Abstract

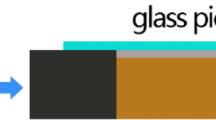

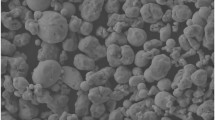

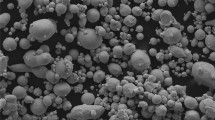

Cu/Sn-9Zn-30Cu/Cu 3D packaging solder joints were prepared by transient liquid phase (TLP) bonding. The effect of bonding time on microstructure, shear strength, and fracture surfaces of the solder joints was studied. The results show that the interface reaction zone of Cu/Sn-9Zn-30Cu/Cu solder joints consisted of Cu6(Sn, Zn)5 phase and Cu3Sn phase at a bonding time of 15 min. With increasing bonding time, the scallop-type Cu6(Sn, Zn)5 phase gradually transformed into the layer-type Cu3Sn phase, and the thickness of the interfacial intermetallic compound (IMC) layer gradually increased. The interfacial reaction zone entirely consisted of the layer-type Cu3Sn after bonding for 60 min. The in situ reaction zone of Cu/Sn-9Zn-30Cu/Cu solder joint consisted of Cu6(Sn, Zn)5, Cu3Sn, Cu particles, and Zn-rich phase at a bonding time of 15 min. The Cu6(Sn, Zn)5 increased content and evenly distributed in the in situ reaction zone at 30 min, resulting the microstructure gradually refined. The Zn-rich phase disappeared in the in situ reaction zone after bonding 90 min, and the in situ microstructure gradually coarsened and cracks initiated as bonding time increased. The shear strength of solder joints first increased and then declined with increasing bonding time, and the maximum shear strength reached 22.25 MPa at a bonding time of 60 min. The fracture location of the solder joint shifted from the in situ reaction zone to the interface reaction zone with increasing bonding time, and the fracture mechanism of the solder joints always exhibited brittle fracture.

Similar content being viewed by others

Data availability

The data provided in this study can be obtained from the corresponding author upon reasonable request.

References

Y. Liu, Y. Bai, J. Chen, H. Chen, Z. Zhu, Y. Li, Control of intermetallic compounds in ultrasonic-assisted Sn soldering of Mg/Al alloys. Mater. Des. 223, 111235 (2022)

Z. Xu, Z. Li, Z. Xu, Z. Ma, S. Chen, X. Liu, J. Yan, Avoiding degradation and increasing joint strength of Al alloys by rapid ultrasonic soldering at low temperature. J. Mater. Process. Technol. 300, 117397 (2022)

M. Zhang, Z. Ma, G. Chen, F. Xia, X. Yu, Spreading behavior of molten solder with alternative currents under the action of electromagnetic ultrasound. J Mater Res Technol. 18, 3700 (2022)

Z. Liu, X.Y. Wang, L. Yang, L.B. Sun, X.X. Jiao, H.M. Gao, Z.T. Zhang, Y.C. Zhang, Microstructure and shear properties of Sn-xZn transient liquid phase bonding in 3D-Chip stacking packaging. Trans. Indian Inst. Met. 76, 2757 (2023)

F. Li, C. Pu, C. Li, J. Yang, Y. Jia, C. Geng, X. Zhang, Q. Bao, S. Guo, J. Yi, J. Zhang, Study on the effects of Ag addition on the mechanical properties and oxidation resistance of Sn-Zn lead-free solder alloy by high-throughput method. J. Mater. Sci-Mater. El. (2023). https://doi.org/10.1007/s10854-022-09756-8

A.K. Gain, L. Zhang, Nanoindentation Creep, elastic properties, and shear strength correlated with the structure of Sn-9Zn-0.5nano-Ag alloy for advanced green electronics. Metals. 10, 1137 (2020)

J.Y. Li, J. Peng, R.C. Wang, Y. Feng, C.Q. Peng, Effects of Co addition on shear strength and interfacial microstructure of Sn-Zn-(Co)/Ni joints. J. Mater. Sci-Mater. El. 29, 19901 (2018)

Y. Hu, S. Xue, H. Ye, Z. Xiao, L. Gao, G. Zeng, Reliability studies of Sn-9Zn/Cu and Sn-9Zn-0.06Nd/Cu joints with aging treatment. Mater. Des. 34, 768 (2012)

