Abstract

TiO2–NiO and TiO2–WO3 nanocomposites were prepared by hydrothermal and surface modification methods. The samples were analyzed using X-ray diffraction, Scanning Electron Microscope images, Transmission Electron Microscope, Energy dispersive analysis, Zeta potential, Electrophoretic mobility and Photocatalysis activity measurement. XRD data sets of TiO2–NiO, TiO2–WO3 powder nanocomposite have been studied for the inclusion of NiO, WO3 on the anatase-rutile mixture phase of TiO2 by Rietveld refinement. The cell parameters, phase fraction, the average grain size, strain and bond lengths between atoms of individual phases have been reported in the present work. Shifted positional co-ordinates of individual atoms in each phase have also been observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the emerging field of materials science and technology, significant evolution has been made using different transition metal oxide [1–3]. Among this, TiO2 have solutions to the most pressing issues in energy generation with not detrimental to the environement. Therefore researchers are attracted towards the preparation of TiO2 based solar cells and solar energy materials. Any modification in the semiconducting property or crystalline phase of the TiO2 will change its application significantly thus making it an excellent candidate for wide applications in the field of energy and environment. From the previous prior research articles, the electrical conductivity of TiO2 is poor under direct solar irradiation. By the incorporation of TiO2 matrix with another semiconductor, the conductivity of TiO2 was increased by reducing the photogenerated electron–hole pair recombination, properly directing the excess photogenerated electrons.

The performance photocatalytic activity is increases by the use of several mixtures of transition metal oxides such as TiO2–V2O5 [4], TiO2–SiO2 [5], TiO2–ZnO [6], TiO2–SnO2 [7, 8], TiO2–CoO [9] and, TiO2–SrO [10] that are nanocomposites. TiO2, WO3 and NiO are known as transition metal oxides with the direct band gap of 3.2–3.35 eV, 2.8 eV and 3.5–4.0 eV respectively. Recently, TiO2–NiO [11] and TiO2–WO3 nanocomposites have been attracting more attention because of their better electrochromic behavior and outstanding performance as solid electrodes for solar cells [4]. The frontier of precision nanocomposites and comprehensive knowledge about structural parameters, structural factors relating properties and their relative performance in a certain application and also materials engineering leads to solving the new challenges.

In this research paper is mainly focused on the nanocomposites with the following objectives: Synthesis and Characterization of TiO2 nanoparticles by hydrothermal method; TiO2 nanoparticles were added to NiO and WO3 respectively and nanocomposites were synthesized by surface modified process then annealed at 550 °C. The prepared samples were characterized by XRD and DRS UV-Vis-IR spectroscopy techniques. The particle size and morphology of the nanocomposites was studied by SEM and TEM technique respectively. Zeta Potential and Electrophoretic mobility is studied by Dynamic light scattering method. The elemental analysis was carried out by EDAX. In this research paper, for the first time, two mixed polymorphs of TiO2 were investigated with the insertion of NiO and WO3 by the Rietveld refinement process. Photocatalytic measurement was made under direct solar irradiation and eosin-Y used as dye for decomposition.

2 Synthesis of TiO2 nanoparticles by hydrothermal method

The TiO2 colloidal solution was prepared by hydrolysis of titanium tetra isopropoxide (TTIP) (Aldrich Chemicals, USA). In a typical process, 1 M of titanium tetra isopropoxide was mixed together with 4 M of acetic acid. The resultant solution was mixed with double distilled water and stirred vigorously for 1 h to obtain a clear solution. After an aging period of 24 h, the solution was kept in an oven at 70 °C for 12 h to the obtain Ti(OH)4 colloidal solution. This was transferred into a stainless steel autoclave and placed in oven at 180 °C for 12 h. Then the autoclave was cooled down to room temperature. The solution was dried at 100 °C to get TiO2 crystals and then crushed into fine powder with mortar and pestle [12–22].

