Abstract

In this work, the hierarchical NiCo2O4 self-assembled by lamellar flakes were successfully synthesized by a simple solvothermal route and subsequent thermal treatment. The composition and microstructure of the hierarchical NiCo2O4 were characterized by XRD and SEM, respectively. The microwave absorption properties were also evaluated. An optimum reflection loss (RL) of − 45.5 dB at 4.6 GHz with a composite thickness of 4.2 mm and effective bandwidth (RL < − 10 dB) of 7.7 GHz were obtained. The excellent electromagnetic wave absorption property of the hierarchical NiCo2O4 is due to the conduction loss and dielectric loss of NiCo2O4, the hierarchical structure could also enhance the microwave absorbing properties by the strong multi-reflections and scattering of microwave between stacking layers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In recent years, with the development of social science and technology, people’s lives become more convenient, but there still have a large number of ecological problems [1, 2]. One of which is electromagnetic radiation pollution, the main cause of this pollution is the extensive use of electronic products [3,4,5]. The deterioration of the electromagnetic environment will not only affect the normal operation of electronic equipment, but also endanger human’s health [6, 7]. Therefore, considerable efforts have been devoted recently to the development of various materials and structures that can be used to steal or shield unwanted electromagnetic waves, such as carbon nanostructures and nanocomposites [8,9,10], metal–organic frameworks [11], magnetic materials [12, 13], 2-D materials and their nanocomposites [14, 15]. However, the fabrication of a high performance, light weight and low cost microwave absorbent is still facing challenges.

NiCo2O4 has attracted great interest in the fields of batteries [16], microwave absorbing materials [17, 18], due to its high specific surface area, unique electric and electrochemical properties [19, 20]. Min Zhou et al. revealed that the complex permittivity and corresponding microwave absorption performance of NiCo2O4 nanoflakes with different thickness [17], and the complex permittivity depends on the thickness of nanoflakes [21]. Jing Zhan et al. obtained an excellent reflection loss (RL) of − 35.76 dB at 14.86 GHz with a composite thickness of 1.50 mm and effective bandwidth (RL < − 10 dB) of 11.18 GHz with the Quasione-dimensional NiCo2O4 nanostructure [22]. The above research showed that the morphology of nanomaterial has profound effects on their microwave absorption properties. Therefore, an hierarchical NiCo2O4 self-assembled by lamellar flake may own much more excellent microwave absorption property.

In this work, the hierarchical NiCo2O4 has been successfully synthesized by a simple solvothermal method and subsequent thermal treatment, which is non-toxic low cost, easy processing techniques for the preparation of nanomaterials [23, 24]. The complex permittivity and microwave absorption properties of the hierarchical NiCo2O4 was also investigated.

2 Experimental

2.1 Materials preparations

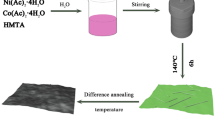

All chemicals were of analytical grade and used as received without further purification. In the simple solvothermal processing, 0.58 g Ni(NO3)2, 1.16 g Co(NO3)2 and 4.8 g of urea were dissolved in the mixture of 45 mL isopropanol and 15 mL deionized water, the as-obtained solution was then dispersed under continuous stirring for 30 min, then the resulting mixture was transferred into a Teflon-lined autoclave and heated at 150 °C for 15 h. After that, the pale pink precipitate was washed with deionized water and ethanol for three times, and finally dried in air for 24 h. The hierarchical NiCo2O4 was prepared through calcinating the above precursor at 400 °C for 2 h in air with a heating rate of 5 °C/min.

2.2 Materials characterization

The phase and purity of the product were characterized by powder X-ray diffraction (XRD) analyses (XD-3, Cu Kα radiation, λ = 1.54178 Å. Beijing Purkinje General Instrument Co. Ltd). The morphologies of the as-synthesized nickel products were observed with field emission scanning electron microscopy (FE-SEM, FEI). The thermal properties of the precursor were researched by differential scanning calorimeter (DSC, STA 409 PC/4/H). The samples of hierarchical NiCo2O4 were pressed into a toroidal shape (φout = 7.00 mm, φin = 3.04 mm). The relative complex permittivity (εr = ε′–jε″) and permeability (μr = μ′–jμ″) of the hierarchical NiCo2O4-paraffin composites were performed by a vector network analyzer (Agilent, N5244A) in the 2–18 GHz range using the transmission/reflection method, and the hierarchical NiCo2O4 were uniformly blended with wax matrix (which is transparent to microwaves) at 50% weight fraction (50 wt%).

