Abstract

Metal-organic frameworks (MOFs) have emerged as highly promising adsorbents for removing heavy metals from wastewater due to their tunable structures, high surface areas, and exceptional adsorption capacities. This review meticulously examines and summarizes recent advancements in producing and utilizing MOF-based adsorbents for sequestering heavy metal ions from water. It begins by outlining and contrasting commonly employed methods for synthesizing MOFs, such as solvothermal, microwave, electrochemical, ultrasonic, and mechanochemical. Rather than delving into the specifics of adsorption process parameters, the focus shifts to analyzing the adsorption capabilities and underlying mechanisms against critical metal(loid) ions like chromium, arsenic, lead, cadmium, and mercury under various environmental conditions. Additionally, this article discusses strategies to optimize MOF performance, scale-up production, and address environmental implications. The comprehensive review aims to enhance the understanding of MOF-based adsorption for heavy metal remediation and stimulate further research in this critical field. In brief, this review article presents a comprehensive overview of the contemporary information on MOFs as an effective adsorbent and the challenges being faced by these adsorbents for heavy metal mitigation (including stability, cost, environmental issues, and optimization), targeting to develop a vital reference for future MOF research.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water scarcity is a serious concern as the population is continually growing and is expected to reach 9 billion by 2050 (Ghumman et al. 2022, 2021). On the other hand, water pollution is shrinking water resources. Water pollution remains a severe issue in environmental management. Heavy metal (HM) pollution is of particular concern as these pollutants are considered to be highly toxic and non-degradable. Heavy metals like chromium, arsenic, mercury, cadmium, copper, and lead are the most common pollutants, which are considered to be carcinogenic, mutagenic, and teratogenic. These HM pollutants can retain themselves in water and migrate with water flow, enrich in plants and animals, ultimately reaching humans via food. The health issues caused by a specific exposure to HM, such as liver protein enzyme alteration, damage to the nervous, respiratory, and digestive systems, and even death due to long-term exposure, cannot be ignored (Chen et al. 2023a, b).

Over time, innumerable methods have been designed and improved to remove HM ions from wastewater, such as coagulation, ion exchange, chemical precipitation, membrane separation, reverse osmosis, electrolysis, phytoremediation, reduction and oxidation, and adsorption. Despite improvements, these techniques still suffer from low selectivity, high cost, secondary pollution, and complex designs except adsorption. Adsorption offers numerous advantages, such as simplicity, high efficacy, and low-cost operation, making it the most effective HM removal technique. Numerous adsorbents, such as activated carbon, chitosan, polymers, biomass, coke, metal oxides, and zeolites, have been utilized for HM removal (Zhang and Liu 2023). Nonetheless, certain challenges like low selectivity, low adsorption capacity, low reusability, and high synthesis cost make them less effective adsorbents and limit their upscaling. Therefore, developing novel adsorbents with stupendous selectivity and uptake capacity for HM removal is a task that must be indefinitely pursued (Z. Chen et al. 2023a, b).

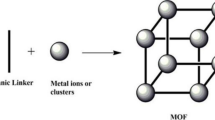

Metal-organic frameworks (MOFs) (coordination polymers) are structurally engineered hybrid materials composed of metal clusters connected with organic ligands via strong covalent bonds. Recently, these materials have attracted a lot of research attention as novel adsorbents for wastewater treatment due to their high surface area, pore volume, flexible ultrahigh porosity (up to 90% free volume), specific surface charge, tunable geometry, and adsorptive sites (El-Mehalmey et al. 2018; Forghani et al. 2020; Guo et al. 2019; Harvey 2023; Qiu et al. 2018; Yang et al. 2016). These materials have shown promising results as adsorbents for the remediation of various pollutants, including heavy metals. MOFs have been divided mainly into three groups such as MOFs, Materials of Institute Lavoisier (MIL), University of Oslo, and zeolite imidazole framework (ZIF), as shown in Fig. 1. The MOF concept was originally proposed by Robson et al. in 1989, and the first MOF was successfully synthesized by Yaghi’s team in 1995 (Manoj et al. 2022). Prior to 2009, studies on MOF’s capacity to remove heavy metals from wastewater were not often published. This changed once MOF’s water stability was improved. Ji et al. (“Design and synthesis of an exceptionally stable and highly,” 1999) produced an effective Hg(II) adsorbent by incorporating organic ligands with -SH functional groups into MOF-808. This adsorbent has outstanding selectivity, reproducibility, and a large adsorption capacity for Hg(II) (977.5 mg/g) (“Design and synthesis of an exceptionally stable and highly,” 1999). In a single pot, Wang et al. (2020) produced a novel Zr-MOF using zirconium chloride and mercaptosuccinic acid. The adsorbent can remove Hg(II) and Pb(II) from wastewater and drop their concentrations below international standards by chelation and electrostatic contact. Maximum Hg(II) and Pb(II) adsorption capabilities for Zr-MOF were 1080 mg/g and 510 mg/g, respectively, under ideal circumstances. Goyal et al. doped Fe into HKUST-1 MOF to produce a bimetallic MOF adsorbent with a maximum capture capacity of 565 mg/g for removing Pb(II). These studies demonstrate the MOFs’ potential as a heavy metal remediation adsorbent (Rathi and Kumar 2021).

Several review papers have been published on MOF recently. However, most of them focuses only on one type of MOFs like MOF composites (Xie et al. 2023) and ZIF and MIL (H. Zhang et al. 2022a, b) series. This review intends to present the review of recent advances in MOFS development for HM removal from wastewater to build a purposeful reference for developing and designing MOFs. A detailed review of synthesis, functionalization, and their utilization for HM removal was conducted.

Synthesis and modification of metal-organic frameworks

Synthesis of MOFs

Numerous methods have been utilized to synthesize pristine MOFs, including solvothermal/hydrothermal, microwave-assisted, mechanochemical, sonochemical, and electrochemical, for heavy metal removal, as shown in Fig. 2. Researchers also modified MOFs to improve the adsorption performance by introducing adsorption favorable groups like -NH2, -SH, and -OH. All these methods can produce MOFs effectively, but they have different advantages and drawbacks to offer. In the subsequent sections, we will elaborate on all methods and explain the limitations and advantages these can offer (Shah et al. 2024).

Solvothermal/hydrothermal

Solvothermal is one of the most widely used approaches to synthesize MOFs. This approach involves the dissolution of metal salts and organic ligands in a solvent, followed by a reaction in a closed vessel under autogenous pressure and a temperature of about 100–500 °C (above the solvent’s boiling point) for 12–48 h (Meek et al. 2011). This method is generally considered simple, convenient, and suitable for laboratory trials (Riou et al. 1998; Serre et al. 2002). The only difference between hydrothermal and solvothermal is that organic solvent is replaced by aqueous solution in the hydrothermal process (G. Lin et al. 2023a, b). The independent variables of this process, like temperature, organic solvent, heating method, and pressure, can greatly influence the properties of the resultant MOF. This process can yield a MOF with high crystallinity, large specific surface area, tunable morphology and topology, and uniform size, which is considered its most notable advantage. Such properties are beneficial for the adsorption of HM ions from wastewater (Pi et al. 2018; Wang et al. 2016a, b). These properties can make MOFs highly selective adsorbents for HM ions with high adsorption capacity. However, the MOFs produced using these methods have shown certain drawbacks, particularly low yield (< 50%), use of perilous solvents, and required long time and high temperature for synthesis (Liang et al. 2018a, b; Lin et al. 2023a, b; Luo et al. 2016; Zhang et al. 2022a, b). The most notable examples of MOFs produced using this method are UIO-66, MIL-125, MIL-153(Fe), etc.

Microwave assisted

Microwave-assisted heating technique for synthesizing nanomaterials has been extensively used (Bilecka and Niederberger 2010; Zhu and Chen 2014). This technique was first extended to synthesize MOFs in 2005 (Lin et al. 2023a, b). The recipe for developing MOFs is somewhat similar to the solvothermal method, except the heating source is microwaves (Lee et al. 2013). This technique promotes the nucleation and crystal growth of MOFs due to the uniform and swift heating of the liquid medium. This happens because of the molecular vibration and collision caused by electromagnetic waves and the permanent dipole moment of the molecules (Lee et al. 2013; Vakili et al. 2018; Xu et al. 2006). MIL-100(Cr) was the first MOF produced using this technique; the reaction was completed in just 4 h compared to 4 days by conventional heating methods with the same yield (Jhung et al. 2005), showing the potential of the microwave-assisted technique to reduce the reaction time. The properties of the MOF produced using this technique are similar to the one produced using solvothermal methods, except for the crystal size; as reported by Jhung et al. (2007), the crystal size of the MIL-101 was smaller and more heterogenous compared to the conventionally produced; moreover, the crystal size decreased with the crystallization time.

Compared to the solvothermal method, this technique has shown the advantages of shorter reaction time, smaller crystal size, high purity, and high energy efficacy (Klinowski et al. 2011; Ni and Masel 2006). Moreover, the phase selectivity (Laybourn et al. 2017) and facile morphology (Lee et al. 2013) are controllable. Despite the potential benefits this technique offers, it may inherit some challenges, such as low yield, high temperature, and usage of perilous solvents.

Electrochemical

The electrochemical method utilizes the principle of electrolysis to synthesize MOFs. Two different synthesis methods are utilized in this technique. The organic ligands are dissolved in an electrolyte solution, and the anode is made of the corresponding metal. The electrochemical oxidation at the anode releases metal ions to the electrolyte solution resulting in interaction with organic ligands yielding a MOF; this process is well known as anodic synthesis. In cathodic synthesis, the metal salts and organic ligands are continuously dissolved in an electrolyte solution. The electrolysis of water generates -OH, which compels the combination of metal with organic ligands through protonation to balance -OH (Li and Dincǎ, 2011).

