Abstract

Pb(Mn1/3Sb2/3)0.01(Ni1/3Nb2/3)0.495(Zr0.3Ti0.7)0.495O3+x wt% Ta2O5 (PMS–PNN–PZT, x = 0, 0.2, 0.4, 0.6, 0.8) lead piezoelectric ceramics were prepared by a traditional two-step solid-state reaction method. The effect of Ta2O5 content on the phase structure, microstructure, electrical properties and dielectric relaxation of PMS–PNN–PZT ceramics was investigated. The XRD patterns show that all ceramics have pure perovskite structure. Ta2O5 doping can promote the grain growth and improve electrical properties. And the ceramics have high relaxation behavior. When x = 0.4, it exhibits optimum electrical performance: d33 = 805 pC/N, kp = 66%, εr = 6838, tanδ = 1.4%, Tc = 118.5 °C, γ = 1.9618, Ec = 3.652 kV/cm, Pr = 21.91 µC/cm2. This indicates that Ta2O5 can be used as an effective dopant in PMS–PNN–PZT ceramics and the ceramics can be used as the main material for multilayer ceramic capacitors and electro-strictive actuators.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

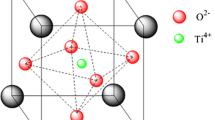

Lead based piezoelectric ceramics are widely used in national defense, information and communication, aerospace, navigation, medicine, bioengineering, agriculture and other fields [1,2,3]. In recent years, lead nickel niobate (PNN) based and lead zirconate titanate (PZT) based piezoelectric ceramics have been widely researched. Pb(Nix, Nby)O3 are relaxor ferroelectrics with high dielectric constant and piezoelectric constant [4]. Pb(Zrx, Tiy)O3 have high piezoelectric properties, especially at the morphotropic phase boundary (MPB). It has the advantages of convenient preparation and low cost [5]. At present, many scholars have studied how to improve the performance of piezoelectric ceramics for meeting the needs of social development. The performance of piezoelectric ceramics is improved by introducing elements and doping trace elements [6]. So, there are appearing some composite piezoelectric ceramic systems now. The main examples are as follows: Pb(Ni1/3Nb2/3)x(Zr,Ti)yO3 (PNN–PZT) [7], Pb(Mg1/3Nb1/3)O3–Pb(Zr,Ti)O3 (PMN–PZT) [8], Pb(Mn1/3Sb2/3)O3–PbZrO3–PbTiO3 (PMS–PZT) [9], Pb1−xBax(Zn1/2Nb1/2)y(Ni1/3Nb2/3)z(Zr,Ti)1−y−zO3 (PZN–PNN–PZT–BZT) [10], yPb(In1/2Nb1/2)O3–(1–x–y)Pb(Mg1/3Nb2/3)O3-xPbTiO3 (PIN–PMN–PT) [11], PbHfO3–PbTiO3–Pb(Mg1/3Nb2/3)O3 (PMN–PST) [12], PbHfO3–PbTiO3–Pb(Mg1/3Nb2/3)O3 (PMN–PHT) [13]. Meanwhile, PNN–PZT based piezoelectric ceramics are represented by high piezoelectric properties, but dielectric loss of the system is relatively high. PMS based ceramics are typical relaxor ferroelectrics with good piezoelectric properties, especially low dielectric loss. PMS–PNN–PZT piezoelectric ceramics were selected in this experiment. On the other way, in order to satisfy the requirement of different electrical products, many researchers try to achieve the desired requirements by doping trace elements.

The results show that appropriate doping of trace elements in lead based piezoelectric ceramics will improve their properties [14,15,16]. Ta2O5 is a kind of high-valence oxide. Some researchers doped it into the lead-free piezoelectric ceramics and studied the improvement of lead-free piezoelectric ceramics [17, 18]. Lin et al. [19] found that piezoelectric constant and electromechanical coupling coefficient are effectively improved by adding Ta5+ into the K0.5Na0.5Nb1−xTaxO3 system. Du et al. [20] reported that BiFe0.5Ta0.5O3 doping into KNN system can availably increase the grain size and improve piezoelectric performance.