D. Jaiswal, S. Kumar, C.K. Behera, Electrochemical behavior of Sn-9Zn-xCu solder alloy in 3.5 wt% NaCl solution at room temperature. Mater. Today Commun. 33, 104627 (2022)

M.L. Huang, N. Kang, Q. Zhou, Y.Z. Huang, Effect of Ni Content on Mechanical Properties and Corrosion Behavior of Al/Sn-9Zn-xNi/Cu Joints. J. Mater. Sci. Technol. 28, 844 (2012)

Y.Z. Peng, C.J. Li, J.J. Yang, J.T. Zhang, J.B. Peng, G.J. Zhou, C.J. Pu, J.H. Yi, Effects of Bismuth on the Microstructure, Properties, and Interfacial Reaction Layers of Sn-9Zn-xBi Solders. Metals. 11, 538 (2021)

Y.-A. Shen, Effect of indium addition on mechanical, thermal, and soldering properties of eutectic Sn-9Zn alloy. Mater. Chem. Phys. 315, 128992 (2024)

R. Yi, C. Chen, H. Li, Y. Ma, Ultrasonic soldering silica glass and 2024 alloy in low temperature. Sci. Technol. Weld. Joining 27, 455 (2022)

L. Yang, H. Wu, Y. Zhang, K. Lu, Q. Lin, Effect of CuZnAl particle addition on the microstructure and shear property of Cu/In-48Sn/Cu solder joints by transient liquid phase bonding. Weld. World. 68, 61 (2023)

N.R.A. Razak, X.-F. Tan, M.A.A.M. Salleh, S.D. McDonald, M.J. Bermingham, H. Yasuda, K. Nogita, Controlling the distribution of porosity during transient liquid phase bonding of Sn-based solder joint. Mater. Today Commun. 31, 103248 (2022)

Z.Y. Wu, T.C. Wang, Y.C. Wang, R.W. Song, S.Y. Tsai, J.G. Duh, Enhancing mechanical properties via adding Ni and Zn in Cu/Sn3.5Ag/Cu transient liquid phase bonding for advanced electronic packaging. J. Mater. Sci-Mater. El. 33, 3016 (2022)

L. Yang, J. Qiao, Y.C. Zhang, H.M. Gao, Y. Yang, F. Xu, Effect of bonding time on microstructure and shear property of Cu/In-50Ag/Cu TLP solder joints. J. Electron. Mater. 49, 4300 (2020)

L. Yang, Y. Yang, Y. Zhang, F. Xu, J. Qiao, W. Lu, B. Yu, Microstructure evolution and mechanical properties of the In-Sn-20Cu composite particles TLP bonding solder joints. Appl Phys A-Mater. 126, 343 (2020)

Y. Tang, G.Y. Li, S.M. Luo, K.Q. Wang, B. Zhou, Diffusion wave model and growth kinetics of interfacial intermetallic compounds in Sn-3.0Ag-0.5Cu-xTiO2 solder joints. J. Mater. Sci-Mater. El. 26, 3196 (2015)

C.Y. Yu, J.G. Duh, Stabilization of hexagonal Cu6(Sn, Zn)5 by minor Zn doping of Sn-based solder joints. Scr. Mater. 65, 783 (2011)

L. Cornet, L. Yedra, E. Héripré, V. Aubin, J.H. Schmitt, M.L. Giorgi, In situ TEM characterization of phase transformations and kirkendall void formation during annealing of a Cu-Au-Sn-Cu diffusion bonding joint. J. Electron. Mater. 51, 1568 (2022)

V. Vuorinen, G. Ross, A. Klami, H. Dong, M. Paulasto-Krockel, T. Wernicke, A. Poenninger, Demonstrating 170 °C low-temperature Cu-In-Sn wafer-level solid liquid interdiffusion bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 12, 446 (2022)

Y. Yang, Y. Li, H. Lu, C. Yu, J. Chen, First-principles calculations of Zn substitutions in Cu6Sn5. Comput. Mater. Sci. 65, 490 (2012)

