Abstract

The regularities of the influence on the magnetic properties of temperature and the strength of the longitudinal magnetic field, which is much less than the saturation field, during annealing of an amorphous soft magnetic alloy based on Fe were studied. The possibility of efficiency of such treatment in comparison with traditional annealing without a field is demonstrated. It is shown that the change in magnetic properties during annealing is not related to the crystallization processes of the amorphous alloy. Annealing in unsaturated field at a temperature of 410 °C showed the greatest efficiency in achieving the highest soft magnetic properties of the alloy (low coercive force Hc = 3 A/m, high maximum and low-field permeability µmax = 101,000, µ2 = 5019) among short-term treatments with a holding time of 10 min. The results obtained are discussed taking into account the processes of magnetic anisotropy induction and stress relaxation in the alloy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Magnetically soft amorphous materials are widely used in electrical engineering and instrumentation for the manufacture of transformer cores, chokes of electromagnetic interference suppression filters, magnetic screens, sensors and other products, so the research of soft magnetic materials is still a very crucial topic [1]. Amorphous soft magnetic alloys based on Fe are often used in the manufacture of various electrical devices due to their good soft magnetic properties (low coercive force and core losses and high magnetic permeability), which, in particular, make it possible to achieve energy saving when it is used in industry. Almost always, in order to improve soft magnetic properties annealing without a magnetic field or annealing in a magnetic field is used [2,3,4,5,6,7].

The main processes during heat treatment affecting the magnetic properties of amorphous alloys are stress relaxation and induction of magnetic anisotropy due to directional ordering [8]. Stress relaxation reduces magnetoelastic anisotropy and, as a rule, facilitates the processes of remagnetization. The induction of magnetic anisotropy by annealing below the Curie point in a saturating magnetic field allows, if necessary, to create a macroscopic axis of light magnetization along the axis of the amorphous ribbon (annealing in a longitudinal magnetic field) or perpendicular to this axis (annealing in a transverse magnetic field) [9,10,11,12,13]. In this case, a rectangular hysteresis loop can be formed in the first case (the squareness coefficient of the hysteresis loop Ks = Br/Bm (where Br is the residual induction, Bm is the maximum induction), is greater than 0.9), and in the second case, a linear hysteresis loop (Ks is less than 0.1).

Annealing below the Curie point without a magnetic field leads to the induction of magnetic anisotropy inside the domain boundaries and their stabilization [8, 14], which inevitably leads to degradation of the soft magnetic properties of the amorphous alloy [15]. To destabilize the domain boundaries, a larger field can be applied during heat treatment (annealing in a magnetic field that exceeds the saturation field for this alloy in magnitude) [7]. Annealing in a rotating magnetic field [16] or annealing above the Curie point followed by rapid cooling can also be used to combat this negative effect of domain boundary stabilization due to directional ordering [2]. But to create a rotating magnetic field, complex equipment is needed, besides, the method is not applicable to the most commonly used in practice ring samples obtained by winding an amorphous ribbon on a mandrel. The second method is not applicable in the case of alloys with a Curie temperature above the crystallization start temperature.

In this article, annealing below the Curie point in unsaturated magnetic field is considered as another way to avoid stabilization of domain boundaries due to directional ordering [17]. The value of the field during annealing is selected individually for each alloy, but in order of intensity corresponds to the field of maximum permeability for this alloy in the rapid-quenched state [18]. This field is much lower than the saturation field, but should be large enough to lead to the almost complete disappearance of the ferromagnetic domain structure. In such a field, there are no movable domain boundaries in a ferromagnet [19], and therefore, during annealing, there is no stabilization of domain boundaries and deterioration of soft magnetic properties.

Earlier in [20] it was shown that annealing in a small magnetic field with an induction of 250 µT (which approximately corresponds to a strength of 200 A/m) can be effectively used as a way to improve the magnetically soft properties of the amorphous Fe80Si9B11 alloy. However, in the existing studies, the effect of annealing in fields corresponding in order of intensity to the field of maximum permeability of amorphous alloys (about one-tens of A/m) on the formation of hysteresis magnetic properties has not been investigated anywhere.