2.1 Nanocomposite preparation

Nanocomposites were synthesized by dispersing 0.1 gm of Nickel oxide and 3 gm of TiO2 in 50 ml of chloroform. This suspension was stirred for 3 h at 70 °C. After stirring, the mixture was filtered and repeatedly washed with chloroform and the resulting solid was dried in an oven at 100 °C for 1 h. This process was repeated for TiO2–WO3 nanocomposite preparation. Finally the fine powder was annealed at 550 °C for 1 h.

3 Result and discussion

3.1 Structural analysis

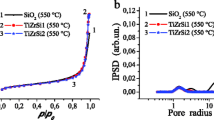

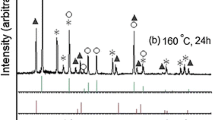

XRD pattern of both nanocomposites were recorded using Philips X’PERT PRO powder diffractometer with Cu–Kα1 (λ = 1.54056 Å) as the target in 2θ range of 3°–120° in steps of 0.05° as the intervals at SAIF Cochin. The TiO2–NiO and TiO2–WO3 nanocomposites, the TiO2 relative peak positions were consistent with the standard powder diffraction profile of anatase (JCPDS # 21-1272) and rutile (JCPDS # 21-1276), NiO (JCPDS # 47-1049), NiTiO3 (JCPDS # 330960) and WO3 (JCPDS # 43 1035) respectively. Figure 1 shows narrow peaks that were obtained by increasing both anatase and rutile diffracted crystallographic planes.

The nanocomposite structural features were analyzed using the Rietveld refinement method Jana 2006 software for the first time [23, 24]. In both the nanocomposites, TiO2 crystallites exhibited two mixed polymorphs such tetragonal structure of anatase and rutile belongs to the space group of I41/amd (a = 3.785 Å, c = 9.514 Å) and P42/mnm (a = 4.59373 Å, c = 2.95812 Å) respectively. The input atomic coordinates for anatase was x = y = z = 0 for Ti and x = y = 0, z = 0.2066 for O. Similarly, that for rutile was x = y = 0.30530, z = 0 for O. The cubic crystal system of NiO belongs to the space group of \(Fm\bar{3}m\) (a = b = c = 4.17 Å) and x = y = z = 0 Wyckoff position 4a for the Ni atom and also x = y = z = 0.5 for the 4b O atom [25]. The monoclinic crystal system of WO3 belongs to the space group \(~{{P}_{21}}/n\) (a = 7.297 Å, b = 7.539 Å, c = 7.688 Å) and WO3 Wyckoff positions were taken from the reported results of Woodward et al. and Emil Indrea et al. [26, 27]. Figure 2 depicts the observed and calculated XRD profile for structural parameters, lattice parameters, peak shift, background profile and preferred orientations were used to minimize differences. The goodness of fit for all refinement process was close to unity.

The structural parameters and phase fractions of both the nanocomposites were obtained from the Rietveld refinements as shown in Table 1. The results of the reliable position refinement are presented in Table 2. Supplementary Figure 2a and Figure 2b give the observed and calculated structure factors of TiO2–NiO and TiO2–WO3 nanocomposites with each phases. The anatase to rutile phase transformation occured with increase in annealing temperature and with respect to the oxygen vacancy. TiO2 annealed at 550 °C showed better photocatalytic activity because it was 87.04% anatase and 12.96% rutile as per prior research papers [12, 28]. But in the obtained phase fraction of TiO2–NiO nanocomposite, the phase fraction of the anatase decreased from 87.04 to 57.9%, when (O2−) oxygen vacancy site in anatase TiO2 was coupled with NiO. The NiTiO3 diffraction peak was observed at 2θ = 33.08°, 35.65° from Figs. 1a and 2a and the annealed temperature of 550 °C was enough for the existence of NiTiO3 [28].