3 Results and discussion

To ensure the appropriate temperature of the thermal conversion of the NiCo2O4 precursor, the temperature change behavior in the air has been investigated at a heating rate of 10 °C/min. The TG-DSC curves are shown in Fig. 1a, which obviously reveals that there was an endothermic peak in the DTA curve and a corresponding sharp mass loss from 200 to 400 °C, indicating that the decomposition temperature of the precursor started from 200 °C then completely decomposed at 400 °C [25]. Previous studies revealed that NiCo2O4 is unstable above 400 °C and decomposes into NiO and Co3O4 [17]. According to the TG-DSC curves, we choose 400 °C as thermal treatment of the precursor to ensure that it has been completely decomposed.

The calcined NiCo2O4 was then confirmed by XRD in order to obtain the crystal structure, as shown in Fig. 1b. All the indexed peaks could be attributed to (111), (220), (311), (222), (400), (422), (511), (440) planes of the cubic NiCo2O4 (JCPDS 20-0781) [18]. No peaks attributed to impurities are observed, indicating the formation of pure NiCo2O4 product, which is consisted with the results of TG-DSC. The crystallite size of NiCo2O4 was also evaluated using the Scherrer equation [26,27,28]:

where, D is the crystallite size, β is the full width at half-maximum height (FWHM), and θ is the Bragg diffraction angle (°), λ is the wavelength of the X-ray radiation (Cu Kα = 0.15 nm), and K is the Scherrer constant. The average crystallite size calculated for NiCo2O4 was almost 28 nm.

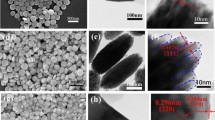

The morphology and microstructure of the precursor and calcination products were studied by SEM techniques, as shown in Fig. 2. The as-prepared precursor is flower-like microspheres with interdigitated pieces, the diameter of the microspheres is about 2–3 μm, as shown in Fig. 2a. The unique hierarchical nanostructure still remained after the precursors were annealed at 400 °C, as shown in Fig. 2(b–c), indicating that the decomposition process is an in situ reaction during the annealing treatment, and robustness of the structures is brilliant. Furthermore, this hybrid structure may benefit to the multi-reflection and scattering for absorptions of microwave energy [29].

It is well known that the real permittivity (ε′) and the real permeability (μ′) symbolize the storage ability of electric and magnetic energy, while the imaginary permittivity (ε″) and the imaginary permeability (μ″) signify the dissipation ability of electric and magnetic energy [30, 31]. Figure 3a shows the frequency dependence of real parts (ε′), imaginary parts (ε″) of complex relative permittivity and real parts (μ′), imaginary parts (μ″) of complex relative permeability of NiCo2O4-paraffin composites. Owing to the absence of magnetic components, the real part (µ′) and imaginary part (µ″) of complex permeability were almost 1 and 0, respectively. It is also observed that the ε′ values of the sample decrease from 14.7 at 14 GHz to 7.5 at 18 GHz (the ε′ values of the sample decrease from 8 at 15.2 GHz to 5 at 18 GHz), which is associated with resonant behavior [32], and with little fluctuation in the frequency range of 2–14 GHz. This kind of fluctuation is due to the polarization, which cannot keep up with the pace of electric field change at GHz frequency [33].

a Frequency dependence of real parts (ε′) and imaginary parts (ε″) of complex relative permittivity and real parts (μ′) and imaginary parts (μ″) of complex relative permeability of NiCo2O4-paraffin composites. b Reflection loss curves of NiCo2O4-paraffin composites with 50% NiCo2O4 at various of thicknesses

To further evaluate the electromagnetic absorption properties of the different mass fraction NiCo2O4 samples, the reflection loss (RL) values of 50% of the NiCo2O4 composites were simulated through the following equations, based on the measured complex permeability and complex permittivity with a given absorber thickness and tested frequency [34,35,36,37].