Therefore, the aim of this work was to study the regularities of the influence of temperature, as well as the strength of the unsaturated magnetic field during annealing on the magnetic properties of an amorphous Fe–Ni–Si–B alloy. As a result of studying these regularities, it is possible to obtain the state of an amorphous alloy with a reduced coercive force, which can be further used in the manufacture of magnetic circuits of such products as saturation chokes, transformers and circuit breaker devices.

2 Materials and methods

The material for the study in this work was an industrial amorphous soft magnetic alloy of the 2NSR brand with an average chemical composition of Fe77Ni1Si9B13 (the numbers in the formula represent the values of the atomic fractions of a chemical element, expressed as a percentage), which was produced at Ashinskiy Metallurgical Works.

The elemental composition of the alloy under study was monitored using an EDX microanalyser on a TESCAN VEGA3 SB scanning electron microscope. A typical EDX spectrum obtained from a section of an amorphous ribbon is shown in Fig. 1.

The samples for heat treatment and further studies had a toroidal shape and were obtained by winding an amorphous ribbon onto a ceramic mandrel with a diameter of 15 mm. The ribbon was obtained by spinning the melt using a single-roll method and had a width of 10 mm and a thickness of 25 µm.

The heat treatment of the samples was carried out in a resistance furnace in an air atmosphere at temperatures from 150 to 425 °C. The holding time was 10 min. The magnetic field was created by passing current from a stabilized power source through the magnetizing winding of the ring sample. The field was turned on at the start of holding and turned off when the sample was cooled to 80 °C. After holding, the samples were cooled in air.

The treatment temperatures were selected based on the work [21] in order to achieve varying degrees of completeness of stress relaxation processes during annealing.

The strength of the longitudinal magnetic field applied to the samples during annealing and created using a DC source corresponded to the maximum permeability field for the Fe77Ni1Si9B13 alloy in the rapid-quenched state (before heat treatment), as well as its twofold and 20-fold values (16, 32 and 320 A/m, respectively).

To evaluate the efficiency of annealing in unsaturated magnetic field in terms of the possibility of improving the soft magnetic properties, annealing without a magnetic field was also carried out on samples of an amorphous alloy at similar temperatures and holding time.

Static hysteresis loops and magnetization curves for amorphous alloy samples before and after heat treatment were measured by induction-pulse method on an automatic magnetic measuring unit MK-3E in a maximum field of 800 A/m. The relative measurement error for a confidence probability of 0.95 when measuring coercive force does not exceed 2%, when measuring magnetic permeability—5%.

The amorphousness of the alloy ribbons in the rapid-quenched state, as well as after heat treatment, was checked by X-ray diffraction with Co-Kα radiation with a shooting step of 0.1° at an exposure value of 3 s.

To assess the degree of relaxation of quenching stresses in an amorphous ribbon during heat treatment, the degree of relaxation of bending stresses was determined by the Luborsky method [22]. The stress relaxation parameter γ, which characterizes the proportion of bending stresses that did not relax during annealing, was determined by subtracting from the unit the ratio of the radius of the mandrel R0, on which one turn of the amorphous ribbon was wound before processing, to the residual radius of curvature RT of the ribbon after annealing and removal from the mandrel: γ = 1 − R0/RT.

3 Results and discussion

Figure 2 shows a graph of the dependence of the parameter γ, which characterizes the degree of relaxation of quenching stresses in an amorphous ribbon, on the temperature of annealing in a magnetic field.

As a result of atomic rearrangements in the amorphous phase, its structure changes in the direction corresponding to the most equilibrium state during annealing under the influence of bending stresses arising when winding an amorphous ribbon on a cylindrical mandrel. As a consequence, bending stresses in the ribbon decrease to a certain level—due to atomic rearrangements, relaxation of these stresses occurs [21, 23].

