Abstract

Pure Bi25FeO40, Bi2Fe4O9, and different weight ratios of Bi25FeO40/Bi2Fe4O9 composite photocatalysts have been synthesized via a hydrothermal process combined with a mixing-calcination method and evaluated as visible-light responsive catalyst for the degradation of Rhodamine B (RhB). All the as-prepared samples have been characterized by a range of techniques including X-ray diffraction (XRD), Fourier transform infrared spectra (FT-IR), UV–vis absorption spectra (DSR), Field Emission Scanning Electron Microscope (FE-SEM), Transmission electron microscope (TEM) and High-resolution TEM (HRTEM). The XRD, FT-IR, TEM and HRTEM results confirm that the composite only consists of Bi25FeO40 and Bi2Fe4O9. In the Bi25FeO40/Bi2Fe4O9 composites, closely contacted interfaces have been observed. Compared with the single-phase Bi25FeO40 and Bi2Fe4O9, Bi25FeO40/Bi2Fe4O9 composites exhibit enhanced visible-light responsive photocatalytic activities. The photocatalytic efficiency of optimized Bi25FeO40/Bi2Fe4O9 composite with Bi2Fe4O9 weight ratio of 30% is about 8.8 and 6.2 times higher than that of pure Bi25FeO40 and Bi2Fe4O9, respectively. On the basis of electronic energy-band structure analysis, the active species trapping experiments and the electrochemical impedance spectrum (EIS) performance, a heterojunction-type charge transfer mechanism interpreting the enhanced photocatalytic activities of the composite are proposed and discussed. In addition, the effects of different Bi25FeO40/Bi2Fe4O9 weight ratios and their geometry architecture on photocatalytic activities are also thoroughly discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As a family of environment-friendly metal oxide, Bismuth ferrite (BFO) displays outstanding characteristics including multiferroic [1, 2], electronic [3], optical [4], and gas-sensoring properties [5] in the past decades. Recently, BFO has also obtained wide attentions as a visible-light-driven semiconductor photocatalysis candidate because they have owned fascinating abilities in terms of photodegradation of organic pollutants, photocatalytic water splitting, photovoltaic and photoelectrochemical conversion [6,7,8,9]. They have three types of crystalline phases: perovskite-type BiFeO3, mullite-type Bi2Fe4O9 and selenite-type Bi25FeO40. By virtue of narrowing band gaps of about 2.2 eV and 1.7-2.2 eV respectively, both perovskite-type BiFeO3 and mullite-type Bi2Fe4O9 are found to be sensitive to visible light and exhibit visible-light responsive photocatalytic capacity for the decomposition of Rhodamine B, Congo red, Bisphenol A and other organic pollutions [10,11,12,13]. Meanwhile, selenite-type Bi25FeO40 with a suitable bandgap (< 2.8 eV) features in a body-centered cubic structure (the cubic space group I23), which favors an eminent mobility of photo-generated charges, good nonlinear optical effect and great optical response, making it also an ideal visible-light-driven photocatalysis [14,15,16]. However, the visible-light responsive photocatalytic efficiency of single-component BFO are not very impressive due to the low quantum efficiency, the fast recombination of photogenerated electron–hole pairs and the inefficient light absorption, all of which restrict its practical application [6].

In general, it is still a great challenge to prepare phase-purity BFO structure owing to the kinetics of phase formation of Bi2O3/Fe2O3 and the high volatility of bismuth [17]. Thermodynamic studies demonstrate that the appearance of Bi2Fe4O9, Bi25FeO40, Bi2O3 or Fe2O3 as by-products is difficult to be completely eliminated during the preparation of BiFeO3 [18]. On the contrary, the phase evolution from Bi2Fe4O9 to BiFeO3 and then to Bi25FeO40 in a wide temperature range between 720 K and 1040 K is experimentally observed during the hydrothermal synthesis of BFO as long as the process parameters are changed [19,20,21]. It is notable that the presence of BFO impurities in Bi2O3/Fe2O3 system will bring charge unbalance and structure defects, resulting in the deterioration of its functional properties [22,23,24]. In terms of promoting photocatalytic activity of pure BFO, copious efforts have been exploited mainly including tailoring morphology [14, 25,26,27], controlling exposed facets [12, 13], reducing dimension [8, 28, 29] and doping with metal or nonmetal ions [30,31,32]. For example, Ji et al. also synthesize Bi25FeO40 microtetrahedra, microcubes and microsphere respectively, and the microcubes exhibit 88% photo-Fenton photocatalytic degradation of RhB within 120 min due to its exposed (001) facets with the active O atoms [14]. Hao et al. and Gao et al. demonstrate that reducing the particle size of BiFeO3 can obviously improve its photocatalytic activity, which is mainly ascribed to the increased surface active catalytic-sites and the shortened migrate distances of photogenerated carriers [28, 29]. More importantly, the mixed-phase structure, that is, the coexistence of BFO main phase and BFO impurities, is found to be beneficial to favor the visible light harvesting and boost photocatalytic activity compared to that of pure phases [13, 24, 33,34,35,36,37]. Yang et al. observe that mixed-phase BiFeO3/Bi2Fe4O9 nanoflakes show much better photocatalytic activities than that of pure BFO, which could completely degrade RhB within 240 min under UV irradiation [33]. Similar results have also been found in the BiFeO3/Bi2Fe4O9 composites with 71.45% degradation rate of Congo red in 90 min owing to the formation of hybrid structure and large specific surface area [13]. Since impurities seem to be unavoidable, a novel and feasible strategy in further improving photocatalytic property of BFO is to utilize impurities to construct heterojunction comprising BFO main phase and BFO impurities via a semiconductor coupling technology. Coupling of two semiconductor photocatalysis with staggered alignment of band structures can not only dominate the transport direction, but also effectively facilitate the separation of photogenerated electrons/holes, leading to the enhancement of photocatalytic and electrochemical property [37,38,39,40,41]. For instance, Wang’s group discovers that PtO coupled g-C3N4 exhibit excellent hydrogen production performance, which is mainly due to the strong interaction between the co-catalyst and the host g-C3N4 [38]. Zhao and coworkers design novel Bi4Ti3O12/Bi2Ti2O7 heterostructure nanofibers and observe a dramatic enhancement in the photocatalytic hydrogen evolution activity, which can be ascribed to the internal electric field formed in this composite [41]. Moreover, Zhang et al. synthesize 3D hierarchical CoWO4/Co3O4 structure with the synergetic effect of diverse materials and fast transmission of electrons and ions, demonstrating a high superior rate capability [39]. Following this strategy, Kong et al. find that BiFeO3/(Bi/Fe)2O3 heterojunction displays 2.5 times higher photocatalytic destruction of gaseous toluene than bare BiFeO3, which can be ascribed to carrier transfer between BiFeO3 and (Bi/Fe)2O3 interfaces over nano junctions [35]. Recently, BiFeO3/Bi2Fe4O9 heterojunction nanofibers have also commendable photocatalytic capacity due to a Z-Scheme mechanism based on the results of electronic energy-band structure analysis [7]. Similar phenomena have also been reported in other Bi-based semiconductor photocatalysis [42, 43]. Very recently, Xia’s group prepares an n-SrTiO3/p-BiOI heterojunction by loading SrTiO3 particles onto the surface of BiOI nanoflakes via a two-step method. The obtained n-SrTiO3/p-BiOI composite exhibits excellence photocatalytic performance for the degradation of crystal violet solution [42].

