Abstract

Here, gallium oxide (Ga2O3) thin films were investigated as gate dielectric for thin-film transistors (TFTs) using the solution process method. The optical, microstructure, morphology, oxygen vacancy defect states and electrical performance metrics of Ga2O3 thin films annealed at different stages of temperature were explored. The excellent dielectric property of amorphous Ga2O3 thin films was found, but it was deteriorated after crystallization when the annealing temperature increased. The optimized Ga2O3 thin film exhibits a low leakage current density of 1.9 × 10–6 A cm−2 at 1.5 MV cm−2 and a large dielectric constant of 10.8. Furthermore, low-voltage operation oxide TFTs were demonstrated using this optimized amorphous Ga2O3 as gate dielectric. The device exhibits excellent bias stress stability with a high mobility of 8.5 cm2/Vs, a threshold voltage of -1.4 V, a current on/off ratio of 104 and a subthreshold swing of 0.41 mV/Dec.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the past decade, owing to their high transparency, high electron mobility and outstanding uniformity, metal oxide (MO) thin-film transistors (TFTs) have been extensively explored as electrical switch element in flat panel display, functional sensor arrays and other emerging electronic circuits [1,2,3]. Especially, many efforts have been made to develop high-k dielectric for the portable electronic devices, which is an effective way to enhance capacitive coupling and achieve low-operating voltage. Numerous candidate high-k materials, like ZrO2, Y2O3, HfO2, and Ga2O3 have been investigated [4,5,6]. Among them, Ga2O3 with the features of wide bandgap, large dielectric constant and excellent thermal stability leads to reduce direct-tunneling leakage current [7]. However, as far as we know, the literatures of Ga2O3 as gate dielectric for oxide TFTs are seldom reported. Although Chang et al. presented a-IGZO TFTs with Ga2O3 gate dielectric deposited by RF sputtering method, a SiO2 interlayer is still required to reduce the leakage current and off-state current [8]. Moreover, it was reported that the Ga2O3 dielectric significantly reduce interfacial density states and lower leakage current for III-V semiconductor field-effect transistors [9].

Up to now, various growth techniques have been carried out to prepare Ga2O3 thin films, such as atomic layer deposition (ALD), chemical vapor deposition (CVD), molecular beam evaporation and solution process method [10, 11], among which solution process usually exhibits many advantages including simplicity, large-area uniformity, atmospheric processing, and low fabrication cost. As for the solution-processed metal oxide dielectrics, annealing conditions have great influence on chemical composition and physical properties. Although Xu et al. reported solution-processed Ga2O3 dielectric for low-voltage oxide TFTs, the relation of the electrical properties and the microstructure of Ga2O3 thin films need to be further investigated [12]. In this regard, solution-processed Ga2O3 thin films will be attractive and worthy of in-depth study for high-performance electronic devices. In this work, high-k Ga2O3 dielectric was fabricated by facile solution process method. The optical constant, phase composition, oxygen defects states, surface and dielectric properties of Ga2O3 thin films were systematically researched. Finally, solution-processed high performance In2O3 TFTs were integrated on the optimized amorphous Ga2O3 dielectrics.

2 Experimental details

2.1 Precursor preparation

All chemicals and solvents were purchased from Sigma-Aldrich. 0.2 M Ga2O3 precursor solution was prepared by dissolving Ga(NO3)3·xH2O in 2-methoxyethanol. 0.1 M In2O3 precursor solution was prepared by dissolving In(NO3)3)·xH2O in 2-methoxyethanol. Finally, the solutions were stirred overnight at room temperature.

