity and continuous accumulation [81]. Table 2 gives a summary of the various MOFs-based materials that are used for the removal of heavy metals from water. Based on the flexible structure of these metals, MOFs are capable in removing them from water efficiently as an alternative for conventional adsorbents. Additionally, MOFs are capable of overcoming the presence of coexisting ions [17, 77].

Chen et al. [82] reported on the modification of UiO-66, Zr-based MOF, by formic acid and aminobenzene compounds for the removal of toxic hexavalent chromium (Cr6+) from water. Although pristine UiO-66 is easy to prepare and very stable, its application is limited by its low adsorption capacity. After the modification, a novel MOF referred as Form-UiO-66-NH2 with increased specific surface area, crystal size and pore size and enhanced adsorption capacity was formed. The authors reported that the adsorption capacity of Cr6+ was found to be 338.98 mg/g and it was stated to be higher when compared to the unmodified UiO-66. The enhanced adsorption capacity of Cr6+ by the modified Form-UiO-66-NH2 was attributed to the high specific surface area and surface charge. Additionally, Form-UiO-66-NH2 showed selective adsorption to Cr6+ in a mixture of wastewater with typical non-metallic water quality standards and other toxic heavy metal ions. Nie et al. [83] conducted a study on the preparation of a multifunctional adsorbent for the removal of several metal ions from water by incorporating ethylenediaminetetraacetic acid (EDTA) into pristine UIO-67 to form UIO-67-EDTA. The new adsorbent was employed in the removal of fifteen (15) different heavy metal ions which included hard acids, dissolved minerals, borderline acids and soft acids through batch studies and packed column. The results indicated that at a low pH of 4, above 98% removal efficiency was observed within 10 min, with the highest static adsorption capacity of some of the metal ions given as 416.67 mg/g, 256.41 mg/g and 312.15 mg/g for Cr3+, Hg2+ and Pb2+, respectively. Moreover, the adsorbent showed excellent stability and reusability where the removal efficiency of the metal ions was above 93% even after five repeated cycles. A study by Abdel-Magied et al. [84] synthesized magnetic composites of Fe3O4@UiO-66–NH2 and Fe3O4@ZIF-8 for the specific removal of toxic heavy metal ions such as Pb(II) and Cd(II) from aqueous solutions. The authors noted that the adsorption efficiency of the nanocomposites was largely influenced by the pH of the solution. The maximum adsorption capacity for the nanocomposites was found at pH 6 where with Fe3O4@UiO-66–NH2 was 714.3 mg/g for Cd (II) and 833.3 mg/g for Pb(II) and with Fe3O4@ZIF-8 it was 370 mg/g for Cd(II) and 666.7 mg/g for Pb(II). Moreover, both nanocomposites showed great reusability after four repeated cycles and also maintaining their efficiencies. Another study by Wang et al. [85] developed a new adsorbent of AMO-MOF by using 5-formyl-2-hydroxybenzoic acid and diaminomaleic acid by reacting them with Zirconium tetrachloride (ZrCl4) to produce MOFs and finally hydrolyzing in hydroxylamine solution (NH2OH⋅H2O) to get the new adsorbent, for the adsorption of Pb2+ ions from water through batch experiments. The authors reported that under optimal conditions the adsorption capacity reached 472.73 mg/g and the presence of coexisting ions did not have an effect on the adsorption of Pb2+ ions. Electrostatic attraction and chelation were the dominant adsorption mechanism during the process. Moreover, AMO-MOF demonstrated excellent selectivity to Pb2+ ions. After at least five consecutive cycles, the adsorbent still exhibited great removal efficiency of over 82.41%. A similar study in the removal of Pb2+ ions was done by Lee and Choi [86] where they prepared a copper-based MOFs (Cu-BTCMOF) using a one-step solvothermal synthesis technique for the adsorption of Pb2+ ions from aqueous solutions. The adsorption capacity was evaluated at different temperatures of 10, 25 and 40 °C and were found to be 890.94, 896.04, and 958.37 mg/g, respectively. Ion exchange was found to be the predominant mechanism of adsorption. Sun et al. [87] investigated the synthesis of metal-organic framework/polymer composite (Fe-BTC/PDA) from Fe-BTC and dopamine which spontaneously converts to polydopamine (PDA) inside the exposed metal sites of Fe3+ ions, used for Pb2+ ions removal from aqueous solution. The authors noted that the incorporated PDA within the surfaces of MOFs has added advantages of increased porosity which results in the composite adsorbing more pollutants by removing more than 99.8% (e.g., Hg2+ and Pb2+). Interestingly, it was observed that other metal ions like Na+ did not cause any interference in the adsorption of Pb2+ even when their concentration was higher than that of Pb2+. Moreover, with high concentrations of typical organic interferents such as humic acid, the composite demonstrated resistant to fouling and showed high reusability after several cycles. A study on the removal of the highly poisonous arsenite (As(III)) from water was conducted by Hou et al. [87], where they used sulfite (S(IV)) and cobalt-based MOFs ZIF-67 to treat water. It was observed that As(III) removal from the multi-component water was enhanced, which was due to the S(IV) activation on the surfaces of ZIF-67 through various reactions such as intramolecular electron transfer and surface complexation, that not only produces SO4- radicals for immediate oxidation of As(III) to As(V), but also for the oxidized As(V) it provides additional active sites for immobilization. Moreover, the combined processes reduced the As(III) concentration to acceptable limits. Cui et al. [88] used a two-step method to modify a zirconium-based MOFs (UiO-66) with two functional groups of -COOH and -NH2 to form UIO-66-NH2(-COOH) and then incorporated them onto fiberglass membranes to finally produce fiberglass@UIO-66-NH2(COOH), (F-MOFs-M), for the multifunctional treatment of anionic and cationic heavy metal ions. From the targeted metal ions, they found that the adsorption capacity of AsO43−, CrO42−, Ni2+, Pb2+ and SbO3– was 55, 189, 16, 133 and 342 mg/g, respectively. The authors also noted the stability of F-MOFs-M where in a continuous experiment ran effectively for seven days and was reused repeatedly with no substantial loss in the removal efficiency even after five consecutive cycles and with easy regeneration. Haso et al. [89] used the hydrothermal synthesis method to prepare copper diphenylamine metal-organic framework (Cu-DPA MOF) for adsorption removal of heavy metal ions including lead (Pb), cadmium (Cd) and chromium (Cr). The effectiveness of the process was evaluated at various optimized adsorption parameters, where the results indicated optimum removal efficiency of 97.6% for Cd, 99.5% for Cr and 99.5% for Pb. The authors noted that the high specific surface area and the porous characteristics of the composites contributed to the high removal efficiency. Abdelmoaty et al. [90] also modified UiO-66 with melamine to produce MUiO-66 using the hydrothermal method to improve the adsorption capacity of MOFs. Lead (Pb2+) and cadmium (Cd2+) ions were used to determine the adsorption efficiency of the as-prepared adsorbent. From the structural characterization, the increased active sites and high specific surface area which ranged from 1080 m2/g to 1160 m2/g were well noted. The maximum adsorption capacity for Pb2+ ions was 177.5 mg/g and for Cd2+ was 146 mg/g. The adsorbent also showed efficient reusability with three consecutive cycles. The adsorption efficiency in the treatment of heavy metal using different MOFs has been established, however, their performance in the removal of dyes from water cannot be overlooked.

