Abstract

0.71BiFeO3–0.29BaTiO3 piezoelectric ceramics with Mn modification (BF–BT–x %Mn) sintered in air and O2 atmospheres have been investigated to understand the effects of sintering atmosphere on structure, dielectric, ferroelectric and piezoelectric properties. All ceramics exhibited the pseudo-cubic phase, while the O2 sintered ceramics possessed larger grain sizes and more homogeneous distribution. Dielectric, ferroelectric and piezoelectric properties of BF–BT–xMn ceramics were improved obviously after O2 atmospheres sintering, especially for the compositions with Mn contents less than 1.2 mol%. The evidence of impedance spectroscopy indicated that the concentration of oxygen vacancies decreased significantly by the introduction of O2 atmosphere. The dielectric loss tanδ was decreased down to 1/2 and the resistivity ρ enhanced 11 times for BF–BT–0 %Mn ceramics by the introduction of O2 atmosphere. The strains of BF–BT–0.5 %Mn increased from 0.09 to 0.22 and the d *33 increased from 119 to 284 pm/V after sintering in O2 atmosphere. The Curie temperature and piezoelectric constant of O2 sintered BF–BT–1.2 %Mn reached up to 500 °C and 353 pm/V, respectively. This work suggests that sintering in the O2 oxygen atmosphere is an effective way to improve the dielectric and piezoelectric properties of BiFeO3–BaTiO3 solid solutions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

BiFeO3–BaTiO3 (BF–BT) solid solutions have been received much attention because of lead-free trait and high Curie temperature. The BF–BT system was considered as a new potential lead-free candidate for high temperature piezoelectric applications [1, 2]. However, the low resistivity caused by oxygen vacancies and valence fluctuation of iron ions (Fe3+ and Fe2+) makes poling process difficultly and limits their device applications [3–5].

It was reported that Mn modification could reduce the leakage current of the BF–BT solid solutions [6–8] by restraining the conversion of Fe3+ → Fe2+. The sintering atmosphere also played an important role in the properties of BiFeO3-based ceramics [8, 9]. Yao et al. reported that the Mn-doping 0.8BiFeO3–0.2BaTiO3 ceramics sintered in O2 atmosphere possessed the enhanced properties with piezoelectric constant d 33 = 125 pC/N, remnant polarization P r = 25.1 μC/cm2 and high Curie temperature T C = 637 °C, respectively. The Mn-modified 0.75BF-0.25BT system was prepared by Leontsev et al. sintered in O2 atmosphere possessing d 33 = 116 pC/N with T C = 619 °C and the resistance enhanced from 2.7 × 107 to 7.6 × 1012 Ω. Zhu et al. studied the effect of O2-sintered on DC resistivity of 0.67BiFeO3–0.33PbTiO3 prepared by conventional solid state reaction, which the ceramics sintered in O2 atmosphere shown improved resistivity. As reported in the literature, the piezoelectric properties of BF–BT solid solutions reached the maximum at Rhombohedral and Cubic phase boundary located at about BF of 0.7. However, there was little attention have been paid on the effects of sintering atmosphere on the microstructure, dielectric, ferroelectric and piezoelectric properties of BF–BT near the phase boundary ceramics with different Mn contents.

In this work, the 0.71BiFeO3–0.29BaTiO3 ceramics with different Mn contents were prepared by traditional solid state reaction method. The ceramics were sintered under air and O2 atmospheres at the same conditions (dwelling time and sintering temperature). The microstructure, dielectric, ferroelectric and piezoelectric properties of 0.71BiFeO3–0.29BaTiO3 ceramics sintered under different atmospheres were investigated.

2 Experimental

The ceramics in the 0.71BiFeO3–0.29BaTiO3-x mol% MnO2 (BF–BT–x %Mn) binary system sintered in air and O2 atmospheres were fabricated by conventional solid state reaction method, where x = 0, 0.3, 0.5, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0. A stoichiometric amount of Bi2O3(99 %), Fe2O3(99 %), BaCO3(99 %), TiO2(99 %), MnO2(99 %) were weighted based on the chemical formula for each composition, all the raw materials were first mixed thoroughly in the polyethylene jar with ethanol for 24 h with stabilized zirconia balls. After drying, the mixed powders were calcined in crucibles at 750 °C for 4 h. Then, the calcined powders were milled in ethanol again for 24 h to reduce the particle size. Finally, the powders were pressed into pellets with a diameter of 12 mm at 120 MP. The pellets were sintered at 1000–1100 °C for 2 h in air and O2 atmospheres (O2 flow was 200 ml/min) followed by furnace cooling to room temperature.