2.2 Device fabrication

The TFTs were constructed on a heavily phosphor-doped n+-Si substrate. Firstly, the substrate was ultrasonically cleaned and treated with an oxygen plasma. Then, Ga2O3 solutions were spin-coated on Si substrate at 3000 rpm for 30 s, followed immediately by annealing 20 min at 150 °C. Next, the films were post-annealed at 250, 350, 450 and 550 °C for 1 h after repeating the above operation four times. To investigate their dielectric properties, Metal-insulator-semiconductor (MIS) structure capacitors were fabricated by evaporate Al on the surface of Ga2O3 thin films. The area of Al electrode was 0.2 mm × 0.2 mm. For TFTs fabrication, the In2O3 precursor solution was spin-coated on the obtained Ga2O3 dielectrics and then annealed 20 min at 250 °C. Finally, Al was evaporated through a shadow mask to form source/drain electrodes with a channel length of 100 μm, and channel width of 1000 μm.

2.3 Thin film and device characterization

The film thickness and refractive indices were measured by a J.A. Woollam M2000U ellipsometer. Grazing incidence X-ray diffraction (GIXRD) were performed on a Rigaku ATXG diffractometer using Cu Kα (λ = 1.542 Å). X-ray photoelectron spectroscopy (XPS) was performed on Thermo Scientific Escalab 250 Xi spectrometer. The surface morphologies were measured by a Veeco Dimension Icon atomic force microscopy (AFM). The electrical properties of the capacitors and TFTs were measured using a Keithley 4200.

3 Results and discussion

Figure 1a shows the GIXRD patterns of Ga2O3 thin films annealed at various temperature. Obviously, the film remains amorphous state when the temperature is lower than 450 °C. However, several diffraction peaks can be observed when the annealing temperature reaches to 550 °C. These peaks can be recognized and consistent with the primary planes of the β-Ga2O3 structure listed in the JCPDS 41-1103, even if their intensities are not absolutely homologous to those shown in this file, which may indicate exit of alignment or texturing effect [13]. For crystallized oxide dielectrics, the grain boundary usually leads to impurity diffusion and acts as prior path of leakage current, which seriously affects the reliability of devices. Figure 1b shows the refractive index curves of Ga2O3 films performed in the range 350–1000 nm. The thickness of the films annealed at 250, 350, 450 and 550 °C were determined as 73, 69, 66, 63 nm by fitting with a Cauchy model, respectively. It also can be seen that the refractive indices decrease with the increase of wavelength and increase with the increase of annealing temperature. The difference of the thickness and optical constant can be explained by the densification process and phase transformation. It has been known from GIXRD patterns that as-deposited Ga2O3 films is amorphous and often contains many structural defects. With the annealing temperature increasing, the Ga2O3 films become denser. When the annealing temperature reaches to 550 °C, the β-Ga2O3 crystal structure formed and led to a larger increase of refractive indices due to the growth of crystal grains. From surface morphologies measured by AFM shown in Fig. 2, the root mean square (RMS) roughness of films annealed at 250 °C, 350 °C, 450 °C, 550 °C were 0.118, 0.121, 0.128, 0.463 nm, correspondingly. The Ga2O3 thin films show relatively smooth surface when the annealing temperature is less than 450 °C. The increased RMS value of 550 °C annealing film can be attributed to the crystallization, which is consistent with the result of GIXRD. Generally, a smooth surface can suppress gate leakage current, however, a rough surface would generate electronic traps or defects due to field-intensification inhomogeneous and deteriorate the transistor performance.