3.1.2 Adsorptive Performance of MOFs in Dye Removal from Water

Dyes are used in various industries such as textiles, food, cosmetics, plastics, paper, leather, and rubbers. However, the discharge of dye effluents into water sources could be harmful to human health, animals and aquatic life. Dyes have the capacity to obstruct sunlight and deplete the dissolved oxygen in the water surfaces, affecting the growth and development of aquatic life and threatening the environment. In general, dyes are either anionic or cationic in nature. The toxicity of dye effluents is typically caused by its carcinogenic, teratogenic and mutagenic characteristics and its high colour intensity [17, 91, 92]. Thus, appropriate disposal and removal of dyes from water is crucial. Dye removal from water using MOFs is highly promising and is extensively being explored. Moreover, MOFs are either negatively charged which are attracted to cationic dyes or positively charged which are attracted to anionic dyes. Although the interaction mechanism between dyes and MOFs is depended on various factors, the electrostatic interaction is a driving force and most common mechanism [93]. Table 3 gives a summary of the various MOFs-based materials that are used for the removal of dyes from water.

Yang et al. [94] reported on the removal of Congo red, methylene blue and methyl orange from aqueous solutions using cerium oxide-doped zirconium MOFs (Ce(III)-doped UiO-67) synthesized using the solvothermal synthesis method. The obtained results indicated that the adsorption capacity for methylene blue using Ce(III)-doped UiO-67 was 398.9 mg/g which was higher than that of pristine UiO-67 by more than 85%. The results were explained by the adsorption isotherms and zeta potential analyses. Thus, it was observed that electrostatic attraction took place between Ce(III)-doped UiO-67 and methylene blue, whereas electrostatic repulsion took place between pristine UiO-67 and methylene blue. Moreover, Ce(III) doping was observed to have facilitated the π–π interactions between the adsorbent and the adsorbate. In contrast, Ce(III)-doped UiO-67 showed low adsorption capacities for methyl orange and Congo red when compared to pristine UiO-67 due to the reduced adsorption sites and the electrostatic repulsion that occurred between the adsorbent and the two anionic dyes. These results revealed that the combination of adsorption sites, electrostatic interactions and π–π interactions hindered the adsorption capacity of anionic dyes while it promoted the adsorption capacity of cationic dye. Another study by Eltaweil et al. [95] prepared iron-benzene dicarboxylate based metal organic framework (MIL-101(Fe)) by the solvothermal synthesis method for methylene blue removal from aqueous solutions. Various parameters that have an influence on dye removal were evaluated and optimized and the optimum adsorption capacity was found to be 58.82 mg/g at pH 9 and 35 °C when using 10 mg MIL-101(Fe). The authors further mentioned that MIL-101(Fe) demonstrated improved adsorption capacity for cationic methylene blue dye when compared with anionic methyl orange dye. The thermodynamic studies indicated that the adsorption of methylene blue by MIL-101(Fe) was observed to be endothermic and spontaneous. Moreover, the MIL-101(Fe) adsorbent demonstrated high reusability in methylene blue removal with an efficiency of above 70% after ten successive cycles. Alzahrani et al. [96] reported on a hybrid composite that was prepared by embedding magnetic iron nanoparticles within a porous and amino-functionalized La-MOF (MOF/NH2) to form MOF/NH2/Fe3O4 composite that is highly effective and reusable for the removal of anionic methyl orange. The magnetic composite was observed to be highly effective in the removal of methyl orange which gave an adsorption capacity of 618 mg/g, which the authors pointed out that it was improved compared to other reported commercial adsorbents. The improved adsorption capacity was attributed to the synergetic effect of the magnetic nanoparticles, the available active sites and large specific area of the adsorbent. Additionally, the composite exhibited selective adsorption of methyl orange from a dye mixture which was attributed to the electrostatic attraction. The composite of MOF/NH2/Fe3O4 was also found to be highly reusable which maintained over 90% efficiency in the removal of dye after six consecutive cycles. Another study by Zhao et al. [97] prepared a magnetic MOFs composite (Fe3O4/Cu3(BTC)2) by incorporating Fe3O4 and Cu3(BTC)2 (where BTC stands for benzene-1,3,5-tricarboxylate) by a novel technique in the removal of methylene blue from synthetic water. The magnetic composites were reported to have great magnetic response of 14.89 emu/g and a specific surface area of 79.52 m2/g. The adsorption capacity reached 84 mg/g with methylene concentration of 30 mg/L, whereas the adsorption capacity reached 245 mg/g with methylene blue concentration of 300 mg/L. Furthermore, the pH of the solution was observed to not have a significant influence on the adsorption process, indicating the hydrophobic interaction and/or π-π stacking interactions between methylene blue and the composite, (Fe3O4/Cu3(BTC)2). Furthermore, the composite exhibited great reusability after being used in at least five repeated cycles, suggesting its potential for dye removal from water. A study by Cai et al. [98] reported on the removal of Congo red, lead ions (Pb2+) and malachite green from water using a hollow carbonised nanocomposite of MOF/LDH nanocomposite prepared using zeolitic imidazolate framework (ZIF-67/LDH@C) as the precursor. The maximum adsorption capacity was 526.32 mg/g for Congo red, 662.25 mg/g for lead ions and 1729.83 mg/g malachite green. The thermodynamic studies showed that the adsorption process for all the evaluated pollutants onto ZIF-67/LDH@C was endothermic and spontaneous in nature. The adsorption mechanism between the nanocomposite and the pollutants was due to hydrogen bonding interaction, π-π interaction, electrostatic attraction and surface complexation. The authors further mentioned that the nanocomposite was stable and there was no interference from competing metal ions and the results were significant. Zhao et al. [16] used an ultrasonic wave-assisted ball milling technique to synthesize nickel-based metal-organic framework/graphene oxide composites (Ni-MOF/GO) for the adsorption of Congo red from aqueous solution. The Ni-MOF/GO composite reached an adsorption capacity of 2479 mg/g, which the authors stated was higher than previously reported results. It was observed that the introduction of more active sites significantly enhanced the adsorption capacity of the pollutant. The authors also commended that the ultrasound-assisted technique used for the preparation of the composites was a first to be reported from their laboratory and it was a cost effective, environmentally friendly and a fast process. Kumar and Veni [62] conducted a study on the preparation of Zirconium-2,6-naphthalenedicarboxylate MOFs (Zr-NDC MOF) by ultrasound-assisted method for cationic dye removal, crystal violet. The results revealed that with 10 mg/L concentration of the dye, more than 99.45% of the dye was removed, whereas with 100 mg/L concentration the adsorption capacity reached 454.2 mg/g. With all influencing parameters evaluated, the study concluded by stating that Zr-NDC MOF is a promising adsorbent for crystal violet removal in aqueous solutions. Li et al. [64] reported on the synthesis of Cu-based MOFs material (Cu(PABA)) by the solvothermal technique for the removal of direct red 31 (DR-31). The maximum adsorption capacity for the dye by Cu(PABA) at room temperature reached 1244.8 mg/g. The results were satisfactory in which it was concluded that Cu(PABA) which exhibited a mesoporous structure, and a specific surface area of 84 m2/g was a potential adsorbent for dye removal.

