Abstract

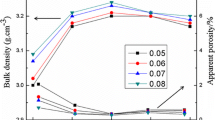

(Mg1-xZnx)2SiO4 (x = 0.2, 0.4, 0.6, 0.8) ceramics were prepared by different molding methods, the sintering characteristics and high-frequency dielectric properties of ceramics with different ratios were studied, and the optimum Mg/Zn ratio was determined under the experimental conditions. X-ray diffraction (XRD) patterns show that the specimens have a Forsterite structure when x < 0.4, while when x ≥ 0.4, the specimens have a Willemite structure. SEM images suggested that the density of hot pressing (Mg0.4Zn0.6)2SiO4 ceramics is better than that of dry pressing. The (Mg1-xZnx)2SiO4 ceramics obtained by hot pressing show an overall increase in bulk density. (Mg0.4Zn0.6)2SiO4 ceramics have the best high-frequency dielectric properties when sintered at 1325 °C, and the performance parameters of dry pressing and hot pressing are εr = 6.74, tanδ = 8.88 × 10–4 and εr = 6.36, tanδ = 1.35 × 10–3, respectively.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

References

W. Lei, W.Z. Lu, X.H. Wang, F. Liang, J. Wang, J. Am. Ceram. Soc. 94, 20 (2010). https://doi.org/10.1111/j.1551-2916.2010.04247.x

M.T. Sebastian, R. Ubic, H. Jantunen, Int. Mater. Rev. 60, 392 (2015). https://doi.org/10.1179/1743280415y.0000000007

R.J. Cava, J. Mater. Chem. 11, 54 (2001). https://doi.org/10.1039/b003681l

X. Xue, X. Li, J. Guo, H. Wang, J. Eur. Ceram. Soc. 42, 6527 (2022). https://doi.org/10.1016/j.jeurceramsoc.2022.07.047

B. Huang, T. Xia, F. Shang, G. Chen, J. Eur. Ceram. Soc. 43, 6107 (2023). https://doi.org/10.1016/j.jeurceramsoc.2023.07.004

M. Zang, M. Zheng, M. Zhu, Y. Hou, J. Eur. Ceram. Soc. 44, 293 (2024). https://doi.org/10.1016/j.jeurceramsoc.2023.09.029

P.S. Anjana, M.T. Sebastian, J. Am. Ceram. Soc. 92, 96 (2009). https://doi.org/10.1111/j.1551-2916.2008.02756.x

T.S. Sasikala, C. Pavithran, M.T. Sebastian, J. Mater. Sci. Mater. Electron. 21, 141 (2009). https://doi.org/10.1007/s10854-009-9882-7

G. Dou, D. Zhou, M. Guo, S. Gong, Y. Hu, J. Mater. Sci. Mater. Electron. 24, 1431 (2012). https://doi.org/10.1007/s10854-012-0945-9

G. Dou, D. Zhou, M. Guo, S. Gong, J. Alloys Compd. 513, 466 (2012). https://doi.org/10.1016/j.jallcom.2011.10.089

O. Tamada, K. Fujino, S. Sasaki, ACTA CRYSTALLOGR B. 39, 692 (1983). https://doi.org/10.1107/s0108768183003250

K. Sohn, B. Cho, H. Chang, H.D. Park, J. Electrochem. Soc. 146, 2353 (1999). https://doi.org/10.1149/1.1391939

T. Tsunooka, T. Sugiyama, H. Ohsato, K. Kakimoto, M. Andou, Y. Higashida, H. Sugiura, Key Eng. Mater. 269, 199 (2004). https://doi.org/10.4028/www.scientific.net/kem.269.199

C. Kosanović, N. Stubičar, N. Tomašić, V. Bermanec, M. Stubičar, J. Alloys Compd. 389, 306 (2005). https://doi.org/10.1016/j.jallcom.2004.08.015