With an increase in the annealing temperature, the value of the stress relaxation parameter γ did not change to a temperature of 150 °C, and then decreased from the initial value of 1. Thus, annealing of amorphous alloy samples at a temperature of 250 °C or more with a holding time of 10 min led to the development of bending stress relaxation processes, the degree of completeness of which differed at different processing temperatures—in the case of an annealing temperature of 250 °C, less than 50% of the stresses in the amorphous ribbon were relaxed (γ = 0.66), and at annealing temperatures above 350 °C—more than 90% (γ less than 0.1). The process of stress relaxation in an amorphous ribbon is inextricably linked with the rate of diffusion of atoms at the selected processing temperature. Thus, at annealing temperatures below 350 °C, the diffusion rate is low, as a result of which short-term annealing does not lead to complete or almost complete stress relaxation. On the contrary, due to the high diffusion rate in the case of an annealing temperature of 425 °C with a short-term holding of 10 min, a completely relaxed state (γ = 0) can be obtained.

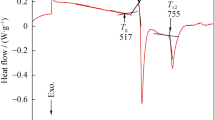

Figure 3 shows X-ray diffraction spectra from samples of amorphous alloy Fe77Ni1Si9B13 after spinning, as well as after heat treatment at a maximum temperature of 425 °C for this study with a holding time of 10 min (unsaturated magnetic field annealing (UMFA), as well as non-field annealing (NFA)). On all the spectra, only a diffuse diffraction maximum (amorphous halo) can be observed, which indicates the presence of only an amorphous phase in the studied samples.

Based on stress relaxation data, for further study of the effect of the unsaturated magnetic field during annealing on magnetic properties, a processing temperature of 410 °C was selected, at which annealing does not lead to the development of crystallization processes, but provides almost full completion of relaxation processes in an amorphous ribbon. The dependencies of the magnetic properties of an amorphous alloy on the intensity of the unsaturated magnetic field corresponding to the maximum permeability field for the Fe77Ni1Si9B13 alloy in the rapid-quenched state (before heat treatment), as well as its twofold and 20-fold values, when annealed at a temperature of 410 °C with a holding time of 10 min are shown in Fig. 4.

For comparison, Fig. 4 also shows the magnetic properties of an amorphous alloy in a rapid-quenched state, as well as after annealing without a magnetic field. It is worth noting that all the studied samples of amorphous alloy are characterized by a higher level of soft magnetic properties compared to the sample before heat treatment, which may be due to the elimination of internal quenching stresses [23, 24]. The application of a magnetic field with a strength of 16 and 32 A/m during annealing reduces the coercive force of an amorphous alloy more significantly than during annealing without a field (by 17 and 33%, respectively). A further increase in the field during annealing to 320 A/m leads to a smaller decrease in the coercive force (by 7% compared to annealing without a field). At the same time, the smallest coercive force was obtained after annealing in a magnetic field with a strength of 32 A/m. It should be noted that in terms of establishing the possibility of an additional increase in the maximum magnetic permeability compared to annealing without a field, there are practically no differences from the application of a magnetic field during annealing by values equal to two and twenty times the values of the maximum permeability field (the difference in the values of maximum permeability after these treatments was less than 7%). At the same time, in the case of a field with annealing of 320 A/m, the lowest low-field permeability of µ2 (measured in a field of 2 A/m) is observed.

At the same time, analyzing the values of the squareness coefficient of the hysteresis loop Ks for samples of an amorphous alloy, it can be argued that after annealing in a magnetic field of 16 A/m, an almost completely magnetic isotropic state was obtained (Ks was about 0.5), while after treatments in fields of 32 and 320 A/m for samples, Ks turned out to be almost identical and amounted to more than 0.7, which indicates a significant and similar degree of magnetic anisotropy, as well as that the proportion of longitudinal domains in these samples is higher than the transverse ones. Since magnetization by shifting the domain boundaries, characteristic in the presence of a longitudinal magnetic texture in the sample, occurs more easily than by rotating the vectors of spontaneous magnetization, this also explains the higher level of maximum magnetic permeability for samples after annealing in the fields of 32 and 320 A/m. At the same time, a high degree of longitudinal magnetic texture leads to a decrease in low-field permeability, which was also observed in this study [25].