3.1.3 Adsorptive Performance of MOFs in Emerging Contaminants Removal from Water

Emerging contaminants are classified under biological compounds as synthetic and natural chemicals that are of serious concern due to their unknown or suspected adverse effect on the environment and human health [99]. Some of these pollutants include pharmaceuticals and personal care products (PPCPs), pesticides and polyaromatic hydrocarbons and endocrine-disrupting chemicals (EDCs) [100]. Due to their continuous use in everyday life, their uninterrupted discharge into the environment, although in low concentrations, they could result in long-term risk [101, 102]. The removal of emerging contaminants in water using MOFs either by catalytic degradation, adsorption and membrane procedures is an attractive and ongoing study. Table 4 gives a summary of the various MOFs-based materials that are used for the removal of emerging contaminants from water.

A study on the removal of three different antibiotics (nalidixic acid, ciprofloxacin and tetracycline) often found in water was conducted by Bhattacharyya et al. [103], where they synthesized a magnetic coral-like Co@Co3O4/C nanohybrids using the wet chemical method. The results revealed that Co@Co3O4/C nanohybrids is a potential adsorbent for nalidixic acid removal with 99.98% removal efficiency at pH 6 within 120 min, and for ciprofloxacin and tetracycline, the removal efficiency was found to be 95.69% and 66.67%, respectively. The adsorbent also showed its reusability with four consecutive adsorption-desorption cycles with no substantial alterations in the removal efficiency. Moreover, the effectiveness of the adsorption process was attributed to the π–π interactions and the electrostatic interaction between the different antibiotics and the adsorbent. A stable and porous zirconium-ellagate framework (SU-102) was synthesized and evaluated for the removal of emerging organic contaminants from wastewater treatment plant [104]. The results showed that, of the seventeen pollutants that were targeted in the water, the SU-102 showed high removal efficiency with ten pollutants. It was observed that cationic pollutants were predominantly adsorbed onto the anionic SU-102 and the selectivity and removal efficiency could be improved by adjusting the solution pH, which could benefit the adsorption-desorption cycle. Seo et al. [105] reported on the adsorption of three antibiotics (metronidazole, dimetridazole and menidazole), from the nitroimidazole antibiotics (NIABs) by modifying MIL-101(Cr) with urea and melamine. The authors reported that the modified MIL-101(Cr) was highly porous and showed high efficiency in the adsorption of the selected NIABs. For instance, it was reported that urea-MIL-101 gave high adsorption capacity with metronidazole and hydrogen bonding was the mechanism of interaction. The stability and reusability of both urea and melamine modified MIL-101(Cr) were confirmed in which the authors concluded that they were promising for the adsorption of NIABs. Wei et al. [106] prepared a bimetallic framework of Zr and Fe (Zr/Fe-MOFs/GO) composites using the solvothermal synthesis method for tetracycline hydrochloride and orange II removal. The highest removal efficiency of tetracycline hydrochloride and orange ll was found to be 96.1% and 98.8%, respectively, which was observed to decrease with more pollutant concentration. From these results, it is highly expected that (Zr/Fe-MOFs/GO) composites will be extensively used in water treatment of various pollutants. A study by Wang et al. [107] prepared a nanocomposite, ZIF-67/D201, from commercial polystyrene anion exchanger D201 and zeolitic imidazolate frameworks-67 (ZIF-67) using the alternate deposition technique for the removal of benzotriazole (BTA), an emerging organic pollutant. The results indicated that the nanocomposites were efficient in the removal of benzotriazole and the adsorbent was reusable for several cycles with a slight decrease in adsorption capacity. Also, when benzimidazole (BMA) which has a similar structure with benzotriazole coexisted, ZIF-67/D201 showed selective adsorption and preference to benzotriazole with much higher adsorption capacity. Furthermore, three mechanisms including π − π interaction, coordination and electrostatic attraction were found to be responsible for the improved adsorption, and coordination interaction was more predominant. Reduced graphene oxide and aluminum metal organic framework MIL-68(Al) were used by Wu et al. [108] to synthesize MA/RG composite using solvothermal method for p-nitrophenol removal from water. The results indicated that MA/RG-15% had enhanced adsorption capacity of 332.23 mg/g than the individual materials, which was 64% more than MIL-68(Al) and 123% higher than reduced graphene oxide. The authors pointed out that the enhanced composite porosity was responsible for the increased adsorption capacity, and the π − π interaction and hydrogen bond were predominant for the endothermic and spontaneous process. A study by Chen et al. [109] pyrolyzed Fe3+-modified MOF-5 to produce magnetic porous carbon-based adsorbent (MPCS) for the removal of 4-nitrophenol, atrazine, bisphenol A, carbamazepine and norfloxacin from aqueous solutions. A higher adsorption capacity for 4-nitrophenol was observed, whereas atrazine showed a low adsorption capacity. It was noted that the π − π electron donor-acceptor interactions were the driving force for 4-nitrophenol and norfloxacin, whereas the hydrogen bonds and hydrophobic effects played a key role in the adsorption mechanism of bisphenol A, atrazine and carbamazepine. Jia et al. [110] prepared adsorptive membranes of PES-SPES/amino-MIL-53(Al)/PTFE using polyethersulfone-sulfonated polyethersulfone (PES-SPES), polytetrafluoroethylene(PTFE) and amino-MIL-53(Al) for p-nitrophenol removal from water. The results for amino-MIL-53(Al) showed a higher adsorption capacity of 297.85 mg/g for p-nitrophenol, whereas the sandwich membranes exhibited the highest adsorption efficacy (breakthrough volume, saturation volume, dynamic adsorption capacity and static adsorption capacity). Moreover, the sandwich membranes showed remarkable reusability with four consecutive cycles. Pan et al. [111] used zinc-methylimidazolate framework-67 (ZIF-67) for phenol removal from water using a batch reactor and a fixed-bed column. The results showed that the predominant mechanism for adsorption was the electrostatic interaction between ZIF-67 and phenol. The highest adsorption capacity for batch studies was found to be 378.89 mg/g. Additionally, thermal regeneration was used on the adsorbent at 120 °C which showed minimal loss in the adsorption capacity and was reused two times. Seo et al. [112] investigated the adsorption of pharmaceuticals and personal care products (PPCPs) (ibuprofen, oxybenzone and naproxen) from water with a porous MOFs of MIL-101. The results indicated effective adsorption of naproxen with MIL-101 functionalized with –OH and –NH2 groups, although a decreased porosity was observed. And for oxybenzone and ibuprofen, functionalized MIL-101 with –OH and –(OH)2 showed excellent adsorption capacity attributed to the surface area of the adsorbent. The results also confirmed the predominance of the hydrogen bonding mechanism. Furthermore, MIL-101-OH which gave a higher adsorption capacity was observed to be highly competitive in comparison with pristine MIL-101, mesoporous materials and carbon materials. Moreover, the adsorbent was reusable in multiple cycles and ethanol was used to wash the spent adsorbent. Adsorption and photocatalysis techniques are similar, therefore, the performance of catalysts-based MOFs is briefly discussed.