Here Z0 is the impedance of free space, Zin is the input characteristic impedance, εr is the complex permittivity, μr is the complex permeability, f is the frequency, c is the velocity of light, and d is the absorber’s thickness. Figure 3b depicts the calculated reflection loss (RL) curves of 50% NiCo2O4,with different absorber thickness. The optimal reflection loss of − 45.5 dB was observed at 4.6 GHz, 4.2 mm, which corresponds to the effective absorbing band which was 3.6–11.3 GHz (7.7 GHz), as shown in Fig. 3b. The 3D plane simulation reflection loss curves of NiCo2O4-paraffin composites with 50% NiCo2O4 at various of thicknesses was shown in Fig. 4, which shows that the main focus was on the low-frequency band.

The associated loss mechanism of electromagnetic waves firstly due to the good conductivity of NiCo2O4, the electromagnetic waves can be attenuated by the conductive loss, because there were more high surface electrons in the lamellae. Secondly, the chemical bonds were increased in the surfaces of hierarchical NiCo2O4, a large number of chemical bonds let the dipole polarizations enhanced. Thirdly, the presence of the stacking layer caused multiple reflections of the microwave on the surface, increased the probability of dissipation with microwave internal. Good impedance matching of lamella spherical NiCo2O4 was a key factor in perfect microwave absorbing performance.

4 Conclusions

In summary, lamella spherical NiCo2O4 was successfully prepared by a simple solvothermal method and subsequent thermal treatment. The minimum reflection loss was − 45.5 dB at 4.6 GHz when the absorber thickness was 4.2 mm and the effective absorbing band is 3.6–11.3 GHz (7.7 GHz). The excellent electromagnetic wave absorption property of the hierarchical NiCo2O4 is generated by the conduction loss and dielectric loss of NiCo2O4, the hierarchical structure could also enhance the microwave absorbing properties by the strong multi-reflections and scattering of microwave between stacking layers.

References

Y. Li, J. Zhang, Z. Liu, M. Liu, H. Lin, R. Che, J. Mater. Chem. C 2, 5216–5222 (2014)

M. Zhou, X. Zhang, J. Wei, S. Zhao, L. Wang, B. Feng, J. Phys. Chem. C 115, 1398–1402 (2011)

R. Zhuo, Y. Wang, D. Yan, S. Li, Y. Liu, F. Wang, Mater. Lett. 117, 34–36 (2014)

J. Zhu, S. Wei, N. Haldolaarachchige, D.P. Young, Z. Guo, J. Phys. Chem. C 115, 15304–15310 (2011)

L. Kong, X. Yin, Y. Zhang, X. Yuan, Q. Li, F. Ye, L. Cheng, L. Zhang, J. Phys. Chem. C 117, 19701–19711 (2013)

T. Su, B. Zhao, F. Han, B. Fan, R. Zhang, J. Mater. Sci. 30, 475–484 (2018)

M. Mishra, A.P. Singh, B.P. Singh, V.N. Singh, S.K. Dhawan, J. Mater. Chem. A 2, 13159–13168 (2014)

C. Wang, V. Murugadoss, J. Kong, Z. He, X. Mai, Q. Shao, Y. Chen, L. Guo, C. Liu, S. Angaiah, Z. Guo, Carbon 140, 696–733 (2018)

P. Xie, H. Li, B. He, F. Dang, J. Lin, R. Fan, C. Hou, H. Liu, J. Zhang, Y. Ma, J. Mater. Chem. C 6, 8812–8822 (2018)

N. Wu, C. Liu, D. Xu, J. Liu, W. Liu, H. Liu, J. Zhang, W. Xie, Z. Guo, J. Mater. Chem. C 7, 1659–1669 (2019)

N. Wu, D. Xu, Z. Wang, F. Wang, J. Liu, W. Liu, Q. Shao, H. Liu, Q. Gao, Z. Guo, Carbon 145, 433–444 (2019)

J. Guo, H. Song, H. Liu, C. Luo, Y. Ren, T. Ding, M.A. Khan, D.P. Young, X. Liu, X. Zhang, J. Mater. Chem. C 5, 5334–5344 (2017)

