Abstract

The synthesized novel flavonol was studied by 1H NMR spectroscopy, 13C NMR spectroscopy, FTIR, GC–mass spectrometry. And moreover, the metal complexes (M = Fe, Ni, Cu) with TiO2 nanocomposites are synthesized and studied by UV–Vis–NIR spectroscopy, GC–mass spectrometry, UV–Vis–DRS, XRD profile, SEM and TEM techniques. The performance of photocatalytic degradation of malachite green (MG) under visible light irradiation by Metal (M = Fe, Ni, Cu,) complex of 3-hydroxy-2-(3-nitrophenyl)-4H-chromen-4-one of nanocomposite was studied. In photocatalytic degradation of MG, the detail investigations are made by the effect of catalyst concentration; initial MG concentration and addition of inorganic salts. The MG photo degradation result of different ML–TiO2 is as follows Cu(II) > Fe(II) > Ni(II). Interestingly, the CuL–TiO2 has better photocatalytic efficiency of 97% as compared to the other ML–TiO2 in visible light at 80 min. The adsorption malachite green on ML–TiO2 was found to boost by the Langmuir and Freundlich approach.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Most of the industrial waste dyes are harmful to the surrounding environment. Among these organic pollutants, MG has been considerable attention due the stable chemical behavior of the environment. Removal of organic/inorganic pollutant from the ecosystem is a great challenge to the researchers. In the past few decades, the researcher identified TiO2 has a substantial role in the removal of the later said pollutants. On the other hand, TiO2 as the photocatalyst have (i) low sensitivity in the range of visible region (ii) high rate of recombination of photogenerated electron–hole pair. The above identified problems of TiO2 are removed in recent research by organic/inorganic composites. Because of the absorption is shifted towards the higher frequency, which means that the greater the photon energy gives more energy to the photogenerated electron–hole pair. Recently numerous research articles are published for the removal of environmental hazards by the process of photocatalytic activity, such as N-benzyl-ocarboxymethyl Chitosan magnetic nanoparticles [1] Halloysite nanotubes [2] Amino functioned graphemes [3] Fibrous sodium titanate [4] poly GMA/DVB [5]. Among them, surface modified TiO2 by metal complexes have better photocatalytic activity. The efficient performance of coordination metal complexes are takes place as functional materials for the enhanced adsorption and photodegradation [6,7,8]. Because of the metal complexes are acting as high energy photon sensitizer for efficient the photocatalytic activity of semiconductors. Metal complexes (ML) materials are an effect of combination of ML and TiO2 (ML–TiO2 or ML/TiO2), it has attractable structures, large surface areas, microporous sizes and adsorbate–ML interaction sites [9]. Moreover, pore volume utilizing catenation and creation of open metal sites and incorporation of different functional groups in metal complexes at octahedral environment. Because the correlation between metal complex structures and potential properties [10,11,12]. In general the functional properties of metal complexes are depends on their pores. In this research paper, to examine for novel photocatalyst with suitable conditions a complete photodegradation of the organic pollutants can be achieved and the general mechanisms are also investigated.

2 Materials and methods

2.1 Synthesis of ligands (3-hydroxy-2-(3-nitrophenyl)-4H-chromen-4-one)

4-Nitrobenzaldehyde and 1-(2-hydroxyphenyl) ethanone in 1:1 molar ratio were mixed and refluxed over a water bath for complete the reaction. The resulting chalcone separated out upon cooling, and then further add 30% H2O2 and NaOH. The resulting Flavonol was filtered, washed with ethyl acetate, and dried.

