Abstract

The (1 − x)(Bi0.5Na0.42K0.08)0.96Sr0.04Ti0.975Nb0.025O3–xBiAlO3 (x = 0, 0.01, 0.02, 0.03, 0.05) lead-free ceramics were synthesized by means of the traditional solid-state reaction method. Influences of the BiAlO3 doping on structure, dielectric, and ferroelectric properties of the ceramics were systematically investigated. The X-ray diffraction (XRD) measurement was used to detect phase structure. The samples exhibit pseudocubic symmetry and dense microstructures. All of the ceramics, whether they were poled or unpoled, exhibit two dielectric anomalies on the dielectric spectra between room temperature and 350 °C, and no dielectric anomaly related to depolarization behavior was observed. The polarization loops and strain curves exhibit pinching-type shape and sprout shape, respectively. The corresponding mechanism was also discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Piezoelectric materials are important for the application of transducers. As traditional transducer materials, Pb(Zr,Ti)O3and PbMg1/3Nb2/3O3-PbTiO3-based ceramics have been widely investigated in the field of various electromechanical applications [1,2,3]. However, taking into account irreversible ecological and health issues caused by lead-based components, lead-free materials with alternative properties have been widely studied. Excellent electrical properties have been explored in lead-free materials. For example, giant piezoelectric constant d33 of 755 pC/N and \({d}_{33}^{\ast}\) of 2027 pm/V were achieved in highly textured BaTiO3-based ceramics [4]. Ultrahigh discharge energy density of 10.5 J/cm3 and efficiency of 87% were obtained in BiFeO3–BaTiO3 ceramic multilayers [5]. In particular, exploring lead-free ferroelectric materials with large strain is of great significance for developing transducers. As one of lead-free materials, (Bi0.5Na0.5)TiO3 (BNT)-based ceramics are particularly attractive because Bi3+ and Pb2+ have similar electron configurations with 6s2 [6]. Among BNT-based ceramics, Bi0.5Na0.5TiO3–Bi0.5K0.5TiO3 (BNKT) solid solutions have been concerned intensively due to the relaxor ferroelectric behavior with high electromechanical properties. The BNKT-based ceramics are often accompanied by relatively high strain under an appropriate electric field. For instance, a large field-induced strain up to 0.438% at a low electric field of 5 kV/mm was obtained in Nb5+-doped BNKT-based ceramics due to the reversible phase transition between an ergodic relaxor (ER) phase to a ferroelectric (FE) phase [7]. Tan et al. studied the same system and achieved a giant strain of 0.7% via the two-step sintering method [8]. Zhou et al. reported a high strain of 0.32% with good temperature insensitivity in the same system [9]. The long-range ferroelectric domains could be decomposed into active polar nanoregion (PNRs) by appropriate chemical modification, which could be transformed into an unstable polar ferroelectric order under external electric fields, and reverted back to the virgin state after removal of the electric fields [9, 10]. Meanwhile, the highly asymmetric strain behavior caused by strong internal bias field should be avoided [11].

The ceramics BiMO3 (M = Al3+, Fe3+, Ga3+, In3+, etc.) have large remanent polarization and high Curie temperature [12, 13]. BiAlO3 has been paid much attention due to its good ferroelectric properties as well as relatively inexpensive constituent elements [14]. Furthermore, the electric charge of Al3+ is stable. It has been reported that BiAlO3 shows rhombohedral perovskite symmetry, high Curie temperature (527 °C), and large spontaneous polarization (~ 76 µC/cm2) [15, 16]. BiAlO3 has been added into BNT-based ceramics to tune microstructure and electrical properties. Fu et al. synthesized (1 − x)Bi0.5(Na0.82K0.18)0.5TiO3–xBiAlO3 ceramics with decreased grain sizes and improved ferroelectric properties [17]. Shi et al. fabricated (1 − x)(0.72Bi0.5Na0.5TiO3–0.28SrTiO3)–xBiAlO3 ceramics and showed that dielectric constant and piezoelectric coefficient decreased with the increase in BiAlO3 content because of relaxor behavior [18]. Wang et al. reported the influence of the doping amount of BiAlO3 on microstructure and electrical properties of (1 − x)(0.93Bi0.5Na0.5TiO3–0.07BaTiO3)–xBiAlO3 ceramics and found that the addition of BiAlO3 could effectively disrupt ferroelectric order and led to a degradation of the remanent polarization and coercive field [19]. It is also reported that the addition of BiAlO3 into BNKT significantly disrupted ferroelectric order and enhanced strain due to the formation of a ferroelectric-relaxor phase boundary [14,15,16, 20].