Y.W. Wang, T.L. Yang, J.Y. Wu, C.R. Kao, Pronounced effects of Zn additions on Cu-Sn microjoints for chip-stacking applications. J. Alloys Compd. 750, 570 (2018)

J. Chen, H. Zhang, P. Zhang, Z. Yu, Y. Zhang, C. Yu, H. Lu, The Zn accumulation behavior, phase evolution and void formation in Sn-xZn/Cu systems by considering trace Zn: a combined experimental and theoretical study. J Mater Res Technol. 8, 4141 (2019)

M. Xiong, L. Zhang, L. Sun, P. He, W. Long, Effect of CuZnAl particles addition on microstructure of Cu/Sn58Bi/Cu TLP bonding solder joints. Vacuum 167, 301 (2019)

C. Chen, L. Zhang, X. Wang, X. Lu, Y. Guo, Microstructure and properties of Sn58Bi/Ni solder joint modified by Mg particles. J Mater Res Technol. 24, 514 (2023)

Y. Tian, N. Ren, Z. Zhao, F. Wu, S.K. Sitaraman, Ag3Sn compounds coarsening behaviors in micro-joints. Materials. 11, 2509 (2018)

I. Ahmad, M.F.M. Nazeri, N.-A. Salleh, S. Kheawhom, A.M. Erer, A. Kurt, A.A. Mohamad, Selective electrochemical etching of the Sn-3Ag-0.5Cu/0.07 wt% graphene nanoparticle composite solder. Arabian J. Chem. 14, 103392 (2021)

Y. Zhang, X. Xu, Machine learning tensile strength and impact toughness of wheat straw reinforced composites. Mach. Learn. Appl. 6, 100188 (2021)

Y. Zhang, X. Xu, Modulus of elasticity predictions through LSBoost for concrete of normal and high strength. Mater. Chem. Phys. 283, 126007 (2022)

S. Dong, J. Zhou, D. Hui, Y. Wang, S. Zhang, Size dependent strengthening mechanisms in carbon nanotube reinforced metal matrix composites. Compos. Part A Appl. Sci. Manuf. 68, 356 (2015)

D. Cao, Q. Duan, S. Li, Y. Zhong, H. Hu, Effects of thermal residual stresses and thermal-induced geometrically necessary dislocations on size-dependent strengthening of particle-reinforced MMCs. Compos. Struct. 200, 290 (2018)

J.C. Shao, B.L. Xiao, Q.Z. Wang, Z.Y. Ma, K. Yang, An enhanced FEM model for particle size dependent flow strengthening and interface damage in particle reinforced metal matrix composites. Compos. Sci. Technol. 71, 39 (2011)

Y. Zhang, X. Xu, Predicting springback radii and angles in air bending of high-strength sheet steel through gaussian process regressions. Int. J. Interact. Des. Manuf.—Ijidem. 16, 863 (2022)

J. Chen, Y.S. Lai, P.F. Yang, C.Y. Ren, D.J. Huang, Structural and elastic properties of Cu6Sn5 and Cu3Sn from first-principles calculations. J. Mater. Res. 24, 2361 (2009)

W.Q. Shao, C.Y. Yu, W.C. Lu, J.G. Duh, S.O. Chen, Study of the Zn occupancy leading to the stability improvement for Cu6Sn5 using a first-principles approach. Mater. Lett. 93, 300 (2013)

Acknowledgements

This research was financially supported by the National Natural Science Foundation of China (Grant No. 52165068), the Natural Science Foundation of Guangdong Province (Grant No. 2024A1515012861).

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 52165068), the Natural Science Foundation of Guangdong Province (Grant No. 2024A1515012861).

Author information

Authors and Affiliations

Contributions

All authors contributed to the conception and design of the research. Yuezhang Yang: Sample preparation, Data analysis, Writing. Zheng Liu: Survey, Methodology. Li Yang and Yaocheng Zhang: Supervision, Review, Modification. Huiming Gao and Zhitao Zhang: Data collection.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest related to this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Y., Liu, Z., Yang, L. et al. Effect of bonding time on reliability of Cu/Sn-9Zn-30Cu/Cu solder joints for 3D packaging. J Mater Sci: Mater Electron 35, 1394 (2024). https://doi.org/10.1007/s10854-024-13146-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-13146-7