3.2 Synthesis Methods of MOFs-Based Photocatalyst in Water Treatment

The major difference between adsorption and photocatalysis is the introduction of visible light into the system which then speed up the reaction to degrade the toxic pollutants into less harmful products. There are different kind of synthesis routes adopted for the development of MOFs-based photocatalyst as presented in Fig. 3. The major synthesis routes such as solvothermal assisted route, hydrothermal reaction synthesis, solution precipitation method, sonication method and microwaves methods used in the development of powder or particle form of MOFs are also utilized in the synthesis of MOFs based photocatalyst.

Although photogenerated carriers generated by MOFs migrate through their active sites under visible light, charge recombination exists in the MOFs. In some cases, constructed covalent bonds could be created between MOFs as migration channels to effectively mitigate charge recombination. Metal-organic frameworks are widely recognized as a prominent semiconductor photocatalyst and a popular option for photocatalysis. Metal-organic frameworks have the potential to enhance their photocatalytic capabilities by forming heterojunction structures with other semiconductors. Furthermore, depending on the synthesis technique, MOFs photocatalysts can also be coupled with non-core-shell and core-shell structures, which are often designated as MOF@COF and MOF/COF, respectively. The MOF-COF photocatalysts work by mechanisms that include photodegradation and photocatalytic hydrogen evolution (PHE).

The factors to consider in the design of a MOFs-based photocatalyst are stability, the tunable energy band structure, selective oxidation, and electrical conductivity [113]. Furthermore, the creation of heterojunctions between two materials has emerged as a viable strategy for improving photocatalytic activity. It can efficiently aid in the expansion of the visible zone and the separation of electron holes. There have been reports of six primary synthesis techniques to improve MOFs’ photocatalytic performance.

To boost the active centre and enhance photocatalytic activity, the first strategy involves combining metals or ligands by solvothermal synthesis, exchange facilitated by ligands, and post-synthesis modification. Ligand functionalization is the second strategy, which lowers the prohibited bandwidth. The third technique involves immobilizing metal ions or ligands, which increases light absorption while inhibiting photogenerated electron-hole complexes [114].

Schematic illustrations of synthesis strategies of MOFs-based photocatalysts [115]

The fourth method involves loading metal nanoparticles, which can also improve light absorption because MOFs are naturally porous and can hold low-Fermi-energy nanoparticles inside their pores or on their surface. The fifth method is the formation of heterogeneous structures, where more active centres are created by coupling the MOF with other semiconductor materials, allowing more efficient separation of photogenerated charges. The sixth method is the decoration of carbon materials, such as carbon quantum dots (CQDs) and graphene oxide (GO), as more typical carbon materials. However, the process variables that influenced the performance of MOFs-based photocatalysts include; solution pH, catalysts dosage, and pollutant’s initial concentration [116].

3.2.1 Application of MOFs-Based Photocatalysts in Pollutants Removal from Water

Metal-organic frameworks prepared using the procedures presented in Fig. 3 have been used efficiently in the removal of pollutants from water. For instance, a study by Wei et al. [117] prepared iron-based metal-organic frameworks (Fe-MOFs) using trimeric acid alongside microwave-assisted ball mill method. The composite was used in the degradation of methyl orange and methylene blue from aqueous solutions. In the first 120 min, their results showed that almost all methyl orange and methylene blue were removed indicating the effectiveness of the prepared Fe-MOFs. Moreover, the mechanisms that promoted the dye degradation was electrostatic attractions and π-electrons between the Fe-MOFs and the two organic dyes.

Ramezanalizadeh et al. [118] conducted a study on the synthesis of MOF-catalyst (MOF/CuWO4) using a facile synthesis route. The synthesized MOF/CuWO4 composite was characterized with commonly used analytical techniques such as x-ray diffraction (XRD), x-ray fluorescence analysis (XRF), UV–Vis diffuse reflectance spectroscopy (DRS), scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FT-IR), Brunner-Emmet-Teller (BET) model, photoluminescence (PL), and transmission electron microscopy (TEM). The photocatalytic performance of the composite was assessed in the degradation of methylene blue and 4-nitrophenol in water. The highest photocatalytic activity of the composite was exhibited with a weight ratio of (1:1), which performed much better when compared to the other composites reported in their study. The high performance achieved was attributed to the separation of electron-hole pairs, higher surface area, and prolonged of recombination of valence and conduction band observed with the use of 1:1 MOF/CuWO4.

The solvothermal assisted route is another synthesize route for MOFs-based photocatalysts. Ag-MOF (AMOF) nanosheets was synthesized and used for the degradation of various dyes including methyl orange (MO), methylene blue (MB) and crystal violet (CV). The photocatalytic performance of the AMOF nanosheets was reported to be excellent in the degradation of all investigated dyes. The percentage degradation was observed to be 74.5% for MO, 85.5% for CV and 90.7% for MB after irradiation of 120 min. The effect of photogenerated holes (h+) and superoxide radicals (O2−) on the removal of dye pollutants was also evaluated by the use of radical scavenger trapping method. Furthermore, the reusability of the photocatalyst was confirmed by stability studies which showed up to five consecutive cycles [119, 120]. A summary of the MOFs-based photocatalyst performance in water treatment is presented in Table 5.

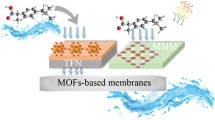

3.3 Synthesis Methods of MOFs-Based Membrane in Water Treatment

Membrane technology uses selectivity and permeability of the membrane pores by allowing liquids, inorganic ions, small molecules etc., to pass through while retaining large particles and molecules. However, the use of membrane technology is affected by permeability, selectivity and fouling. The vast majority of membranes are made of an ultrathin and selective polymeric layer, that has been highly crosslinked during the interfacial polymerization process. And due to the extent of crosslinking, the water permeability of these membranes is relatively low [88, 127]. Hence, the combination of other materials with the polymeric materials for preparing membranes to effectively enhance the properties of membranes and increase performance is imperative. For instance, MOFs have good prospect as fillers due to their chemical properties, porous and adjustable structure and can effectively enhance the performance of membranes in their different classification as microfiltration (MF), reverse osmosis (RO), ultrafiltration (UF) and nanofiltration (NF) [128]. Metal-organic frameworks are promising in that they provide additional channels for water permeation, ensure excellent performance for long treatments by improving fouling and hydrophilic properties of the membranes, hence, resulting in increased water flux. Several preparation techniques for MOFs-based membranes are available which include electrodeposition, solvothermal, blending, grafting, in situ growth, interfacial polymerization, and phase inversion [129,130,131]. Moreover, membrane-based water treatment is suitable for operation of both batch and continuous treatment of various pollutants.