Up till now, there have been seldom reports on Bi25FeO40/Bi2Fe4O9 composites. Herein, a novel Bi25FeO40/Bi2Fe4O9 composite will be necessary to be systematically investigated for offering new insight into the design and application of BFO based high-efficiency photocatalyst. Inspired by the above facts, a series of Bi25FeO40/Bi2Fe4O9 composites were synthesized via the method of facile hydrothermal route and mixing-calcination in this paper. Various techniques including XRD, FI-TR, SEM, TEM (HRTEM) and UV–vis DSR are employed to characterize phase structure, microstructure and optical properties of as-prepared samples. The visible-light responsive photocatalytic activities of Rhodamine B (RhB) over Bi25FeO40/Bi2Fe4O9 composites are evaluated, and the optimal weight ratio of Bi2Fe4O9 to Bi25FeO40 is determined. The Bi25FeO40/Bi2Fe4O9 composites exhibit much higher visible-light responsive photodegradation efficiency of RhB than that of pure Bi25FeO40 and Bi2Fe4O9 respectively. The heterojunction-type photocatalytic mechanism is proposed to interpret charge transfer across Bi25FeO40/Bi2Fe4O9 interfaces, as evidenced by the energy band gap structure analysis, the reactive species trapping experiments and the electrochemical impedance spectra (EIS) measurements. The effects of Bi25FeO40/Bi2Fe4O9 weight ratios on photocatalytic activities of composites are thoroughly investigated.

2 Experimental

2.1 Synthesis

The chemical reagents, that is, Bi(NO3)3·5H2O, Fe(NO3)3·9H2O, HNO3 solution, NaOH mineralizer and KNO3 additive, were used to synthesize pure-phase Bi25FeO40 and Bi2Fe4O9 powders via a simple hydrothermal process. All the chemicals were of analytical grade and used without further purifications. For preparing Bi25FeO40, 12 mmol Bi(NO3)3·5H2O and 1 mmol Fe(NO3)3·9H2O were dissolved and stirred in 20 ml HNO3 solution. Subsequently, the NaOH solution with the concentration of 4 M was slowly added in the solution until the Fe3+ and Bi3+ ions were deposited completely under continuous stirring. The precipitates were withdrawn and washed repeatedly by distilled water before being dissolved in 4 M NaOH solution again. Next, 0.05 mol KNO3 was added into the above solution to control morphology of products. After 1 h of stirring, the mixtures were poured into a stainless-steel Teflonlined reactor, and then heated at 180 °C for 12 h. The powders were finally obtained by centrifugation, being washed several times with water and alcohol, and being dried at 80 °C for 6 h. The Bi2Fe4O9 samples were synthesized using the same hydrothermal procedure except for an initial Bi/Fe ratio of 1:2 (1 mmol Bi(NO3)3·5H2O and 2 mmol Fe(NO3)3·9H2O) [34]. The Bi25FeO40/Bi2Fe4O9 composites were fabricated by a facile mixing-calcination method: a certain amount of Bi2Fe4O9 and Bi25FeO40 powders were mixed, thoroughly grounded in an agate mortar and heated at 300 °C for 1 h. In this manner, the obtained products with different weight ratios of Bi2Fe4O9 to Bi25FeO40/Bi2Fe4O9 composite at 0% (pure Bi25FeO40), 10, 30, 50 and 100% (pure Bi2Fe4O9) were defined as S1, S2, S3, S4 and S5 respectively.

2.2 Characterization

X-ray powder diffraction (XRD) measurements of samples were identified on Philips X’pert PW3373/10 diffractometer by employing Cu Kαradiation (λ = 1.5406 Å) in the 2θ range of 10–80° to identify crystal structures. Fourier transform infrared spectra (FT-IR) of powders were recorded in a Nicolet 6700 spectrophotometer with the wavelength ranging from 400 to 4000 cm−1 at room temperature. The morphology and microcrystalline structure characteristics of samples were performed by a Field Emission Scanning Electron Microscope (FE-SEM, HITACHI UHR FE-SEM SU8000), High-resolution TEM (HRTEM, JEM-2100, JEOL). UV–vis absorption spectra (DSR) of as-prepared powders were measured on a UV–vis spectrophotometer (UV2550, Shimadzu). The photoelectrochemical test was carried out using a typical three-electrode cell on CHI760 electrochemical workstation (Shanghai Chenhua Instrument Co. Ltd). The obtained photocatalysts thin films covered on fluorine-doped tin oxide (FTO) glass by using drop-casting method were used as working electrode. A platinum wire was used as counter electrode, and a saturation calomel electrode (SCE) served as the reference electrode respectively. The 0.5 M Na2SO4 solution was used as electrolyte.

2.3 Photocatalytic activity

The visible-light-driven photocatalytic activities of pure Bi25FeO40, Bi2Fe4O9 and a series of Bi25FeO40/Bi2Fe4O9 composites were evaluated by degradation of RhB aqueous solution. A 500 W Xe lamp equipped with a cutoff filter (λ > 420 nm) was employed as the visible light source. 100 mg photocatalysis was dispersed in 100 mL of 10 mg/L RhB aqueous solution. Before irradiation, the suspension was continuously stirred in dark for 1 h to get absorption–desorption equilibrium between the photocatalysis and RhB. At every 1 h time interval, 3 ml of the suspension was taken from the reactor and centrifuged at 12,000 rpm for 30 min, then analyzed on UV–vis spectrophotometer at a wavelength of 533 nm to determine the RhB concentration. Active species capturing experiments over Bi25FeO40/Bi2Fe4O9 composite were also carried out during the identical photocatalytic procedure by adding 1 mmol scavengers, namely, 2-propanol (IPA), pbenzoquinone (BQ) and disodium ethylenediamine tetraacetic acid (EDTA-2Na), into the RhB solution to trap hydroxyl radicals (·OH), superoxide radicals (·O2−) and holes (h+) respectively [44].