Electrochemical technique for synthesis is not as famous as solvothermal and microwave, but it offers a wide range of advantages such as rapid kinetics, low reaction temperature required, does not generate any by-product anions, effective utilization of organic ligands, and high Faraday efficacies (Antonio et al. 2019; Campagnol et al. 2013). However, the high maintenance and operation cost, perilous solvents requirement, and other delicate equipment requirements limit this technique’s upscaling.

Mechanochemical

This technique utilizes mechanical force to break the intramolecular bonds. The metal salts and organic ligands are ground which results in a chemical reaction leading to the formation of MOFs (Khan and Shahid 2022). Typically, this method can be categorized into three categories such as without solvent or neat grinding (NG), with solvent or liquid-assisted grinding (LAG) (solvents are added in the grinding process), and ion-and-liquid-assisted grinding (ILAG) (solvent and salt are used as additive) (Chen et al. 2019). Pichon et al. (2006) produced MOF using mechanical mixing for the first time in 2006, and the product was formed in just 10 min. This process can be carried out in mild conditions and less time, but the MOFs formed are low in purity and bad crystal form. Pilloni et al. (2015) used a vibratory ball mill to synthesize MIL-100(Fe). The MOF was produced within 1 h, and 5 ml of tetramethylammonium hydroxide (TMAOH) was used. The noteworthy benefits of this process are that it does not or rarely requires solvent usage, making it eco-friendly (Chen et al. 2019), less reaction time required (10–60 min), and mild conditions (room temperature and pressure) (Khan and Shahid 2022). Moreover, this process has enabled the utilization of immiscible or less soluble organic ligands, expanding the family of MOFs (Chen et al. 2019; Crawford and Casaban 2016). Certain challenges are still there, such as low purity (requires solvent usage for further purification) (Rubio-Martinez et al. 2017), and the particle is uncontrollable and usually very small because of grinding (Szczesniak et al. 2020).

Sonochemical

The sonochemical method involves the usage of ultrasonic irradiation of the mixture of organic ligands, metal salts, and solvents. Ultrasound waves cause cavitation, a process of microbubble formation, growth, and collapse, creating an ultrahigh localized pressure (~ 1000 bars) and temperature (~ 5000 K). These harsh conditions facilitate the mass transfer and nucleation of MOF crystals (Khan and Shahid 2022). MOFs produced using ultrasonic waves have a higher surface area and crystallinity compared to those synthesized by solvothermal methods, as reported by Chalati et al. by synthesizing MIL-88A (Chalati et al. 2011). The high temperature, pressure, and strong shear force facilitate the generation of high-energy molecules and bond breakage, creating free radicals, which rearrange to form MOFs (Lee et al. 2016). This process offers high energy efficacy, reduced reaction time, and convenient operation (Vaitsis et al. 2019). A few disadvantages of this method include low yield, side reactions, and impurities in the final product (Amaro-Gahete et al. 2019; Ghanbarian et al. 2018).

Modification/functionalization of MOFs

Enhancing surface area

The surface area of the MOFs is tunable by changing the size of the organic ligands. The long-chain organic ligands can increase the porosity of the MOFs. For instance, Eddaoudi et al. (2002) reported that the expansion of the pore size of MOF-5 by using different organic ligands with dicarboxylic acid structure yielded similar topology MOFs, but surprisingly, the aperture of MOF changed from 3.8 to 28.8 Å and 7 times greater pore size (Eddaoudi et al. 2002). Enlarging the surface area offers potential benefits, making pore characteristics favorable for adsorption and promoting ion diffusion. However, it increases the cost and can cause structural collapse due to the MOF’s crystal structure distortion caused by long organic ligands (G. Lin et al. 2023a, b).

Functionalizing organic ligand

MOFs are typically considered the most effective adsorbent because of their remarkable specific surface, controllable topology, and pore characteristics. These properties facilitate the physical adsorption of pollutants on native MOFs. To further enhance the adsorption performance of MOFs, researchers tried to introduce pollutant-favorable binding functional groups in MOFs. This was done utilizing two methods: (i) post-synthetic modification (by impregnating the organic ligand onto the MOFs) or (ii) by reacting metal salts directly with functional groups containing organic ligands to synthesize MOFs in a one pot. Fu et al. Fu et al. (2019) modified the UiO-66-NH2 using 2,3-dimercapto-1,3,4-thiadiazole utilizing the post-synthetic modification technique. Abdelhameed et al. (2019) reported the post-synthetic modification MIL-125 using bis-quinoline Mannich. Both showed that the modification improved the adsorption tremendously; however, the organic ligand blocked the pores of the native MOFs, which resulted in reduced surface area. Wang et al. (2020) utilized mercaptosuccinic acid (containing -OH functional group favorable for Hg+2) to react with ZnCl4, and in another study, they utilized bifunctional (Wang et al. 2022) organic ligand to produce functionalized MOF in one pot eliminating the need for post-synthetic modification. The one-pot strategy is more economical, fast, eco-friendly and feasible compared to post-synthetic modification, but research is still needed to be done to control the morphology and crystal shape of the MOFs.

Functionalizing metal node

Similarly, this modification can be done in two ways: (i) post-synthetic modification of metal node and (ii) doping of metal onto MOFs. In a post-synthetic modification, prepared MOFs are modified by functionalizing the metal node with specific molecules. For instance, Ke et al. (2011) took advantage of the coordinatively unsaturated Cu metal center and functionalized it with a thiol-containing organic monomer (dithioglycol) through facile coordination. This modification of the Cu-MOF enhanced its adsorption performance tremendously for Hg+2 (714.269 mg/g). Typically, the strategy to functionalize the metal node rather than the organic node is more active and easier to coordinate. However, increasing the amount of molecule used for functionalization can lead to worse crystallinity, morphology, and reduced surface area and pore volume (Ke et al. 2011). Doping the metals onto MOFs can also enhance their adsorption performance and can help to regulate the structure and porosity of the MOFs, which in turn improve the selectivity, activity, and stability of the MOF. For example, Goyal et al. (2022) reported iron doping on HKUST-1 by substituting Cu(II) sites. Compared to HKUST-1, Fe-HKUST-1 (5 mol% Fe) showed improved water stability as it retained 86% crystallinity and 89% surface area after being exposed to water for 2 h and demonstrated remarkable adsorption performance for Pb(II) (565 mg/g). However, over-doping (> 10%) can also cause structural collapse and weekend the hydrostability indicating that the optimum amount of doping should be done to have favorable adsorption properties (Goyal et al. 2022).

Composite formation

Composite formation is an effective technique to enhance the MOFs’ properties and tailor their functionalities by combining them with other components such as metal nanoparticles, graphene, carbon nanotubes, silica, and polymers. For instance, Huang et al. (2022) inserted magnetite nanoparticles (Fe3O4) into NH2-MIL-125(Ti), followed by its post-synthetic functionalization by thiol and amino functional groups, which yielded a magnetic composite MOF (BDB-MIL-125(Ti)@Fe3O4. The magnetite inclusion imparted superparamagnetic properties, making removing the MOF after adsorption easy and reducing the overall cost. Graphene oxide (GO), an innovative nanomaterial, demonstrated a promising ability to remove heavy metals. GO prevents particle agglomeration and improves dispersive force within the MOF structure, thus improving stability. Generally, GO increases the active sites for improved pollutant removal and provides a substrate for nano MOF growth, increasing the MOF’s stability. For example, Wang et al. (2019a, b) prepared a composite of zeolite imidazole framework and graphene oxide for Pb(II) removal, as shown in Fig. 3. The GO inclusion helped the dispersion and imparted active sites, which improved the Pb(II) adsorption, reaching the maximum adsorption capacity of 356 mg/g. It can be concluded that the composite formation of MOFs with other functional materials has proven to be an effective technique for improving properties and stability and tailoring functionality for a specific application.

MOFs integrated with fiber by electrospinning

The manufacturing of MOF-based nanofibers through electrospinning is gaining significant attention due to its convenience and unique properties. This process produces nanofibers with a large surface area, high porosity, easy size control, and allows for straightforward surface modification. Different strategies are generally used to produce MOF-based nanofibres, namely “MOF-in-fiber,” “MOF-on-fiber,” and “MOF-seed-fiber”(Peng et al. 2023).

The MOF-in-fiber strategy involves mixing MOF powder and polymer in a spinning solution, which gets the MOFs wrapped in fiber runder high voltage (Shah et al. 2024). For instance, Wang et al. (2019a, b), produced MOF-PAN film by electrospinning the nanofibrous solution of Cu-based MOF (HKUST-1) with polyacrylonitrile (PAN). The following steps involving carbonization, azide reaction, and perfluorination (PF) treatment enhance the resulting copper azide film, imparting outstanding electrostatic stability and remarkable detonation performance. Energy-dispersive spectroscopy (EDS) analysis confirmed the successful modification of the copper azide film, revealing uniform dispersion of Si and F elements throughout the film. The MOF-in-fiber approach involves encapsulating MOFs within the polymer matrix, leading to a reduction in the active sites accessible to MOFs. Consequently, the functionality of MOFs is somewhat constrained by this encapsulation process (Q. Wang et al. 2019a, b).

Unlike the MOF-in-fiber approach, where MOFs are encapsulated within the fiber during a single process, the MOF-on-fiber method involves synthesizing MOFs separately and then depositing them onto the surface of a blank fiber (Peterson et al. 2021). Unlike the encapsulation seen in the MOF-in-fiber method, there are instances of swelling and agglomeration with this approach. However, the MOF-on-fiber method allows MOF particles to attach to the fiber surface, providing more exposed sites for functionality (Lee et al. 2017).