3-Hydroxy-2-(4-nitrophenyl)-4H-chromen-4-one, 60c mp, 206–209° C (aq.ethanol); yield: 90% UVλmax (MeOH): 372 nm, IR (Fig. 2a) (KBr, cm−1): 3080.32 (OH-3), 1757.14 (C=O), C–N (str) 1601.78, 1541.12, 1517.98. 1H NMR (Fig. 2b) (500 MHZ, CDCl3): δ 6.57–7.72 (m, 8H, Ar–H), 11.23 (s, 1H, OH-3). 13C NMR (Fig. 2b) (125 MHz, CDCl3): δ 114.91, 121.78, 122.55, 123.22, 124.97, 136.02, 138.43, 144.03, 155.83, 171.17, (CO). Anal.Calcd for C15H9NO5: C 63.61; H 3.20, found: C 63.65%; H 3.22%. The mass of the molecular ion (M+) at m/z 283.04 ((M–OH)+), base peak at m/z 221 ((M–OH)+), suggesting the presence of OH group. The position of the OH group at C (3) is evident from retro-Diels–Alder fragment ion at m/z 121 (A, +H) and 105 (B2+).

2.2 Synthesis of metal complex (C15H9 M NO5): (M = Cu, Fe, Ni)

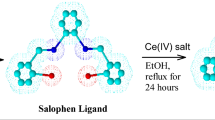

The complex was prepared in a moderate yield from the reaction of MCl2·2H2O with the prepared ligand in 1:2M ratio. The ligand (0.61 g, 2 mM) dissolved in methanol was added slowly to a methanolic solution of MCl2·2H2O (0.24 g, 1 mM) with continuous stirring which was followed by a change in the color of solution to brown. After for 24 h at room temperature, a brown precipitate obtained was separated out. This precipitate was then washed with hexane and dried in vacuo. The scheme of synthesis is shown in Fig. 1.

Yield 69% m.p. 279° C. Anal. (%) Calc. For (C15H9 Cu NO5): C, 62.02; H, 3.63; Cu, 9.94; N, 4.38; O, 20.03. Molar conductance, (1 × 10−3 M, methanol): 210 Ω−1 cm2 mol−1 (1:2 electrolytes). From the Fig. 2a, selected IR data on KBr pellet (γ/m cm−1); 1705.70 (C=O); 1266.18 (NO2); 749.14 (Cu–O); UVλmax (MeOH): 350 nm. Figure 3a reveals that the ESI–MS (m/z) 346.68 [C15H9NO5Cu]+ (m/z) 629.90[(C30H16N2O10)2Cu].

Yield 65% m.p. 254° C. Anal. (%) Calc. For (C15H9 Fe NO5): C, 62.77; H, 3.66; Fe, 8.84; N, 4.44; O, 20.27. Molar conductance, (1 × 10−3 M, methanol): 180 Ω−1 cm2 mol−1 (1:2 electrolytes). Moreover Fig. 2a selected IR data on KBr pellet (γ/m cm−1); 1718.12 (C=O); 1278.96 (NO2); 761.92 (Fe–O); UVλmax (MeOH): 347 nm. Figure 3b illustrates that the ESI–MS (m/z) 347 [C15H9NO5Fe]+ (m/z) 631[(C30H16N2O10)2 Fe].

Yield 68% m.p. 265° C. Anal. (%) Calc. For (C15H9 Ni NO5): C, 62.49; H, 3.66; Ni, 9.25; N, 4.42; O, 20.27. Molar conductance, (1 × 10−3 M, methanol): 150 Ω−1 cm2 mol−1 (1:2 electrolytes). As shown in Fig. 2a, selected IR data on KBr pellet (γ/m cm−1); 1744.16 (C=O); 1227.17 (NO2); 723.59 (Ni–O); UVλmax (MeOH): 328 nm. Figure 3c shows that the ESI–MS (m/z) 341 [C15H9NO5Ni]+ (m/z) 624[(C30H16N2O10)2Ni]+.