But few researchers studied the effect of Ta5+ on the electrical properties of lead based piezoelectric ceramics. Ta5+ and Nb5+ have similar chemical properties. Doping Nb5+ can improve electrical properties [21]. So, Ta2O5 was introduced into 0.01PMS–0.495PNN–0.495PZT ceramics to study effects of Ta5+ additive on the phase structure, micro-structure, electric properties and relaxation behavior in this paper. The results show that addition of Ta2O5 effectively improves the piezoelectric performance. Moreover, the ceramics exhibit obvious dielectric relaxation behavior. It is indicated that the PMS–PNN–PZT + xTa5+ piezoelectric ceramics can be applied at multilayer ceramic capacitors and electro-strictive actuators.

2 Experimental procedure

Pb(Mn1/3Sb2/3)0.01(Ni1/3Nb2/3)0.495(Zr0.3Ti0.7)0.495O3+x wt% Ta2O5 (x = 0, 0.2, 0.4, 0.6, 0.8) piezoelectric ceramics were synthesized by traditional solid sintering method. The raw materials are analytical-grade metal oxides powders: Pb3O4(99.0%), ZrO2(99.5%), TiO2(99.6%), Nb2O5(99.5%), Ni2O3(99.0%), MnO2(99.0%), Sb2O3 (99.0%) and Ta2O5(99.99%). Firstly, each raw material needed to be calculated according to the chemical formula and measured with a balance. In order to compensate for the volatilization of Pb during sintering process, the Pb3O4 weighed with excess 1 wt%. Then the mixture was placed a ball mill with alcohol. The purpose of adding alcohol was to make the powder more refined. The mixtures were ball-milled in alcohol for 10 h. The ball milled materials were dried and then burned for 4 h at 920 °C. The calcined powders were ball-milled again for 10 h. After drying, the powders were pressed into tablets with 6 wt% paraffin waxes under 5 MPa with the size of ϕ12 mm × 1 mm. Subsequently, samples were placed in a sintering furnace and sintered for 2 h at 1260 °C under closed conditions. The heating rate was 2 °C per minute. Then samples were cooled down to room temperature with the furnace.

The crystal phase composition of samples was measured by using an X-ray diffractometer (XRD, Model Panalytical/X’pert-PRO, Holland). The cross-sectional microstructure of specimens was observed by scanning electron-microscopy (SEM, Model SUPRA40, Germany). Samples were applied silver paste on both sides and heated for 20 min at 700 °C. Then they were poled in silicon oil at 50 °C under DC electric field of 2 kV/mm for 30 min. The piezoelectric constants of ceramics were determined by using a quasi-static d33 meter (ZJ-3A; Institute of Acoustics Academic Science, China). The electromechanical coupling coefficients (kp) were calculated by resonance and anti-resonance techniques using an electric oscillator (Model UX21) under 1 kHz. The relative permittivity and dielectric loss as functions of temperature were evaluated with an LCR meter (TZDM system), which connects to a computer-controlled temperature chamber. The test frequencies range from 1 kHz to 1 MHz. According to the following formula [22, 23]:

The free space dielectric constant value ε0 is 8.85 × 10− 12 F/m, C denotes capacitance (units 10− 12 F), d denotes the sample thickness (mm), S denotes the area (mm2), ϕ denotes the sample diameter.

The fr is resonance frequency (Hz), fa is antiresonance frequency (Hz). Qm is the minimum impedance at fr (ohm) resonance impedance, C is capacitance mechanically free at 1 kHz.

3 Results and discussion

After samples preparation, the conclusions of X-ray diffraction, scan electron-microscopy, piezoelectric, dielectric and ferroelectric properties have been done for evaluating the quality of PMS–PNN–PZT based piezoelectric ceramics.