In the case of TiO2–WO3 nanocomposite, it was noticed that the content of anatase decreased by 73.9% and was due to WO3 incorporation on the surface of the tetragonal tunnel surrounded by TiO6 octahedrons. Figure 2c shows the 3D electron density distributions of TiO2 anatase and rutile are derived from the Rietveld analysis using visualization software called VESTA [29]. The Ti 6+ ions octahedrally coordinated to six O2− ions were distorted, with the apical (Ti–O)* bond length being slightly longer than the equatorial (Ti–O)# bond length. The Ti–Ti, W–O and Ni–O bond length is tabulated in Table 3. The rutile phase apical bond length (Ti–O#) and Ti–Ti bond lengths increased and another four equatorial oxygen atoms (Ti–O*) decreased respectively from the Cromer et al. [30] and Wolfgang Sigmund et al. [31] reported values, which could be due to lattice strain by adding NiO, WO3 respectively. Moreover the inclusion of NiO, WO3 to the TiO2 matrix, produces little changes in the positions of both metal oxide systems due to energy minimization.

The size broadening due to the crystallite size distribution [32, 33] is given by

B is the FWHM (Full Width at Half Maximum) in radians. K is a constant—usually 0.9 for a spherical sample of cubic symmetry. λ is the wavelength used, d is the crystallite size (size of the coherently diffracting domain—different from particle size) and θ is the Bragg angle of the reflection. Strain broadens due to the strains present in the sample (due to lattice displacements of atoms from their original positions, surface strains, dislocations, impurities, non-stoichiometry in mixed systems, etc.—usually predominant in thin films, low order and nano structures).

B is the FWHM, e is the strain. The crystalline size was retarded by the insertion of NiO on both mixed anatase-rutile phase TiO2, so that anatase was 23.24 nm, rutile was 15.33 nm, which can be compared to previous research papers. The crystalline size of NiO was 44.92 nm. But in the case of TiO2–WO3 nanocomposite, the size of the crystallites increased. Anatase was 30.96 nm and rutile was 25.49 nm due to the accumulation of WO3 on anatase-rutile mixture of TiO2. The size of WO3 crystallites was 19.57 nm (Table 1).

3.2 Morphological analysis

The nanostructure of the TiO2–NiO and TiO2–WO3 nanocomposites were observed by SEM as shown in Fig. 3. The morphologies of TiO2–NiO and TiO2–WO3 nanocomposite could be seen as particles with great aggregation and the particle size was around few tens of nanometer. Figure 3 evidently illustrate that the close contact nanoparticles served as a beneficial path to easily move electrons from one grain to another. Figure 3 show that TiO2–NiO and TiO2–WO3 nanocomposites receive an increasing attention in the field of solar materials and solar cell application due to their small grain size and high density of grain boundaries.

Figures 4 and 5 illustrate TiO2–NiO and TiO2–WO3 nanocomposites the particle size distribution examined by the TEM. In TiO2–NiO nanocomposites size of the particles was not uniform but had a spherical, cubic and hexagonal shape as shown in Fig. 4a, b. The size of the nanoparticles was in the range of 31–44 nm and the particle size distribution was completely crystallized. Figure 5a, a suggests that, on anatase-rutile mixed phase TiO2, WO3 nanoparticles tend to aggregate with each other to form bigger particle size distribution as compared to TiO2–NiO nanocomposites. The TiO2–WO3 nanocomposite size distributions matured as large as 18–64 nm due to recrystallization.

Figure 4d, e illustrate the direct evidence of crystalline nature of NiO, anatase and rutile TiO2 nanoparticles. HRTEM images shows clear lattice fringes, which allowed for the identification of crystallographic spacing. Figure 4d shows the interplanar distance of 0.352 nm was close to the d spacing of the (1 0 1) planes of the anatase TiO2. Figure 4e shows the lattice spacing of 0.25 nm was related to the (1 0 1) plane of rutile TiO2. Moreover the lattice spacing of 0.27 nm was correlated to the (1 0 4) plane of NiTiO3 (JCPDS# 330960), which confirms the presence of anatase TiO2, rutile TiO2 and NiO. Figure 4f shows the Selected Area Electron Diffraction (SAED) pattern of TiO2–NiO nanocomposite. The synthesized TiO2–NiO nanocomposite was further confirmed by the result of SAED pattern. All reflected crystallographic plane in electron diffraction pattern of TiO2–NiO composite were good agreement with the XRD results.

