Abstract

Pb(Zn1/3Ni2/3)c(Ni1/3Nb2/3)a(ZrxTiy)bO3 (PZN–PNN–PZT, the ratios of PNN/PZT a/b were 0.88, 1 and 1.136) piezoelectric ceramics were prepared by a traditional solid-state reaction method. The effects of PNN/PZT ratio on phase structure, microstructure and electric properties as well as the relaxation behaviors of PZN–PNN–PZT ceramics were investigated. The XRD patterns showed that all ceramics samples had a pure perovskite phase structure. Meanwhile, it was found that the phase structure undergoes a tetragonal, tetragonal-rhombohedral to rhombohedral transition as ratios of PNN/PZT increased. With the increasing of a/b from 0.88 to 1.136, the dielectric constant and diffusive phase coefficient decreases, it was indicated that relaxation behaviors also decreased. When ceramics with a/b was 1.136, the dielectric relaxation γ reached the minimum and electrical properties were poor. The electric properties of ceramics with a/b was 1.00 have an excellent properties, it was indicated that ceramics reached an optimization at the MPB structure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solid solution soft lead zirconate titanate (PZT)—based piezoelectric ceramic materials have a good electrical properties are widely used in electrome-chanical devices, including sensors, piezoelectric actuators and acoustic transducers [1–3].

The PZT-based complex perovskite piezoelectric ceramics have a higher piezoelectricity especially at a composition near the morphotropic phase boundary (MPB) which has coexistence of tetragonal (T) and rhombohedral (R) phases, so it has attracted many attentions by researchers [4, 5].

Among the composite perovskite piezoelectric material systems, the most interesting ones are as follows: Pb(Zn1/3, Nb2/3)O3–Pb(Zr, Ti)O3(PZN–PZT), Pb(Mg1/3, Nb1/3)O3–Pb(Zr, Ti)O3(PMN–PZT) and Pb(Ni1/3, Nb1/3) O3–Pb(Zr,Ti) O3(PNN–PZT), all of them have been investigated extensively. Both materials are probably best known for their good electrical properties. In order to complement characteristics of each other, it is expected that excellent properties can be obtained from perovskite ceramic in compound systems of PZN–PNN–PZT, PMN–PNN–PZT and PZN–PMN–PZT.

Kondo et al. [6] investigated the ternary system of 0.5PNN–xPZ–(0.5 − x)PT solid solution and found that the composition of 0.5PNN–0.35PT–0.15PZ with large piezoelectric properties was the new MPB in this system. While Vittayakorn et al. [7] argued that the MPB of the solid solution (1 − x)PNN–xPZT (Zr/Ti = 50/50) is located at x = 0.8. The Cao et al. [8] report that 0.3Pb(Ni1/3Nb2/3)O3–xPbTiO3–(0.7 − x)PbZrO3 (x = 0.33–0.43) when x = 0.39, the ceramics exist MPB and have a good electric properties, and dielectric relaxation γ reaches the minimum. Although many previous studies focus on PNN–PZT perovskite ferroelectric materials have reported [9–11]. However, the report about relationships between phase structure, electrical properties and relaxation behavior of the solid solutions in the PZN–PNN–PZT ceramics have rarely been studied.

In this study, the phase formation characteristics of PZN–PNN–PZT ceramics were examined as the rations of PNN/PZT changed, the PZN content is a fixed value, which effect the position of MPB in PZN–PNN–PZT ceramic, a new MPB was found by adjusting the PNN/PZT ratio. The important part focused on the correlation between phase structure, electrical properties and relaxation behavior will be studied and discussed.

2 Experimental procedure

Pb(Zn1/3Ni2/3)c(Ni1/3Nb2/3)a (ZrxTiy)bO3 (abbreviated as cPZN–aPNN–bPZT, a + b+c = 1, c is a fixed value and the ratios of a/b are 0.88, 1 and 1.136) piezoelectric ceramics was prepared by a traditional solid-state reaction method. The raw materials were analytical-grade metal oxides powders: Pb3O4 (99.0 %), ZrO2 (99.5 %), TiO2 (99.6 %), Nb2O5 (99.5 %), Ni2O3 (the content of Ni is 72.5 %), ZnO (99 %). The powders of raw materials were weighed according to mole ratio. After finish the above process, then thoroughly mixed-together through ball-milled with alcohol (99 %) for 16 h. The obtained powders were dried in an oven, and pre-sintered at 900 °C for 4 h. Then pre-sintered powders were ball-milled with alcohol again. After drying, the mix-powders was pressed into tablets with paraffin of 5 wt% added as a binder under 5 MPa with the size of \(\emptyset 12\,{\text{mm}} \times 1.2\,{\text{mm}}\). Subsequently, the samples were sintered at 1200 °C for 2 h in a closed alumina crucible under the PbO atmosphere in order to decrease the volatilization of PbO.

The crystal phase composition of ceramics was measured by using a X-ray diffractometer (XRD, Model PANalytical/X’pert-PRO, Holland). The cross-sectional microstructure of the specimens was observed by scanning electron-microscopy (SEM, Model SUPRA40, Germany). The electrical properties of ceramics were measured after poling in silicone oil at 80 °C under a DC electric field of 2–3 kV mm−1 for 30 min. Piezoelectric constant (d33) was measured by a quasistatic piezo-d33 meter (ZJ-3A; Institute of Acoustics Academic Science, Beijing, China). The capacitance tester (Model TH2618B) was used to measure dielectric loss (tan δ) and capacitance(C) at room temperature at 1 kHz, then the dielectric constant was calculated with capacitance. The electro-mechanical coupling coefficient (kp) was calculated by resonance and anti-resonance techniques using an electric oscillator (Model UX21) under 1 kHz. The relative permittivity and dielectric loss as functions of temperature were evaluated with an LCR meter (Agilent, E4980A) connected to a computer-controlled temperature chamber by measuring at 1 kHz–1 MHz.