3.1 Phase structure of ceramic

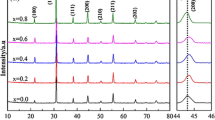

Figure 1a shows the X-ray diffraction (XRD) patterns of 0.01PMS–0.495PNN–0.495PZT ceramics with different Ta2O5 content sintered at 1260 °C. In the Fig. 1a, no detectable secondary phase peak can be found, which indicates that all the samples are pure perovskite structure. It proves that Ta5+ diffused into the lattice and fused with the substrate to form a solid solution. Figure 1b shows the magnified XRD patterns of ceramics in the range of 44–46°. It can be clearly observed that location of peaks changes with increase of Ta2O5 amount, the diffraction peak near the 45° shifts to lower angles. With Ta2O5 doping, elements substitution occurs in the system. According to the principle of ionic radius similarity, when Ta5+ doped into the main lattice of the system, it will give priority to the substitution of B-site ion. So, it makes the lattice constant of crystal larger and the diffraction peak offsets to the lower angle. This phenomenon indicates that doping Ta5+ not only causes lattice distortion, but also changes the phase composition of samples. All samples exhibit the tetragonal phase structure without phase structure transformation.

3.2 Sectional microstructure of ceramics

Figure 2 shows the SEM images of the PMS–PNN–PZT+x wt% Ta2O5 (x = 0, 0.2, 0.4, 0.6, 0.8) ceramics sintered at 1260 °C for 2 h. It can be seen from Fig. 2 that when moderate amount of Ta2O5 was doped, the grains inside the ceramics become full, and the grain size distribution is more uniform. At x = 0.4, the structure is the most compact. At this point, it exhibits optimum electrical performance value. However, there are many fine grains when x > 0.4. This is due to excessive Ta5+ concentrate on the grain boundary without entering the lattice and forming a solid solution. The specific surface area between the fine grains is increased. The dislocation will tangle at the grain boundary, which hinders the motion of the domain. And it has the clamping effect on the domain [24]. So, polarization of the domain is difficult and electrical properties become worse.

3.3 Electrical properties of ceramics

Figure 3 shows the electrical properties of PMS-PNN-PZT+x wt% Ta2O5 ceramics. In the Fig. 3a, it can be seen that the Ta5+ doping can effectively improve performance of the piezoelectric ceramics. With the increase of Ta5+ doping, the piezoelectric constant (d33) and the electromechanical coupling coefficient (kp) have different degrees of improvement. When the amount of doping is 0.4 wt%, d33 and kp show the maximum values. It is due to the increase of the lattice constant caused by doping, resulting in an increase in the electrical dipole moment. B-site ions are further away from the center. So, the piezoelectric performance is improved. In the other hand, due to the occurrence of high-valent ion substitution, cation vacancies are formed, which improves the mobility of the crystal structure. Thereby promoting the deflection of the domain, the ceramic sample is more polarized. The d33 and kp values are effectively improved.

In the Fig. 3b, the εr value increases with increase of Ta5+ content. It may be that the incorporated Ta5+ replaces Mn2+. Mn2+ ions can effectively reduce εr values of system [25]. The dielectric constant gradually increases when content of Mn2+ ions decreases in this system. For the change of tanδ value, it is probable that substitution of high-valent ions makes the electrovalency unbalance. This system forms the cation vacancy, which is beneficial to the motion of domain boundary. The tanδ value begins to increase gradually. However, when the content of Ta5+ ions is more than 0.4 wt%, change of tanδ is not obvious. Excessive Ta5+ ions stockpile at the grain boundary, make the domain boundary deflection more difficult. Thus, the tanδ value does not increase further.

3.4 Dielectric properties of ceramics

Figure 4a shows temperature dependence of the dielectric constant for PMS–PNN–PZT + x wt% Ta2O5 ceramics at the frequency of 10 kHz. The test temperature ranges from room temperature to 280 °C. Figure 4b is the Curie temperature at 10 kHz. It can be seen from the Fig. 4 that the Curie temperature (Tc) decreases with increase of Ta5+ content. Tc value of piezo-ceramic materials reflects the difficulty of B-bite ions deviating from the center position in BO6 oxide octahedral. Because of increase of lattice constant caused by ion-doping, the distance between B-site ions and oxygen ions will increase. As the distance increases, the interaction between the B-site ions and oxygen ions weakens and transition energy of phase structure will be reduced. So, Tc decreases with increase of Ta5+ content. It is shown from Fig. 4a that the maximum permittivity of the dielectric constant increases with increase of Ta5+ content and no other peaks are found from room temperature to 280 °C. The results also show that there is no transition from rhombohedral to tetragonal phase in this system. It is in accordance with the results of the XRD graph analysis.