The interplanar distance of 0.38 nm, 0.352 nm and 0.25 nm was corresponds to (0 0 2) planes of the WO3, (1 0 1) planes of the anatase TiO2, (1 0 1) plane of rutile TiO2 as shown in Fig. 5d, e, which confirms the presence of anatase TiO2, rutile TiO2 and WO3. Figure 5f shows the SAED pattern of TiO2–WO3 nanocomposite were good agreement with the XRD results.

The chemical composition of the prepared TiO2–NiO nanocomposites are presented in Fig. 6 and Table 4. The content of TiO2–NiO nanocomposites of both anatase and rutile were high (at.%) as compared to NiO.

3.3 DRS UV-Vis-IR analysis

The optical absorbance spectrum of nanocomposite is shown in Fig. 7a, b, which showing strong absorption and this could be due to the surface morphology of both the nanocomposites. The different particle size of nanocomposites absorbed wavelengths in this range and it was blue and red shifted. In order to determine the optical band gap of the nanocomposites, the absorption coefficient (α) was calculated from the absorbance spectrums using Eq. (3).

where E g is the optical bandgap. Figure 7c, d gives the typical Tauc plot of \({{(\alpha h\nu )}^{2}}\) vs \(h\nu\) for TiO2–NiO and TiO2–WO3 nanocomposites. The values of band gap have been estimated by taking the intercept of the extrapolation to zero absorption co-efficient with photon energy axis. Figure 7c, d indicates the direct allowed transition present in the TiO2–NiO and TiO2–WO3 nanocomposites.

The band gap value of TiO2–NiO nanocomposite decreased to 2.44 eV and this was due to the structural parameters. Ti –Ti bond length in anatase phase was greater than in rutile phase, whereas apical and equatorial bond lengths were shorter. The anatase to rutile phase fractions decreased when annealed at 550 °C after the inclusion of NiO to TiO2 matrix. These structural changes led to different electronic configurations. Moreover NiO (6.67 g/cm3) had higher density than rutile (4.23 g/cm3) and anatase (3.78 g/cm3) phase TiO2, therefore the band gap values of TiO2–NiO nanocomposite at 550 °C (2.44 eV) decreased. The tauc plot (Fig. 7d) of TiO2–WO3 nanocomposite annealed at 550 °C depicted band gap value of 2.40 eV. Because of the annealing temperature led to bigger particle size due to the agglomerated WO3 particles on the TiO2 matrix as shown in Fig. 5b. Tables 1 and 2 show the structural parameters for the 550 °C annealed TiO2–NiO and TiO2–WO3 nanocomposites.

3.4 Photocatalytic analysis

The photocatalytic activity for anatase, rutile and two mixed polymorphisms of TiO2 with NiO, WO3 nanocomposite yielded good results due to the competing charge transportation to the surface and comparative declination in the surface area due to the large crystallites. In addition, after the insertion of NiO or WO3 to the TiO2 systems, changes could be observed in the unit cell, positions and bond lengths, which are key factors for their peculiar properties as compared to parent system. The energy minimization (equilibrium) of the TiO2–NiO or TiO2–WO3 system led to internal rearrangements within the constrained, which could be resovled many problems such as oxygen defects, lattice defects at its surface and interface, electron–hole pair recombinations and so on.

The photocatalytic activity was assessed by degrading 0.1 mM of eosin-Y in aqueous solution (eosin-Y concentration 0.1mM; TiO2–NiO/(or TiO2–WO3): 0.2 gm). The changes of eosin-Y concentration with direct solar irradiation were observed by measuring the absorption spectra using a Thermo-spectronic UV–Vis spectrometer. The samples were taken out every 10 min to record the absorption spectra. Figure 8a shows the intensity of the absorbance spectra of eosin-Y, with the presence of TiO2–NiO nanocomposites, which decreased after direct solar irradiation was incident on it. In nanocomposites, absorption at 516 nm was taken into account to determine the rate of degradation. Figure 8c shows the absorbance spectra of direct solar irradiated eosin-Y solution which had better photocatalytic activity.