Performance of MOFs as a HM ion adsorbent

Pristine MOFs

Pure metal-organic frameworks have received great attention due to their promising surface properties and exceptional gas adsorption capability. These materials have also been studied extensively for their potential to filter pollutants from aqueous solutions. For instance, Ding et al. (2018) effectively synthesized UIO-66 from ZrCl4 and 1,4-benzene dicarboxylic acid to adsorb Hg(II) with an adsorption capacity of 36.45 mg/g. According to the available literature, ZIF-90 was prepared using imidazole-2-carboxyaldehyde and Zn(NO3)2·4H2O and then activated by 3 days of soaking in CH3OH. Only 47 mg/g of Hg(II) was adsorbed despite attaining a substantial specific surface area of 1222 m2/g (Yin et al. 2018). Similar to this, the hydrothermally produced pristine MOFs (MIL-101 (Cr)) only adsorb 75 mg/g of mercury(II) (L. Liang et al. 2018a, b).

Cheang et al. (2022) synthesized MIL-101(Fe) for Pb(II) adsorption with a regular crystal shape with the use of a microwave, and the capture capacity through electrostatic contact was 40.5 mg/g. The application situations are constrained by the fact that this material works best at moderate pH levels. Furthermore, Pb(II) reusability has to be improved (Cheang et al. 2022). Morcos et al. (2021) produced UIO-66 and UIO-67 using terephthalic acid and 4,4′-biphenyldicarboxylic acid as the appropriate organic linkers, and the adsorption quantities were 48.7 mg/g and 55.8 mg/g, respectively. Because of its larger specific surface area and more adsorption-friendly pore size and volume, the longer organic linker chain may be the reason for UIO-67’s slightly higher adsorption capacity. It is reasonable to assume that physical adsorption will thus be predominant throughout the procedure. Unexpectedly, the native MOFs’ adsorbent, MOF-5, displayed a remarkable capacity for adsorbing Pb(II), reaching 658.5 mg/g at the optimal pH of 5.0. The Zn2+ in the Zn4O complex in the adsorbent coordinated with the O atoms of the water throughout the adsorption process due to electrostatic or van der Waals interactions. As a result, benzoate ions were liberated and combined with Pb(II) to effectively remove the metal (Rivera et al. 2016).

At pH = 7.0, ZIF-8 nanoparticles only successfully adsorb 60.03 mg/g of As+5 and 49.49 mg/g of As+3, respectively (Jian et al. 2015). Two variables mainly cause the low capture levels. The adsorbent cannot withstand acidic conditions, which is the first factor. At a pH of 2.0 to 6.0, the adsorbent gets dissolved, releasing Zn+2 into the solution and diminishing the adsorption of arsenic. Second, owing to the adsorbent’s minor electropositive property, electrostatic contact is hardly detectable under neutral conditions. As(V) has a larger capacity for adsorption than As(III) because it has a more substantial negative charge, which shows that electrostatic interaction significantly affects ZIF-8 adsorption. While As(V) and As(III) capture quantities of 68.21 and 205 mg/g, respectively, He et al. UIO-66’s demonstrated the opposite adsorption effects of arsenic, in contrast to ZIF-8 (He et al. 2019). With UIO-66, As(V) and As(III) may form bidentate mononuclear and binuclear complexes, respectively, and chemisorption is the key catalyst for the reaction. The two investigations show that a superior adsorption outcome may be obtained when chemisorption dominates the process. The dominance of chemisorption considerably improves the adsorption action and results in the capture of 124 and 128 mg/g, respectively, of As(V), as was previously seen in MIL-101(Fe) and MIL-101(Al) (Cai et al. 2018).

Pristine MOFs have also demonstrated exceptional performance for Cr(VI) removal; for example, UIO-66 has a 36.4 mg/g uptake capacity for Cr+6 at pH 3. At this pH, the adsorbent has shown a positive charge which contributed to electrostatic interaction with Cr(VI), resulting in high adsorption capacity, as reported by Wang et al. (2017). Although MIL 101(Cr) showed swift adsorption kinetics and achieved adsorption equilibrium within 30 min, the uptake capacity was only reported to be 40.34 mg/g for Cr+6 removal (Liu et al. 2020a, b, c). Another pristine MOF MIL-101(Fe) with a high positive charge at pH = 2 was hypothesized to remove Cr(VI) with electrostatic interaction at pH = 02 as Cr(VI) occurs as Cr2O72− and HCrO4− but was only capable of removing 30.45 mg/g of Cr(VI) (Forghani et al. 2020). These studies suggest that pristine MOFs are inefficient for chromium removal from wastewater, which needs further modification to improve their adsorption capacity.

Table 1 summarizes the performance of the pristine MOFs as adsorbents for heavy metals. An extensive literature review shows that pristine MOFs are inefficient heavy metal adsorbents despite their high surface area and tunable properties. This could be because of insufficient binding groups available on these MOFs although MOFs have shown exceptional performance in gas separation, which mainly depends on their surface area and pore characteristics, which is not the case in heavy metal removal. An efficient adsorbent for heavy removal must have sufficient adsorption favorable groups and be hydrated enough to make bonds with water.

Functionalized MOFs

Physical adsorption predominates since the performance of virgin MOFs often hinges on the surface properties (such as area and pore characteristics). Nonetheless, introducing organic ligands containing many adsorption-favorable sites can enhance the adsorption properties of pure MOFs. By grafting thiourea and tetrahydropyran (THP), Yin et al. improved the ZIF-90, which resulted in a decrease in surface area compared to the original ZIF-90 (1222 to 600 m2/g with THP and 212 m2/g with THF). The organic ligands provided appropriate favorable binding sites with N, O, and S, and they nevertheless showed outstanding adsorption kinetics, with a Hg(II) adsorption capacity of 596 mg/g (THP) and 403 mg/g (THF) (Yin et al. 2018). The mercury mitigation from wastewater has improved significantly after adding -NH and -SH functional groups to the original MOFs. For instance, Ji et al. (2022), by grafting thioglycolic acid onto MOF-808 with a moderate surface area of 636 m2/g, added a thiol functional group, removing more than 99% of the Hg+2 from wastewater and displaying a maximum adsorption capacity of 977.5 mg/g. The MOF-808 and MOF-808-SH’s structure and SEM micrographs are depicted in Fig. 4. The key adsorption site was identified by the XPS spectra as the -SH group, and excellent selectivity was achieved by selective inner sphere coordination with Hg+2 (Ji et al. 2022). Chai et al. modified the UIO-66 by introducing the -NH2 functional group to produce UIO-66-NH2, which captured the Hg+2 due to the bond between NH2 and Hg(II) with an adsorption capacity of 480 mg/g. Further improving the Hg(II) adsorbability, UIO-66-NH2 was modified with glutaraldehyde and 4,6-diamino-2-mercaptopyrimidine, demonstrating an exceptional uptake capacity of 822 mg/g. The XPS and DFT calculation revealed that the bond between Hg(II) and S and N was the main reason for high adsorption, with S as a dominant site for adsorption (Chai et al. 2022).

a Schematic structure of MOF-808 and MOF-808-SH and SEM micrographs at 500 nm scale of b MOF-808 and c MOF-808-SH (Ji et al. 2022)

Carboxyl-functionalized MIL-101 (MIL-101-(COOH)2) was prepared by Cheang et al. (2022) to improve the uptake capacity of pristine MIL-101 for effective removal of Pb(II) from aqueous feed. The modified MIL-101-(COOH)2 demonstrated a 468 mg/g adsorption capacity, almost 12 times more than the uptake capacity of virgin MIL-101 for Pb(II), because of the presence of carboxylic acid (Cheang et al. 2022). Using the one-pot method, MOF-MA was prepared by reacting ZrCl4 with mercaptosuccinic acid, which demonstrated remarkable uptake capacity for both Pb(II) and Hg(II), which was estimated to be 510 mg/g and 1080 mg/g, respectively. The adsorption mechanism was unveiled using XPS, which shows that the coordination and electrostatic played a critical part in the pollutants’ adsorption (Wang et al. 2020). Zhong et al. modified copper-based MOF (Cu-BTC) by adding 4-thioureidobenzoicacid (Th), imparting -NH2 and =S functional group in MOF. The modified MOF exhibited a 732.86 mg/g uptake capacity for Pb+2. Nevertheless, the amount of Th needs to be smartly optimized. The higher amount could negatively impact the performance (Zhong et al. 2022).

MOFs have also been widely studied for arsenic removal from water. Face-centered cubic unit topology SUM-8 (hexanuclear Zr-oxo) was prepared by covalent coupling of in situ nitroso groups. The prepared MOF demonstrated nearly 152.52 mg/g, mainly due to the complexation between arsenic ion with -OH and -Zr-oxo node or by replacing Zr bounded carboxylate forming As-O-Zr. Zr-oxo nodes played a dominant role in removing As (Song et al. 2022). Functionalized Zn-MOF-74 was synthesized to remove As(III) and As(V) from model wastewater, which demonstrated an adsorption capacity of 325 mg/g and 211 mg/g for As(V) and As(III), respectively. This high adsorption capacity was due to the coordination interaction between Zn+2 ions with H2AsO4− and H2AsO3− forming Zn-O-As, as revealed by XPS (Yu et al. 2019). Gu et al. functionalized the MOF, making it a bimetallic MOF effective for adsorbing pollutants. These bimetallic nanospindle MOFs (Fig. 5) were produced by reacting terephthalic acid with Fe/Mg ions. Changing the molar ratio of the Fe/Mg structure of the corresponding MOF and adsorption performance can be controlled. The optimized MOF, with a 0.5 Fe/Mg molar ratio, exhibited an excellent adsorption capacity of 303.6 mg/g. This exceptional performance was mainly due to the active sites generated by the bimetallic center node enabling swift adsorption kinetics (Gu et al. 2019a). Another bimetallic MOF was prepared by Sun et al. (2018a, b) using Fe/Co = 2/1, producing Fe2Co1 MOF-74, which exhibited high adsorption capacity of 266.52 and 292.2 mg/g for As(III) and As(V), respectively. This was because of the electrostatic interaction and coordination of metal-hydroxyl and metal-oxygen groups with arsenic ions (J. Sun et al. 2018a, b). Fang et al. (2023) did the post-synthetic modification of MIL-101(Fe) with an amino group to produce NH2-MIL-101(Fe) to remove arsenic ions from river water samples, which showed an adequate performance with adsorption capacity of 147.7 and 153.4 mg/g compared to 82.8 and 131.2 mg/g for As(V) and As(III), respectively. The XPS revealed that the adsorption was due to the complexation between Fe and As, as NH2 increases the iron content. Surprisingly the -NH2 and As(V) electrostatic interaction was the primary reason for adsorption.