3.5 Relaxation behavior of ceramics

Figure 5 shows the inverse dielectric constant as a function of temperature for 0.01PMS–0.495PNN–0.495PZT + x wt% Ta2O5 ceramics at 10 kHz. For normal ferroelectrics, when temperature is higher than the Curie temperature, dielectric permittivity should follow the Curie–Weiss law described by Ref. [26]:

where C is the Curie–Weiss constant and Tcw is the Curie–Weiss temperature. The Tcw can be obtained by formula (4). Through the Fig. 5 can observe the relationship between dielectric constant and temperature, it does not follow the Curie–Weiss formula. The degree of the deviation from the Curies–Weiss law is defined by ΔTm as formula (5) [27]:

TB is the initial temperature where the dielectric constant conforms to Curie’s law and Tm is corresponding temperature of the maximum dielectric constant. Table 1 shows some values about dielectric properties. From the Table 1, there is no obvious change about ΔTm with increase of Ta5+ content. It indicates that the dielectric relaxation of all samples is relatively close.

For the relaxation ferroelectric, it can be studied according to the modified Curie–Weiss law [28,29,30]:

where C1 is the Curie constant, εm and Tm are the maximum dielectric constant and temperature correspondingly, γ is called a diffusion coefficient ranging from 1 (normal ferroelectric) to 2 (complete relaxor ferroelectric). Figure 6 shows that plot of ln(1/εr − 1/εm)/ln(T − Tm) at 10 kHz for ceramics. Figure 6f is the variation of dispersion coefficient of Ta5+ ceramics doped with different contents and the dispersion coefficient (γ) is fitted by formula (6). The dispersion values of all samples are > 1.90, indicating that they have obvious dielectric relaxation behavior. With increase of Ta5+ content, the dispersion coefficient has hardly changed, indicating that doping in this range will not affect dielectric relaxation degree of this system.

3.6 Ferroelectric behavior of ceramics

Figure 7a shows P–E hysteresis loops of samples with different Ta2O5 content. Figure 7b shows remnant polarization (Pr) and coercive field (Ec) of samples. From Fig. 7, all samples show typical ferroelectric hysteresis loops. With increase of Ta2O5 content, the remnant polarization (Pr) and the coercive field (Ec) increase first and then decrease. But the changes are not obvious. When x = 0.4, Pr reaches the maximum value (21.91 µC/cm2) and Ec value is smaller, which is 3.652 kV/cm. In addition, the hysteresis loop is the fullest and the polarization is the most sufficient, which further verifies the change of electrical properties. To sum up, it is suggested that Ta2O5 doping can strengthen the ferroelectric properties of the ceramics.

4 Conclusions

In conclusion, Pb(Mn1/3Sb2/3)0.01(Ni1/3Nb2/3)0.495(Zr0.3Ti0.7)0.495O3+x wt% Ta2O5 (PMS–PNN–PZT, x = 0, 0.2, 0.4, 0.6, 0.8) lead piezoelectric ceramics were prepared by a traditional two-step solid-state reaction method. The effects of Ta2O5 on the phase structure, micro-structure, electrical properties and relaxation behavior of the ceramics were systematically studied. The result of XRD diagram shows that all samples are pure perovskite structure. They all show obvious dielectric relaxation behavior. The dispersion coefficient value almost does not change, indicating that incorporation of Ta5+ does not affect the degree of dielectric relaxation in the system. When x = 0.4, it exhibits optimum electrical performance: d33 = 805 pC/N, kp = 66%, εr = 6838, tanδ = 1.4%, Tc = 118.5 °C, γ = 1.9618, Ec = 3.652 kV/cm, Pr = 21.91 µC/cm2. These results confirm that the ceramic is with the potentialities to be applied in multilayer ceramic capacitors and electro-strictive actuators.