Figure 8b shows the photocatalytic activity of TiO2–NiO nanocomposite. It could be seen that the inclusion of NiO nanoparticles on the matrix of anatase-rutile mixed TiO2 exhibits a significant influence on the photocatalytic activity. In the presence of a small amount of NiO nanoparticles was obviously enhanced the photocatalytic acitivity as compared to pure anatase-rutile TiO2 nanoparticles. Figure 8b illustrate the TiO2–NiO nanocomposite photocatalytic mechanism. Under the direct solar irradiation, the photogenerated electrons on the conduction band of TiO2 can transfer to NiO. The recombination of photogenerated electrons and holes are retarded by inclusion of NiO nanoparticles on anatase-rutile mixed TiO2 matrix. Moreover the reason for this efficient achievement was tentatively credited to the inhibition of recombination of electron–hole pairs on the surface of the TiO2. This is due to the (O2−) oxygen vacancy site in anatase-rutile TiO2, which coupled with NiO, to produce a close contact TiO2–NiO nanocomposite particle providing a successful lane for electrons to move from one grain to another.

Figure 8d illustrate the photocatalytic activity mechanism of TiO2–WO3 nanocomposite. Better photocatalytic efficiency was achieved for TiO2–WO3 nanocomposite. The increased efficiency of this materials could be attributed to the light absorption of TiO2–WO3 shifted towards the visible region. An efficient charge separation could be assured because the photogenerated electrons from TiO2 are transferred into the lower energy conduction band of WO3. The generated holes in the valence band of WO3 are moved into the higher energy valence band of TiO2, which makes charge separation more efficient. In this way, life time of photogenerated electron–hole pairs is increased. In addition, to it can suppressed the photogenerated electrons from recombination, thus increasing the charge transfer efficiency. The result was that the TiO2–WO3 nanocomposite photocatalyst exhibited even higher photocataltic activity than that of TiO2–NiO nanocomposites.

Even though more number of Bragg’s diffraction planes were informed that the TiO2–WO3 nanocomposite have better electrons transport track as compared to the TiO2–NiO nanocomposite as shown in Figs. 1, 2. The bigger and uniform particle size distribution of TiO2–WO3 nanocomposites was clear evidence for the better photocatalytic activity. In addition, Table 5 shows the 550 °C annealed TiO2–WO3 nanocomposite in a suspension had large zeta values, which repelled each other and did not have a tendency flocculate. The higher zeta value indicated the greater stability of TiO2–WO3 nanocomposite in aqeuos solution. TiO2–WO3 nanocomposites had better zeta potential, electrophoretic mobility and optical band gap as compared to the TiO2–NiO nanocomposites.

4 Conclusion

TiO2–NiO and TiO2–WO3 nanocomposites were prepared by hydrothermal and surface modification methods and analyzed using X-ray diffraction, SEM, TEM, EDAX, Zeta potential, electrophoretic mobility and Photocatalytic activity measurements. The nanocomposite structural features were investigated using the Rietveld refinement method Jana 2006. The cell parameters, phase fraction, crystallite size, particle size, atomic position and bond length between atoms in each phase is affected by the addition of NiO and WO3 to the mixed anatase-rutile TiO2. The photocatalyst performance was found to increased by the usage of TiO2–WO3 nanocomposites as compared to TiO2–NiO nanocomposite, which was due to the light absorption shifted towards the visible region, reduced the photogenerated electron–hole recombination and the life time of photogenerated electron–hole pairs increased. In addition, the larger and uniform particle size distribution of TiO2–WO3 nanocomposites created better photocatalytic efficiency.