FESEM micrographs of a Fe-MOF, b Fe/Mg-MIL-88B(2), c Fe/Mg-MIL-88B (1), d Fe/Mg-MIL-88B (0.5), e TEM micrograph, and f EDX mapping of Fe/Mg-MIL-88B (0.5) (Gu et al. 2019a)

Xingyue et al. prepared rhombic dodecahedral cobalt-based-zeolitic imidazole framework (ZIF-67) with a 1676 m2/g surface for chromium remediation from wastewater. Adsorbent demonstrated fast adsorbate uptake kinetics and reached equilibrium within 20 min. The adsorption was mainly governed by electrostatic interaction as the adsorbent possess positive charge in acidic conditions which attract the anionic chromium. Despite the large surface area, the maximum uptake capacity was observed to be 15.4 mg/g. This low adsorption capacity could be attributed to the lack of presence of chelating groups on the surface of the adsorbents. Surface functionalization with chelating groups, mineralization, composite formulation, and carbonization are common modification adopted by the researchers to further increase the absorptivity of the MOFs (Li et al. 2015). Nasrollahpour et al. functionalized MIL-100(Fe) with acidic chloroaluminate ionic liquid (IL). The functionalization although reduces the surface area of the MIL-100(Fe) from 2352 to 1451 m2/g increased the adsorbate uptake capacity 9 times (from 30 to 286 mg/g) compared to virgin MIL-100(Fe). This high adsorption capacity is due to the presence of IL sites, π orbitals of organic sites, polarized OH, and functional groups on the surface of the adsorbents. Mineralization is another technique used to improve the surface functionality of MOFs (Nasrollahpour and Moradi 2017). Fang et al. utilized HF, TMAOH, and Na2CO3 as a mineralizing agent to further improve the adsorption capacity of the MIL series of the MOFs. Na2CO3 was observed to be the best mineralizing agent. The adsorption capacity indicates that mineralizing process is not a promising technique to improve the adsorption capacity of the MOFs compared to the addition of chelating groups, as the MIL-100(Fe) mineralized with Na2CO3 demonstrated 45 mg/g of maximum adsorption capacity compared to 30 mg/g of virgin MIL-100(Fe); however, mineralization process has improved the physiochemical properties of the MOFs compared to IL functionalization (Fang et al. 2018). UiO series of MOFs have not demonstrated much improvement in adsorption capacity with surface functionalization. For example, Uio-66 which contains hexanuclear zirconium cluster linked with terephthalates was utilized as an adsorbent for aqueous chromium remediation and showed an adsorption capacity of 35 mg/g with a surface area of 800 m2/g, whereas amino-functionalized Uio-66 (Uio-66-NH2) showed uptake capacity of 32 mg/g with 710.3 m2/g. The reason behind this is yet unexplored (Wu et al. 2018). Carbonization is another method reported in the literature to effectively remove the Cr(VI) from aqueous solution. Carbonized MOFs are converted into metal-carbon nanocomposites after the carbonization which effectively remove the Cr(VI) through electrostatic attraction and reduction of Cr(VI) to Cr(III) followed by precipitation of Cr(III) on the surface of the adsorbent. For example, Wang et al. did the pyrolysis of MIL-100(Fe) at different temperatures (700–900 °C) to produce nanoscale zero-valent iron (nZVI) functionalized porous carbon. The Fe–O clusters of Mil-100(Fe) were reduced to nZVI by in situ method. The developed adsorbents demonstrated dramatic increase in adsorption capacity (234 mg/g) compared to virgin MIL-100(Fe) (30.5 mg/g). However, the kinetics of adsorption was observed to be slow compared with MIL-100(Fe) (18 h vs 3 h) which could be because of chemical reduction of the Cr(VI) to Cr(III) and precipitation of Cr(III) on the surface of the adsorbent (Wang et al. 2018a, b).

Table 2 summarizes the performance of functionalized MOFs. The literature review revealed that imparting functional groups in MOFs can surprisingly improve the adsorption of the MOFs.

MOF composites

Carbonous materials such as graphene oxide and carbon nanotubes have demonstrated good adsorbability for HM ions (Nasser Abdelhamid et al. 2023). These materials provide a base to prevent particle agglomeration and improve repulsive force within the structure of the MOFs, which increases the stability while providing more active sites for adsorption when combined with MOFs to form composites (Liu et al. 2023). The composite of graphene oxide (GO) and MIL-53(Al) was prepared using the hydrothermal method which was explored for Pb(II) removal wastewater. The addition of GO in MIL-53(Al) increases by almost 18% surface area compared to pristine MIL-53(Al). It provides epoxy and hydroxyl functional groups to the precursor MOF increasing its adsorption capacity to 232 mg/g (Pb(II)) due to the coordination bond between Pb2+ with -OH and epoxy (Chowdhury et al. 2021). Wang et al. (2019a, b) prepared the composite of ZIF and GO by growing ZIF-8 on GO, which enables ZIF nanoparticles to be effectively dispersed on GO making it conducive for metal ion removal. The adsorption performance revealed that the composite could effectively remove Pb2+ with a maximum adsorption capacity of 356 mg/g due to the synergistic effect of GO and ZIF (J. Wang et al. 2019a, b). Other graphene derivatives have also been utilized, but the most notable is reduced graphene oxide (rGO), which is well known for its easy synthesis and ultra-thin 2D structure (Ge et al. 2013). To remove arsenic (As(III) and As(V)), the composite of rGo and MIL-100(Fe), which was intercalated oxidantt δ-MnO2 for preparation of MIL-100(Fe)/rGO/ δ-MnO2. The composite demonstrated the maximum adsorption capacity of 192.6 mg/g and 162 mg/g for As3+ and As5+, respectively (Ploychompoo et al. 2020). The higher adsorption for As3+ was due to the coordination of As3+ with δ-MnO2 to form Mn-O-As and oxidation of As(III) to As(V), whereas As5+ cannot be oxidized. Reduced graphene oxide acting as a carrier to disperse MIL-100(Fe) and δ-MnO2 increases the electrostatic interaction due to the active pores’ provision and promotes Mn oxidation (Ploychompoo et al. 2020).

The composite formulation of the MOFs with polymers has also improved the adsorption properties. The nanocomposite of polyacrylonitrile (PAN) and MOF-808 (Zr-based MOF) was prepared, demonstrating 225.05 mg/g adsorption capacity for Cd2+. This exceptionally high adsorption was due to the electrostatic interaction of Cd2+ with composite (Efome et al. 2018). Chitosan has recently emerged as natural polymer widely utilized for MOF composite development due to the presence of -OH and -NH2 functional groups, which can provide additional active sites for adsorption (Li et al. 2020; Liang et al. 2018a, b; Wang et al. 2016a, b). Nevertheless, chitosan in its raw form shows poor adsorption properties because of instability and tend to agglomerate in water. But by addition of inorganic material in chitosan polymer, the adsorption characteristic can be improved (Fu et al. 2017). The stability of the chitosan can be enhanced by composite formation which also supports mass transfer through porous structure (Q. Liu et al. 2020a, b, c). For example, Samuel et al. prepared a composite of MOF with graphene oxide and chitosan (GO-CS@MOF) for Cr(VI) adsorption. Graphene oxide and chitosan provided the NH2 and OH functional, which improved the adsorption capacity to 145 mg/g despite their low surface area of 37 m2/g in acidic conditions (pH = 3). This high adsorbate uptake capacity can be attributed to the protonation of NH2 to NH3 at acidic pH, which helps to adsorb HCrO4 chromium ions through electrostatic attraction and complexation of the chelating group with chromium ion (Samuel et al. 2018). Beads can effectively enhance the interaction pollutants with metal ion which facilitates their removal. Omar et al. produced the magnetic microbeads of aminated chitosan with Fe3O4 (to impart magnetic properties) and ZIF-67 for Cr6+ removal. The produced showed an adsorption capacity of 119.05 mg/g, mainly because of the protonation of -NH2 at low pH and electron donor group of -OH and -NH2 at the surface help reduction of Cr6+ to Cr+3 (Omer et al. 2021).