The phase of ceramics was analyzed by X-ray diffraction (XRD, Rigaku-D/MAX-2000) with Cu K α radiation at room temperature. Scanning electron microscopy (SEM, Hatichi S-3400 N) was used to examine the fresh fracture surfaces microstructure. For dielectric and ferroelectric measurements, the sintered pellets were polished to 0.4 mm, and electroded with a post-fire silver paste. Dielectric properties measurements as a function of temperature were made using a computer controlled Agilent4294A impedance analyzer. For piezoelectric measurements, the BF–BT–xMn ceramics were poled in silicone oil under a DC electric field of 80 kV/cm at 100 °C for 30 min. The piezoelectric constant d 33 was measured by a quasi-static piezoelectric meter (ZJ-2, Beijing Institute of Acoustics). The polarization versus electric field hysteretic loops was characterized by a ferroelectric test system Precision Premier II (Radiant Co.).

3 Results and discussion

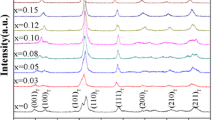

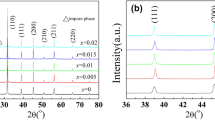

Figure 1 shows the XRD patterns of BF–BT–x %Mn ceramics sintered in air and O2 atmospheres. All the XRD patterns exhibit a single perovskite structure without any secondary phases. BF–BT–x %Mn ceramics exhibit pseudo-cubic phase confirmed by XRD analysis, and there is no apparent phase difference between ceramics sintered in air and O2 atmospheres. The diffraction peaks of O2 sintered ceramics are sharper than that of air sintered ceramics indicating that better crystallinity was obtained.

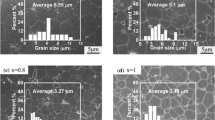

Figure 2 presents the SEM images of BF–BT–x %Mn ceramics sintered in air and O2 atmospheres derived from fresh fracture surfaces. The relative bulk density of air sintered ceramics is in the range of 93–96 %, while increase to 94–98 % for O2 sintered ceramics. It can be found that the grain sizes of BF–BT–x %Mn ceramics sintered in O2 atmosphere are more homogeneous and larger than that of air sintered ceramics, indicating that the O2 atmosphere improves the rate of grain growth. The O2 sintered ceramics possess better compactness by comparing the porosity, which may contribute to improving the dielectric, ferroelectric and piezoelectric properties.

Figure 3 depicts the variation of dielectric constant ε r and dielectric loss tanδ for BF–BT–x %Mn ceramics sintered in air and O2 atmospheres as a function of frequency. The values of ε r for all BF–BT–x %Mn ceramics have a general tendency to decrease with the increasing frequency, which may result from space charge polarization due to the inevitable oxygen vacancies, A-site vacancies and the coexistence of Fe3+/Fe2+ [10]. As shown in Fig. 3b, the tanδ shows a dramatic drop from about 0.15 to 0.07 at 100 Hz by sintering in O2 atmosphere for BF–BT–0 %Mn ceramics. The tanδ of air sintered BF–BT–0.5 %Mn ceramics exhibits 0.058 at 100 Hz, when the ceramics sintered in O2 atmosphere this value decreases to 0.046. When x = 1.2, the tanδ decreases from 0.043 to 0.036 at 100 Hz after sintering in O2 atmosphere. All the O2 sintered ceramics exhibit lower tanδ comparing to the air sintered especially at low frequency. This result shows that the defects of BF–BT–x %Mn ceramics are reduced by sintering in O2 atmosphere.

Figure 4 presents the dielectric constant and loss of air and O2 sintered BF–BT–x %Mn ceramics as a function of temperature at 106 Hz. All ceramics exhibit only a dielectric peak and the Curie temperature T C determined by the dielectric peak is obtained. All O2 sintered BF–BT–x %Mn ceramics almost keep the similar T C with the air sintered ceramics. While the dielectric peak of O2 sintered BF–BT–x %Mn ceramics is sharper than the air sintered. The O2 sintered ceramics exhibit relatively small tanδ in high temperature, especially for BF–BT–0 %Mn ceramics. The tanδ of air sintered BF–BT–0 %Mn ceramics at 400 °C is 7.2 about 14 times that of the O2 sintered ceramics. This phenomenon implies that the electric insulation of O2 sintered in high temperature is better than the air sintered.

Figure 5 shows the impedance spectroscopy of BF–BT–x %Mn ceramics measured at 573 k. The impedance spectroscopy is characterized by the appearance of semicircular arcs, and the entire plots show single arc suggesting that the electrical process contribution is mainly from grain interior [11]. The total resistivity ρ of air sintered ceramics are increased with increasing the Mn content up to x = 1.2, subsequently decrease with increasing the Mn content. The ρ of O2 sintered BF–BT–0 %Mn ceramics is 600 kΩ cm about 11 times that of the air sintered. The ρ of O2 sintered BF–BT–0.5 %Mn ceramics is 2100 kΩ cm, 7.5 times that of the air sintered. The values of ρ for air and O2 sintered BF–BT–1.2 %Mn ceramics are 700 and 3150 kΩ cm, respectively. This result suggests that the O2 atmosphere can improve the insulation effectively, especially to the slightly Mn doping ceramics.