References

S.M. Hosseinpour-Mashkani, M. Maddahfar, A. Sobhani-Nasab, Precipitation synthesis, characterization, morphological control and photocatalyst application of ZnWO4 nanoparticles. J. Electron. Mater. 45(7), 3612–3620 (2016)

S.M. Hosseinpour-Mashkani, M. Ramezani, A. Sobhani-Nasab, M. Esmaeil-Zare, Synthesis, characterization and morphological control of CaCu3Ti4O12 through modified sol-gel method. J. Mater. Sci. 26, 6086–6091 (2015)

S.M. Hosseinpour-Mashkani, M. Maddahfar, A. Sobhani-Nasab, Novel silver-doped CdMoO4: synthesis, characterization and its photocatalytic performance for methyl orange degredation through the sonochemical method. J. Mater. Sci. 27, 474–480 (2016)

S. Choi, M.-S. Lee, D.-W. Park, Photocatalytic performance of TiO2/V2O5 nanocomposite powder prepared by DC arc plasma. Curr. Appl Phys. 14, 433–438 (2014)

K. Balachandran, R. Venckatesh, R. Sivaraj, P. Rajiv, TiO2 nanoparticles versus TiO2–SiO2 nanocomposites: a comparative study of photo catalysis on acid red 88. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 128, 468–474 (2014)

J. Wang, Z. Jiang, L. Zhang, P. Kang, Y. Xie, Y. Lv, Xu Rui, X. Zhang, Sonocatalytic degradation of some dyestuffs and comparison of catalytic activities of nano-sized TiO2, nano-sized ZnO and composite TiO2/ZnO powders under ultrasonic irradiation. Ultrason. Sonochem. 16, 225–231 (2009)

Z. Liu, K. Pan, M. Wang, M. liu, Q. Lü, Y. Bai, T. Li, Influence of the mixed ratio on the photocurrent of the TiO2/SnO2 composite photoelectrodes sensitized by mercurochrome. J. Photochem. Photobiol. A 157, 39–46 (2003)

R. Subasri, T. Shinohara, Investigations on SnO2–TiO2 composite photoelectrodes for corrosion protection. Electrochem. Commun. 5, 897–902 (2003)

G. Zhang, H. Huang, L. Wenfang, Y. Fei, W. Huijun, L. Zhou, Enhanced photocatalytic activity of CoO/TiO2 nanotube composite”. Electrochim. Acta 81, 117–122 (2012)

H. Qin, W. Congcong, L. Cao, B. Chi, J. Pu, L. Jian, A novel TiO2 nanowires/nanoparticles composite photoanode with SrO shell coating for high performance dye-sensitized solar cell. J. Power Sources 226, 8–15 (2013)

X. Qi, G. Su, G. Bo, L. Cao, W. Liu, Synthesis of NiO and NiO/TiO2 films with electrochromic and photocatalytic activities. Surf. Coat. Technol. 272, 79–85 (2015)

M. Liang, M. Liu, T. Peng, K. Fan, L. Lu, K. Dai, Fabrication and properties of meso-macroporous electrodes screen-printed from mesoporous titania nanoparticles for dye-sensitized solar cells. Mater. Chem. Phys. 118, 477–483 (2009)

G.-S. Guo, H. Chao-Nan, Z.-H. Wang, F.-B. Gu, D.-M. Han, Synthesis of titania and titanate nanomaterials and their application in environmental analytical chemistry”. Talanta 72, 1687–1692 (2007)

Y. Liu, C.-Y. Liu, Q.-H. Rong, Z. Zhang, Characteristics of the silver-doped TiO2 nanoparticles. Appl. Surf. Sci. 220, 7–11 (2003)

B. Jiang, H. Yin, T. Jiang, J. Yan, Z. Fan, L. Changsheng, W. Jing, Y. Wada, Size-controlled synthesis of anatase TiO2 nanoparticles by carboxylic acid group-containing organics. Mater. Chem. Phys. 92, 595–599 (2005)