As demonstrated above, BiAlO3 is one of important chemical modifiers. In order to tune dielectric and ferroelectric behavior, (1 − x)(Bi0.5Na0.42K0.08)0.96Sr0.04Ti0.975Nb0.025O3–xBiAlO3 (BNKTBA/x) lead-free ceramics were prepared by means of the solid-state reaction method. The effects of BiAlO3 on phase structure, microstructure, dielectric properties, and ferroelectric properties of the ceramics were systematically studied.

2 Experimental procedure

The (1 − x)(Bi0.5Na0.42K0.08)0.96Sr0.04Ti0.975Nb0.025O3–xBiAlO3 (BNKTBA/x, x = 0, 0.01, 0.02, 0.03, 0.05) ceramics were achieved via the traditional solid-state reaction method using powders Na2CO3 (99.8%), Bi2O3 (98.9%), K2CO3 (99%), Nb2O5 (99.5%), SrCO3 (99%), TiO2 (98.0%), and Al2O3 (99.99%) as starting raw materials. The powders were baked at 120 °C for 24 h before weighing. Each raw material was weighed according to the chemical formula and their mixture were ball-milled for 24 h in ethanol with zirconia balls, and then calcined at 850 °C for 3 h after drying. The calcined powders were ball-milled for 12 h again. After drying, the powders were compacted into pellets with the size of 1.2 mm in thickness and 10 mm in diameter under cold isostatic press 200 Mpa for 5 min. The pellets were buried in the powders with the same composition in an alumina crucible and then sintered at 1145 °C for 3 h.

Bulk densities of the sintered pellets were determined according to the Archimedes method. Phase structure of the ceramics was measured using an X-ray diffraction instrument (XRD, Rigaku D/Max 2550). Lattice parameters were extracted based on the XRD data by means of the software Jade 6. Microstructure of the ceramics was investigated with the Nova Nano 450 scanning electron microscope (SEM, FEI). For measuring SEM images, the fractured surfaces of the ceramics were polished and then thermally etched at 945 °C for 30 min.

Silver electrodes were coated on both polished sample surfaces and heated at 650 °C for 30 min. Ferroelectric behavior including polarization hysteresis loops and strain curves were recorded using a ferroelectric measurement system (Radiant Technologies Inc., Albuquerque, NM). The samples were poled at 50 kV/cm for 30 min at room temperature. Piezoelectric constant d33 of each poled ceramic was measured using a quasi-static d33 meter (ZJ-4A). Dielectric spectra were measured by means of an Agilent E4980A LCR meter.

3 Results and discussion

The XRD curves for the BNKTBA/x ceramics are displayed in Fig. 1a. All of the ceramics have ABO3 perovskite structure. Some secondary peaks are visible on the XRD curves of the samples with x > 0. These additional XRD peaks can be attributed to the reaction products between Al3+ and Bi3+, such as Bi2Al4O9 [14, 15, 21, 22] and Bi48Al2O75 [16], which are always observed in the BiAlO3-doped BNT-based ceramics [14,15,16, 21,22,23]. The position of the XRD peaks shifts towards high angle direction as x increases from 0 to 0.02 (Fig. 1b), indicating contraction of the lattice. All the ceramics exhibit pseudocubic symmetry, which can be indexed according to the JCPDS No. 89-3109 [24]. Based on the JCPDS No. 89-3109, the extracted lattice parameters a are 3.909(6) Å, 3.907(7) Å, 3.903(8) Å, 3.905(2) Å, and 3.905(1) Å for the samples with x = 0, 0.01, 0.02, 0.03, and 0.05, respectively. The radius of Al3+ (0.535 Å, coordination number CN = 6) is smaller than that of Ti4+ (0.605 Å, CN = 6) or Nb5+ (0.64 Å, CN = 6). The entrance of Al3+ into the B-site will cause contraction of the lattice due to the smaller radius of Al3+. For the ceramics with x ≥ 0.03, the XRD peaks almost do not shift with increasing x, implying that no more Al3+ ions entered into these samples.