The framework flexibility, defect and grain orientation of pure MOFs membranes, MOFs filler aggregation, plasticization and aging of the polymer matrix, and interfacial compatibility of mixed matrix membranes (MMMs) are the parameters influencing the separation performance of both pure MOFs membranes and MMMs. In the meanwhile, it is usual practice to use MOFs-based membranes for gas separation, such as CO2, H2, and olefin/alkane separation. Furthermore, it is crucial to use MOFs-based membranes for liquid phase separation applications such chiral resolution, organic solvent separation, and water purification [132].

Engineering of MOFs-based membrane for waste water treatment: Synthesis, applications and future challenges – ScienceDirect [132]

3.3.1 Application of Ultrafiltration MOFs-Based Membrane in Water Treatment

Ultrafiltration is one of the filtration methods used in water treatment because of its high separation/removal efficiency, stability and low operating pressure. Ultrafiltration is a low-pressure membrane technique that is frequently employed to remove various organic pollutants, high molecular substances and particles from water. The pore sizes of UF membranes range from 0.001 to 0.1 mm. And because of their pore sizes, UF membranes are suitable and easy to treat wastewater and recover the solutes. Conventional UF membranes use polymer materials like polysulfone (PSF), polyethersulfone (PES), and polyvinylidene fluoride (PVDF), which are prone to membrane fouling and hydrophobic in nature resulting in low water flux and antifouling performance [133,134,135,136]. Thus, membrane fouling affects the performance of the membrane by changing the selectivity of the membrane, reducing the flux, decreasing the lifespan of the membrane and escalating operational costs. However, the technique often yields poor results when removing emerging contaminants because of the reduced retention capacity of UF membranes. Hence, the increased development of UF membranes to be incorporated as hybrid membranes with materials that possess high surface area and are hydrophilic in nature to enhance water flux and decrease membrane fouling [133, 137].

Al-Shaeli et al. [136] used PES and sulfonated polyethersulfone (SPES) and mixed with two different MOFs of UiO-66 and UiO-66-NH2 to produce PES and SPES membranes, and investigated the stability, water permeability and fouling resistance of the membranes. The addition of MOFs nanoparticles into PES membranes were observed to improve the membrane performance which could be due to the porous nature of their structure, stability and the hydrophilic properties. In particular, the -NH2 functional group in the UiO-66-NH2 readily reacts with the oxygen functional groups of SPES, therefore preventing the non-selective voids between PES matrix and UiO-66-NH2. Both MOFs, UiO-66 and UiO-66-NH2 significantly increased the flux recovery ratio of the PES membrane by more than 99%. Moreover, the MOFs maintained their stability and were structurally intact even after submerging the membranes in water for 3, 6 and 12 months, which indicated that UiO-66 and UiO-66-NH2 were great fillers to incorporate membrane matrix for lasting stability and enhanced antifouling performance.

To enhance the performance of ultrafiltration in cellulose acetate (CA) membranes, Yang et al. [133] synthesized a CA ultrafiltration membrane with enhanced properties by mixing CA with MOFs (HKUST-1) and graphene oxide (GO) by using phase inversion method. The authors noted that the new membranes of CA/MOF@GO exhibited improved hydrophilicity and pure water flux as compared to CA/GO membranes, which was attributed to HKUST-1 materials interacting homogeneously with GO and preventing agglomeration of GO layers by providing better characteristics to the HKUST-1@GO composite. For CA/MOF@GO membranes, an increased water flux permeability was observed and the antifouling results were better than those of CA membranes, which had 40.32% for total fouling ratio and 88.13% for flux recovery ratio. The results demonstrated the attractiveness of HKUST-1@GO as a filler for enhanced performance of ultrafiltration membranes. Wang et al. [138] used the thermally induced phase separation-hot pressing (TIPS-HoP) approach to prepare flexible membranes with high MOF loading using the high molecular weight polyethylene incorporating MOFs particles of UiO-66- NH2- PE MMM, MIL-100(Cr) PE MMM, Zn-BLD PE MMM, and NH2-UiO-66-MIL-100(Cr) PE MMM for protein, dye and racemate separation. The diverse TIPS-HoP makes it possible to incorporate different fillers with different properties and loadings within the polymer matrix. It was observed that MOFs uses its porous structure to reject solutes through the adsorption process and the micron size channels between its surfaces that contributes to high water permeability. The results demonstrated the ability of the membranes in rejecting more than 99% of the organic dyes with a high flux. The electrostatic attraction was found to be responsible for dye selectivity where the porous structure of MOFs contributed to both dye removal and high-water flux. Fan et al. [139] synthesized ultrathin membranes of UiO-66 polycrystalline with a size range of 210 nm within an hour by ultrasonic-assisted nucleation and microwave-assisted membrane growth. The as-prepared UiO-66 membranes demonstrated exceptional metal ions removal with over 99.6% Na+ rejection with a continuous and long experiment of at least 700 h. Samari et al. [140] investigated on the preparation of UF membrane using PES and modified melamine zirconium-based MOFs (UiO-66-NH2) using the phase inversion method for treatment of oily water in different conditions. The addition of modified MOFs to the PES matrix was observed to enhance the performance of the membrane. Moreover, modified membranes were observed to have a significant increase in porosity when compared to undoped membranes.

The optimal loading percentage for MOFs into the polymer matrix was found to be 0.1 wt% which gave an increased flux recovery ratio from 59.2 to 95.22% and also the antifouling performance were found to have increased for longer separations. The oil removal studies indicated a sharp decline in the performance of undoped PES membrane after 500 min, indicating a blockage in the pores of the membrane and even at 5 bar there was no flux. For the membrane with modified MOFs, a significant increase in the membrane permeation was observed. With a low oily water concentration of 300 ppm, the permeation increased in comparison with a higher concentration of 500 ppm, which was attributed to less foulants to clog the membrane pores.