The variation of conductivity for air and O2 sintered BF–BT–x %Mn ceramics as a function of temperature is exhibited in Fig. 6. With the temperature increases, the mobile charges have sufficient thermal energy to get activated and jump over the barrier. According to the Arrhenius relationship:

the activation energies for the BF–BT–x %Mn ceramics are estimated and exhibited in Fig. 7. The obtained activation energies for x = 0, 0.5, 1.2, 1.8 sintered in air were 0.65, 0.88, 0.92, 0.91 eV, respectively, indicating the ionic charge carriers may be the oxygen vacancies [12]. The activation energies of O2 sintered ceramics increase firstly and then decrease with increasing the Mn content, reaching the maximum value 0.94 eV with x = 1.2. The activation energy of O2 sintered BF–BT–0 %Mn ceramics is 0.73 eV, 0.8 eV larger than the air sintered one. According to the Kroger–Vink notation [13], the conduction electrons may be created by the following reactions:

with increases the temperature, the electrons trapped by Ti4+ or Mn3+ ions [14] or oxygen vacancies are thermally activated, resulting in the decreasing of resistance. Therefore, the ceramics exhibit larger activation energy meaning that the ceramics possess lesser defects. The variation of activation energies for air and O2 sintered ceramics shows that the O2 atmosphere can reduce the defects effectively, meanwhile, the effects of sintering atmosphere on resistivity for BF–BT–x %Mn ceramics lie on the Mn content.

Figure 8 exhibits the room temperature P–E loops of the BF–BT–x %Mn ceramics sintered in air and O2 atmospheres. The remnant polarization P r of O2 sintered BF–BT–0 %Mn ceramics is 14 μC/cm2, while only 7.5 μC/cm2 obtained from the air sintered. The observed P r of BF–BT–0.8 %Mn ceramics increases from 11 to 21 μC/cm2 when the sintering atmospheres change from air to O2. The value of P r for BF–BT–1.8 %Mn ceramics is also enhanced by sintered in O2 atmosphere. According to the results of impedance spectroscopy analysis, it is possible that the freely movable charges may contribute to the electrical hysteresis loop for air sintered BF–BT–0 %Mn ceramics, characterized by the rounded features of the loop. Yet, the less rounded features of the loops show that the contribution to the polarization from the freely movable charges is reduced for O2 sintered BF–BT–0 %Mn ceramics. The enhancement of insulation for O2 sintered ceramics caused by the reduced oxygen vacancies makes it more possible to completely pole the ceramics, and thus the larger remnant polarization P r may be obtained. Furthermore, the O2 sintered ceramics possess larger and better interlinked grains and better grain boundary junction observed in Fig. 2, which may contribute to percolating inter-grain transport current and favor inhibiting the leakage current and hence improve the electric polarization [15]. The BF–BT–1.2 %Mn ceramics exhibit almost the same P r no matter ceramics sintered in air and O2 atmospheres. These results suggest that the effects of sintering atmosphere on ferroelectric properties for BF–BT–x %Mn ceramics depend on the concentration of Mn doping.

The piezoelectric properties of BF–BT–x %Mn ceramics are shown in Fig. 9. Figure 9a–d show the unipolar curves at room temperature of BF–BT–x %Mn ceramics sintered in air and O2 atmospheres. The strains of BF–BT–0 %Mn ceramics are enhanced from 0.07 to 0.09, meanwhile, the strains of BF–BT–0.5 %Mn increase from 0.09 to 0.22 after sintering in O2 atmosphere. The strain of BF–BT–1.2 %Mn is 0.28, showing good piezoelectric properties. The piezoelectric constants d *33 exhibited in Fig. 9e are calculated from Fig. 9a–d. It is notable that the d *33 of BF–BT–0.5 %Mn ceramics increases from 119 to 284 pm/V and the d *33 of O2 sintered BF–BT–1.2 %Mn reaches to 353 pm/V. The piezoelectric constants d 33 of all BF–BT–x %Mn ceramics sintered in air and O2 atmospheres are exhibited in Fig. 9f. The observed d 33 of air sintered x = 0, 0.3, 0.5, 0.8 ceramics are 75, 82, 95, 124 pC/N, respectively. After sintering in O2 atmosphere, the d 33 of x = 0, 0.3, 0.5, 0.8 ceramics are 112, 152, 155, 153 pC/N, showing great enhancement. These results imply that the O2 atmosphere plays a crucial role in enhancing the piezoelectric properties of BF–BT–x %Mn ceramics especially to the slightly Mn doping. It is reported that the piezoelectric properties of the polycrystalline ceramics materials are mainly affected by the intrinsic and extrinsic factors [16]. The grain size is one of the important aspects to affect the extrinsic factor of ceramics which is contributed to piezoelectric properties. Therefore, the improvement piezoelectric properties may due to the increasing grain size and enhanced electrical insulation.