3 Results and discussion

3.1 XRD and FT-IR analysis

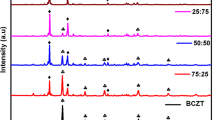

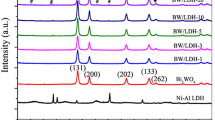

Figure 1 shows X-ray diffraction patterns of Bi25FeO40, Bi2Fe4O9 and Bi25FeO40/Bi2Fe4O9 composites. For pure Bi25FeO40 and Bi2Fe4O9, all characteristic diffraction peaks can be perfectly indexed to the single-phase orthorhombic structure Bi2Fe4O9 (JCPDS card No. 74-1098) and body-centered cubic structure Bi25FeO40 (JCPDS card No. 46-0416) respectively, which retains consistency with previous literatures [9, 12]. The sharp diffraction peaks in their spectra indicate that they are highly-crystallized. The characteristic diffraction peaks of Bi25FeO40/Bi2Fe4O9 composites does not change greatly and can be also in good agreement with either cubic Bi25FeO40 or orthorhombic Bi2Fe4O9, displaying the coexistence of Bi25FeO40 and Bi2Fe4O9 in the composites. No other impurity peaks are found, further confirming that the composites are two phases system [45]. However, although the XRD pattern of the sample S2 is quite similar to that of pure Bi25FeO40, it possess some weak diffraction peaks of Bi2Fe4O9 (28.2° and 28.9°), which is probably due to the low content of Bi2Fe4O9 and the overlapped peaks between Bi25FeO40 and Bi2Fe4O9 in the composite [46]. As predicted, the intensity of the three most intense Bi2Fe4O9 peaks at about 28.2°, 28.9° and 29.8°, which correspond to (121), (211) and (002) crystalline orientations, increases obviously with increasing Bi2Fe4O9 content in the composites. As a consequence, the XRD results suggest that Bi25FeO40/Bi2Fe4O9 composites are successfully fabricated.

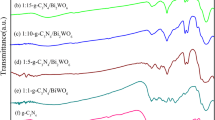

The FT-IR spectra of Bi25FeO40, Bi2Fe4O9 and Bi25FeO40/Bi2Fe4O9 composites are presented in Fig. 2. In the spectra of Bi25FeO40, three main absorption bands in the region 400–700 cm−1 are attributed to the typical absorption bands for the Bi–O and Fe–O [15]. The strong absorptive peaks located at 461 and 522 cm−1 are assigned to Bi–O vibration modes and the remaining peak at 578 cm−1 is associated with the stretching vibration of Fe–O bond, demonstrating the cubic characteristic of sillenite-type Bi25FeO40 [47]. The peak around 1322 cm−1 is due to the stretching vibration of C–OH [48]. With respect to Bi2Fe4O9, the peaks in the range from 444 to 473 cm−1 being assigned to Fe–O stretching vibrations in the FeO6 octahedral, the peaks at 640 and 810 cm−1 corresponding to Fe–O stretching vibrations in the FeO6 tetrahedral, and the appearance of absorption peaks around 523 and 609 cm−1 being attributed to O–Fe–O and Fe–O–Fe bending vibration in the FeO4 tetrahedral, all of these reflect the orthorhombic characteristic of mullite-type Bi2Fe4O9 [49]. Furthermore, these observed peaks of pure Bi25FeO40 and Bi2Fe4O9 are detected and overlapped in the Bi25FeO40/Bi2Fe4O9 composites, confirming that Bi2Fe4O9 is composited well with Bi25FeO40 in our final samples. With the increase of Bi2Fe4O9 content from the sample S2 to S4, the FT-IR peaks of Bi2Fe4O9 (e.g. 640 and 810 cm−1) increase and Bi25FeO40 (e.g. 522 and 578 cm−1) decrease and even disappear, which is similar to those of g-C3N4/Bi2MoO6, g-C3N4/SmVO4 and g-C3N4/BiFeO3 composites [50,51,52]. Those results are in accordance with our XRD results.

3.2 SEM and TEM observations

Figure 3 demonstrates FE-SEM images of Bi25FeO40, Bi2Fe4O9 and Bi25FeO40/Bi2Fe4O9 composites, which reflect different morphology and surface textural. Apparently, pure Bi25FeO40 particles present cubic morphology with an average size of about 10 μm and its surfaces are smooth (Fig. 3a). In Fig. 3e, pure Bi2Fe4O9 particles have a sheet-like appearance with ca. 2 μm in length and width [34]. After surface decorating with Bi2Fe4O9 in the samples, as shown in Fig. 3c, the FE-SEM image clearly shows that smaller Bi2Fe4O9 microsheets homogeneously anchor on and tightly attached to the whole surface of bigger Bi25FeO40 microcubes, which leads to the successful formation Bi25FeO40/Bi2Fe4O9 heterojunctions. However, when the content of Bi2Fe4O9 decreases, Bi2Fe4O9 microsheets randomly disperse on the surface of Bi25FeO40 microcubes and some of cubes are barren (Fig. 3b), implying the limited formation of Bi25FeO40/Bi2Fe4O9 hybrid. Conversely, the excessive amount of Bi2Fe4O9 in the composite leads to thick Bi2Fe4O9 layer growing on the Bi25FeO40 microcubes (Fig. 3d), which has been proven to be harmful for photodegradation process [48, 53, 54]. The different Bi25FeO40/Bi2Fe4O9 weight ratios in the composites have a major influence on photocatalytic behavior optimizing, which will be thoroughly discussed below. The detailed microstructural features of Bi25FeO40/Bi2Fe4O9 composite are further characterized by and TEM and HRTEM analysis, and the sample S3 is taken as an example. As shown in Fig. 4a, the sample S3 consists of cubic texture of micro-sized Bi25FeO40 tightly surrounded by small Bi2Fe4O9 microsheets, which is consistent with our SEM results. Meanwhile, the HRTEM image is also displayed in Fig. 4b. The two types of clear lattice fringes demonstrate the coexisting of Bi25FeO40 and Bi2Fe4O9, in which the 0.273 nm and 0.220 nm of interplanar spacing are in good agreement with the (321) plane of selenite-type Bi25FeO40 and (212) plane of mullite-type Bi2Fe4O9, respectively [44, 54]. Considering the ultrasonication treatment of TEM sample preparation, it is inferred that there are intimate interfaces and strong interaction between Bi25FeO40 and Bi2Fe4O9 in the composite [47, 55]. Our SEM and TEM results therefore provide robust evidence that the Bi25FeO40/Bi2Fe4O9 composites with the close interfaces are prepared successfully via a hydrothermal process combined with a mixing-calcination method, which could facilitate the separation of photogenerated carriers.