References

R. Cao, G. Li, J. Zeng et al., The Piezoelectric and dielectric properties of 0.3Pb(Ni1/3Nb2/3)O3-xPbTiO3-(0.7-x)PbZrO3 ferroelectric ceramics near the morphotropic phase boundary. J. Am. Ceram. Soc. 93(3), 737–741 (2010)

W.P. Chu, C.P. Chong, C.K. Liu et al., Placement of piezoelectric ceramic sensors in ultrasonic wire-bonding transducers. Microelectron. Eng. 66(1), 750–759 (2003)

Z.H. Peng, D.Y. Zheng, T. Zhou et al., Effects of Co2O3 doping on electrical properties and dielectric relaxation of PMS-PNN-PZT ceramics. J. Mater. Sci. Mater. Electron. 5, 1–8 (2018)

G.G. Peng, D.Y. Zheng, S.M. Hu et al., Effects of rare-earth Sm2O3 addition on relaxation behavior and electric properties of 0.5PNN-0.5PZT ceramics. J. Mater. Sci. Mater. Electron. 27(6), 5509–5516 (2016)

T. Stevenson, D.G. Martin, P.I. Cowin et al., Piezoelectric materials for high temperature transducers and actuators. J. Mater. Sci. Mater. Electron. 26(12), 9256–9267 (2015)

Q. Liao, X. Chen, X. Chu et al., Effect of Fe doping on the structure and electric properties of relaxor type BSPT-PZN piezoelectric ceramics near the morphotropic phase boundary. Sensors Actuators A Phys 201(10), 222–229 (2013)

E.F. Alberta, A.S. Bhalla, Piezoelectric and dielectric properties of transparent Pb(Ni1/3Nb2/3)1-x-yZrxTiyO3 ceramics prepared by hot isostatic pressing[J]. Int. J. Inorg. Mater. 3(01), 987–995 (2015)

S. Fujii, E. Fujii, R. Takayama et al., Preparation of Pb(Mg1/3Nb2/3)O3-Pb(Zr,Ti)O3 thin films by RF-magnetron sputtering and their electrical and piezoelectric properties. Jpn. J. Appl. Phys. 48(1), 015502–015502 (2009)

K. Brajesh, A.K. Himanshu, H. Sharma et al., Structural, dielectric relaxation and piezoelectric characterization of Sr2+ substituted modified PMS-PZT ceramic. Phys B Condens. Matter 407(4), 635–641 (2012)

T. Yu, G. Zhang, Y. Yu et al. Pyroelectric energy harvesting devices based-on Pb[(MnxNb1–x)1/2(MnxSb1–x)1/2]y(ZrzTi1–z)1–yO3 ceramics. Sensors Actuators A Phys, 223, 159–166 (2015)

D. Wang, M. Cao, S. Zhang, Phase diagram and properties of Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 polycrystalline ceramics. J. Eur. Ceram. Soc. 32(2), 433–439 (2012)

D. Wang, M. Cao, S. Zhang, Investigation of ternary system PbHfO3-PbTiO3-Pb(Mg1/3Nb2/3)O3 with morphotropic phase boundary compositions. J. Am. Ceram. Soc. 95(10), 3220–3228 (2012)

Y. Li, D. Wang, W. Cao et al., Effect of MnO2 addition on relaxor behavior and electrical properties of PMNST ferroelectric ceramics. Ceram. Int. 41(8), 9647–9654 (2015)

D. Wang, J. Li, M. Cao et al., Effects of Nb2O5 additive on the piezoelectric and dielectric properties of PHT-PMN ternary ceramics near the morphotropic phase boundary. Phys Status Solidi 211(1), 226–230 (2014)

D. Wang, Q. Zhao, M. Cao et al., Dielectric, piezoelectric, and ferroelectric properties of Al2O3 and MnO2 modified PbSnO3-PbTiO3-Pb(Mg1/3Nb2/3)O3 ternary ceramics. Phys Status Solidi 210(7), 1363–1368 (2013)

Y. Li, J. Yuan, D. Wang et al., Effects of Nb, Mn doping on the structure, piezoelectric, and dielectric properties of 0.8Pb(Sn0.46Ti0.54)O3-0.2Pb(Mg1/3Nb2/3)O3 piezoelectric ceramics. J. Am. Ceram. Soc. 96(11), 3440–3447 (2013)