2.3 Synthesis of metal complex modified TiO2 (ML–TiO2) nanoparticles

ML–TiO2 was synthesized from dispersing 0.1 g of Metal complex and 3 g of TiO2 in 50 ml of chloroform. This mixture was taken in a round bottom flask equipped with a reflux condenser. The whole mixture was refluxed at 70 °C for 3 h. After that the mixture was cooled, filtered and repeatedly washed with chloroform to remove the unreacted metal complex. The resulting solid was dried in an oven at 100 °C for 1 h.

3 Result and discussion

ML (Cu, Fe and Ni)—TiO2 nanoparticles are studied form the SEM and TEM. Figure 4a as it can be seen in the spherical like morphology with uniform size of CuL–TiO2 sample show particles with great aggregation. Figure 4b, c, the typical TEM images of the Fe and Ni metal complex TiO2 nanoparticles indicates that the TiO2 nanoparticles are uniform in size with agglomerates of 5–10 crystallites and highly crystalline TiO2 aggregates composed of nanoparticles with particle size of 71–126 nm for Fe metal complex TiO2 and 100–206 nm for Ni metal complex TiO2. The XRD pattern of the ML (Cu, Fe, and Ni)-TiO2 (Fig. 4d) illustrates the sharp peaks are observed at diffraction angles 2θ value for ML–TiO2 (JCPDS card # 21-1272). The average crystallite size of CuL-TiO2, FeL-TiO2 and NiL-TiO2 is determined as 34 nm, 31 nm and 46 nm using the Scherer’s formula respectively.

B is the Full Width at Half Maximum in radians. K is a constant. \(\lambda\) is the wavelength, D is the crystallite size and \(\theta\) is the Bragg angle [13].

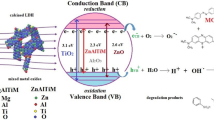

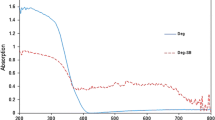

UV–Vis DRS, free TiO2 has a strong absorption in the region of 397 nm which was greatly improved after being sensitized by NiL–TiO2, FeL–TiO2 and CuL–TiO2 leading to the red shift of absorption towards the visible region. The absorption efficiency of the photocatalysts is analyzed by Tauc approach. The optical band gaps are highly suitable for receiving visible light. The energy band gap of the Metal complex (C15 H9 M NO5)-TiO2 are determined by extrapolation of the linear portion of the curves of (αhv)2 vs hv as shown in Fig. 5 [14]. The intra ligand bands are slightly shifted to longer wavelength upon complexation with metal ions. The \(n\to {\pi }^{*}\) (forbidden transition) takes place in 3-hydroxy-2-(3-nitrophenyl)-4H-chromen-4-one is due to unsymmetrical nuclear vibrations, but in Metal complexes (Fig. 1.) \(\pi \to {\pi }^{*}\) (allowed transition) is occurred by symmetrical nuclear vibrations. The shift of the π –π* bands to for the longer wavelength region the metal complexes are due to the C=O and N=O bond being weakened and its act as a flurophores the enhanced conjugation system on complexation. Tauc plot of Fig. 5 gives band gap of 2.39 eV, 2.26 eV, 2.15 eV, for ML–TiO2 (M = Cu2+, Ni2+ and Fe2+) and it showing small variation, may be due to the rigid phenyl cores in three compounds are inert and also supports the fact that the two O atoms of the carbonyl moiety are the nodal points in the arrangement of the valance band (VB) and conduction band (CB) of the orbitals [15]. The decreasing band gap level from TiO2 to ML–TiO2, more number of electrons able to transfer from valance band to conduction band compare to the naked TiO2 (3.12 eV). Synthesized ML–TiO2 has significantly absorption intensity the visible region compared to the free TiO2 [Ti4+ has no unpaired electron in distorted octahedron structure (Fig. 6a)], which is due to the ligand to metal charge transfer (LMCT) from ML to Ti (Ti3+ has only one d-electron in octahedron structure (Fig. 6b)) and it is result shows octahedral coordination structure [13]. Finally, band gap decreased from 3.12 to 2.39 eV, 2.26 eV and 2.15 eV and it shows that photosensitizer nature of the ML was adsorbed on the surface of TiO2.