The intermediate value of the coercive force for an amorphous alloy sample after annealing in a field of 16 A/m in comparison with the other two analyzed treatments demonstrates the need to create a longitudinal magnetic texture in an amorphous ribbon to achieve a high level of magnetic properties [20, 26] (in particular, a low coercive force), however, apparently, the induction of a longitudinal magnetic anisotropy is required only in a large part (as in annealing in the field of 32 A/m), and not in almost the entire volume (as in the case of annealing in the field of 320 A/m) of a ferromagnet.

Thus, for further analysis, the field corresponding to the two-fold field of maximum permeability (32 A/m) was chosen as optimal and providing the most favorable complex of soft magnetic properties of the amorphous alloy Fe77Ni1Si9B13 during annealing.

After determining the optimal value of the magnetic field during heat treatment, a series of annealing in a magnetic field of such intensity at different temperatures was carried out, as well as annealing without a field to evaluate the effectiveness of the treatment proposed in this study.

Figure 5 shows hysteresis loops for the amorphous Fe77Ni1Si9B13 alloy in the rapid-quenched state and after annealing in unsaturated magnetic field and without a field at 150, 350 and 410 °C. The treatment temperatures for a subsequent analysis of shape of hysteresis loops were selected in order to achieve varying degrees of completeness of stress relaxation processes during annealing: the temperature 150 °C corresponds to an unrelaxed state, 350 °C—partially relaxed and 410 °C—fully relaxed.

After annealing in unsaturated field and annealing without a field at 150 °C with a holding time of 10 min, the shape of the hysteresis loops practically does not differ. Compared to the initial state, their width slightly decreased, the maximum induction Bm increased by 4–6%, the residual induction Br after UMFA increased by 4%, while after annealing Br did not change. As a result, the squareness coefficient of the hysteresis loop Ks in the case of a treatment temperature of 150 °C remained at the level of the rapid-quenched state.

As a result of heat treatments at 350 °C, hysteresis loops, both after annealing in unsaturated magnetic field and without the field, became narrower and elongated compared to the initial state: the coercive force Hc decreased due to relaxation of quenching stresses. At the same time, after annealing without a field, Bm increased by 59%, Br decreased by 13%, which is why Ks decreased by almost 45% compared to the rapid-quenched state. After annealing in unsaturated magnetic field, Bm also increased, but not so significantly (by 49%), Br remained unchanged, so Ks decreased by 31%.

The differences between hysteresis loops for an amorphous alloy after annealing without a field and annealing in unsaturated magnetic field at a temperature of 410 °C were the most noticeable: there is a significantly higher squareness of the loop after annealing in unsaturated field compared to annealing without a field due to a sharply increased Br (by 19% compared to the state before processing). Such changes in the shape of the hysteresis loop indicate the achievement of an almost magnetically isotropic state during annealing without a field at 410 °C (Ks was 0.53), while after annealing in unsaturated magnetic field, the formation of a longitudinal magnetic texture is noticeable, leading to an increase in the squareness of the hysteresis loop. The facilitated magnetization of the sample after annealing in a magnetic field leads to the fact that the induction achieved in the same fields in this sample is greater than that of the sample after annealing without a field.

Figure 6, demonstrating the dependence of the coercive force Hc on the temperature of annealing without a field and in unsaturated magnetic field, shows that the application of unsaturated longitudinal magnetic field during annealing affects the coercive force differently at different processing temperatures.

It was experimentally established that the annealing efficiency in unsaturated longitudinal magnetic field depends on the degree of stress relaxation. This is shown by a comparison of Figs. 2 and 6.