3.3 UV–vis DRS analysis

The optical absorption behaviors of all samples are analyzed via a UV–vis DRS technique, as present in Fig. 5a. It can be seen that both pure Bi25FeO40 and Bi2Fe4O9 particles respond to visible light in relationship with the absorption edges locating at approximately 640 nm and 670 nm, respectively. Compared with pure Bi25FeO40, the composites exhibit not only a redshift in their absorption but also an increase of the absorption intensities as Bi2Fe4O9 microsheets gradually cover the surface of Bi25FeO40 microcubes, which can be ascribed to the intermolecular interaction between Bi2Fe4O9 and Bi25FeO40 [15, 56]. It is proven to be beneficial to visible light harvesting and photocatalytic performance improvement [15]. These results imply that all these samples could be regarded as a visible-light-driven semiconductor photocatalysis. Usually, the band gap associated with the UV–vis absorption edge can significantly affect the photocatalytic performance of a semiconductor photocatalysis. According to Kubelka–Munk (K-M) function [44], the band gaps of Bi25FeO40 and Bi2Fe4O9 can be determined to be 1.94 eV and 1.87 eV using the plot of (F(R)) 1/2 versus the energy (hv) respectively, as is shown in Fig. 4b. These values are close to those of early reports [16, 30].

3.4 Visible-light-driven photocatalytic activities

The visible-light-driven photocatalytic activities of as-prepared samples (S1, S2, S3, S4 and S5) are evaluated by photodegrading RhB under visible-light (Fig. 6a). Pure Bi25FeO40 and Bi2Fe4O9 powders present poor photocatalytic efficiencies of about 13% and 20% toward RhB within 5 h of reaction, which is mainly due to the strong recombination of photoexcited electron–hole pairs [16, 34, 37]. Compared with either of components, all the Bi25FeO40/Bi2Fe4O9 composites show significantly enhanced photocatalytic activity of RhB, and their photodegradation efficiencies are 44%, 70% and 28% of S2, S3 and S4 under 5 h visible-light irradiation, respectively. It has been found that 30 wt% of Bi2Fe4O9 in the composite (the sample S3) is the optimal loading since it demonstrates the best photocatalytic activity, revealing the synergism between Bi25FeO40 and Bi2Fe4O9. The synergic effect in the composite will result in the separation of photogenerated carriers and then boost its photocatalytic performance [57]. As shown in the Fig. 6b, the photocatalytic reaction pathways of RhB degradation in all samples approximately follows pseudo-first-order kinetics model [13], and the slope of the fitting line corresponds to the values of rate constants k. In Fig. 6b, remarkable improvement of photocatalytic activity in Bi25FeO40/Bi2Fe4O9 composite is further evidenced. The rate constants k are estimated to be 0.0314 h−1, 0.1221 h−1, 0.2772 h−1, 0.0557 h−1 and 0.0449 h−1 for the samples S1, S2, S3, S4 and S5, respectively. Moreover, with the increase of Bi2Fe4O9 content from 10 to 50%, the photocatalytic efficiencies of composites firstly increase to a maximal value and then decrease. The photocatalytic activity of the sample S3 reaches the maximum at 0.2772 h−1, which is about 8.8 times higher than that of pure Bi25FeO40, 6.2 times higher than that of pure Bi2Fe4O9, 2.5 times higher than that of the sample S2 and 4.9 times higher than that of the sample S4. The decreased photocatalytic efficiencies of the sample S2 and S4 can be ascribed to the inappropriate amount of Bi2Fe4O9 microsheets coving the surface of Bi25FeO40 microcubes. Similar phenomena have been also observed in the Ag3PO4/CuBi2O4 and g-C3N4/CeVO4 composites [57, 58]. In order to clarify the active radicals working during the photocatalytic process and the related possible photocatalytic mechanism, the active species trapping experiments over Bi25FeO40/Bi2Fe4O9 composite have been performed. In this work, different radical scavengers including the 2-propanol (IPA), pbenzoquinone (BQ) and disodium ethylenediamine tetraacetic acid (EDTA-2Na) are used as the quenchers for ·OH, ·O2− and h+ respectively. Figure 7 presents the photocatalytic activities of RhB in the sample S3 in the presence of different scavengers. When the IPA is introduced, the photocatalytic efficiencies of RhB decrease from 70 to 36.8%, suggesting that ·OH is the main active species in the composite. However, in the presence of BQ and EDTA-2Na, the photodegradation rate only decreases to 65.6% and 65.1% respectively, indicating that ·O2− and h+ have a few impacts on photodegradation of RhB. The above trapping experiments reveal that even though active radicals (·OH, ·O2− and h+) play roles in the degradation process, the predominant active species for degradation of RhB in Bi25FeO40/Bi2Fe4O9 composite is ·OH rather than ·O2− and h+. Zhang et al. has also found that ·OH radical is the main active species during the degradation process in BiFeO3/Bi2Fe4O9 heterojunction photocatalysis [7].

3.5 Photocatalytic mechanism

In order to investigate the enhanced photocatalytic performance of Bi25FeO40/Bi2Fe4O9 composites, the band-edge potential positions of Bi25FeO40 and Bi2Fe4O9 photocatalysis are identified by using the famous Mulliken electronegativity theory since band edge play an important role in exploring the generation, separation, and movement pathways of photogenerated charge carriers [46]. The valence band (VB) and conduction band (CB) edge energy can be calculated using the following Eqs. (1) and (2) [50]:

In these equations, EVB and ECB are the VB and CB edge potential respectively; X is absolute electronegativity of a semiconductor (the geometric mean of the electronegativity of all constituent atoms, X for Bi25FeO40 and Bi2Fe4O9 are 6.24 eV and 6.00 eV [34, 59]); E0 is the energy of free electrons on the hydrogen scale (~ 4.5 eV); and Eg is the band gap energy for a semiconductor (Eg for Bi25FeO40 and Bi2Fe4O9 are 1.94 and 1.87 eV vs NHE, respectively). Therefore, the EVB of Bi25FeO40 and Bi2Fe4O9 are calculated to be 2.71 and 2.44 eV. Accordingly, the ECB of Bi25FeO40 and Bi2Fe4O9 are 0.77 and 0.57 eV. On the basis of the band alignments of Bi25FeO40 and Bi2Fe4O9, the schematic diagram of electronic energy-band structure and the heterojunction-type photocatalytic mechanism is proposed in Fig. 8. The scheme shows clearly that the VB top of Bi25FeO40 is higher than that of Bi2Fe4O9, and the CB bottom of Bi25FeO40 is also higher than that of Bi2Fe4O9. The electronic band structures of Bi25FeO40 and Bi2Fe4O9 in the composite match well with each other. Under the visible-light irradiation, both Bi2Fe4O9 and Bi25FeO40 catalysis can be excited with photogenerated e−/h+ carriers due to their suitable bandgap. After coupling Bi2Fe4O9 with Bi25FeO40, the two semiconductors are closely combined together and consequently the intimate interfaces are formed, as confirmed by our SEM and TEM results. In this manner, the photogenerated holes in the CB of Bi25FeO40 will inject into that of Bi2Fe4O9 with more positive potential, while the photogenerated electrons in the VB of Bi2Fe4O9 will move to that of Bi25FeO40 with more negative potential when the composite system is irradiated with visible light, leading to the separation of interfacial electron and holes between Bi25FeO40 and Bi2Fe4O9. As a result, Bi25FeO40/Bi2Fe4O9 composite effectively reduces the recombination of photogenerated charge carriers, which is in favor of the enhancement of photocatalytic activity. Recent works also demonstrate that the formation of BiFeO3/Fe2O3/Bi2Fe4O9 heterojunction-like interfaces and the mixed-phase BiFeO3/Bi25FeO40 could reduce the electron and holes recombination rate and promote photocatalytic performance [36, 37]. More importantly, the accumulated holes in the CB of Bi2Fe4O9 can react with H2O to produce ·OH groups because the VB potential (2.33 eV) is more positive than that of ·OH/H2O (2.27 eV). The accumulated holes in the CB of Bi2Fe4O9 will transfer to the surface of particles and are captured by H2O molecules adsorbed on the surface of the photocatalysts, producing ·OH radicals to decompose RhB into small molecular products and then into H2O and CO2 [60]. However, the accumulated electrons in the CB of Bi25FeO40 cannot absorb dissolved O2 to generate ·O2− radical that can oxidize RhB due to more positive CB (0.77 eV) than that of O2/O2·− (− 0.33 eV). The photocatalytic process of Bi25FeO40/Bi2Fe4O9 composite follows via heterojunction-type mechanism, which is mainly governed by ·OH, rather than by ·O2− and h+. The proposed photocatalytic mechanism matches well with our active species trapping experiments. Those above photocatalytic reactions are described as follows:

The electrochemical impedance spectra (EIS) measurements is used to affirm the advantage of Bi2Fe4O9 over Bi25FeO40 composite in the process of photogenerated charge carries separation and migration, as displayed in Fig. 9. The qualitative analysis of EIS can evaluate the electron-transfer efficiency. Generally speaking, the arc radius represents the electron-transfer efficiency; the smaller arc radius in the impedance spectrum is, the higher the separation of photoexcited charge carriers obtained and the quicker the charge transfer across the electrode/electrolyte interface achieved [50]. In Fig. 9, the sample S3 shows a smaller arc radius than that of the pristine Bi25FeO40 and Bi2Fe4O9, which means a more efficient separation of photogenerated electrons/holes pairs, faster interfacial charge transfer and hence better photocatalytic performance. On the other hand, the transient photocurrent is also believed to be a useful tool to evaluate the separation rate of photogenerated electron–hole pairs in the semiconductor-based photocatalytic composite [46]. The transient photocurrent responses of S1, S3 and S5 samples are recorded over several on–off cycles under visible-light irradiation and shown in Fig. 10. Apparently, the current density of pure Bi25FeO40 and Bi2Fe4O9 are both 0.04 μA/cm2 with light on, while the current density of Bi25FeO40/Bi2Fe4O9 composite has a great improvement, and it can reach around 0.08 μA/cm2, which is almost two times than that of pure Bi25FeO40 and Bi2Fe4O9. These indicate that Bi25FeO40/Bi2Fe4O9 composite has the enhanced separation of photogenerated carriers and can thus facilitate its photocatalytic performance.

It is also generally accepted that the optimal weight ratio of every component in composite photocatalyst is related to their geometry architecture, which is essentially beneficial for photocatalytic activity [53]. Based on our SEM and TEM observations, the architecture diagrams of Bi25FeO40/Bi2Fe4O9 composites with different weight ratios (the sample S2, S3 and S4) are presented in Fig. 11. When the weight ratio of Bi2Fe4O9 to Bi25FeO40 is low, the smaller Bi2Fe4O9 microsheets are randomly anchored on the surface of the bigger Bi25FeO40 microcubes and a large number of surfaces are barren. It means that only a few Bi25FeO40/Bi2Fe4O9 heterojunction solid–solid interfaces are formed. Consequently, the efficiency of photogenerated charge carrier separation and transfer cannot be promoted adequately and thus the photocatalytic activity improves a little. When the weight ratio reaches the optimal value, Bi2Fe4O9 microsheets uniformly cover the surface of Bi25FeO40 microcubes and a thin Bi2Fe4O9 layer is formed. The highest visible-light-driven photocatalytic activity in the sample S3 is achieved via this surface structure, which can be explained by the increased number of heterojunctions, enough electron transfer channels and the effective separation of electron–hole pairs [61,62,63,64,65,66]. However, when the weight ratio further increases, an overlapping surface structure comes into being. The excessive Bi2Fe4O9 will reduce the effective heterojunction interfaces, decrease the amount of exposed Bi25FeO40/Bi2Fe4O9 heterojunction, depress the active sites on the heterojunction and hinder the utilization efficiency of visible light, all of which damages the photocatalytic activity [7, 44]. In addition, another possible reason is that the thick Bi2Fe4O9 layer will extend the electron transfer distance from inner Bi25FeO40 to outer Bi2Fe4O9, which suppresses the interfacial charge transfer and aggregate the bulk electron–hole recombination [66]. Therefore, the suitable proportion of Bi2Fe4O9 to Bi25FeO40 will construct the appropriate geometry architecture in the composite, which is one of key issues on the enhancement of photocatalytic properties.