Kim et al. [137] investigated the removal of pharmaceutical active compounds which included 17 α-ethinyl estradiol, ibuprofen and other natural organic matter (NOM) such as tannic acid and humic acid from aqueous solutions using a combination of MOFs such as MIL-100(Fe) and MIL-101(Cr) with a UF membrane to form a hybrid MOFs-UF system. The MOFs were found to be attractive fillers in the MOFs-UF membrane to remove the selected pollutants due to their adjustable porosity and also decreasing fouling in the MOFs-UF membrane. For instance, with an UF membrane alone, the retention rate was 36.7% for pharmaceutical pollutants but the retention rate was enhanced with MOFs-UF membrane to 53.2%; and for NOM the retention rate was 75.7% and 86.1% for UF membrane and MOFs-UF membrane, respectively. Moreover, the average normalized flux for UF membrane was 0.74 which increased to 0.79 for MOFs-UF membrane. This was attributed to the robust porous structure of MOFs which made it easy for the pollutants to effectively adsorb on. Additionally, unlike the pharmaceutical pollutants, fouling in NOM solutions was found to be greatly influenced by the solute sizes in the solution. Cheng et al. [140] used MIL-53(Al) and combined it with PVDF to enhance its separation properties using casting solution to form MIL-53(Al)/ LiCl@PVDF UF membranes using the phase separation method. The surface characterization results revealed that MIL-53(Al) incorporation into PVDF increased the pore sizes of the membrane and enhanced the hydrophilicity of the membrane. With 5 wt% of MIL-53(Al) added to the membrane matrix, the pure water flux permeability increased which maintained 82.09% rejection for Bovine Serum Albumin (BSA). In addition, the MIL-53(Al)/LiCl@PVDF membranes demonstrated remarkable antifouling performance. Gholami et al. [128] blended PES and TMU-5 MOF to produce a PES UF membrane and investigated the fouling properties and pure water flux. The results showed that at a low concentration of 0.1 wt%, the addition of MOFs enhanced the rejection rate, increased the pure water flux and gave good fouling performance in comparison to undoped PES membrane. For instance, the antifouling properties showed that with a concentration of 40 000 ppm of an oil-water mixture, the as-prepared membranes gave a good performance which was advantageous for oil and water separations. Jian et al. [141] used two dimensional aluminum tetra-(4-carboxyphenyl) porphyrin framework (denoted as Al-MOF) nanosheets and assembled to produce 2D-Al-MOF laminar membranes which demonstrated almost 100% rejection rate of the inorganic ions that were targeted. The permeation results of the investigated ions were very low which were attributed to the obstruction of Al-MOF pores. This is because the inherent pores of Al-MOF nanosheets provide vertically oriented aperture channels, which is mainly where the majority of water movement takes place. Ma et al. [134] deposited UiO-66 on graphene nanosheets to take advantage of its porous structure, to effectively prevent graphene oxide sheets from aggregating, to introduce and enhance the properties of the produced composite, UiO-66@66GO. A UF membrane was prepared from UiO-66@66GO composite and PES, UiO-66@GO/PES which demonstrated enhanced performance of water treatment and high hydrophilicity. Composite membranes incorporated with 3 wt% of UiO-66@GO indicated a significant increase of the water flux which reached 351% in comparison with PES membranes. The membrane composites UiO-66@GO/PES, also showed great antifouling performance and high solute rejection. For PES membrane, the rejection performance of methyl orange was found to be 84.9% and for direct red 80 to be 92.9%. However, the rejection performance for UiO-66@GO/PES membrane was 89.0% for methyl orange and 98.3% for direct red 80, which showed a slight increase from PES membrane. The composite membranes also showed stability which is advantageous for industrial water treatment.

3.3.2 Application of Reverse Osmosis MOFs-based Membrane in Water Treatment

Reverse osmosis is another conventional water treatment method. The process occurs by applying pressure on a solution against a semi-permeable membrane where water is separated from other pollutants. The most preferred use of RO is water desalination and sometimes used to remove organic pollutants. Reverse osmosis is more energy efficient when compared to other thermal-based methods for water desalination and can produce cost effective potable water. Various RO membranes have been developed and optimized, largely through the incorporation of nanostructured fillers for effective removal of solutes, high water flux and selectivity [127, 130, 133]. A study by Park et al. [142] indicated that thin film nanocomposites membranes incorporated with UiO-66- and MIL-125 showed enhanced water flux and salt rejection, although the effectiveness still depended on the nanoparticle loading. A similar study by Duan et al. [143] showed that the salt rejection and RO water flux depended on the loading ratios of ZIF-8 in the polyamide membrane where the salt rejection would increase with more loading ratios.

Duan and his co-workers [143] took the advantage of the high compatibility of zeolitic imidazolate framework-8 (ZIF-8) with polyamide (PA) matrix and used the hydrothermal method to incorporate ZIF-8 into thin film nanocomposite membranes of polyamide for desalination purposes. With 0.4% of the ZIF-8 nanoparticles with sizes of approximately 200 nm loaded within the membranes, the nanoparticles were found to increase the water permeance by more than 162% as compared to pristine PA membranes, while maintaining 98% NaCl rejection with brackish water in RO conditions. This was due to the high hydrophilic nature and less crosslinking of thin film nanocomposite membranes in comparison to pristine PA.

Wen et al. [144] produced an ultra-selective membrane of PA and amphiphilic CuBDC (copper-1,4-benzene dicarboxylate) MOFs nanoflakes, denoted as MARIP membranes for boron and N-nitrosodimethylamine (NDMA) removal from aqueous solutions. The regulation of trans-interface heat exchange and the in situ generated gas nanobubbles and the improved trans-interface movement of diamine monomers are among the mechanisms responsible for producing highly effective membranes with MOFs nanoflakes present. Thus, the produced RO membranes exhibited remarkable desalination results with high permeability, selectivity and high rejection capacity of above 90% of the small molecules of boron and NDMA which are often found challenging to remove with the existing RO membranes. Moreover, the PA membranes from MARIP produced water that adheres to the stringent requirements for potable water quality, making them highly attractive and efficient for water desalination and reuse. Xu et al. [127] incorporated the porous and hydrophilic MIL-101 (Cr) into PA) on polysulfone (PS) UF support to produce a new thin film nanocomposite (TFN) membrane of TFN-MIL-101 (Cr) RO membranes for water desalination. It was noted that MIL-101-(Cr) formed of water channels in the PA matrix for water molecules to pass through instantly due to its porous nature, resulted in increased membrane water permeability. Furthermore, MIL-101-(Cr) nanoparticles were reported to have increased the water permeability by 44% more than pristine PA membranes while keeping the rejection of NaCl at above 99%. Aljundi [145] conducted a study on the addition of ZIF-8 nanoparticles into PA membranes to produce thin film nanocomposite RO membranes with enhanced fouling in water desalination. The ZIF-8 nanoparticles were loaded into the membranes in different ratios where it was observed that with 0.4 wt% (PZ4), the permeate flux increased more than 53% in comparison to pristine PA membranes with brackish water while keeping the rejection of the salt above 99.4%. Fouling studies were conducted with BSA as a model foulant, where it was observed that more than 50% of pristine PA membrane initial flux was lost, whereas for PZ4, only 13% was lost after 4 h of continuous running. Some of the influencing factors for PA membranes to have higher fouling tendency than the nanocomposites are the physicochemical properties of the membrane which includes hydrophilicity, roughness and surface charge. These results demonstrated the potential of ZIF-8 nanoparticles to greatly improve the fouling resistance of polyamide, where with PZ4 membrane, fouling significantly decreased with over 75%. Guo et al. [146] prepared MIL-101(Fe) for the adsorption of silicic acid to remove the silica scaling using RO membranes. The study was prompted by the damage caused by silica scaling on RO membranes which resulted in the deterioration of the membrane performance. The results revealed that MIL-101(Fe) possesses exceptional properties for silicic acid which gave an adsorption capacity of 220 mg/g. Furthermore, the anti-scaling studies showed that the membrane flux dropped by 13% after 24 h of continuous RO filtration, after MIL-101(Fe) was used to pretreat the feed solution to the RO systems by adsorption, demonstrating that MIL-101(Fe) adsorption treatment could be an effective approach to use in RO systems to reduce silica scaling.