At a processing temperature of 150 °C, in the absence of relaxation processes in the amorphous ribbon, the application of unsaturated magnetic field during annealing does not affect the coercive force. At temperatures from 250 to 350 °C, when the samples are in a partially relaxed state, annealing without a field reduces the coercive force more strongly than annealing in unsaturated field—the difference in Hc values between annealing in a magnetic field and without a field at different temperatures from the specified range was from 7 to 23%. In other words, at such processing temperatures, the application of a magnetic field during annealing reduces the efficiency of heat treatment.

The higher coercive force in the case of processing temperatures 250–350 °C after annealing in unsaturated magnetic field compared to annealing without a field can be explained by the fact that with an increase of the temperature of annealing in a magnetic field, the constant of induced magnetic anisotropy Ki should increase so that it becomes comparable to the constant of magneto-elastic anisotropy Kme, which decreases with stress relaxation. The formation of a special magnetic-anisotropic state of the sample during annealing in unsaturated magnetic field may become noticeable: the macroscopic axis of the easy magnetization is not induced in the entire volume (as with conventional annealing in a magnetic field in the saturation field), but only in that part of it that is magnetized by a displacement of the domain boundaries by 180°. The consequence of this is an increase in the effective anisotropy constant Keff = Kme + Ki and an increase in the specific energy of the 180-degree boundaries of the region and its coordinate derivative. As a result, coercive force should increase. Experimental data and a model confirming such an effect of uniaxial magnetic anisotropy on Hc are given, for example, in [27]. The considered reason for the growth of Hc when an additional uniaxial magnetic anisotropy is induced in longitudinally magnetized regions can serve as one of the possible explanations of the lower Hc after annealing without a field compared to annealing in unsaturated magnetic field. However, further research is required for a more detailed consideration of this issue.

At processing temperatures from 375 to 410 °C, efficiency of annealing in unsaturated magnetic field in terms of reducing the coercive force of amorphous alloy samples turned out to be higher than annealing without a field—by 3–48% at different processing temperatures. The greatest effect of annealing in unsaturated magnetic field was achieved at a temperature of 410 °C (Hc = 3 A/m), in an almost completely relaxed state of the amorphous ribbon (less than 3% of the initial level of bending stresses in the ribbon did not relax).

Figure 7 shows the dependencies of the maximum and low-field permeability of an amorphous alloy on the temperature of annealing in a magnetic field and without a field.

The maximum permeability of the amorphous alloy Fe77Ni1Si9B13 after annealing in unsaturated magnetic field at all analyzed temperatures was higher by 7–121% compared to the values after annealing without a field. At the same time, with an increase in the temperature of heat treatment, the difference in maximum permeability for samples after annealing in the field and without the field also increased. Such behavior of the maximum permeability during annealing in a magnetic field may be due to partial induction of uniaxial longitudinal magnetic anisotropy in the part of the ferromagnet that is magnetized by the displacement of 180-degree domain boundaries [13, 20, 26]. Partially induced longitudinal magnetic anisotropy may also be the cause of reduced values of low-field permeability after annealing in a magnetic field at temperatures of 375, 400 and 425 °C [28].

It is worth noting that after annealing without a field at a temperature of 410 °C, a minimum is observed on the low-field permeability curve µ2 of the annealing temperature. In addition, annealing without a field at such a temperature led to an increase in the coercive force compared to its minimum value achieved during annealing without a field at a temperature of 400 °C. Such degradation of magnetic properties during annealing without a field at 410 °C may indicate the greatest intensity of the processes of domain boundary stabilization due to directional ordering, which were previously observed by many researchers [2, 16]. Then, the presence of a pronounced maximum at the point corresponding to annealing in unsaturated magnetic field at a temperature of 410 °C on the low-field permeability curve, as well as a minimum of coercive force, can be interpreted as an effect of destabilization of domain boundaries due to directional ordering due to the application of a sufficient magnetic field during annealing.

Figure 8 shows the squareness coefficient of the hysteresis loop Ks of the amorphous alloy Fe77Ni1Si9B13 depending on the temperature of annealing in a magnetic field and without a field.