4 Conclusions

In this work, a series of Bi25FeO40/Bi2Fe4O9 composite photocatalysis have been constructed via a mixing-calcination method followed by a hydrothermal approach. Among all the samples, the Bi25FeO40/Bi2Fe4O9 composite with 30 wt% Bi2Fe4O9 loading has the highest visible-light-driven photocatalytic efficiency of about 70% toward RhB within 5 h of reaction. This enhancement could be attributed to heterojunction structure, which can promote the utilization efficiency of visible light, suppress the recombination of interfacial electron-holes pairs, and exacerbate the transfer of photogenerated charge carriers across the interfaces. The mechanism of effects that different weight ratios of Bi25FeO40/Bi2Fe4O9 and their geometry architecture have on photocatalytic activity has been revealed. This work provides new insights into the design and development of bismuth ferrite-based visible-light-driven photocatalysis.

References

T. Zhao, A. Scholl, F. Zavaliche, K. Lee, M. Barry, A. Doran et al., Electrical control of antiferromagnetic domains in multiferroic BiFeO3 films at room temperature. Nat. Mater. 5, 823–829 (2006)

D.P. Dutta, A.K. Tyagi, Effect of Sm3+ and Zr4+ codoping on the magnetic, ferroelectric and magnetodielectric properties of sonochemically synthesized BiFeO3 nanorods. Appl. Surf. Sci. 450, 429–440 (2018)

D. Sando, Y.R. Yang, E. Bousquet, C. Carrétéro, V. Garcia, S. Fusil et al., Large elasto-optic effect and reversible electrochromism in multiferroic BiFeO3. Nat. Commun. 7, 10718 (2016)

A. Kirsch, M.M. Murshed, M. Schowalter, A. Rosenauer, T.M. Gesing, Nanoparticle precursor into polycrystalline Bi2Fe4O9: an evolutionary investigation of structural, morphological, optical, and vibrational properties. J. Phys. Chem. C 120, 18831–18840 (2016)

S.D. Waghmare, V.V. Jadhav, S.K. Gore, S.J. Yoon, S.B. Ambade, B.J. Lokhande, R.S. Mane, S.H. Han, Efficient gas sensitivity in mixed bismuth ferrite micro (cubes) and nano (plates) structures. Mater. Res. Bull. 47, 4169–4173 (2012)

S.M. Lam, J.C. Sin, A.R. Mohamed, A newly emerging visible light-responsive BiFeO3 perovskite for photocatalytic applications: a mini review. Mater. Res. Bull. 90, 15–30 (2017)

T. Zhang, Y. Shen, Y.H. Qiu, Y. Liu, R. Xiong, J. Shi et al., Facial synthesis and photoreaction mechanism of BiFeO3/Bi2Fe4O9 heterojunction nanofibers. ACS Sustain. Chem. Eng. 5, 4630–4636 (2017)

Q. Zhang, W.J. Gong, J.H. Wang, X.K. Ning, Z.H. Wang, X.G. Zhao, W.J. Ren, Size-dependent magnetic, photoabsorbing, and photocatalytic properties of single-Crystalline Bi2Fe4O9 Semiconductor Nanocrystals. J. Phys. Chem. C 115, 25241–25246 (2011)

M.A. Basith, R. Ahsanm, I. Zarin, M.A. Jalil, Enhanced photocatalytic dye degradation and hydrogen production ability of Bi25FeO40-rGO nanocomposite and mechanism insight. Sci. Rep. 8, 11090 (2018)

N. Wang, L.H. Zhu, M. Lei, Y.B. She, M.J. Cao, H.Q. Tang, Ligand-induced drastic enhancement of catalytic activity of Nano-BiFeO3 for oxidative degradation of Bisphenol A. ACS. Catal. 1, 1193–1202 (2011)

Z.T. Hu, S.K. Lua, T.T. Lim, Cuboid-like Bi2Fe4O9/Ag with Graphene-Wrapping tribrid composite with superior capability for environmental decontamination: nanoscaled material design and visible-light-driven multifunctional catalyst. ACS. Sustain. Chem. Eng. 3, 2726–2736 (2015)

T.L. Wu, L. Liu, M.Y. Pi, D.K. Zhang, S.J. Chen, Enhanced magnetic and photocatalytic properties of Bi2Fe4O9 semiconductor with large exposed (001) surface. Appl. Surf. Sci. 377, 253–261 (2016)

H.C. Wang, H.M. Xu, C.C. Zeng, Y. Shen, Y.H. Lin, C.W. Nan, Visible light photocatalytic activity of bismuth ferrites tuned by Bi/Fe Ratio. J. Am. Ceram. Soc. 99, 1133–1136 (2016)

W.D. Ji, M.M. Li, G.K. Zhang, P. Wang, Controlled synthesis of Bi25FeO40 with different morphologies: growth mechanism and enhanced photo-Fenton catalytic properties. Dalton Trans. 46, 10586–10593 (2017)

Y. Liu, H.G. Guo, Y.L. Zhang, W.H. Tang, X. Cheng, W. Li, Heterogeneous activation of peroxymonosulfate by Sillenite Bi25FeO40: singlet oxygen generation and degradation for aquatic levofloxacin. Chem. Eng. J. 343, 128–137 (2018)

L. Ren, S.Y. Lu, J.Z. Fang, Y. Wu, D.Z. Chen, L.Y. Huang, Enhanced degradation of organic pollutants using Bi25FeO40 microcrystals as an efficient reusable heterogeneous photo-Fenton like catalyst. Catal. Today 281, 656–661 (2017)

P. Sharma, D. Varshney, S. Satapathy, P.K. Gupta, Effect of Pr substitution on structural and electrical properties of BiFeO3 ceramics. Mater. Chem. Phys. 143, 629–636 (2014)

J. Silva, A. Reyes, H. Esparza, H. Camacho, L. Fuentes, BiFeO3: a review on synthesis, doping and crystal structure. Inter. Ferroelectr. 126, 47–59 (2011)

S.M. Selbach, M.A. Einarsrud, T. Grande, On the thermodynamic stability of BiFeO3. Chem. Mater. 21, 169–173 (2009)

L. Wu, C.H. Dong, H. Chen, J.L. Yao, C.J. Jiang, D.S. Xue, Hydrothermal synthesis and magnetic properties of bismuth ferrites nanocrystals with various morphology. J. Am. Ceram. Soc. 95, 3922–3927 (2012)

R. Köferstein, Synthesis, phase evolution and properties of phase-pure nanocrystalline BiFeO3 prepared by a starch-based combustion method. J. Alloy. Compd. 590, 324–330 (2014)

H. Béa, M. Bibes, A. Barthélémy, K. Bouzehouane, E. Jacquet, A. Khodan, J.P. Contour et al., Influence of parasitic phases on the properties of BiFeO3 epitaxial thin films. Appl. Phys. Lett. 87, 72508 (2005)