3.3.3 Application of Nanofiltration MOFs-Based Membrane in Water Treatment

Nanofiltration is a low pressure driven membrane technique that falls between RO and UF in terms of its ability to reject ionic or molecular substances. This technique attains separation by allowing inorganic solvent and salts to pass through the membrane. Nanofiltration is employed in water treatment because of its great characteristics such as high efficiency and low operating costs [147, 148]. Nanofiltration membranes are often neutral and possess a negative surface charge in the solution during desalination process or other similar processes. A negative surface charge has reportedly been found to be unsuitable for some applications including the recovery of heavy metals ions from industrial effluents, where significant multi-cationic selectivity is needed and the recovery of salt from textile wastewater. The recovery of precious minerals from brines and seawater follows the same pattern. However, the membranes exhibit a positive charge when used in extremely acidic conditions. And research is underway to produce positively charged NF membranes that will produce high purity products and also be cost effective in the development and operation process [149].

Fang et al. [150] prepared MOFs-based membranes by the simple direct seeding method to produce UiO-PMAA‐b‐PMMA and UiO‐NH2‐PMAA‐b‐PMMA and then depositing on α‐alumina tubular membrane support from UiO‐66 and UiO-66-NH2 by adding hybrid nanoparticles of poly (methacrylic acid)‐b‐poly (methyl methacrylate) (PMAA‐b‐ PMMA) NPs, for gas permeation and dye separation, rhodamine B. Firstly, the membranes showed great permeability towards gasses such as N2, CO2, He and SF6 without macro defects, but the selectivity was very low. For rhodamine B separation, the authors noted a great stability of UiO‐66 and UiO-66-NH2 in water, which is an important property for practical use in water treatment. The results showed significantly high permeability with excellent dye selectivity, which was stated that the membranes are promising for liquid separation. The average rhodamine rejection was noted as 82% and the dominant mechanism of rejection was acid-base interaction which was attributed to the adsorption of rhodamine into the pores UiO-66-NH2. A study by Xiao et al. [151] hydrophobically modified an aluminum-based MOF (CAU-1) with dodecyl aldehyde which prevented aggregation and enhanced its dispersion in trimesoyl chloride (TMC)/n-hexane solution which were used to synthesize a TFN membrane by incorporating into PA. The authors stated that the prepared NF membrane was of high-performance membrane which showed an increased pure water flux, stability and high rejection. Xie et al. [152] used vacuum filtration technique to prepare graphene oxide/MIL-88 A(Fe) (GO/M88A) membrane for enhanced water treatment of dyes and bisphenol A. According to the synergistic separation/photo-Fenton processes, the GO/M88A membrane demonstrated an improved effectiveness in flux and separation which was six times higher than that of GO membrane. Moreover, the GO/M88A membrane kept its excellent separation efficiency of 97.87% and a near constant flux even after twelve repeated cycles of methylene blue separation. The membrane was also used for photo Fenton degradation of methylene blue and bisphenol A, where it achieved high efficiency of 98.81% and 97.27% in the degradation, respectively. Another study by Zhang et al. [153] synthesized novel UiO-66-(COOH)2/prGO membranes with enhanced purification at low pressure against organic dyes of positively charged methylene blue and negatively charged Congo red and heavy metal ions of Cu2+ and Cd2+. The UiO-66-(COOH)2/prGO membranes showed high rejection of 92.55 ± 2.5% for methylene blue and 98.2 ± 1.7% for Congo red. And for the heavy metal ions, the rejection was greatly enhanced which reached up to 92.6–80.4% for Cd2+ and for Cu2+ 96.5−83.1%, which demonstrated that the electrostatic attraction has an influence on the nanochannels. The results showed that the rejection efficiency of UiO-66-(COOH)2/prGO membranes was significantly greater than that of prGO membranes with 65.4–44.5% and 57.0-33.2% for Cu2+ and Cd2+, respectively. Therefore, based on these results, it was concluded that the surface charges of the membranes had a significant influence in the removal of the heavy metal ions. Nejad et al. [154] employed the in situ decoration method to modify NF membranes of zeolitic imidazolate framework-7 (ZIF-7) on the porous surfaces of PES supports modified with co-deposited sulfobetaine methacrylate (SBMA) zwitterion (ZW) and polydopamine (PDA) for the removal of methylene blue and Congo red from water. The membranes demonstrated its efficiency at very low pressure and a significant water flux of the dye solutions with high rejection efficiency of approximately 99.9% for Congo red and methylene blue was observed. Additionally, the SBMA/PDA membrane demonstrated good antifouling behaviour with notable ability for flux recovery after simple cleaning.

Liu et al. [155] synthesized and modified zirconium-based MOFs, UiO-66-NH2 with palmitoyl chloride in order to prevent aggregation of the MOFs particles and enhance its dispersion ability in organic solutions, and then prepared into TFN NF membrane. The modified UiO-66-NH2 was noted as UiO-66-NH2-PC. The NF results indicated that TFN membranes prepared with UiO-66-NH2 and UiO-66 nanoparticles had high water permeability but poor rejection qualities than those produced with UiO-66-NH2-PC. This was attributed to the nanomaterials that were not modified and showed poor dispersion in the organic phase and agglomeration between the nanoparticles on the surfaces of the membrane.

A study by Wang et al. [156] synthesized a robust UiO-66 (ML-UiO-66) membrane for the treatment of hypersaline waters. The NF results showed that the ultrathin ML-UiO-66 membranes were stable towards chlorine, hot saline, acids and alkaline solutions and favourable salt rejection with higher water flux. Moreover, the membrane demonstrated stability to saline water with both low and high concentrations. A study by Li et al. [156] synthesized ZIF-8 membranes supported on porous PES noted as (ZIF-8/PES) using the interfacial synthesis technique and evaluated its efficiency through NF of rose bengal solution. The authors noted that all evaluated parameters (synthesis time, type of solvent and precursor concentration) greatly influenced the effectiveness of ZIF-8 membranes. A rejection of over 98% for rose bengal solution was observed with the optimized synthesized membranes. Additionally, the PES support was observed to have a significant impact on the performance of the ZIF-8 membrane, where a 2% change in the polymer concentration resulted in the permeance of more than six times.