At treatment temperatures above 250 °C, the Ks of an amorphous alloy after annealing in unsaturated magnetic field is always higher than after annealing without a field. At the same time, at annealing temperatures in a magnetic field above 375 °C, Ks had values from 0.57 to 0.77, which indicates the predominant proportion of longitudinal domains compared to the proportion of transverse domains in the domain structure of samples, as discussed earlier, and can serve as confirmation of the fact of inducing longitudinal anisotropy in part of the ferromagnetic volume at these temperatures. It is noteworthy that such a magnetically anisotropic state is more pronounced the higher the processing temperature and the smaller the proportion of non-relaxed stresses in the amorphous ribbon.

Thus, the application of unsaturated magnetic field during annealing can lead to an additional improvement in the magnetic properties of the amorphous Fe77Ni1Si9B13 alloy compared to annealing without a field. At the same time, the final level of properties during annealing in unsaturated magnetic field is determined by several factors at once (relaxation of internal stresses, destabilization of domain boundaries due to directional ordering, as well as induction of longitudinal magnetic anisotropy in part of the ferromagnetic volume), the degree of influence of which on magnetic properties at different processing temperatures differs. The results obtained in this study may make it possible to further increase the efficiency of annealing in the magnetic field of amorphous alloys by reducing the energy consumption for creating a longitudinal magnetic field of much lower intensity than the saturation field for the processed soft magnetic amorphous alloy.

4 Conclusions

In this paper, the regularities of the influence on the magnetic properties of the temperature and intensity of the longitudinal magnetic field, which is much less than the saturation field, during annealing of an amorphous soft magnetic alloy based on Fe were studied. The possibility of efficiency of such heat treatment in comparison with traditional annealing without a field is demonstrated.

-

(1)

The application of a magnetic field during annealing corresponding in order of intensity to the field of maximum permeability for Fe77Ni1Si9B13 alloy in a rapid-quenched state reduces the coercive force more significantly than annealing in a 20-fold maximum permeability field.

-

(2)

The efficiency of annealing in unsaturated field depends on the degree of stress relaxation in the amorphous ribbon at a given processing temperature. The best soft magnetic properties are obtained in a completely relaxed state.

-

(3)

Annealing in unsaturated longitudinal magnetic field corresponding in order of intensity to the maximum permeability field proved to be more effective for improving the soft magnetic properties of an amorphous iron-based alloy than the annealing without a field: compared with annealing without a field, the maximum permeability increased by 94%, the low-field permeability by 26%, the coercive force decreased by 48%.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Z. Hou, P. Yan, B. Sun, H. Elshekh, B. Yan, Results Phys. 14, 102498 (2019). https://doi.org/10.1016/j.rinp.2019.102498

K. Suzuki, H. Fujimori, K. Hashimoto, Amorphous Metals (Butterworths, London, 1983), p.300

Y.N. Starodubtsev, Physical Properties and Application of Soft Magnetic Materials (Goryachaya liniya - Telekom, Moscow, 2020), p.384

J. Degro, P. Vojtanik, J. Filipensky, P. Duhaj, Mater. Sci. Eng. B 14, 81 (1992). https://doi.org/10.1016/0921-5107(92)90333-90335

J. Li, X.H. Lin, X.H. Wang, M. Tang, Adv. Mater. Res. 926–930, 137 (2014). https://doi.org/10.4028/www.scientific.net/AMR.926-930.137

H. Li, A. He, A. Wang et al., J. Magn. Magn. Mater. 471, 110 (2019). https://doi.org/10.1016/j.jmmm.2018.09.072

C.X. Wang, Z. Wu, X. Feng et al., Intermetallics 118, 106689 (2020). https://doi.org/10.1016/j.intermet.2019.106689

F.E. Luborsky, in Amorphous Metallic Alloys. ed. by F.E. Luborsky (Butterworths, London, 1983), p.356