Figure 3a shows the O 1 s XPS spectra of Ga2O3 films. The peaks were fitted into a low-energy peak centered at 530.3 eV and a high-energy one at 531.9 eV. It was known that the peak at the 530.3 eV is associated with Metal–Oxygen bond species. As well, the peak at 531.9 eV is attributed to Metal-Hydroxide bond groups, such as OH- or H2O on the film surface [11, 14]. For simplicity, O1, O2 and O1 + O2 are defined as the areas of low-energy peak, high-energy peak and the total area of the O 1 s peak. Consequently, O1/(O1 + O2) and O2/(O1 + O2) denote the relative quantity of Metal–Oxygen bond and Metal-Hydroxide bond in the Ga2O3 thin films. The ratio of O1/(O1 + O2) and O2/(O1 + O2) are calculated and plotted in Fig. 3b. We found that the fraction of the Metal–Oxygen bond in Ga2O3 increased from 84.1 to 90.3% and the Metal-Hydroxide bond in Ga2O3 decreased from 15.9 to 9.7% when the annealing temperature goes up from 250 to 550 °C. The XPS results reveal that higher annealing temperature reduces the Metal-Hydroxide bond and improves bulk Metal–Oxygen bond. It was noted that the Metal-Hydroxide bond can discrete energy levels and generate trap states in the forbidden band of Ga2O3 films, leading to the increased leakage current and the reduced breakdown voltage [15, 16]. Figure 3c exhibits the XPS Ga 3d spectra. It can be seen that all the peaks are in the range of 20.0 to 20.3 eV. However, with the annealing temperature rise, Ga 3d peaks are shifted to lower binding energy, which can be attribute to progressive oxidization or decrease of coordination number of Ga3+ in the films [17].

The leakage current density of Ga2O3 thin films is shown in Fig. 4a. For the films annealed at 250 °C, 350 °C, 450 °C and 550 °C, the leakage current densities were 4.2 × 10–6, 2.4 × 10–6, 1.9 × 10–6 and 6.6 × 10–5 A cm−2 (at 1.5MV/cm2), respectively. The leakage current for low temperature annealed films may relate to hydroxyl groups and nitrate which provide leakage paths. Obviously, the 350 °C and 450 °C annealed films show lower leakage currents density, which mainly caused by thermal pyrolysis of nitrate and hydroxyl groups as well as the formation of metal oxide framework [18]. However, the leakage current density increased dramatically when temperature reaches to 550 °C, resulting from the crystallization of Ga2O3 film identified by GIXRD. Figure 4b shows the C-V curves of Al/Ga2O3/Si capacitors at 1 MHz. It was observed that the capacitance at accumulation range increases when the annealing temperature rising, but it dramatically reduces when the temperature reach to 550°C. The relative dielectric constant of the Ga2O3 thin films can calculated by the following formula: C = ε0εrs/d, where C, ε0, εr, s and d are the dielectric capacitance, absolute dielectric constant, relative dielectric constant, the area of electrode and thickness of the dielectric layer, respectively. Assuming 2.5 nm thick native SiO2 with a dielectric constant of 3.9 on the Si bottom electrode, C can be modeled as Ga2O3 and SiO2 capacitor in series, that is 1/C = 1/CGa2O3 + 1/CSiO2. Accordingly, the calculated relative dielectric constant for Ga2O3 films annealed at 250 °C, 350 °C, 450 °C, 550 °C were 7.7, 9.3, 10.8, and 5.7, respectively, consistent with the surface morphology results of AFM.

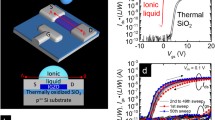

Based on the above analysis, In2O3 TFTs integrated with 450 °C annealed Ga2O3 dielectric were fabricated. The output curves measured with the VGS varied from 0 to 5 V in step of 1 V and transfer curves measured at a fixed VDS of 5 V are shown in Fig. 5a, b. The device exhibits typical n-type field-effect transistor behavior with low operation voltage. The electrical hysteresis was negligible indicating small amounts of interface traps between the Ga2O3 dielectric and the In2O3 channel layer. The mobility (μ) and the subthreshold slope (SS) of the TFTs can be calculated by the following Eqs. (1) and (2) [19, 20].

Here, Ci is the areal capacitance, VT is the threshold voltage. The VT was extracted by fitting the straight line of the square root of IDS vs. VGS in the saturation region and extrapolating to IDS = 0. Just as mentioned above, Ci can be modeled as Ga2O3 and SiO2 capacitor in series and was calculated to be 1382 nF cm−2. The device exhibits a high mobility of 8.5 cm2/Vs with a current on/off ratio of 104, a near zero threshold voltage of −1.4 V and a low SS of 0.41 V/Dec.