Separating the MOFs after the adsorption process is a tedious job and possibly creates secondary pollution, adding another demerit to the account of MOFs. To overcome this issue, the researcher attempted to develop the magnetic composite to ease the separation of the MOFs from aqueous solution using the magnetic separation technique. For example, Yang et al. prepared a MIL-100(Fe) composite with Fe3O4 using the in situ method, which yielded a core shell microstructure with a mean diameter of 350 nm and 50-nm-thick MOF layer. The developed adsorbent demonstrated maximum adsorption in acidic conditions; at pH = 2, the adsorption capacity was observed to be 18 mg/g, which is very low compared to other developed composite MOFs, but obviously, the separation of the spent adsorbent was easily and did not generate any secondary pollution (Yang et al. 2016). Utilizing the same concept and to improve the adsorbate uptake capacity of the magnetic MOF composite, Mahmoud et al. attempted to functionalize the magnetic composite of the MIL-88A(Fe) and Fe3O4 with -NH2 functional group using 3-aminopropyltrimethoxysilane (APTMS) employing microwave green process. The resultant functional adsorbent demonstrated a 1092.2 mg/g maximum adsorption capacity, the highest capacity reported for chromium adsorption using MOFs (Mahmoud et al. 2020). Huang et al. prepared a supermagnetic composite of Fe3O4 with UIO-66, whose terephthalic acid was replaced with mercaptoacetic acid using solvent-assisted ligand exchange. The obtained showed a maximum adsorption capacity of 282 mg/g for Hg2+ with swift kinetics; this was mainly because of the presence of thiol group. The composite demonstrated exception selectivity and reproducibility as well (Huang et al. 2016). Another magnetic composite prepared by encapsulating Fe3O4 in in situ TMU-32 to improve the surface charge followed urea functional group decoration. This composite demonstrated an exceptional adsorption capacity of 1600 and 905 mg/g for Pb(II) and Hg(II) ion, respectively. This high adsorption performance can be attributed to the electrostatic interaction of positively charged Hg(II) and P(II) ions with negatively charged Fe3O4@TMU-32 (Abdollahi et al. 2020).

Silica nanoparticle embeddation into MOFs to form nanocomposites has also shown positive results. For example, Worood et al. developed a composite of amino-functionalized Uio-66 with silica gel; silica gel was utilized as a porous solid support to improve the efficiency of the packing of the column and contact time of the adsorbent solute. Results demonstrated that the silica had increased the adsorption capacity from 32 mg/g (for Uio-66-NH2) to 277.4 mg/g (with silica), with an almost similar surface area of 730 m2/g. This adsorption is because the porous silica did help to stop the blockage of the pores of the adsorbent before the utilization of active sites, which was the case with Uio-66-NH2 (El-Mehalmey et al. 2018). Table 3 summarizes the adsorption performance of MOF composites.

MOF regeneration and water stability

The stability of MOF in water is generally considered an essential factor that controls their application in wastewater remediation. It is estimated through different factors such as acid resistance, the changes in structure that occurred after adsorption, the time in the water, and the number of recycling cycles (G. Lin et al. 2023a, b). Nevertheless, limited relevant literature is available, particularly concerning the long-term stability evaluation of MOF in wastewater. The primary factor governing the MOFs’ stability is the coordination bond of metal and organic ligands (Canivet et al. 2014). Most virgin MOFs face challenges due to low tenacity underwater (X. Liu et al. 2020a, b, c). The MOF-5 is a typical example of an unstable MOF. Greathouse et al. observed the stability of the MOF-5 in water, where they found that the MOF-5 can maintain its structure at low water content but eventually collapse at high water content (Greathouse and Allendorf 2006). Moreover, the MOF-5 lost almost 9.78% Zn(II) after the adsorption of Pb(II) ions, as revealed in experimentation conducted by Rivera et al. (2016). Jian et al. (2015) showed that ZIF-8 can effectively only in neutral conditions; as the pH decreases, it gets dissolved, and the dissolution increases with the decrease of pH. Following the Lewis acid-base theory, stable MOF can be produced. For example, hard bases like carboxylate-base ligands can be reacted with hard acids like Cr(III), Al(III), and Fe(III). Examples of some of the MOFs produced according to this theory are MIL-53, MIL-100, and MIL-101 (Feng et al. 2018). These MOFs have demonstrated tremendous water stability. Particularly, MIL-53(Al) showed high resistance to hydrolysis in both acidic and neutral conditions (Qian et al. 2013); moreover, MIL-100(Fe) retained the crystallinity in the 2-12 pH range (Feng et al. 2018).

Limited data on the regeneration of the spent MOFs after the adsorption of the HM ions is available, and the outputs indicate that MOFs can be reused/regenerated by nitric acid or sodium hydroxide treatment (Gu et al. 2019b; Liu et al. 2018; Ploychompoo et al. 2020). For instance, diluted solutions of NaOH and HCl have been widely used for MOFs utilized for chromium removal (Fang et al. 2018; Forghani et al. 2020; Z. N. Liu et al. 2020a, b, c; Mahmoud et al. 2020). MOF spent for Pb(II) can be regenerated by desorbing Pb using EDTA-2Na and HCl, which have shown promising results (Luo et al. 2015; Mahmoud et al. 2020; Minh Thanh et al. 2018; Wang et al. 2018a, b). The literature has revealed that acidic solutions containing thiourea can effectively regenerate MOFs (Luo et al. 2016; Singh et al. 2021; H. Zhang et al. 2022a, b; Zhang et al. 2019).

Adsorption mechanism

Understanding the adsorption mechanism is essential for adsorbent designing and optimizing the adsorption process (Ighalo et al. 2022). For MOFs, typically, the adsorption process involves physisorption and chemisorption. Physisorption is majorly due to the van der Waal forces between the adsorbent and adsorbate, which do not change the inherent properties of the adsorbate, and the adsorption energy is low, which cannot generally hold the pollutant long. The porosity, surface area, and pore characteristics are active factors that govern physical adsorption (Joseph et al. 2019). In contrast, chemisorption involves the bond formation between the active sites of adsorbent and adsorbate by electrostatic interaction, hydrogen bonding, π-π stacking, or surface complexation (Healy et al. 2020). The commonly used adsorption isotherm models like Langmuir (Armbruster and Austin 1938), Freundlich (Abbasi et al. 2022; Haghseresht and Lu 1998), Temkin (Al-Ghouti and Da’ana 2020), Sips (Lin et al. 2023a, b), and Redlich and Peterson (Saadi et al. 2015) can only explain the adsorption type at the macroscopic level without clarification on the interaction between the adsorbent and adsorbate (G. Lin et al. 2023a, b). Thus, the deep analysis of the adsorption mechanism is critical in understanding the MOFs’ performance, which can be done by characterizing the spent MOF using XPS, SEM, and FTIR. The following sections will delineate the possible interaction of MOF and heavy metal ions (illustrated in Fig. 6).

Electrostatic interaction

Electrostatic interaction is a ubiquitous phenomenon in adsorbing heavy metals onto MOFs, mainly driven by the electrostatic attraction force between oppositely charged adsorbent and adsorbate (Tchinsa et al. 2021). The pH of the wastewater or the nature of the targeted pollutant significantly controls the overall net surface charge of the MOF being utilized for pollutant remediation. Typically, the lower the pH, there is considerable chance that the adsorbate is going to be positively charged due to the protonation. In contrast, most of the adsorbents are prone to be negatively charged. The net surface charge on the MOF surface facilitates the proton exchange between the MOF and the targeted pollutant, thus enhancing electrostatic interaction and adsorption performance (Amenaghawon et al. 2023). Zeta potential is considered the most influential factor that can decide the surface charge of the MOF at different pH of the wastewater (Amin 2009) and can drive the electrostatic interaction. For instance, the result of the zeta potential of nFe3O4@MIL-88A(Fe), as shown in Fig. 7b, demonstrates that the MOF is positively charged at low pH due to the protonation of NH2 to NH3+, which facilitates the electrostatic interaction of MOF with Cr2O7− giving adsorption capacity at pH 1 as shown in Fig. 7a (Mahmoud et al. 2020). Another example is Fe3O4@TMU-32 which was utilized for mercury ion removal from wastewater. The MOF possessed a negative charge at a pH higher than 4.1 because it showed maximum adsorption capacity at pH due to the electrostatic interaction between the negatively charged MOF and positively charged mercury ion (Abdollahi et al. 2020).

a The effect of pH on the chromium adsorption by nFe3O4@MIL-88A(Fe) and b zeta potential of nFe3O4@MIL-88A(Fe) (Mahmoud et al. 2020)

Hydrogen bonding

As reported in the literature, hydrogen bonding between adsorbate and MOFs considerably stimulates the adsorption capacity of the MOFs (Amenaghawon et al. 2023). As reported by Yoskamtorn et al. (2021), the addition of hydrogen bond functionality in the structure of MOF significantly increases their adsorbability. The dipole-dipole interaction between the electronegative atoms like O, S, F, and N and hydrogen creates a hydrogen bond. The hydrogen bond generally forms between the lone pairs of the H atom and electronegative atoms, as observed in fluorine-hydrogen, oxygen-hydrogen, or nitrogen-hydrogen (Amenaghawon et al. 2023; Zhou et al. 2017). Two types of hydrogen bonds have been observed: (i) hydrogen bonds existing between the different atoms of the same material, known as intramolecular hydrogen bonds, and (ii) an intermolecular hydrogen bond formed between the different atoms of different materials (Tchinsa et al. 2021). Li et al. observed that the As removal was enhanced because of the hydrogen bond between As and MIL-53(Al) (Li et al. 2014).

π-π stacking

Π-π stacking interaction, which involves the attraction between the negatively charged MOFs and positively charged target pollutants similar to electrostatic interaction, is a well-known adsorption mechanism for heavy metal adsorption on MOFs (Park et al. 2013). This mechanism involves the interaction of electrons of the π-system with the cationic, anionic, or neutral metal ion or another π-system facilitating the adsorption of the target pollutant. For example, Akpinar et al. (2019) demonstrated that the π-π interaction was the influential factor for the enhanced adsorption of the pollutant onto the Zr-based MOF.