P. Marín, A. Hernando, Appl. Phys. Lett. 94, 122507 (2009). https://doi.org/10.1063/1.3091401

M. Liu, Z. Wang, Y. Xu, IEEE Trans. Magn. 51, 2004704 (2015). https://doi.org/10.1109/TMAG.2015.2439295

I. Škorvánek, J. Marcin, J. Turčanová, J. Kováč, P. Švec, J. Alloys Compds. 504S, S135 (2010). https://doi.org/10.1016/j.jallcom.2010.04.033

D. Mishra, P. Saravanan, A. Perumal, A. Srinivasan, J. Appl. Phys. 109, 07A306 (2011). https://doi.org/10.1063/1.3533256

M.J. Garcia-Prieto, E. Pina, A. Zhukov et al., Sens. Actuator A Phys. 81, 227 (2000). https://doi.org/10.1016/S0924-4247(99)00129-6

C.K. Kim, I.H. Lee, Y.C. Chung, R.C. O’Handley, Mater. Sci. Eng. A 76, 211 (2000). https://doi.org/10.1016/S0921-5107(00)00450-5

M. Vargaa, R. Vargaa, P. Vojtaníka et al., Acta Phys. Pol. 118, 804 (2010). https://doi.org/10.12693/APhysPolA.118.804

O. Kohmoto, H. Fujishima, K. Shibata, Mater. Sci. Eng. 99, 53 (1988). https://doi.org/10.1016/0025-5416(88)90290-X

O.I. Boriskin, D.I. Blagoveshchenskiy, VYu. Vvedenskiy, G.A. Nuzhdin, Chernye Metally 1045(1), 60 (2019)

VYu. Vvedenskiy, G.A. Nuzhdin, E.A. Shuvaeva, Kontrol’ Diagnostika 1, 51 (2013)

F.E. Luborsky, Amorphous Metallic Alloys (Butterworths, London, 1983), p.534

Y. Zhang, Y. Yang, Z. Wu et al., Intermetallics 134, 107200 (2021). https://doi.org/10.1016/j.intermet.2021.107200

P.S. Mogilnikov, Izvestiya. Ferrous Metall. 59(11), 837 (2016). https://doi.org/10.17073/0368-0797-2016-11-837-839

F. Luborsky, J. Walter, Mater. Sci. Eng. 35(2), 255 (1978). https://doi.org/10.1016/0025-5416(78)90127-1

Y.H. Xu, Z.H. Zhu, L. Yin, J.L. Liu, Mater. Sci. Eng. 242, 012024 (2017). https://doi.org/10.1088/1757-899X/242/1/012024

X.F. Liang, A.N. He, A.D. Wang et al., J. Alloys Compds. 694, 1260 (2017). https://doi.org/10.1016/j.jallcom.2016.10.107

VYu. Vvedenskiy, I.B. Kekalo, Phys. Met. Metallogr. 81(1), 73 (1996)

A.M. Severino, A.D. Santos, E.P. Missell, J. Magn. Magn. Mater. 96, 167 (1991). https://doi.org/10.1016/0304-8853(91)90625-K

VYu. Vvedenskiy, I.B. Kekalo, Phys. Met. Metallogr. 86(5), 80 (1998)

K. Suzuki, G. Herzer, Scr. Mater. 67, 548 (2012). https://doi.org/10.1016/j.scriptamat.2012.03.006

Acknowledgements

We are grateful to M.V. Gorshenkov and I.V. Schetinin for their assistance in conducting the EDX analysis.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors read and approved the final manuscript. ET—Writing—Original draft; Investigation; Visualization; Formal analysis. VV—Writing—Review and Editing; Conceptualization; Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tokmakova, E.N., Vvedenskiy, V.Y. Effect of annealing in unsaturated magnetic field on the magnetic properties of an amorphous alloy Fe77Ni1Si9B13. J Mater Sci: Mater Electron 34, 1509 (2023). https://doi.org/10.1007/s10854-023-10931-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-10931-8