Y. Guo, H. Ohsato, K. Kakimoto, J. Eur. Ceram. Soc. 26, 1827 (2006). https://doi.org/10.1016/j.jeurceramsoc.2005.09.008

T. Tsunooka, M. Ando, S. Suzuki, Y. Yasufuku, and H. Ohsato, Jpn. J. Appl. Phys. 52, 09KH02 (2013) https://doi.org/10.7567/jjap.52.09kh02

E.R. Segnit, A.E. Holland, J. Am. Ceram. Soc. 48, 409 (1965). https://doi.org/10.1111/j.1151-2916.1965.tb14778

K.X. Song, X.M. Chen, C.W. Zheng, Ceram. Int. 34, 917 (2008). https://doi.org/10.1016/j.ceramint.2007.09.057

Z. Ye, J. Li, G. Wang, Z. Qi, G. Gan, Y. Yang, H. Zhang, Mater. Res. Express. 6, 106313 (2019). https://doi.org/10.1088/2053-1591/ab3f1b

B. Li, Y. Yuan, S. Zhang, H. Jiang, Bull. Mater. Sci. 34, 921 (2011). https://doi.org/10.1007/s12034-011-0215-0

L. Li, Y. Wang, W. Xia, X. He, P. Zhang, J. Electron. Mater. 41, 684 (2012). https://doi.org/10.1007/s11664-011-1899-z

J. Luo, X.R. Xing, R.B. Yu, Q.F. Xing, G.R. Liu, D.F. Zhang, X.L. Chen, J. Alloys Compd. 420, 317 (2006). https://doi.org/10.1016/j.jallcom.2005.10.050

K. Zhang, X. Liu, N. Bai, Z. Li, Q. Wu, Z. Yang, J. Mater. Sci. Mater. Electron. 32, 4090 (2021). https://doi.org/10.1007/s10854-020-05150-4

J. Luo, X.R. Xing, R.B. Yu, Q.F. Xing, D.F. Zhang, X.L. Chen, J. Alloys Compd. 402, 263 (2005). https://doi.org/10.1016/j.jallcom.2005.04.153

Z. Huang, J. Qiao, L. Li, Ceram. Int. 49, 37017 (2023). https://doi.org/10.1016/j.ceramint.2023.09.034

Y. Zhang, Y. Yao, J. Ren, H. Kong, B. Wang, Z. Wang, Z. Zhang, J. Wang, J. Alloys Compd. 829, 154546 (2020). https://doi.org/10.1016/j.jallcom.2020.154546

Y. Lai, X. Tang, H. Zhang, X. Liang, X. Huang, Y. Li, H. Su, Mater. Res. Bull. 99, 496 (2018). https://doi.org/10.1016/j.materresbull.2017.11.036

L. Lu, A.N. Chen, Y. Chen, L.J. Cheng, J.M. Wu, R.Z. Liu, Y.S. Shi, Ceram. Int. 47, 4055 (2021). https://doi.org/10.1016/j.ceramint.2020.09.277

Acknowledgements

This work was supported by the National Natural Science Foundation of China [grant number 52272123], the National Key Basic Research and Development Project Subproject [grant number 2017YFC0703204], and the Science and Technology Project of Shaanxi Provincial Market Supervision Administration [grant number 2022KY20].

Funding

This work was supported by the National Natural Science Foundation of China [grant number 52272123], the National Key Basic Research and Development Project Subproject [grant number 2017YFC0703204], and the Science and Technology Project of Shaanxi Provincial Market Supervision Administration [grant number 2022KY20].

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Hanbi Zhang and Kai Zhang designed the experiments. Material preparation, data collection, and analysis were performed by Jiayan Guan, Danni Chen, Miao Zhang, and Ziyao Wei. Xiangchun Liu and Feng Gao contributed reagents/materials/analysis tools and participated in the data discussion. The first draft of the manuscript was written by Hanbi Zhang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, H., Liu, X., Zhang, K. et al. Effect of molding process on sintering and properties of (Mg1-xZnx)2SiO4 high-frequency dielectric ceramics. J Mater Sci: Mater Electron 35, 1702 (2024). https://doi.org/10.1007/s10854-024-13440-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-13440-4