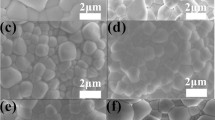

The bulk densities of the BNKTBA/x (x = 0, 0.01, 0.02, 0.03, and 0.05) ceramics are 5.72, 5.75, 5.80, 5.83, and 5.81 g/cm3, respectively, corresponding to the relative densities higher than 96.5% (the theoretical density of 5.92 g/cm3 roughly used for all the samples). Figure 2 shows SEM images of fractured surfaces of the polish and thermally etched ceramics. The dense microstructures have been developed and almost no pores can be found in the bulk of the ceramics, coinciding with the high relative densities.

The dielectric constant (εr) values of the ceramics at 25 °C and 1 kHz are 1889, 1799, 1882, 1740, and 1776 for x = 0, 0.01, 0.02, 0.03, and 0.05, respectively. The corresponding dielectric loss (tanδ) values are 0.06, 0.05, 0.06, 0.05, and 0.06, respectively. The temperature-dependent εr and tanδ of the unpoled ceramics are displayed in Fig. 3. All of the dielectric constant ~ temperature curves present two dielectric anomalies. The shoulder locating at the low-temperature side is denoted as TL. The peak at the high-temperature side is denoted as TH. For all of the samples, there appears frequency dispersion of dielectric constant around TL. As temperature further increases to TH, the values of dielectric constant at different frequencies tend to be same. At temperature higher than TH, frequency dispersion of dielectric constant appears again. The similar phenomena are always reported in BNT-based system [25,26,27,28]. The two dielectric anomalies are related to thermal evolution of polar nanoregions (PNRs) with different structural symmetry [26,27,28]. The temperature TH is always used to determine Curie temperature in BNT-based ceramics [3]. The values of TH change slightly for the ceramics with x = 0, 0.01, 0.02, 0.03, and 0.05, which are 290 °C, 296 °C, 299 °C, 284 °C, and 296 °C, respectively. The dielectric constant at TH is denoted as εm. The εm values of the ceramics are 3892, 3766, 3863, 3449, and 3296 for x = 0, 0.01, 0.02, 0.03, and 0.05, respectively. In the temperature range between approximate 150 °C and TH, the changes in dielectric constant with increasing measurement temperatures become gentle for the ceramics with the high doping amounts due to the decrease of εm. For a given difference in εr between 150 °C and a given temperature Tx (denoted as \(\Delta\varepsilon_{\rm r}=\varepsilon_{{\rm r},150} - \varepsilon_{{\rm r},T_{x}}\)), the temperature window from 150 °C to Tx becomes wider with an increase in BiAlO3 amount, in which εr,150 is dielectric constant at 150 °C, εr,Tx is the dielectric constant at Tx. For example, when Δεr = 500, the Tx values are 214 °C, 216 °C, 219 °C, 223 °C, and 232 °C for x = 0, 0.01, 0.02, 0.03, and 0.05, respectively. The corresponding values of temperature window are 64 °C, 66 °C, 69 °C, 73 °C, and 82 °C, respectively. Moreover, in this temperature range, dielectric loss is stable with changing temperature. The doping of BiAlO3 is beneficial to temperature stability of εr and tanδ in the high-temperature region.

All of the ceramics were poled at room temperature under 50 kV/cm. The electric field of 50 kV/cm is much larger than the values of coercive field (as shown in Fig. 7). The electric field is enough for poling BNT-based ceramics, as also reported elsewhere [29, 30]. However, all of the poled ceramics exhibit piezoelectric constant d33 values close to 0. According to the thermodynamic theory of ferroelectrics [31], d33 is proportional to remnant polarization Pr:

where Q11 represents the electrostrictive coefficient that is constant for a given perovskite material; ε33T represents dielectric constant of the material. As shown in Fig. 7, the Pr values under 50 kV/cm are 3.22 µC/cm2, 4.13 µC/cm2, 3.41 µC/cm2, 3.63 µC/cm2, and 7.24 µC/cm2 for x = 0, 0.01, 0.02, 0.03, and 0.05, respectively. The ceramics exhibit low Pr values, which should correspond to the very low d33 values.