Figure 5c shows the evolution of the transfer properties of In2O3 TFT with different stress durations. A voltage of 3 V was constantly biased to gate electrode and the source electrode were grounded for 1200 s. The device exhibits an insignificant threshold voltage shift of 0.26 V indicating excellent operational stability. This negligible value shift also reveals that there are very few trap defects existing in the dielectric and the channel layer [21].

4 Conclusion

In summary, we have fabricated the solution-processed Ga2O3 thin films and investigated the optical, microstructure, surface morphology, composition and electrical properties. It was found that the dielectric properties of amorphous Ga2O3 thin films are excellent, but it was deteriorated after crystallization when annealing temperature rising. Moreover, oxide TFTs were fabricated using the optimized amorphous Ga2O3 dielectrics. The devices exhibit a high mobility of 8.5 cm2/Vs, a threshold voltage of −1.4 V, a current on/off ratio of 104 and a subthreshold swing of 0.41 mV/Dec as well as excellent bias stress stability.

References

L. Sang Ho, O. Dong Ju, H. Ah Young, H. Dong Suk, K. Shin, J. Jae Kyeong, P. Jong Wan, Improvement in Device Performance of a-InGaZnO Transistors by Introduction of Ca-Doped Cu Source/Drain Electrode. IEEE Electron. Device Lett. 36(8), 802–804 (2015)

J.S. Park, W.-J. Maeng, H.-S. Kim, J.-S. Park, Review of recent developments in amorphous oxide semiconductor thin-film transistor devices. Thin Solid Films 520(6), 1679–1693 (2012)

T. Lin, X. Li, J. Jang, High performance p-type NiOx thin-film transistor by Sn doping. Appl. Phys. Lett. 108(23), 233503 (2016)

J.W. Zhao, X.A. Zhang, S. Li, H.W. Zheng, G. Yang, W.F. Zhang, Performances of transparent indium zinc oxide thin film transistors using ZrO2 as dielectric processed by solution method. Physica Status Solidi(a) (2017). https://doi.org/10.1002/pssa.201600315

M. Esro, G. Vourlias, C. Somerton, W.I. Milne, G. Adamopoulos, High-mobility ZnO thin film transistors based on solution-processed hafnium oxide gate dielectrics. Adv. Funct. Mater. 25(1), 134–141 (2015)

W. Xu, H. Li, J.B. Xu, L. Wang, Recent advances of solution-processed metal oxide thin-film transistors. ACS Appl Mater Interfaces (2018). https://doi.org/10.1021/acsami.7b16010

C.-T. Lee, H.-W. Chen, H.-Y. Lee, Metal–oxide–semiconductor devices using Ga2O3 dielectrics on n-type GaN. Appl. Phys. Lett. 82(24), 4304–4306 (2003)

T.H. Chang, C.J. Chiu, S.J. Chang, T.Y. Tsai, T.H. Yang, Z.D. Huang, W.Y. Weng, Amorphous InGaZnO ultraviolet phototransistors with double-stack Ga2O3/SiO2 dielectric. Appl. Phys. Lett. 102(22), 221104 (2013)

M. Passlack, N. Medendorp, S. Zollner, R. Gregory, D. Braddock, Optical and electrical properties of amorphous GdxGa0.4−xO0.6 films in GdxGa0.4−xO0.6/Ga2O3 gate dielectric stacks on GaAs. Appl. Phys. Lett. 84(14), 2521–2523 (2004)

L. Kong, J. Ma, C. Luan, W. Mi, Y. Lv, Structural and optical properties of heteroepitaxial beta Ga2O3 films grown on MgO (100) substrates. Thin Solid Films 520(13), 4270–4274 (2012)