Acid-base interaction

Acid-based interaction is based on hard and soft acid base theory (HSAB), which explains that the hard acid will attract or can be easily bonded with a hard base and soft acid with soft bases (Pearson 1963). This interaction is vital in removing the heavy metal contaminant from the aqueous solution. MOFs with acidic (H+) or basic (-OH) have been observed to form bonds with the HM ions in the wastewater, ultimately improving the adsorption performance. The central atom with a low positive charge, high polarizability, and large ionic radius is considered soft acid. These atoms have excited external electrons readily available for covalent bonds. Typically, Hg2+, Hg+, Pd2+, Cu+, and Cd2+ are regarded as soft acids. The opposite of these are hard acids; examples are Cu2+, Pb2+, and Ni2+. Functional groups like thiol, amino, and carboxylic are considered as soft bases. Several reports are reporting that acid-base interaction has improved the adsorption capacity. For example, Ji et al. (2022) reported that the interaction between the -SH (soft base) and Hg2+ (soft acid) was the primary reason for the high adsorption capacity (977.5 mg/g) of MOF-808.

Challenges and future direction

MOFs are emerging materials that have shown desirable results in decontaminating heavy metals from wastewater, as revealed in this detailed literature survey. Nevertheless, as demonstrated by several research reports, certain significant challenges continue to be encountered in the advancements of MOFs. Further investigation is still needed into the development of MOFs (to improve their stability and reduce the usage of harmful solvents), modification (green composite development, reduction in cost, and improvement in functionality), and improvement in understanding the adsorption mechanism (essential in designing the MOFs for particular pollutant removal) (Jeong et al. 2023). To unlock the full development potential of MOFS in the future, we present the following aspects as promising prospects:

-

Environmental aspect: the synthesis of MOFs involves the usage of perilous organic solvents like N,N-dimethylformamide, methanol, or tetrahydrofuran. The usage of these solvents directly affects the environment, which should be kept in consideration, and future research should be directed to eliminate the use of these solvents or replace them with somewhat “greener solvents.” Although several attempts have been made to reduce solvent dependency, such as using a ball mill to synthesize, further research is still needed to improve the quality, stability, and yield of MOFs using these techniques.

-

Market aspect: The cost is the major constraint in upscaling MOFs at the industrial level, which has been ignored so far (Witman et al. 2017). DeSantis et al. (2017) demonstrated through techno-economic analysis that the production cost of MOF should be less than $10/kg to make the MOF synthesis process feasible. The cost of MOF preparation mainly depends on the organic solvent used (ranging from $35 to $71 per kg of MOF) in a solvothermal synthesis method. Alternative techniques have shown their potential for price reduction, such as LAG (34–83% reduction) (DeSantis et al. 2017). However, these values are still far from feasible cost. Even reaching the feasible cost for MOF preparation will still make it more expensive than activated carbon ($1.44/kg) (Lee et al. 2018). The cost of MOF development can be reduced if MOFs are produced using natural and environmentally friendly feedstocks. Thus, rigorous research is essential to improve the synthesis process and reduce solvent dependency while enhancing product purity, quality, and desired physical properties (surface area and pore characteristics).

-

Stability aspect: Stability, or in other words, water and acid resistance of MOFs, is crucial to their industrialization for the water treatment process. Numerous MOFs can only work in a mild acidic or neutral environment, limiting their application. To unlock the true potential of the MOFs for heavy metal removal, new techniques are critical to expand their usability in a wide range. Additionally, limited data is available on the stability of MOFs composite, which should be addressed in the future.

-

Development of universal MOF: Through a detailed literature review, it has been revealed that certain MOFs only work for specific pollutants. No MOF has been synthesized, which can simultaneously remove any heavy metal ions. This could be an impossible task to do. But future research could focus on developing MOFs by using new technologies that can simultaneously mitigate several oxyanions or cations of heavy metals.

-

Modification: Several MOFs are produced in crystalline powdered form in the laboratory, which makes their handling difficult. Thus, future research is needed to explore new techniques to convert or modify them to films and beads for their upscaling.

-

Organic ligands: Commonly used organic ligands for MOF synthesis are carboxylic acids or imidazole. To further expand the classes of MOFs and enrich the properties of MOFs, new organic ligands should be explored.

-

Optimization: The properties of developed MOFs are highly reaction conditions, organic ligand, and metal salt dependent. While developing novel MOFs for HM ion remediation, suitability of functional groups present in metal salts and organic ligands should be carefully considered. As the pollutants have different particle sizes and physical properties, the MOFs should be synthesized with pore sizes greater than the particle size of the contaminant to remove them effectively. The pore characteristics can be controlled through reaction conditions like time, temperature, pressure, and solvent. Therefore, future research should optimize these conditions to achieve the desired properties of the MOFs.

Conclusion

MOFs are emerging effective adsorbents for heavy metal remediation because of their tunable structure, excellent pore characteristics, facile modification, and high specific surface area. This article reviews the performance of the MOFs as adsorbents for HM ions, their synthesis, modification strategies, adsorption mechanism, and challenges being faced in their commercialization in detail. Despite that, solvent-based synthesis (solvothermal/hydrothermal) requires high temperatures for the chemical reaction; it has been a widely utilized synthesis method for MOFs due to its advantages, like high yield, good crystal size, and facile operation. MOFs can easily be modified for specific target pollutants through post-synthesis modification or a one-pot synthesis strategy. MOFs’ modification has been proven beneficial for removing HM ions as it provides adsorption-favorable sites; these active sites are being utilized in bond formation with metal ions, thus enhancing the binding capacity of MOFs. This review summarizes the performance of MOFs for HM ions; functionalized MOF and MOF composites have outperformed pristine MOFs in heavy metal ion mitigation because they not only possess the specific functional groups (like -SH, -NH2, or -OH) but also have the features of the other material attached to them. Composite formation offers several advantages, like exceptional stability, fast kinetics, high binding capacity, and magnetic properties (which ease the recovery of the spent MOFs), thus exploring new MOF composites (making new composites with other materials like inverse vulcanized copolymer, which have emerged as new sulfur-based polymers and have shown promising mercury adsorption properties, can be explored for MOF composite formation to enhance the adsorption properties for effective removal of HM ions). Surface complexation, coordination, and electrostatic interaction have been identified as the primary adsorption mechanism for HM ion removal using MOFs. MOFs are facing several challenges for their commercialization, which have been outlined in detail. Briefly, the challenges can be overcome by directing the research toward the search for alternative sustainable, green, and cheap organic ligands.

References

Abbasi A, Yahya WZN, Nasef MM, Moniruzzaman M, Ghumman ASM, Afolabi HK (2022) Boron removal by glucamine-functionalized inverse vulcanized sulfur polymer. React Funct Polym 177:105311. https://doi.org/10.1016/j.reactfunctpolym.2022.105311

Abdelhameed RM, Ismail RA, El-Naggar M, Zarie ES, Abdelaziz R, El Sayed MT (2019) Post-synthetic modification of MIL-125 with bis-quinoline Mannich bases for removal of heavy metals from wastewater. Microporous Mesoporous Mater. 279:26–36. https://doi.org/10.1016/j.micromeso.2018.12.018

Abdollahi N, Akbar Razavi SA, Morsali A, Hu ML (2020) High capacity Hg(II) and Pb(II) removal using MOF-based nanocomposite: cooperative effects of pore functionalization and surface-charge modulation. J Hazard Mater 387:121667. https://doi.org/10.1016/j.jhazmat.2019.121667

Akpinar I, Drout RJ, Islamoglu T, Kato S, Lyu J, Farha OK (2019) Exploiting π-π interactions to design an efficient sorbent for atrazine removal from water. ACS Appl Mater Interfaces. https://doi.org/10.1021/acsami.8b20355

Al-Ghouti MA, Da’ana DA (2020) Guidelines for the use and interpretation of adsorption isotherm models: a review. J Hazard Mater 393:122383. https://doi.org/10.1016/j.jhazmat.2020.122383

Amaro-Gahete J, Klee R, Esquivel D, Ruiz JR, Jiménez-Sanchidrián C, Romero-Salguero FJ (2019) Fast ultrasound-assisted synthesis of highly crystalline MIL-88A particles and their application as ethylene adsorbents. Ultrason Sonochem 50:59–66. https://doi.org/10.1016/j.ultsonch.2018.08.027

Amenaghawon AN, Anyalewechi CL, Osazuwa OU, Elimian EA, Eshiemogie SO, Oyefolu PK, Kusuma HS (2023) A comprehensive review of recent advances in the synthesis and application of metal-organic frameworks (MOFs) for the adsorptive sequestration of pollutants from wastewater. Sep Purif Technol 311:123246. https://doi.org/10.1016/j.seppur.2023.123246

Amin NK (2009) Removal of direct blue-106 dye from aqueous solution using new activated carbons developed from pomegranate peel: adsorption equilibrium and kinetics. J Hazard Mater 165:52–62. https://doi.org/10.1016/j.jhazmat.2008.09.067

Antonio AM, Rosenthal J, Bloch ED (2019) Electrochemically mediated syntheses of titanium(III)-based metal-organic frameworks. J Am Chem Soc 141:11383–11387. https://doi.org/10.1021/jacs.9b05035

Armbruster MH, Austin JB (1938) The adsorption of gases on plane surfaces of mica. J Am Chem Soc 60:467–475. https://doi.org/10.1021/ja01269a066

Bahmani E, Koushkbaghi S, Darabi M, ZabihiSahebi A, Askari A, Irani M (2019) Fabrication of novel chitosan-g-PNVCL/ZIF-8 composite nanofibers for adsorption of Cr(VI), As(V) and phenol in a single and ternary systems. Carbohydr Polym 224:115148. https://doi.org/10.1016/j.carbpol.2019.115148

Bilecka I, Niederberger M (2010) Microwave chemistry for inorganic nanomaterials synthesis. Nanoscale 2:1358–1374. https://doi.org/10.1039/b9nr00377k

Cai J, Mao X, Song WG (2018) Adsorption behavior and structure transformation of mesoporous metal-organic frameworks towards arsenates and organic pollutants in aqueous solution. Mater Chem Front 2:1389–1396. https://doi.org/10.1039/c8qm00002f