4 Conclusion

0.71BiFeO3–0.29BaTiO3 piezoelectric ceramics with Mn modification (BF–BT–x %Mn) sintered in air and O2 atmosphere were fabricated by conventional solid state reaction method. The grain sizes of O2 sintered ceramics were more homogeneous and larger. The impedance spectroscopy results showed that the O2 atmosphere could effectively decrease the oxygen vacancies. The dielectric loss of O2 sintered BF–BT–x %Mn ceramics at room temperature decreased obviously. Meanwhile, the electric insulation of ceramics in high temperature was improved with sintered in O2 atmosphere. The ferroelectric and piezoelectric properties were improved by sintering in O2 atmosphere. By sintering in O2 atmosphere the strains of BF–BT–0.5 %Mn increased 2.5 times and the d *33 increased from 119 to 284 pm/V. Thus, the O2 atmosphere not only reduced defects but enhanced the ferroelectric and piezoelectric properties especially to the ceramics with slightly Mn doping. This work suggested that sintering in O2 atmosphere was an useful method to reduce defects and enhance the dielectric, ferroelectric and piezoelectric properties. The O2 sintered BF–BT–x %Mn ceramics shows promising candidate for high temperature piezoelectric applications.

References

Z. Cen, C. Zhou, H. Yang, Q. Zhou, W. Li, C. Yuan, J. Mater. Sci.: Mater. Electron. 24(10), 3952–3957 (2013)

S.O. Leontsev, R.E. Eitel, J. Am. Ceram. Soc. 92(12), 2957–2961 (2009)

S. Hunpratub, P. Thongbai, T. Yamwong, R. Yimnirun, S. Maensiri, J. Supercond. Nov. Magn. 25(5), 1619–1622 (2012)

A.Z. Simões, C.S. Riccardi, M.L. Dos Santos, F.G. Garcia, E. Longo, J.A. Varela, Mater. Res. Bull. 44(8), 1747–1752 (2009)

J.R. Cheng, N. Li, L.E. Cross, J. Appl. Phys. 94, 5153–5157 (2003)

X.H. Liu, Z. Xu, S.B. Qu, X.Y. Wei, J.L. Chen, Ceram. Int. 34(4), 797–801 (2008)

N. Itoh, T. Shimura, W. Sakamoto, T. Yogo, Ferroelectr 356(1), 19–23 (2007)

Z. Yao, C. Xu, H. Hao, Q. Xu, W. Hu, M. Cao, H. Liu, Int. J. Appl. Ceram. Tec. 13, 549–553 (2016)

W.M. Zhu, Z.G. Ye, Ceram. Int. 30(7), 1435–1442 (2004)

Q. Hang, Z. Xing, X. Zhu, M. Yu, Y. Song, J. Zhu, Z. Liu, Ceram. Int. 38, S411–S414 (2012)

H. Zhang, P. Xu, E. Patterson, J. Zang, S. Jiang, J. Rodel, J. Eur. Ceram. Soc. 35(9), 2501–2512 (2015)

A. Munpakdee, K. Pengpat, J. Tontrakoon, T. Tunkasiri, Smart Mater. Struct. 15(5), 1255 (2006)

S.P.S. Badwal, Processing of the International Seminar on Solid State Ionic Devices (World Scientific Publishing, Singapore, 1988), p. 165

P. Dhak, D. Dhak, M. Das, K. Pramanik, P. Pramanik, Mater. Sci. Eng. B 164(3), 165–171 (2009)

S.K. Pradhan, B.K. Roul, Phys. B 407(13), 2527–2532 (2012)

C.A. Randall, N. Kim, J.P. Kucera, W. Cao, T.R. Shrout, J. Am. Ceram. Soc. 81(3), 677–688 (1998)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Q., Cheng, J. & Chen, J. Reduced dielectric loss and enhanced piezoelectric properties of Mn modified 0.71BiFeO3–0.29BaTiO3 ceramics sintered under oxygen atmosphere. J Mater Sci: Mater Electron 28, 1370–1377 (2017). https://doi.org/10.1007/s10854-016-5670-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5670-3