Figure 4 shows the temperature (T)-dependent εr and tanδ of the poled ceramics. As can be seen, the changes of εr with increasing temperature for the poled samples are almost as same as those for the unpoled samples (Fig. 3). It has been widely reported that there always appears a Td anomaly on the dielectric spectra for the poled BNT-based ceramics, where Td is defined as the temperature corresponding to a sharp peak on the tanδ–T curves and the steepest increase on the εr–T curves [25, 29, 32]. Td is the temperature where an electric field-induced long-range ferroelectric order reverts back to the initial relaxor state upon heating, which marks the depolarization [27, 33]. However, for the present poled samples, no Td anomaly was observed on the dielectric spectra. The results suggest that depolarization occurs for the poled samples at room temperature. The results are consistent with the ferroelectric characteristic of the samples, as shown later.

The diffuse character around TH was studied according to the modified Curie–Weiss law [34]:

where C is Curie-like constant, εm is the maximum dielectric constant at TH, and γ is the degree of diffuseness. In general, the value of γ ranges from 1 to 2, corresponding to a typical ferroelectric to an ideal relaxor ferroelectric. Figure 5 demonstrates the fitting lines of Ln(1/εr− 1/εm) as a function of Ln(T − TH). The γ values of the ceramics are 1.82, 1.85, 1.86, 1.93, and 1.93 for x = 0, 0.01, 0.02, 0.03, and 0.05, respectively. Obviously, the values of γ are close to 2, suggesting diffusion characteristic around TH for all of the samples. The diffuse character of dielectric behavior in BNT-based ceramics is associated with the existence of complex cations, which possess similar radii but different charges and electronic configurations at an equivalent crystallographic site [35,36,37]. With the increase in BiAlO3 doping content, more dopants enter into the crystallite site, causing an increase in the γ values.

The polarization (P)–electric field (E) loops of the ceramics under different electric fields (10 kV/cm–100 kV/cm) measured at room temperature are presented in Fig. 6a–e. The P–E loops display pinching-type shape under various measurement electric fields. The similar observation has been reported in other BNT-based ceramics [28, 38, 39]. Lim et al. attributed this behavior to the existence of pseudocubic phase [40]. Fan et al. argued that the pinched loops are always accompanied by the absence of Td on the εr–T curves, which is related to ergodic relaxor nature [41]. For the present poled ceramics, there is no Td anomaly on the dielectric spectra (Fig. 4). The dielectric behavior implies that no long-range ferroelectric order exists in the samples at room temperature. The doping of various ions into the BNT lattice, including K+, Sr2+, Nb5+, and Al3+, can disrupt the long-range ferroelectric order and result in ergodic relaxor phase, causing the pinched P–E loops [42,43,44]. The remnant polarization (Pr), maximum polarization (Pm), and coercive field (Ec) values as a function of measurement electric fields for all the samples are shown in Fig. 7a–e. For a given sample, the Pm, Pr, and Ec values increase with an increase in measurement electric fields. The increase of Pm from 10 to 100 kV/cm is more remarkable compared to the changes of Pr and Ec, demonstrating electric field-induced increment of polarization. The ceramics with x = 0, 0.01, and 0.02 exhibit gentle variation in Pr and Ec during the whole range of the measurement electric fields. The increases of Pr and Ec become obvious at the high electric fields for the ceramic with x = 0.03 (≥ 90 kV/cm). The ceramic with x = 0.05 shows significant increase in Pr and Ec during the whole measurement electric fields compared to the other samples. The P–E loops of the ceramics measured at 100 kV/cm are compared in Fig. 6f, and the corresponding Pm, Pr, and Ec values are shown in Fig. 7f. The Pm values show a downward trend with the increase of x and reach a maximum value (44.43 µC/cm2) at x = 0.02. The change of Pr for the ceramics from x = 0 to 0.02 is not significant, and the value increases from 3.59 to 4.48 µC/cm2; the increase of Pr is more obvious for the ceramics from x = 0.02 to 0.05, which changes from 4.48 to 9.21 µC/cm2. Accordingly, the Ec values show decreasing trend from 8.48 to 7.35 kV/cm as x changes from 0 to 0.02. As x changes from 0.02 to 0.05, the Ec values increase from 7.35 to 16.89 kV/cm. Among the samples, the ceramic shows relatively low Pr of 4.48 µC/cm2, highest Pm of 44.43 µC/cm2, and lowest Ec of 7.35 kV/cm at x = 0.02.