F.E.N. Ramirez, A.C.P. Gabriel, A.S. Jose, Possible misleading interpretations on magnetic and transport properties in BiFeO3 nanoparticles caused by impurity phase. Phys. Lett. A 379, 1549–1553 (2015)

R.Q. Guo, L. Fang, W. Dong, F.G. Zheng, M.R. Shen, Magnetically separable BiFeO3 nanoparticles with a γ-Fe2O3 parasitic phase: controlled fabrication and enhanced visible-light photocatalytic activity. J. Mater. Chem. 21, 18645–18652 (2011)

X.F. Wang, W.W. Mao, Q.X. Zhang, Q. Wang, Y.Y. Zhu, J. Zhang et al., PVP assisted hydrothermal fabrication and morphology-controllable fabrication of BiFeO3 uniform nanostructures with enhanced photocatalytic activities. J. Alloy. Compd. 677, 288–293 (2016)

K. Suzuki, Y. Tokudome, H. Tsuda, M. Takahashi, Morphology control of BiFeO3 aggregates via hydrothermal synthesis. J. Appl. Cryst. 49, 168–174 (2016)

T. Gao, Z. Chen, F. Niu, D.T. Zhou, Q.L. Huang et al., Shape-controlled preparation of bismuth ferrite by hydrothermal method and their visible-light degradation properties. J. Alloy. Compd. 648, 564–570 (2015)

C.X. Hao, F.S. Wen, J.Y. Xiang, H. Hou, W.M. Lv, Y.F. Lv et al., Photocatalytic performances of BiFeO3 particles with the average size in nanometer, submicrometer, and micrometer. J. Alloy. Compd. 50, 369–373 (2014)

T. Gao, Z. Chen, Y.X. Zhu, F. Niu, Q.L. Huang, L.S. Qin et al., Synthesis of BiFeO3 nanoparticles for the visible-light induced photocatalytic property. Mater. Res. Bull. 59, 6–12 (2014)

G. Wang, S.H. Yan, J. Sun, S.G. Wang, Q.R. Deng, Visible light photocatalytic and magnetic properties of Nd doped Bi2Fe4O9 powders. J. Mater. Sci.: Mater. Electron. 28, 4371–4377 (2017)

Y.L. Pei, C.L. Zhang, Effect of ion doping in different sites on the morphology and photocatalytic activity of BiFeO3 microcrystals. J. Alloy. Compd. 570, 57–60 (2013)

M. Sakar, S. Balakumar, P. Saravanan, S. Bharathkumar, Particulates vs fibers: dimension featured magnetic and visible light driven photocatalytic properties of Sc modified multiferroic bismuth ferrite nanostructures. Nanoscale 8, 1147–1160 (2016)

X. Yang, Y.F. Zhang, G. Xu, X. Wei, Z.H. Ren, G. Shen et al., Phase and morphology evolution of bismuth ferrites via hydrothermal reaction route. Mater. Res. Bull. 48, 1694–1699 (2013)

G.M. Wang, C. Lin, S.T. Liu, Q.R. Deng, Y.W. Mao, S.G. Wang, Hydrothermal synthesis of bismuth ferrite with controllable phase structure, morphology and visible light photocatalytic activities. J. Mater. Sci. 29, 4926–4932 (2018)

J.J. Kong, Z.B. Rui, X.Y. Wang, H.B. Ji, Y.X. Tong, Visible-light decomposition of gaseous toluene over BiFeO3-(Bi/Fe)2O3 heterojunctions with enhanced performance. Chem. Eng. J. 302, 552–559 (2016)

T.A. Gadhi, S. Hernández, M. Castellino, A. Chiodoni, T. Husak, G. Barrera et al., Single BiFeO3 and mixed BiFeO3/Fe2O3/Bi2Fe4O9 ferromagnetic photocatalysts for solar light driven water oxidation and dye pollutants degradation. J. Ind. Eng. Chem. 63, 437–448 (2018)

S. Kalikeri, V.S. Kodialbail, Solar light-driven photocatalysis using mixed-phase bismuth ferrite (BiFeO3/Bi25FeO40) nanoparticles for remediation of dye-contaminated water: kinetics and comparison with artificial UV and visible light-mediated photocatalysis. Environ. Sci. Pollut. R 25, 13881–13893 (2018)

C. Wang, H.Q. Fan, X.H. Ren, Y. Wen, W.J. Wang, Highly dispersed PtO nanodots as efficient co-catalyst for photocatalytic hydrogen evolution. Appl. Surf. Sci. 462, 423–431 (2018)

M.C. Zhang, H.Q. Fan, N. Zhao, H.J. Peng, X.H. Ren, W.J. Wang et al., 3D hierarchical CoWO4/Co3O4nanowire arrays for asymmetric supercapacitors with high energy density. Chem. Eng. J. 347, 291–300 (2018)

H.L. Tian, H.Q. Fan, J.W. Ma, L.T. Ma, G.Z. Dong, Noble metal-free modified electrode of exfoliated graphitic carbon nitride/ZnO nanosheets for highly efficient hydrogen peroxide sensing. Electrochim. Acta 247, 787–794 (2017)

Y.W. Zhao, H.Q. Fan, K. Fu, L.T. Ma, M.M. Li, J.W. Fang, Intrinsic electric field assisted polymeric graphitic carbon nitride coupled with Bi4Ti3O12/Bi2Ti2O7 heterostructure nanofibers toward enhanced photocatalytic hydrogen evolution. Int. J. Hydrog. Energy 41, 16913–16926 (2016)

Y.M. Xia, Z.M. He, J.B. Su, Y. Liu, B. Tang, X.P. Li, Fabrication of novel n-SrTiO3/p-BiOI heterojunction for degradation of crystal violet under simulated solar light irradiation. NANO 13, 1850070 (2018)

M.J. Liang, Z.Y. Yang, Y. Yang, Y. Mei, H.R. Zhou, S.J. Yang, One-step introduction of metallic Bi and non-metallic C in Bi2WO6 with enhanced photocatalytic activity. J. Mater. Sci. 30, 1310–1321 (2019)

G.M. Wang, S.T. Liu, T.C. He, X. Liu, Q.R. Deng, Y.W. Mao, Enhanced visible-light-driven photocatalytic activities of Bi2Fe4O9/g-C3N4 composite photocatalysts. Mater. Res. Bull. 104, 104–111 (2018)