Campagnol N, Van Assche T, Boudewijns T, Denayer J, Binnemans K, De Vos D, Fransaer J (2013) High pressure, high temperature electrochemical synthesis of metal-organic frameworks: films of MIL-100 (Fe) and HKUST-1 in different morphologies. J Mater Chem A 1:5827–5830. https://doi.org/10.1039/c3ta10419b

Canivet J, Fateeva A, Guo Y, Coasne B, Farrusseng D (2014) Water adsorption in MOFs: fundamentals and applications. Chem Soc Rev 43:5594–5617. https://doi.org/10.1039/c4cs00078a

Chai X, Dong H, Zhang Z, Qi Z, Chen J, Huang Z, Ye C, Qiu T (2022) A novel Zr-MOF modified by 4,6-diamino-2-mercaptopyrimidine for exceptional Hg (II) removal. J Water Process Eng 46:102606. https://doi.org/10.1016/j.jwpe.2022.102606

Chalati T, Horcajada P, Gref R, Couvreur P, Serre C (2011) Optimisation of the synthesis of MOF nanoparticles made of flexible porous iron fumarate MIL-88A. J Mater Chem 21:2220–2227. https://doi.org/10.1039/c0jm03563g

Cheang T, Huang W, Li W, Ren S, Wen H, Zhou T, Zhang Y, Lin W (2022) Exposed carboxyl functionalized MIL-101 derivatives for rapid and efficient extraction of heavy metals from aqueous solution. Colloids Surfaces A Physicochem Eng Asp 649:129517. https://doi.org/10.1016/j.colsurfa.2022.129517

Chen D, Zhao J, Zhang P, Dai S (2019) Mechanochemical synthesis of metal–organic frameworks. Polyhedron 162:59–64. https://doi.org/10.1016/j.poly.2019.01.024

Chen Y, Ma J, Yang H, Ji H, Li W, Pi Y, Pang H (2023a) Application of modified metal-organic frameworks in water treatment. Mater. Today Chem 30. https://doi.org/10.1016/j.mtchem.2023.101577

Chen Z, Li Y, Cai Y, Wang S, Hu B, Li B, Ding X, Zhuang L, Wang X (2023b) Application of covalent organic frameworks and metal–organic frameworks nanomaterials in organic/inorganic pollutants removal from solutions through sorption-catalysis strategies. Carbon Res 2. https://doi.org/10.1007/s44246-023-00041-9

Chowdhury T, Zhang L, Zhang J, Aggarwal S (2021) Pb(ii) adsorption from aqueous solution by an aluminum-based metal organic framework-graphene oxide nanocomposite. Mater Adv 2:3051–3059. https://doi.org/10.1039/d1ma00046b

Chowdhury T, Zhang L, Zhang J, Aggarwal S (2018) Removal of arsenic(III) from aqueous solution using metal organic framework-graphene oxide nanocomposite. Nanomaterials 8. https://doi.org/10.3390/NANO8121062

Crawford DE, Casaban J (2016) Recent developments in mechanochemical materials synthesis by extrusion. Adv Mater 28:5747–5754. https://doi.org/10.1002/adma.201505352

Daradmare S, Xia M, Le VN, Kim J, Park BJ (2021) Metal–organic frameworks/alginate composite beads as effective adsorbents for the removal of hexavalent chromium from aqueous solution. Chemosphere 270:129487. https://doi.org/10.1016/j.chemosphere.2020.129487

DeSantis D, Mason JA, James BD, Houchins C, Long JR, Veenstra M (2017) Techno-economic analysis of metal-organic frameworks for hydrogen and natural gas storage. Energy and Fuels 31:2024–2032. https://doi.org/10.1021/acs.energyfuels.6b02510

Ding L, Luo X, Shao P, Yang J, Sun D (2018) Thiol-functionalized Zr-based metal-organic framework for capture of Hg(II) through a proton exchange reaction. ACS Sustain Chem Eng 6:8494–8502. https://doi.org/10.1021/acssuschemeng.8b00768

Eddaoudi M, Kim J, Rosi N, Vodak D, Wachter J, O’Keeffe M, Yaghi OM (2002) Systematic design of pore size and functionality in isoreticular MOFs and their application in methane storage. Science (80-) 295:469–472. https://doi.org/10.1126/science.1067208

Efome JE, Rana D, Matsuura T, Lan CQ (2018) Insight studies on metal-organic framework nanofibrous membrane adsorption and activation for heavy metal ions removal from aqueous solution. ACS Appl Mater Interfaces 10:18619–18629. https://doi.org/10.1021/acsami.8b01454

El-Mehalmey WA, Ibrahim AH, Abugable AA, Hassan MH, Haikal RR, Karakalos SG, Zaki O, Alkordi MH (2018) Metal-organic framework@silica as a stationary phase sorbent for rapid and cost-effective removal of hexavalent chromium. J Mater Chem A 6:2742–2751. https://doi.org/10.1039/c7ta08281a

Fang Y, Wen J, Zeng G, Jia F, Zhang S, Peng Z, Zhang H (2018) Effect of mineralizing agents on the adsorption performance of metal–organic framework MIL-100(Fe) towards chromium(VI). Chem Eng J 337:532–540. https://doi.org/10.1016/j.cej.2017.12.136

Fang Z, Li Y, Huang C, Liu Q (2023) Journal of Environmental Chemical Engineering Amine functionalization of iron-based metal-organic frameworks MIL-101 for removal of arsenic species : enhanced adsorption and mechanisms. J Environ Chem Eng 11:110155. https://doi.org/10.1016/j.jece.2023.110155

Feng M, Zhang P, Zhou HC, Sharma VK (2018) Water-stable metal-organic frameworks for aqueous removal of heavy metals and radionuclides: a review. Chemosphere 209:783–800. https://doi.org/10.1016/j.chemosphere.2018.06.114

Forghani M, Azizi A, Livani MJ, Kafshgari LA (2020) Adsorption of lead(II) and chromium(VI) from aqueous environment onto metal-organic framework MIL-100(Fe): synthesis, kinetics, equilibrium and thermodynamics. J Solid State Chem 291:121636. https://doi.org/10.1016/j.jssc.2020.121636

Fu Q, Wen L, Zhang L, Chen X, Pun D, Ahmed A, Yang Y, Zhang H (2017) Preparation of ice-templated MOF-polymer composite monoliths and their application for wastewater treatment with high capacity and easy recycling. ACS Appl Mater Interfaces 9:33979–33988. https://doi.org/10.1021/acsami.7b10872

Fu L, Wang S, Lin G, Zhang L, Liu Q, Fang J, Wei C, Liu G (2019) Post-functionalization of UiO-66-NH2 by 2,5-dimercapto-1,3,4-thiadiazole for the high efficient removal of Hg(II) in water. J Hazard Mater 368:42–51. https://doi.org/10.1016/j.jhazmat.2019.01.025

Ge J, Yao H. Bin, Hu W, Yu XF, Yan YX, Mao LB, Li HH, Li SS, Yu SH (2013) Facile dip coating processed graphene/MnO2 nanostructured sponges as high performance supercapacitor electrodes. Nano Energy 2:505–513. https://doi.org/10.1016/j.nanoen.2012.12.002

Ghanbarian M, Zeinali S, Mostafavi A (2018) A novel MIL-53(Cr-Fe)/Ag/CNT nanocomposite based resistive sensor for sensing of volatile organic compounds. Sensors Actuators B Chem 267:381–391. https://doi.org/10.1016/j.snb.2018.02.138

Ghumman ASM, Shamsuddin R, Nasef MM, Yahya WZN, Abbasi A, Almohamadi H (2022) Sulfur enriched slow-release coated urea produced from inverse vulcanized copolymer. Sci Total Environ 846:157417. https://doi.org/10.1016/j.scitotenv.2022.157417

Ghumman ASM, Shamsuddin R, Nasef MM, Krivoborodov EG, Ahmad S, Zanin AA, Mezhuev YO, Abbasi A (2021) A degradable inverse vulcanized copolymer as a coating material for urea produced under optimized conditions. Polymers (Basel) 13. https://doi.org/10.3390/polym13224040

Gopi S, Ramu AG, Yun K (2023) A highly stable mesoporous spinel ferrite (CoxFe3−xO4) derived from CoFe-MOF for efficient adsorption of ultratrace As(III) ions from aqueous solution. J Environ Chem Eng 11:110106. https://doi.org/10.1016/j.jece.2023.110106

Goyal P, Paruthi A, Menon D, Behara R, Jaiswal Keerthy AV, Kumar A, Krishnan V, Misra SK (2022) Fe doped bimetallic HKUST-1 MOF with enhanced water stability for trapping Pb(II) with high adsorption capacity. Chem Eng J 430:133088. https://doi.org/10.1016/j.cej.2021.133088

Greathouse JA, Allendorf MD (2006) The interaction of water with MOF-5 simulated by molecular dynamics. J. Am. Chem. Soc. 128:10678–10679. https://doi.org/10.1021/ja063506b

Gu Y, Xie D, Wang Y, Qin W, Zhang H (2019a) Facile fabrication of composition-tunable Fe / Mg bimetal-organic frameworks for exceptional arsenate removal. Chem Eng J 357:579–588. https://doi.org/10.1016/j.cej.2018.09.174

Gu Y, Xie D, Wang Y, Qin W, Zhang H, Wang G, Zhang Y, Zhao H (2019b) Facile fabrication of composition-tunable Fe/Mg bimetal-organic frameworks for exceptional arsenate removal. Chem Eng J 357:579–588. https://doi.org/10.1016/j.cej.2018.09.174

Guo J, Li JJ, Wang CC (2019) Adsorptive removal of Cr(VI) from simulated wastewater in MOF BUC-17 ultrafine powder. J Environ Chem Eng 7:102909. https://doi.org/10.1016/j.jece.2019.102909