Figure 8a–e shows the bipolar electric field-induced strain (S–E) curves of the ceramics under various electric fields (40 kV/cm–100 kV/cm) measured at room temperature. For all the samples, the S–E hysteresis loops are sprout-shaped and negative strain is almost absent. The strain curves of the samples with x ≤ 0.03 are similar, while the ceramic exhibits slender strain curves at x = 0.05. Figure 8f exhibits the maximum strain values under positive electric fields (Sm+) and negative electric fields (Sm−) as a function of measurement electric fields. It is evident that the electric-induced strain strongly depends on the applied electric fields and the strain values increase continuously with an increase in the electric fields for a given sample. The S–E loops of the sample with x = 0 are slightly asymmetric, causing a difference in Sm+ and Sm− at a given measurement electric field. The asymmetry is always attributed to the presence of internal bias field (Ei ) [8, 45]. The values of Ei can be calculated via the formula Ei = |Ec+| − |Ec−|, in which Ec+ and Ec− are electric fields at which the polarization values equal to zero under positive electric field and negative electric field, respectively. For example, the Ec+ and Ec− values are 9.15 kV/cm and − 7.81 kV/cm for x = 0 at 100 kV/cm, respectively; so, the value of Ei is 1.34 kV/cm. In addition, compared to the rapid growth of strain values with increasing E for the samples with low doping content, the growth trend of strain values is obviously slow for the sample with x = 0.05, which is contrary to the variation trends of Pr and Ec with changing E (Fig. 8f). The ceramic shows the Sm+ and Sm− values of 0.35% and 0.32% under 100 kV/cm for x = 0.02, respectively. The ceramic with x = 0.05 shows the smallest strain values, which are 0.16% and 0.17% for Sm+ and Sm−, respectively. The relatively high strain performance for the samples with low doping amount should be related to the coexistence of FE and ER phases [41, 46, 47].

4 Conclusions

Lead-free ceramics BNKTBA/x with dense microstructures were successfully fabricated by means of the conventional solid-state reaction method. The influence of the BiAlO3 doping on dielectric and ferroelectric properties was investigated. All of the ceramics present pseudocubic structure. For a given sample, whether it is poled or not, two dielectric anomalies are observed on the dielectric spectra and no Td anomaly is observed in the studied temperature range. The doping of BA induces relaxor character, resulting in pinched-shape P–E and sprout-shape S–E hysteresis loops. The ceramic BNKTBA/0.02 shows the relatively low Pr of 4.48 µC/cm2, the highest Pm of 44.43 µC/cm2, lowest Ec of 7.35 kV/cm, and large Sm+ of 0.35%.

References

J. Rődel, K.G. Webber, R. Dittmer, W. Jo, M. Kimura, D. Damjanovic, J. Eur. Ceram. Soc. 35, 1659 (2015)

J.L. Xu, H. Deng, Z. Zeng, Z. Zhang, K.Y. Zhao, J.W. Chen, N. Nakamori, F.F. Wang, J.P. Ma, X.B. Li, H.S. Luo, Appl. Phys. Lett. 112, 182901 (2018)

Y.C. Wu, G.S. Wang, Z. Jiao, Y.Z. Fan, P. Peng, X.L. Dong, RSC Adv. 9, 21355 (2019)

Y.C. Liu, Y.F. Chang, F. Li, B. Yang, Y. Sun, J. Wu, S.T. Zhang, R.X. Wang, W.W. Cao, ACS Appl. Mater. Inter. 9, 29863 (2017)