S. Nakade, S. Kambe, M. Matsuda, Y. Saito, T. Kitamura, Y. Wada, S. Yanagida, Electron transport in electrodes consisting of metal oxide nano-particles filled with electrolyte solution. Physica E 14, 210–214 (2002)

B. Tan, B. Gao, J. Guo, X. Guo, M. Long, A comparison of TiO2 coated self-cleaning cotton by the sols from peptizing and hydrothermal routes. Surf. Coat. Technol. 232, 26–32 (2013)

Y.-F. Li, W.-P. Zhang, X. Li, Y. Yu, TiO2 nanoparticles with high ability for selective adsorption and photodegradation of textile dyes under visible light by feasible preparation. J. Phys. Chem. Solids 75, 86–93 (2014)

J. Fana, L. Zhenzhen, W. Zhou, Y. Miao, Y. Zhang, J. Hu, G. Shao, Dye-sensitized solar cells based on TiO2 nanoparticles/nanobelts double-layered film with improved photovoltaic performance. Appl. Surf. Sci. 319, 75–82 (2014)

A. Chowdhury, A. Kudo, T. Fujita, M.-W. Chen, T. Adschiri, Nano-twinned structure and photocatalytic properties under visible light for undoped nano-titania synthesised by hydrothermal reaction in water–ethanol mixture. J. Supercrit. Fluids 58, 136–141 (2011)

D. Zhang, T. Yoshida, K. Furuta, H. Minoura, Hydrothermal preparation of porous nano-crystalline TiO2 electrodes for flexible solar cells. J. Photochem. Photobiol. A 164, 159–166 (2004)

W. Sigmund, H. EI-Shall, D.O. Shah, B.M. Moudgil, Particulate Systems in Nano and Biotechnologie. (CRC press, Taylor and Francis Group, Boca Raton, 2009)

P. Mohanty, S. Saravanakumar, R. Saravanan, C. Rath, TiO2 nanowires grown from nanoparticles: structure and charge density study. J. Nanosci. Nanotechnol. 13, 1–7 (2013)

V. Petricek, M. Dusek, L. Palatinus, The Crystallographic Computing System. (Institute of Physics, Prague, 2006)

S. Saravanakumar, R. Saravanan, S. Sasikumar, Effect of sintering temperature on magnetic properties and charge density distribution of nano-NiO. Chem. Paper (2013). doi:10.2478/s11696-013-0519-1

P.M. Woodward, A.W. Sleight, T. Vogt, Structure refinement of triclinic tungsten trioxide. J. Phys. Chem. Solids 56(10), 1305–1315 (1995)

E. Indrea, E. Bica, E.-J. Popovici, R.-C. Suciu, M.C. Rosu, T.-D. Silipas, Rietveld refinement of powder X-ray diffraction of nanocrystalline noble metals-tungsten trioxide. Rev. Roum. Chim. 56(6), 589–593 (2011)

Y. Ku, C.-N. Lin, W.-M. Hou, Characterization of coupled NiO/TiO2 photocatalyst for the photocatalytic reduction of Cr(VI) in aqueous solution. J. Mol. Catal. A 349, 20–27 (2011)

K. Momma, F. Izumi, VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 44, 1272–1276 (2011)

D.T. Cromer, R. Herrington, The structure of anatase and rutile. J. Am. Chem. Soc. 77(18), 4708–4709 (1954)

L. Vegard, Result of crystal analysis. Phil. Mag. 32(187), 65–96 (1916)

P. Scherrer, Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschanften zu Göttingen 26, 98–100 (1918)

J.I. Langford, A.J.C. Wilson, Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J. Appl. Crystallogr. 11, 102–113 (1978)

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pandi, P., Gopinathan, C. Synthesis and characterization of TiO2–NiO and TiO2–WO3 nanocomposites. J Mater Sci: Mater Electron 28, 5222–5234 (2017). https://doi.org/10.1007/s10854-016-6179-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6179-5