4 Photocatalytic mechanism of MG

ML–TiO2 gives rise to bright colours associated with transition metal complexes in case of ML–TiO2, Ti3+ complex ion (Ti3+ has only one d-electron) the light of the wavelength in the visible region of the spectrum as shown in Fig. 6b, c. In ML–TiO2 when light is absorbed by a complex ion, an electron in one of the lower energy to higher energy. The energy corresponding to the frequency of the absorbed light is equal to energy in octahedral environment. Metal complexes is performed as a photosensitizer and transfer the electrons to ML–TiO2 heterojunction, narrows the band gap of TiO2, hinders the electron–hole pairs recombination, extends the work in visible light, and increase the photocatalytic activity of catalyst. The photocatalyst mainly involve the formation and reaction of ·OH radicals.

4.1 Adsorption studies through batch approach

Figure 7 is designated clearly that the % of adsorption of MG increased with increasing the amount of adsorbents from 0.005 to 0.020 g L−1 due to the subsistence of adsorbents site for the adsorption of MG from polluted aqueous solution. Consequently there is not major increase in the % of adsorption after 0.020 g/L since moves persistently from 0.020 to 0.040 g/L due to no availability of adsorption sites in the all adsorbents.

Batch approach used for studying the Adsorption works by shaking 0.020 g of the adsorbents like CuL–TiO2, FeL–TiO2, NiL–TiO2 and TiO2 in 40 mL solution of MG with 180 ppm concentration for 50 min in the rotator water bath shaker at 250 rpm stirring rate. Then the effect of initial metal-ion concentration and contact time were also determined for the MG adsorption onto various adsorbents. MG concentration in the supernatants after the adsorption onto the different adsorbents was calculated with UV–visible spectrophotometer. The equilibrium adsorption capacity of the all adsorbents was found with this equation:

Where qe is the equilibrium adsorption capacity (mg g−1), Co and Ce is the initial and final MG concentration (mg L−1) at equilibrium, V is the volume of solution (L) and M is the weight (g) of adsorbent [16].

4.2 Adsorption isotherm analysis

Figure 8 indicated that the CO raises from 30 to 180 mg L−1 due to the initial concentration creates essential driving force by the development of concentration gradient between the bulk solution and surface of the four adsorbents [17]. No significant enhance in the adsorption capacity of the four adsorbents beyond 180 mg/L due to the saturation of surface active sites over it. The mechanism between MG and four adsorbents can be identified by the various adsorption isotherm models as Freundlich and Langmuir isotherm models. The values were found from the Figs. 8, 9a, b, 10a, b, 11a, b, 12a, b and are tabulated in Tables 1 and 2:

Where KF (mg g−1) is the Freundlich constant and ‘n’ the Freundlich exponent. Where qe (mg g−1) is the adsorbed amount of MG at equilibrium, Ce (mg L−1) is the equilibrium concentration of MG, Qo (mg g−1) and b (L mg−1) are Langmuir constants related to adsorption capacity and energy of adsorption. Then the Langmuir isotherm noteworthy value as separation factor (RL) can be calculated with the Eq. 4.

The RL value supposed the nature with feasibility of adsorption process is stated in Table 1. The calculated high R2 value proved that the adsorption of MG on four adsorbents can be fitted well with Langmuir isotherm as evaluated to the Freundlich isotherm. The RL value (Table 3) ranges from 0 to 1 proved that the adsorption process is favorable for the four adsorbents [18]. Moreover, CuL–TiO2 exhibited a superior adsorption activity as compared to the other three adsorbents. The value of the n greater than 1 suggested that the concerned environments for adsorption. The adsorption capacities of the four adsorbents and former adsorbents for the removal of MG from aqueous solution or wastewater are stated in Table 4 [1,2,3,4,5].