To improve the selectivity of calcium and magnesium, Morgante et al. [149] synthesized a positively charged NF membrane of NH2-MIL-101(Al) with zinc oxide (ZnO) nanoparticles as a nanofiller to form ZnO/NH2-MIL-101(Al). Initial filtration studies indicated that solutions with single salts of CaCl2, MgCl2, Na2SO4 and NaCl revealed that the ZnO/NH2-MIL-101(Al) membrane with 45 wt% MOFs, 35 wt% ZnO nanoparticles and 20 wt% chitosan showed the highest rejection for CaCl2 with 86.49% and for MgCl2 with 90.10%. In comparison to commercial membranes such as NF90 and NF270 and other positively charged membranes, the authors noted that their prepared membranes demonstrated the highest selectivity towards CaCl2 and MgCl2. Furthermore, the prepared membranes of ZnO/NH2-MIL-101(Al) were evaluated against synthetic seawater and brine where the results still showed the competitiveness of the membranes with NF90 and NF270 with high selectivity with regard to calcium and magnesium. The authors further highlighted that the objective of using ZnO nanoparticles as a nanofiller was due to its positive charge, hydrophilic properties and the potential to enhance the selectivity of Mg2+ rejection while maintaining the permeability of the membrane. Also, ZnO nanoparticles were found to be cost effective compared to other nanofillers and they have very low levels toxicity. He et al. [148] synthesized zirconium-based MOFs, UiO-66 nanoparticles with varying diameters and incorporated them within a TFN membranes for the removal of arsenic (As) and selenium (Se) from aqueous solutions. The membranes were prepared to simultaneously remove both As and Se. Because of their hydrophilicity and small pore sizes, the prepared nanocomposite membranes exhibited higher rejection and pure water permeability for both As and Se. Moreover, of the three different diameters (30 nm, 100 and 500 nm) that were prepared, the membrane containing 30 nm UiO-66 showed the most effective performance among the other TFN membranes. The effect of particle size was evident, where the results also indicated that with a particle loading of 0.15 wt% UiO-66 within the membranes, a significant rejection of 98.6% for HAsO42−, 96.5% for SeO32− and 97.4% SeO42− were achieved. The authors also noted that they attained higher rejection when As and Se were removed simultaneously. Additionally, the as-prepared TFN membranes demonstrated robustness in its stability. A summary of the MOFs-based membrane performance in water treatment is presented in Table 6.

4 Future Prospect of Application of MOFs-Based Product in Water Treatment

Metal-organic frameworks are a new generation of attractive porous materials with exceptional structural features and properties. Owing to their distinctive properties, MOFs are a potential for a wide range of applications, more particularly water treatment. Their adjustable structural characteristics allows MOFs to be applicable for water treatment as adsorbents, photocatalysts and/or membranes. The application of MOFs in water treatment is an imperative one, hence, understanding and exploring the structural orientation of MOFs will assist in improving the stability and selectivity of MOFs for effective removal of pollutants in water. Emphasis should be on the modifying methods to be more economical and yield high purity materials. Issues such as agglomeration that could hinder the effectiveness of MOFs should be addressed and the development of MOFs with broad range of pores to accommodate different pollutants. Additionally, MOFs that could effectively remove various pollutants simultaneously from water are also desirable. The enhanced and new properties of MOFs exhibit promising applications prospects and it will be great if they are effective with less impact on the environment. The effectiveness and sustainability of MOFs in water treatment is dependent on minimal adverse effects to the environment and human health.

Moreover, the application of MOFs in water treatment is largely based on batch scale, therefore, the potential for large scale development of MOFs in water treatment is attractive, but it requires more investigation, primarily taking into account the evaluation of bulk production, operating conditions and the performance of the materials. Developing MOFs that are environmentally friend and cost effective is still a challenge, as producing MOFs is not yet cost effective and this will be a limitation for bulk production. Most methods are also using large quantities of solvents that are harmful and could be replaced with eco-friendly alternatives. Hence, more effective, rapid and green methods are imperative to bring down the production costs. The stability and regeneration of MOFs also plays a huge role in the production and operating costs for water treatment. The stability of MOFs in water is advantageous for practical applications to avoid the collapse of the material in the water that could cause potential threat to human health. For instance, the stability of membranes in water is crucial which requires the combination with MOFs to be seamless and not alter the surface characteristics of the membrane. Thus, possible toxicity and leaching of MOFs into the water should be considered to understand the potential impact and standard procedure be established and regulated.

The regeneration of MOFs after using in water treatment is another crucial factor which is desirable for economic, environmental and commercialization purposes. Cost effective and better methods are required for the regeneration of MOFs. It will also be interesting to see spent MOFs being repurposed to other applications due to their outstanding structural characteristics and reduce any waste that could be generated and secure the environmental impact. Thus, all these findings should be looked into for large scale productions and applications. Metal-organic frameworks are undoubtedly being explored as alternative materials for water treatment and with so much research ongoing, most of the challenges faced with the materials will be overcome.

5 Conclusions

According to the literature, authors deducted that MOFs-based water treatment products are highly competitive to other materials. This review highlights different synthesis routes for the development of MOFs-based materials that could be applied in different water treatment techniques which includes adsorption, photocatalysis, and membrane technology. The synthesis procedure usually depends on water matrix to be treated. The characterization techniques such as SEM, TEM, BET and XRD was reviewed to link the MOFs-based properties with the performance achieved during water treatment. Both the adsorbent properties and solution chemistry greatly influence the efficiency of any MOFs-based adsorbent. Higher rejection of toxic metals is also reported with the use of MOFs-based membrane module. However, there is a paucity of information on the industrial application of MOFs-based water treatment products, therefore more investigation is highly required to explore the possibility of upscaling the product from laboratory scale to large-scale.

Data Availability

No datasets were generated or analysed during the current study.

References

F. Kordbacheh, G. Heidari, Water pollutants and approaches for their removal. Mater. Chem. Horizons. 2, 139–153 (2023)

H. Kaur, N. Devi, S.S. Siwal, W.F. Alsanie, M.K. Thakur, V.K. Thakur, Metal–Organic Framework-based materials for Wastewater Treatment: Superior Adsorbent materials for the removal of Hazardous pollutants. ACS Omega. 8, 9004–9030 (2023)

K. Bunzel, M. Kattwinkel, M. Liess, Effects of organic pollutants from wastewater treatment plants on aquatic invertebrate communities. Water Res. 47, 597–606 (2013)

G. Sriram, A. Bendre, E. Mariappan, T. Altalhi, M. Kigga, Y.C. Ching, H.-Y. Jung, B. Bhaduri, M. Kurkuri, Recent trends in the application of metal-organic frameworks (MOFs) for the removal of toxic dyes and their removal mechanism-a review. Sustainable Mater. Technol. 31, e00378 (2022)

R.M. Rego, G. Kuriya, M.D. Kurkuri, M. Kigga, MOF based engineered materials in water remediation: recent trends. J. Hazard. Mater. 403, 123605 (2021)

V. Selvaraj, T.S. Karthika, C. Mansiya, M. Alagar, An over review on recently developed techniques, mechanisms and intermediate involved in the advanced azo dye degradation for industrial applications. J. Mol. Struct. 1224, 129195 (2021)

S. Velusamy, A. Roy, S. Sundaram, T. Kumar Mallick, A review on heavy metal ions and containing dyes removal through graphene oxide-based adsorption strategies for textile wastewater treatment. Chem. Record. 21, 1570–1610 (2021)

G. Crini, E. Lichtfouse, Advantages and disadvantages of techniques used for wastewater treatment. Environ. Chem. Lett. 17, 145–155 (2019)

A. Saravanan, P.S. Kumar, S. Jeevanantham, S. Karishma, B. Tajsabreen, P. Yaashikaa, B. Reshma, Effective water/wastewater treatment methodologies for toxic pollutants removal: processes and applications towards sustainable development. Chemosphere. 280, 130595 (2021)