H. Wang, S. Liu, Y.L. Zhao, J.N. Niu, P.Z. Feng, Enhanced photocatalytic activity and photostability for novel g-C3N4 decorated Bi2O4 microrod composites. Mater. Res. Bull. 89, 253–262 (2017)

B.S. Li, C. Lai, G.M. Zeng, L. Qin, H. Yi, D.L. Huang et al., Facile hydrothermal synthesis of Z-scheme Bi2Fe4O9/Bi2WO6 heterojunction photocatalyst with enhanced visible light photocatalytic activity. ACS. Appl. Mater. Inter. 10, 18824–18836 (2018)

L. Zhang, Y. Zou, J. Song, C.L. Pan, S.D. Sheng, C.M. Hou et al., Enhanced photocatalytic activity of Bi25FeO40-Bi2WO6 heterostructures based on the rational design of the heterojunction interface. RSC. Adv. 6, 26038–26044 (2016)

Z.T. Hu, Z. Chen, R. Goei, W.Y. Wu, T.T. Lim, Magnetically recyclable Bi/Fe-based hierarchical nanostructures via self-assembly for environmental decontamination. Nanoscale 8, 12736–12746 (2016)

H. Zhang, T. Tong, J.G. Chen, J.R. Cheng, Synthesis and visible light photocatalytic properties of Bi2Fe4O9 particles via EDTA-assisted sol–gel route. J. Sol-Gel. Sci. Technol. 78, 135–143 (2016)

H.P. Li, J.Y. Liu, W.G. Hou, N. Du, R.J. Zhang, X.T. Tan, Synthesis and characterization of g-C3N4/Bi2MoO6 heterojunctions with enhanced visible light photocatalytic activity. Appl. Catal. B-Environ. 160, 89–97 (2014)

T.T. Li, L.H. Zhao, Y.M. He, J. Cai, M.F. Luo, J.J. Lin, Synthesis of g-C3N4/SmVO4 composite photocatalyst with improved visible light photocatalytic activities in RhB degradation. Appl. Catal. B 129, 255–263 (2013)

T. Fan, C.C. Chen, Z.H. Tang, Y. Ni, C.H. Lu, Synthesis and characterization of g-C3N4/BiFeO3 composites with an enhanced visible light photocatalytic activity. Mater. Sci. Semicond. Process. 40, 439–445 (2015)

P. Zhou, J.G. Yu, M. Jaroniec, All-solid-state Z-scheme photocatalytic systems. Adv. Mater. 26, 4920–4935 (2014)

R.M. Cong, H.Q. Yu, Y.J. Luo, J. Li, W.W. Wang, Q.H. Li et al., Synthesis and properties of Bi25FeO40/α-Fe2O3 composite nanoparticle photocatalysts. Chem. J. Chin. U. 39, 629–635 (2018)

Q.L. Xu, B.C. Zhu, C.J. Jiang, B. Cheng, J.G. Yu, Constructing 2D/2D Fe2O3/g-C3N4 direct Z-Scheme photocatalysts with enhanced H2 generation performance. Sol. RRL. 2, 1800006 (2018)

L. Ge, C.C. Han, J. Liu, Novel visible light-induced g-C3N4/Bi2WO6 composite photocatalysts for efficient degradation of methyl orange. Appl. Catal. B 108–109, 100–107 (2011)

W.L. Shi, F. Guo, S.L. Yuan, In situ synthesis of Z-scheme Ag3PO4/CuBi2O4 photocatalysts and enhanced photocatalytic performance for the degradation of tetracycline under visible light irradiation. Appl. Catal. B 209, 720–728 (2017)

L. Li, H.R. Wang, X. Wang, CeVO4 nanofibers hybridized with g-C3N4 nanosheets with enhanced visible-light-driven photocatalytic activity. Solid State Commun. 269, 11–15 (2018)

M.M. Lv, H.B. Yang, Y.L. Xu, Q. Chen, X.T. Liu, F.Y. Wei, Improving the visible light photocatalytic activities of Bi25FeO40/MIL-101/PTH via polythiophene wrapping, J. Envirom. Chem. Eng. 3, 1003–1008 (2015)

L.J. Song, Y.J. Zheng, C.F. Chen, Sonication-assisted deposition–precipitation synthesis of graphitic C3N4/BiOCl heterostructured photocatalysts with enhanced rhodamine B photodegradation activity. J. Mater. Sci. 28, 15861–15869 (2017)

F. Niu, D. Chen, L.S. Qin, N. Zhang, J.Y. Wang, Z. Chen et al., Facile synthesis of highly efficient p–n heterojunction CuO/BiFeO3 composite photocatalysts with enhanced visible-light photocatalytic activity. ChemCatChem. 7, 3279–3289 (2015)

L. Ge, C.C. Han, J. Liu, Novel visible light-induced g-C3N4/Bi2WO6 composite photocatalysts for efficient degradation of methyl orange. Appl. Catal. B 108, 100–107 (2011)

D.H. Xia, W.J. Wang, R. Yin, Z.F. Jiang, T.C. An, G.Y. Li et al., Enhanced photocatalytic inactivation of Escherichia coli by a novel Z-scheme g-C3N4/m-Bi2O4 hybrid photocatalyst under visible light: the role of reactive oxygen species. Appl. Catal. B 214, 23–33 (2017)

Z.T. Liu, L.H. Zhang, M. Shao, Y. Wu, D. Zeng, X. Cai et al., Fine-tuning the quasi-3D geometry: enabling efficient nonfullerene organic solar cells based on perylene diimides. ACS Appl. Mater. Interfaces. 10, 762–768 (2018)

Z.T. Liu, X.L. Zhang, P.C. Li, X. Gao, Recent development of efficient A-D-A type fused-ring electron acceptors for organic solar. Sol. Energy 174, 171–188 (2018)

J.G. Yu, S.H. Wang, J.X. Low, W. Xiao, Enhanced photocatalytic performance of direct Z-scheme g-C3N4-TiO2 photocatalysts for the decomposition of formaldehyde in air. Phys. Chem. Chem. Phys. 15, 16883–16890 (2013)

Acknowledgements

This work was sponsored by the National Natural Science Foundation of China (11704288 and 11504277) and the Scientific Project provided by Wuhan Government (Grant No.: 2016010101010026).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, G., Cheng, D., He, T. et al. Enhanced visible-light responsive photocatalytic activity of Bi25FeO40/Bi2Fe4O9 composites and mechanism investigation. J Mater Sci: Mater Electron 30, 10923–10933 (2019). https://doi.org/10.1007/s10854-019-01436-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-01436-4