4.3 Adsorption kinetics study

Figure 13 clearly suggested that the adsorption process was quick at the beginning of reaction and over in 50 min. As a result, extended successive point for the MG adsorption on four adsorbents was stopped in 80 min. Thus the stability time was 50 min for this adsorption. Further, no considerable change was found due to the happening of more active sites on four adsorbents at the start of reaction and more active sites were not presented on four adsorbents after 50 min. The pseudo-first-order and pseudo-second-order kinetic representations were exploited to inform like adsorption.

Where k1 is the pseudo-first-order rate constant (min−1), qe (mg g−1) is the adsorption capacity at equilibrium, qt (mg g−1) is the adsorbed amount of MG after time t (min), k2 is the pseudo- second-order rate constant (g mg−1 min−1). The all values were determined from Fig. 14a, b as well as tabulated in Table 5. The calculated R2 values of the four adsorbents for pseudo second-order kinetic model is upper than the pseudo-first order kinetic model and then the experimental qe values of the four adsorbents are extremely closer to the determined qe value for pseudo-second-order kinetic model as compared to Pseudo-first-order kinetic model. Hence the adsorption processes of the four adsorbents were followed Pseudo second order kinetic model [19]. Then the adsorbent CuL–TiO2 displayed better adsorption results while compared to the other adsorbents.

5 Conclusion

The successfully synthesized three metal complex materials, CuL–TiO2, FeL–TiO2 and NiL–TiO2 under Sol–gel conditions by the reaction of transition metal chloride salts and flavonol of synthesized organic compound (L:3-hydroxy-2-(3-nitrophenyl)-4H-chromen-4-one). Through three complexes materials were characterized by UV–Vis spectra, IR spectra, 1H NMR spectroscopy, 13C NMR spectroscopy, GC-MASS spectrometry, XRD analysis and HRTEM. The UV–Vis spectra showed that the three complexes were octahedral structures with band gap ranges 2.15–2.39 eV.

In addition we investigated the photodegradation ability of the three complexes for malachite green dye under Visible light. The result showed that three complexes had different degradation ability to MG solution. Further we found that the degradation process was in accordance with pseudo-second-order kinetic model and the correlation constant is as high as 0.9–0.99, which indicates that the rate of adsorption is takes place on surface adsorption. The most significant is that the adsorption capacity of copper complexes (CuL–TiO2) can reach 0.020 g when the MG concentration is 180 ppm and time 50 min. Therefore, these may have a potential effect on our degradation of MG in wastewater.

The electronic configuration of copper(II) ion has Jahn teller distortion, which make excellent candidates for carry stable and more electrons by changing the redox potential as compared to the other metals in the complexes. Copper(II) complex of 3-hydroxy-2-(3-nitrophenyl)-4H-chromen-4-one high frequency sensitive photocatalyst. CuL–TiO2 platform exhibited a superior performance based on all respects especially on adsorption activities compared to other three adsorbents. Hence the built up CuL–TiO2 can be applied efficiently for the elimination of high concentration MG from polluted aqueous solution and waste water in textile industries.

References

A. Debrassi, A.F. Correa, T. Baccarin, N. Nedelko, A. Slawska-Waniewska, K. Sobczak, P. Dłużewski, J.M. Greneche, C.A. Rodrigues, Chem. Eng. J. 183, 284–293 (2012)

G. Kiani, M. Dostali, A. Rostami, A.R. Khataee, Adsorption studies on the removal of malachite green from aqueous solutions onto halloysite nanotubes. Appl. Clay Sci. 54, 34–39 (2011)

X. Guo, Q. Wei, B. Du, Y. Zhang, X. Xin, L. Yan, H. Yu, Removal of basic dyes (malachite green) from aqueous medium by adsorption onto amino functionalized graphenes in batch mode, Desalin. Water Treat. 53, 818–825 (2015)