Guo Z, Hou H, Zhou J, Wu X, Li Y, Hu L (2023) Fabrication of novel 3D PEI-functionalized ZIF-8@alginate aerogel composites for efficient elimination of Pb(II) and Cd(II) from aqueous solution. J Environ Chem Eng 11:110446. https://doi.org/10.1016/j.jece.2023.110446

Haghseresht F, Lu GQ (1998) Adsorption characteristics of phenolic compounds onto coal-reject-derived adsorbents. Energy and Fuels 12:1100–1107. https://doi.org/10.1021/ef9801165

Harvey PD (2023) Sustainable development in the removal and photocatalytic reduction of heavy metals in wastewaters using environmentally friendly and health benign Porphyrin-based Metal-Organic frameworks. Sep Purif Technol 322:124214. https://doi.org/10.1016/j.seppur.2023.124214

He X, Deng F, Shen T, Yang L, Chen D, Luo J, Luo X, Min X, Wang F (2019) Exceptional adsorption of arsenic by zirconium metal-organic frameworks: engineering exploration and mechanism insight. J Colloid Interface Sci 539:223–234. https://doi.org/10.1016/j.jcis.2018.12.065

Healy C, Patil KM, Wilson BH, Hermanspahn L, Harvey-Reid NC, Howard BI, Kleinjan C, Kolien J, Payet F, Telfer SG, Kruger PE, Bennett TD (2020) The thermal stability of metal-organic frameworks. Coord Chem Rev 419:213388. https://doi.org/10.1016/j.ccr.2020.213388

Hou X, Zhou H, Zhang J, Cai Y, Huang F, Wei Q (2018) High adsorption pearl-necklace-like composite membrane based on metal–organic framework for heavy metal ion removal. Part Part Syst Charact 35. https://doi.org/10.1002/ppsc.201700438

Hu S-Z, Huang T, Zhang N, Lei Y-Z, Wang Y (2022) Chitosan-assisted MOFs dispersion via covalent bonding interaction toward highly efficient removal of heavy metal ions from wastewater. Carbohydr. Polym. 277:118809. https://doi.org/10.1016/j.carbpol.2021.118809

Huang L, He M, Chen B, Hu B (2016) A mercapto functionalized magnetic Zr-MOF by solvent-assisted ligand exchange for Hg2+ removal from water. J Mater Chem A 4:5159–5166. https://doi.org/10.1039/c6ta00343e

Huang Z, Xiong C, Ying L, Wang W, Wang S, Ding J, Lu J (2022) A post-functional Ti-based MOFs composite for selective removal of Pb (II) from water. J Hazard Mater 432:128700. https://doi.org/10.1016/j.jhazmat.2022.128700

Ighalo JO, Rangabhashiyam S, Dulta K, Umeh CT, Iwuozor KO, Aniagor CO, Eshiemogie SO, Iwuchukwu FU, Igwegbe CA (2022) Recent advances in hydrochar application for the adsorptive removal of wastewater pollutants. Chem Eng Res Des 184:419–456. https://doi.org/10.1016/j.cherd.2022.06.028

Jeong C, Ansari MZ, Hakeem Anwer A, Kim SH, Nasar A, Shoeb M, Mashkoor F (2023) A review on metal-organic frameworks for the removal of hazardous environmental contaminants. Sep Purif Technol 305:122416. https://doi.org/10.1016/j.seppur.2022.122416

Jhung SH, Lee J, Chang J (2005) 1. Jhung 2005. Bull Korean Chem Soc 26:880–881

Jhung SH, Lee JH, Yoon JW, Serre C, Férey G, Chang JS (2007) Microwave synthesis of chromium terephthalate MIL-101 and its benzene sorption ability. Adv Mater 19:121–124. https://doi.org/10.1002/adma.200601604

Ji C, Ren Y, Yu H, Hua M, Lv L, Zhang W (2022) Highly efficient and selective Hg(II) removal from water by thiol-functionalized MOF-808: kinetic and mechanism study. Chem Eng J 430. https://doi.org/10.1016/j.cej.2021.132960

Jian M, Liu B, Zhang G, Liu R, Zhang X (2015) Adsorptive removal of arsenic from aqueous solution by zeolitic imidazolate framework-8 (ZIF-8) nanoparticles. Colloids Surfaces A Physicochem Eng Asp 465:67–76. https://doi.org/10.1016/j.colsurfa.2014.10.023

Jiang X, Su S, Rao J, Li S, Lei T, Bai H, Wang S, Yang X (2021) Magnetic metal-organic framework (Fe3O4@ZIF-8) core-shell composite for the efficient removal of Pb(II) and Cu(II) from water. J. Environ Chem Eng 9:105959. https://doi.org/10.1016/j.jece.2021.105959

Joseph L, Jun BM, Jang M, Park CM, Muñoz-Senmache JC, Hernández-Maldonado AJ, Heyden A, Yu M, Yoon Y (2019) Removal of contaminants of emerging concern by metal-organic framework nanoadsorbents: a review. Chem Eng J 369:928–946. https://doi.org/10.1016/j.cej.2019.03.173

Ke F, Qiu LG, Yuan YP, Peng FM, Jiang X, Xie AJ, Shen YH, Zhu JF (2011) Thiol-functionalization of metal-organic framework by a facile coordination-based postsynthetic strategy and enhanced removal of Hg 2+ from water. J Hazard Mater 196:36–43. https://doi.org/10.1016/j.jhazmat.2011.08.069

Khan MS, Shahid M (2022) Synthesis of metal-organic frameworks (MOFs): routes to various MOF topologies, morphologies, and composites. Electrochem. Appl Met Fram Adv Futur Potential 17–35. https://doi.org/10.1016/B978-0-323-90784-2.00007-1

Klinowski J, Almeida Paz FA, Silva P, Rocha J (2011) Microwave-assisted synthesis of metal-organic frameworks. Dalt Trans 40:321–330. https://doi.org/10.1039/c0dt00708k

Lam ITY, Yuan Y, Bang K-T, Choi S-J, Shin D-M, Lu D, Kim Y (2023) Towards the fastest kinetics and highest uptake of post-functionalized UiO-66 for Hg 2+ removal from water. Nanoscale 15:10558–10566. https://doi.org/10.1039/d3nr01959d

Laybourn A, Katrib J, Ferrari-John RS, Morris CG, Yang S, Udoudo O, Easun TL, Dodds C, Champness NR, Kingman SW, Schröder M (2017) Metal-organic frameworks in seconds via selective microwave heating. J Mater Chem A 5:7333–7338. https://doi.org/10.1039/c7ta01493g

Lee YR, Kim J, Ahn WS (2013) Synthesis of metal-organic frameworks: a mini review. Korean J Chem Eng 30:1667–1680. https://doi.org/10.1007/s11814-013-0140-6

Lee YR, Cho SM, Baeck SH, Ahn WS, Cho WS (2016) Ti-MIL-125-NH2 membrane grown on a TiO2 disc by combined microwave/ultrasonic heating: facile synthesis for catalytic application. RSC Adv 6:63286–63290. https://doi.org/10.1039/c6ra09438d

Lee DT, Zhao J, Oldham CJ, Peterson GW, Parsons GN (2017) UiO-66-NH2 metal-organic framework (MOF) nucleation on TiO2, ZnO, and Al2O3 atomic layer deposition-treated polymer fibers: role of metal oxide on MOF growth and catalytic hydrolysis of chemical warfare agent simulants. ACS Appl Mater Interfaces 9:44847–44855. https://doi.org/10.1021/acsami.7b15397

Lee YJ, Chang YJ, Lee DJ, Hsu JP (2018) Water stable metal-organic framework as adsorbent from aqueous solution: a mini-review. J Taiwan Inst Chem Eng 93:176–183. https://doi.org/10.1016/j.jtice.2018.06.035

Li M, Dincǎ M (2011) Reductive electrosynthesis of crystalline metal-organic frameworks. J Am Chem Soc 133:12926–12929. https://doi.org/10.1021/ja2041546

Li J, Wu YN, Li Z, Zhu M, Li F (2014) Characteristics of arsenate removal from water by metal-organic frameworks (MOFs). Water Sci Technol 70:1391–1397. https://doi.org/10.2166/wst.2014.390

Li X, Gao X, Ai L, Jiang J (2015) Mechanistic insight into the interaction and adsorption of Cr(VI) with zeolitic imidazolate framework-67 microcrystals from aqueous solution. Chem Eng J 274:238–246. https://doi.org/10.1016/j.cej.2015.03.127

Li L, Xu Y, Zhong D, Zhong N (2020) CTAB-surface-functionalized magnetic MOF@MOF composite adsorbent for Cr(VI) efficient removal from aqueous solution. Colloids Surfaces A Physicochem Eng Asp 586:124255. https://doi.org/10.1016/j.colsurfa.2019.124255

Li Y, Tan M, Liu G, Si D, Chen N, Zhou D (2022) Thiol-functionalized metal-organic frameworks embedded with chelator-modified magnetite for high-efficiency and recyclable mercury removal in aqueous solutions. J Mater Chem A 10:6724–6730. https://doi.org/10.1039/d1ta10906e

Li Z, Ma S, Sang L, Qu G, Zhang T, Xu B, Jin W, Zhao Y (2023) Enhanced arsenite removal from water using zirconium-ferrocene MOFs coupled with peroxymonosulfate:oxidation and multi-sites adsorption mechanism. Chemosphere 319:138044. https://doi.org/10.1016/j.chemosphere.2023.138044

Liang L, Liu L, Jiang F, Liu C, Yuan D, Chen Q, Wu D, Jiang HL, Hong M (2018a) Incorporation of In2S3 nanoparticles into a metal-organic framework for ultrafast removal of Hg from water. Inorg Chem 57:4891–4897. https://doi.org/10.1021/acs.inorgchem.7b03076