G. Wang, J.L. Li, X. Zhang, Z.M. Fan, F. Yang, A. Feteira, D. Zhou, D.C. Sinclair, T. Ma, X.L. Tan, D.W. Wang, I.M. Reaney, Energy Environ. Sci. 12, 582 (2019)

R.A. Malik, A. Hussain, M. Acosta, J. Daniels, H.S. Han, M.H. Kim, J.S. Lee, J. Eur. Ceram. Soc. 38, 2511 (2018)

R.A. Malik, J.K. Kang, A. Hussain, C.W. Ahn, H.S. Han, J.S. Lee, Appl. Phys. Express 7, 061502 (2014)

X.M. Liu, X.L. Tan, Adv. Mater. 28, 574 (2016)

X.F. Zhou, Z.N. Yan, H. Qi, L. Wang, S.Y. Wang, Y. Wang, C. Jiang, H. Luo, D. Zhang, J. Eur. Ceram. Soc. 39, 2310 (2019)

D.S. Yin, Z.H. Zhao, Y.J. Dai, Z. Zhao, X.W. Zhang, S.H. Wang, J. Am. Ceram. Soc. 99, 2354 (2016)

T.Y. Li, X.J. Lou, X.Q. Ke, S.D. Cheng, S.B. Mi, X.J. Wang, J. Shi, X. Liu, G.Z. Dong, H.Q. Fan, Y.Z. Wang, X.L. Tan, Acta Mater. 128, 337 (2017)

T. Wang, X.M. Chen, Y.Z. Qiu, Ferroelectrics 510, 161 (2017)

R. McQuade, T. Rowe, A. Manjon-Sanz, L. de la Puente, M.R. Dolgos, J. Alloys Compd. 762, 378 (2018)

A. Ullah, C.W. Ahn, A. Hussain, S.Y. Lee, I.W. Kim, J. Am. Ceram. Soc. 94, 3915 (2011)

A. Ullah, C.W. Ahn, A. Hussain, S.Y. Lee, I.W. Kim, Curr. Appl. Phys. 10, 1174 (2010)

A. Ullah, C.W. Ahn, A. Hussain, I.W. Kim, H.I. Hwang, N.K. Cho, Solid State Commun. 150, 1145 (2010)

P. Fu, Z.J. Xu, R.Q. Chu, X.Y. Wu, W. Li, M.J. Zhao, J. Alloys Compd. 535, 5 (2012)

P. Shi, L.G. Zhu, W.W. Gao, Z.H. Yu, X.J. Lou, X.J. Wang, Z.M. Yang, S. Yang, J. Alloys Compd. 784, 788 (2019)

J. Wang, X.M. Chen, X.M. Zhao, X.X. Liang, J.P. Zhou, P. Liu, Mater. Res. Bull. 67, 94 (2015)

T. Zheng, J.G. Wu, D.Q. Xiao, J.G. Zhu, Prog. Mater. Sci. 98, 552 (2018)

H.C. Yu, Z.G. Ye, Appl. Phys. Lett. 93, 112902 (2008)

Z. Liu, W.J. Ren, P. Peng, S.B. Guo, T. Lu, Y. Liu, X.L. Dong, G.S. Wang, Appl. Phys. Lett. 112, 142903 (2018)

Z.L. Yu, Y.F. Liu, M.Y. Shen, H. Qian, F.F. Li, Y.N. Lyu, Ceram. Int. 43, 7653 (2017)

Joint Committee on Powder Diffraction Standards-International Center for Diffraction Data (JCPDS-ICDD) Card (2002)

H.S. Han, W. Jo, J. Rődel, I.K. Hong, W.P. Tai, J.S. Lee, J. Phys. Condens. Mater. 24, 365901 (2012)

X.S. Qiao, X.M. Chen, H.L. Lian, J.P. Zhou, P. Liu, J. Eur. Ceram. Soc. 36, 3995 (2016)

W. Jo, S. Schaab, E. Sapper, L.A. Schmitt, H.J. Kleebe, A.J. Bell, J. Rődel, J. Appl. Phys. 110, 074106 (2011)

C. Wang, T.D. Xia, X.J. Lou, Ceram. Int. 44, 7378 (2018)

R.Y. Jing, X.M. Chen, H.L. Lian, X.S. Qiao, X.J. Shao, J.P. Zhou, J. Eur. Ceram. Soc. 38, 3111 (2018)