T.S. Lay, Y.Y. Liao, W.H. Hung, M. Hong, J. Kwo, J.P. Mannaerts, Depth-profile study of the electronic structures at Ga2O3(Gd2O3) and Gd2O3–GaN interfaces by X-ray photoelectron spectroscopy. J. Cryst. Growth 278(1–4), 624–628 (2005)

W. Xu, H. Cao, L. Liang, J.-B. Xu, Aqueous solution-deposited gallium oxide dielectric for low-temperature, low-operating-voltage indium oxide thin-film transistors: a facile route to green oxide electronics. ACS Appl. Mater. Interfaces 7(27), 14720–14725 (2015)

C. Hebert, A. Petitmangin, J. Perrière, E. Millon, A. Petit, L. Binet, P. Barboux, Phase separation in oxygen deficient gallium oxide films grown by pulsed-laser deposition. Mater. Chem. Phys. 133(1), 135–139 (2012)

M.K. Yadav, A. Mondal, S. Das, S.K. Sharma, A. Bag, Impact of annealing temperature on band-alignment of PLD grown Ga2O3/Si (100) heterointerface. J. Alloys Compd. 819, 153052 (2020)

H. Du, W. Liang, Y. Li, M. Gao, Y. Zhang, C. Chen, Y. Lin, Leakage properties of BaTiO3 thin films on polycrystalline Ni substrates grown by polymer-assisted deposition with two-step annealing. J. Alloys Compd. 642, 166–171 (2015)

A. Liu, Z. Guo, G. Liu, C. Zhu, H. Zhu, B. Shin, E. Fortunato, R. Martins, F. Shan, Redox chloride elimination reaction: facile solution route for indium-free, low-voltage, and high-performance transistors. Adv. Electron. Mater. 3(3), 1600513 (2017)

H. Yang, Y. Qian, C. Zhang, D.-S. Wuu, D.N. Talwar, H.-H. Lin, J.-F. Lee, L. Wan, K. He, Z.C. Feng, Surface/structural characteristics and band alignments of thin Ga2O3 films grown on sapphire by pulse laser deposition. Appl. Surf. Sci. 479, 1246–1253 (2019)

G. Jiang, A. Liu, G. Liu, C. Zhu, Y. Meng, B. Shin, E. Fortunato, R. Martins, F. Shan, Solution-processed high-k magnesium oxide dielectrics for low-voltage oxide thin-film transistors. Appl. Phys. Lett. 109(18), 183508 (2016)

A. Liu, G. Liu, H. Zhu, H. Song, B. Shin, E. Fortunato, R. Martins, F. Shan, Water-induced scandium oxide dielectric for low-operating voltage n- and p-type metal-oxide thin-film transistors. Adv. Funct. Mater. 25(46), 7180–7188 (2015)

X. Zhang, B. Wang, X. Sun, H. Zheng, S. Li, P. Zhang, W. Zhang, Highly Transparent and conductive W-Doped ZnO/Cu/W-doped ZnO multilayer source/drain electrodes for metal-oxide thin-film transistors. IEEE Electron Device Lett. 39(7), 967–970 (2018)

J.W. Hennek, J. Smith, A. Yan, M.G. Kim, W. Zhao, V.P. Dravid, A. Facchetti, T.J. Marks, Oxygen “getter” effects on microstructure and carrier transport in low temperature combustion-processed a-InXZnO (X = Ga, Sc, Y, La) transistors. J. Am. Chem. Soc. 135(29), 10729–10741 (2013)

Acknowledgements

This work was supported by Natural Science Foundation of Henan Province (Grant No. 202300410036), Key research project in University of Henan Province (20A510003) and the National Natural Science Foundation of China (Grant No. U1504625).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yuan, L., Li, S., Song, G. et al. Solution-processed amorphous gallium oxide gate dielectric for low-voltage operation oxide thin film transistors. J Mater Sci: Mater Electron 32, 8347–8353 (2021). https://doi.org/10.1007/s10854-021-05408-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05408-5