B. Zhao, G. Shao, B. Fan, W. Zhao, R. Zhang, Phys. Chem. Chem. Phys. 17, 2531–2539 (2015)

F. Shahzad, M. Alhabeb, C.B. Hatter, B. Anasori, S.M. Hong, C.M. Koo, Y. Gogotsi, Science 353, 1137–1140 (2016)

B. Dai, B. Zhao, X. Xie, T. Su, B. Fan, R. Zhang, R. Yang, J. Mater. Chem. C 6, 5690–5697 (2018)

W. Zhao, X. Li, R. Yin, L. Qian, X. Huang, H. Liu, J. Zhang, J. Wang, T. Ding, Z. Guo, Nanoscale 11, 50–59 (2019)

M. Zhou, F. Lu, T. Lv, X. Yang, W. Xia, X. Shen, H. He, X. Zeng, J. Phys. D 48, 215305 (2015)

S. Wei, X. Wang, B. Zhang, M. Yu, Y. Zheng, Y. Wang, J. Liu, Chem. Eng. J. 314, 477–487 (2017)

L. Hu, L. Wu, M. Liao, X. Hu, X. Fang, Adv. Funct. Mater. 22, 998–1004 (2012)

L. Shen, Q. Che, H. Li, X. Zhang, Adv. Funct. Mater. 24, 2630–2637 (2014)

M. Zhou, F. Lu, B. Chen, X. Zhu, X. Shen, W. Xia, H. He, X. Zeng, Mater. Lett. 159, 498–501 (2015)

J. Zhan, Y. Yao, C. Zhang, C. Li, J. Alloy. Compd. 585, 240–244 (2014)

D. Dastan, Appl. Phys. A 123, 699 (2017)

D. Dastan, N. Chaure, M. Kartha, J. Mater. Sci. 28, 7784–7796 (2017)

B. Zhao, B. Fan, Y. Xu, G. Shao, X. Wang, W. Zhao, R. Zhang, ACS Appl. Mater. Interfaces. 7, 26217–26225 (2015)

D. Dastan, S.L. Panahi, N.B. Chaure, J. Mater. Sci. 27, 12291–12296 (2016)

D. Dastan, P.U. Londhe, N.B. Chaure, J. Mater. Sci. 25, 3473–3479 (2014)

D. Dastan, S. Leila Panahi, A.P. Yengntiwar, A. Banpurkar, Adv. Sci. Lett. 22, 950–953 (2016)

C. Li, Y. Ge, X. Jiang, Z. Zhang, L. Yu, J. Mater. Sci. 30, 3124–3136 (2019)

Y.-J. Chen, P. Gao, R.-X. Wang, C.-L. Zhu, L.-J. Wang, M.-S. Cao, H.-B. Jin, J. Phys. Chem. C 113, 10061–10064 (2009)

B. Zhao, B. Fan, G. Shao, W. Zhao, R. Zhang, ACS Appl. Mater. Interfaces 7, 18815–18823 (2015)

B. Zhao, G. Shao, B. Fan, W. Zhao, Y. Xie, R. Zhang, Phys. Chem. Chem. Phys. 17, 8802 (2015)

P. Liu, Z. Yao, V.M.H. Ng, J. Zhou, L.B. Kong, Mater. Lett. 248, 214–217 (2019)

R.C. Che, C.Y. Zhi, C.Y. Liang, X.G. Zhou, Appl. Phys. Lett. 88, 033105 (2006)

R. Che, L.M. Peng, X.F. Duan, Q. Chen, X. Liang, Adv. Mater. 16, 401–405 (2004)

R. Che, C. Zhi, C. Liang, X. Zhou, Appl. Phys. Lett. 88, 3105 (2006)

X.G. Liu, D.Y. Geng, H. Meng, P.J. Shang, Z.D. Zhang, Appl. Phys. Lett. 92, 3 (2008)

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) (51602287 and 51672254), and Dr. Bingbing Fan thanks the China Scholarship Council (CSC scholarship No 201907045064) for an academic visitor scholarship.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, B., Lv, S., Guo, W. et al. Preparation of hierarchical NiCo2O4 self-assembled by lamellar flakes and its microwave absorption. J Mater Sci: Mater Electron 30, 17358–17362 (2019). https://doi.org/10.1007/s10854-019-02084-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-02084-4