J.P. Ma, X.M. Chen, H.L. Lian, Q. Zhang, J.Q. Liu, J. Eur. Ceram. Soc. 39, 264 (2019)

M.J. Haun, E. Furman, S.J. Jang, L.E. Cross, Ferroelectrics 99, 13 (1989)

X.S. Qiao, X.M. Chen, H.L. Lian, W.T. Chen, J.P. Zhou, P. Liu, J. Am. Ceram. Soc. 99, 198 (2016)

J. Zhang, Z. Pan, P.X. Nie, Y.S. Cui, B. Yang, J. Chen, S.T. Zhang, Appl. Phys. Lett. 106, 232904 (2015)

W.P. Cao, J. Sheng, Y.L. Qiao, L. Jing, Z. Liu, J. Wang, W.L. Li, J. Eur. Ceram. Soc. 39, 4046 (2019)

T. Wang, X.M. Chen, Y.Z. Qiu, H.L. Lian, W.T. Chen, Mater. Chem. Phys. 186, 407 (2017)

L.N. Liu, X.M. Chen, R.Y. Jing, H.L. Lian, W.W. Wu, Y.P. Mou, P. Liu, J. Mater. Sci.: Mater. Electron. 30, 5233 (2019)

R.Y. Jing, X.M. Chen, J.P. Ma, H.L. Lian, W.W. Chen, J. Mater. Sci. 53, 574 (2018)

S. Manotham, P. Jaita, C. Randorn, G. Rujijanagul, D.P. Cann, J. Alloys Compd. 808, 151655 (2019)

P. Jaita, R. Sanjoom, N. Lertcumfua, G. Rujijanagul, RSC Adv. 9, 11922 (2019)

D.H. Lim, M. Saleem, I.S. Kim, M.S. Kim, B.K. Koo, S.J. Jeong, Sensors Actuators A 282, 163 (2018)

P.Y. Fan, Y.Y. Zhang, B. Xie, Y.W. Zhu, W.G. Ma, C. Wang, B. Yang, J.L. Xu, J.Z. Xiao, H.B. Zhang, Ceram. Int. 44, 3211 (2018)

R.A. Malik, A. Hussain, A. Maqbool, A. Zaman, C.W. Ahn, J.U. Rahman, T.K. Song, W.J. Kim, M.H. Kim, J. Am. Ceram. Soc. 98, 3842 (2015)

X. Liu, J.W. Zhai, B. Shen, F. Li, Y. Zhang, P. Li, B.H. Liu, J. Eur. Ceram. Soc. 37, 1437 (2017)

J.G. Hao, Z.J. Xu, R.Q. Chu, W. Li, J. Du, P. Fu, RSC Adv. 5, 82605 (2015)

G. Du, R.H. Liang, L. Wang, K. Li, W.B. Zhang, G.H. Wang, X.L. Dong, Ceram. Int. 39, 7703 (2013)

R.F. Cheng, Z.J. Xu, R.Q. Chu, J.G. Hao, J. Du, G.R. Li, J. Eur. Ceram. Soc. 36, 489 (2016)

P.Y. Fan, Y.Y. Zhang, Q. Zhang, B. Xie, Y.W. Zhu, M.A. Mawat, W.G. Ma, K. Liu, J.Z. Xiao, H.B. Zhang, J. Eur. Ceram. Soc. 38, 4404 (2018)

Acknowledgements

This work was supported in part by National Natural Science Foundation of China (No. 51972202) and Fundamental Research Funds for the Central Universities (No. GK201901005).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, X., Chen, Xm., Liu, Ln. et al. Effect of BiAlO3 doping on dielectric and ferroelectric properties of (Bi0.5Na0.42K0.08)0.96Sr0.04Ti0.975Nb0.025O3 lead-free ceramics. J Mater Sci: Mater Electron 31, 17491–17501 (2020). https://doi.org/10.1007/s10854-020-04305-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04305-7