F. Rubio-Marcos, J.F. Fernandez, D.A. Ochoa et al., Understanding the piezoelectric properties in potassium-sodium niobate-based lead-free piezoceramics: interrelationship between intrinsic and extrinsic factors. J. Eur. Ceram. Soc. 37(11), 3501–3509 (2017)

F. Zeng, Q. Liu, E. Cai et al., Relaxor phenomenon of (1-x)(Ba0.85Ca0.15)(Zr0.09Ti0.91)O3-xTa+ 0.6wt.%Li2CO3, ceramics with high piezoelectric constant and Curie temperature. Ceram. Int. 44, 10677–10684 (2018)

D. Lin, K.W. Kwok, H.L.W. Chan, Phase transition and electrical properties of (K0.5 Na0.5)(Nb1 – xTax)O3 lead-free piezoelectric ceramics. Appl. Phys. A 91(1), 167–171 (2008)

J. Du, F. An, Z. Xu et al., Effects of BiFe0.5Ta0.5O3 addition on electrical properties of K0.5Na0.5NbO3 lead-free piezoelectric ceramics. Ceram. Int. 42(1), 1943–1949 (2016)

M. Pereira, A.G. Peixoto, M.J.M. Gomes, Effect of Nb doping on the microstructural and electrical properties of the PZT ceramics. J. Eur. Ceram. Soc. 21(10–11), 1353–1356 (2001)

G.G. Peng, D.Y. Zheng, C. Cheng et al., Effect of rare-earth addition on morphotropic phase boundary and relaxation behavior of the PNN-PZT ceramics. J. Alloys Compds. 693, 1250–1256 (2017)

J. Ji, B. Fang, X. Zhao et al., Effects of nano-sized BCZT on structure and electrical properties of KNN-based lead-free piezoceramics. J. Mater. Sci. Mater. Electron. 29(6), 1–10 (2017)

Z. LI, L. ZHANG, X. YAO, Dielectric properties anomaly of (1-x) Pb(Ni1/3Nb2/3)-xPbTiO3 ceramics near the morphotropic phase boundary. J. Mater. Res. 16(3), 834–836 (2001)

Y. Yu, J. Wu, T. Zhao et al., MnO2 doped PSN-PZN-PZT piezoelectric ceramics for resonant actuator application. J. Alloys Compds. 615(31), 676–682 (2014)

H. Cheng, H. Du, W. Zhou et al., Bi(Zn2/3Nb1/3)O3-(K0.5Na0.5)NbO3 high-temperature lead-free ferroelectric ceramics with low capacitance variation in a broad temperature usage range. J. Am. Ceram. Soc. 96(3), 833–837 (2013)

N. Pisitpipathsin, P. Kantha, K. Pengpat et al., Influence of Ca substitution on microstructure and electrical properties of Ba(Zr,Ti)O3 ceramics. Ceram. Int. 39(2), S35–S39 (2013)

R. Nie, Q. Zhang, Y. Yue et al., Properties of low-temperature sintering PNN-PMW-PSN-PZT piezoelectric ceramics with Ba(Cu1/2W1/2)O3 sintering aids. Int. J. Appl. Ceram. Technol. 13(6), 1119–1124 (2016)

M. Promsawat, A. Watcharapasorn, Z. Ye et al., Enhanced dielectric and ferroelectric properties of Pb(Mg1/3Nb2/3)0.65Ti0.35O3 ceramics by ZnO modification. J. Am. Ceram. Soc. 98(3), 848–854 (2015)

C. Lei, K.P. Chen, X.W. Zhang et al., Study of the structure and dielectric relaxation behavior of Pb(Ni1/3Nb2/3)-PbTiO3 ferroelectric ceramics. Solid State Commun. 123(10), 445–450 (2002)

Acknowledgements

The authors acknowledge the support of project of Guizhou Provincial Education Department (QJH KY Z [2017]001) and Guizhou Provincial Science and Technology Department (QKH LH Z [2017]7248).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, HW., Zheng, DY., Wang, XJ. et al. Effects of Ta2O5 addition on relaxation behavior and electric properties of PMS–PNN–PZT ceramics. J Mater Sci: Mater Electron 29, 16864–16871 (2018). https://doi.org/10.1007/s10854-018-9781-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9781-x