J. Huang, M. Zhao, H. Chen, L. Dong, X. Guo, X. Liu, Preparation of fibrous sodium titanate and its adsorption property toward neutral red, methylene blue, malachite green and crystal violet, Optoelectron. Adv. Mater. 9, 471–477 (2015)

D. Husaain, M. Najam-ul-Haq, A. Saeed, F. Jabeen, M. Athar, M.N. Ashiq, Synthesis of poly GMA/DVB and its application for the removal of malachite green from aqueous medium by adsorption process, Desalin. Water Treat. 53, 2518–2528 (2015)

S.G. Chen, Z.Z. Shi, L. Qin, H.L. Jia, H.G. Zheng, Photodeegradation of some organic dyes over metal-organic frameworks with especially high efficiency for safranine T. Cryst. Growth Des. 17, 67–72 (2017)

P.D.C. Dietzel, H. Kitagawa, Metal-organic frame work- heading towards applications. Eur. J. Inorg. Chem. 27, 4267–4270 (2016)

A.V.I. Desai, B. Manna, A. Karmakar, A. Sahu, S.K. Ghoush, A water-stable cationic metal-organic framework as a dual adsorbent of oxoanion pollutants. Angew. Chem. Int. Ed. 55, 7811–7815 (2016)

H.L. Jiang, Xu, Porous metal-organic frame works as platforms for functional applications. Q. Chem. Commun. 47, 3351–3370 (2011)

C.J. Doonan, D.J. Tranchemontagne, T.G. Glover, J.R. Hunt, O. Yaghi, M.Nat. Exceptional ammonia uptake by a covalent organic frame work. Chem. 2, 235–238 (2010)

H.X. Deng, C.J. Doonan, H. Furukawa, R.B. Ferreira, J. Towne, C.B. Knobler, B. Wang, Yaghi, Multiple fuctioanl groups of varying ratios in metal-organic frame works. O. M. Science 327, 846–850 (2010)

J.R. Li, R.J. Kuppler, H.C. Zhou, Selective gas adsorption and separation in metal- organic frame works. Chem. Soc. Rev. 38, 1477–1504 (2009)

P. Pandi, C. Gopinathan, Synthesis and Characterization of TiO2–NiO and TiO2–WO3 nanocomposites. J. Elect. Mater. 28, 7, 5222–5234 (2017)

Y. Dong Jianga, D. Xua, Y. Wua, Suna, Visible-light responsive dye-modified TiO2 photocatalyst. J. Solid State Chem. 181, 593–602 (2008)

F. Farukh Arjmand, M. Sayeed. Muddassir, Synthesis of new chiral heterocyclic Schiff base modulated Cu(II)/Zn(II) complexes: their comparative binding studies with CT-DNA, mononucleotides and cleavage activity. J. Photochem. Photobiol. B 103, 166–179 (2011)

S.D. Khattri, M.K. Singh, Colour removal from dye wastewater using sugar cane dust as an adsorbent. Adsorpt. Sci. Technol. 17, 269–282 (1999)

O. Hamdaoui, Batch study of liquid-phase adsorption of methylene blue using cedar sawdust and crushed brick. J. Hazard. Mater. 135, 264–273 (2006)

S.S. Tahir, N. Rau, Removal of a cationic dye from aqueous solutions by adsorption on to bentonite clay. Chemosphere 63, 1842–1848 (2006)

J. Zhang, Y. Li, C. Zhang, C. and Y. Jing, Adsorption of malachite green from aqueous Solution onto carbon prepared from Arundo donax root. J. Hazard. Mater. 150, 774–782 (2008)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rajendran, S., Arulantham, X., Pitchai, P. et al. Metal (II) complexes with derived from 3-hydroxy-2-(3-nitrophenyl)-4H-chromen-4-one; synthesis and photocatalytic activity. J Mater Sci: Mater Electron 30, 6669–6679 (2019). https://doi.org/10.1007/s10854-019-00976-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-019-00976-z