3 Results and discussion

3.1 Phase structure of ceramics

Figure 1 is the crystal structure sketch of ABO3 perovskite structure. Different composition of the piezoelectric ceramic will lead to the deformation of crystal structure, which can be showed by phase diagram and X-ray diffraction patterns indirectly. The ternary phase diagrams of PNN + PZN composition as a function shows in the Fig. 2, it could be explained by microscopic composition fluctuations occurring in these perovskite materials, which will lead to some small changes of ABO3 perovskite structure and induce some stresses in the particles of PZN–PNN–PZT ceramics, which determine the co-existence of tetragonal-rhombohedral phases [9, 12].

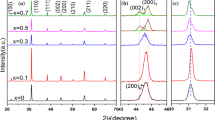

Figure 3 shows the XRD patterns of PZN–PNN–PZT ceramics with different ratios of PNN/PZT (a/b is 0.88, 1.00 and 1.136). In the Fig. 3, there is a solid solution of pure perovskite structure (ABO3) in all specimens, without any trace of pyrochlore phases. It is indicated that optimum change of PNN/PZT has not lead to the change of pure perovskite structure, but some small differences can be found in ceramics with different ratios of a/b. Nadolisky et al. [13] research reports that, the morphotropic phase boundary(MPB) is a two phase coexist region of rhombohedral phase (R) and tetragonal phase (T). Which are characterized by T (002), R (200) and R (200) peaks splitting the diffraction line around 2θ of 44–46. Through XRD patterns of Fig. 3b analysis, (200) peaks indeed showed a transition from a double-peak pattern to a single-peak pattern that occurred with change of a/b from 0.88 to 1.136. There is existence of split peaks of T (200) and R (002) when ceramics with a/b ratio is 1.00, it is standing for a coexistence of tetragonal and rhombohedral phases in the ceramics, which implied that samples exist MPB. The ceramic with the a/b is 1.136, that shows only one R (200) sharp peak (Fig. 3) confirming its exist rhombohedral phase, it is implied that ceramic has not exist MPB, which in accord with electric properties well. Furthermore, the crystal structure of the samples was varied clearly by the change of a/b ratios, as revealed by changing of the split (200) and (002) peaks, as presented in Fig. 3b.

3.2 Cross-sectional microstructure of ceramics

Figure 4 shows the SEM images of PZN–PNN–PZT ceramics with different ratios of PNN/PZT. As the Fig. 4 shows, when the ratios of PNN/PZT was ranged from 0.88 to 1.136, there was an obvious variation in the grain size as a function of a/b, and all of ceramics possess a very dense structure, the average grain sizes of ceramic decrease gradually; when the ratios of PNN/PZT reach at 1.00, it is obvious seen that grains are uniform and satiation, the angle of boundary between grains and grains are about 120 in Fig. 4d, it is good for the motion of electric domain; when ceramic with a/b is 0.88, the grains are huge and inhomogeneous; and when ceramic with a/b is 1.136, the grain growths not well as the ceramics with a/b is 1.00, the grains are not uniform. The results indicate that proper ratios of PNN/PZT can make grain grow well, this results are in accord with electric properties variation well.

3.3 Electric properties of ceramics

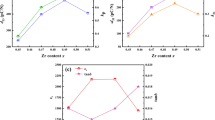

Figure 5 shows the electrical properties of PZN–PNN–PZT ceramics with different ratios of PNN/PZT. In the Fig. 5, it is observed that the change tendency of kp is similar to d33 and εr, the value of εr, d33 and kp first increase and then decrease with the increase of a/b, when the a/b is 1.00, all of them reach at maximum value. The value of tan δ increased with the increasing of a/b gradually. When the a/b is 1.00, the specimens exhibits an excellent comprehensive electric properties as follow: d33 = 800 pC/N, tan δ ~ 2.31 %, kp = 0.63, εr ~ 6020.Through associate XRD and SEM analysis, the piezoelectric properties of ceramics with a/b is 1.00 in this study, the piezoelectric reach at highest level, d33 = 800 pC/N. The reasons are that both perovskite phase, MPB structure and grains are well in specimens, which are good for the motion of electric-domain under polarization. When electric polarization, the same number of domains along the electric field decreases, and the intensity of the residual polarization is increased, so the piezoelectric effect is enhanced [14]. The above results further demonstrate that the MPB structure existed in ceramics with a/b = 1.00.

3.4 Dielectric properties of ceramics

Temperature dependence of the relative dielectric constant εr and dissipation factor tan δ for ceramics, the frequency changed from 1 kHz to 1 MHz is given in Fig. 6, test temperature range from room temperature to 250 °C. It is found that when the ratios of PNN/PZT are changed from 0.88 to 1.136, the ceramics exhibit a strong frequency-dependent response, the Tm increases and the maximum dielectric permittivity decreases with the increase of testing frequency, which is the characteristic of relaxaor ferroelectric piezoelectric materials [15, 16]. There is an obvious shift temperature of ferroelectric phase and para-electric phase in Fig. 6, which is called Curie temperature (TC). The temperature at maximum peak of the dielectric loss is increased with the increasing of a/b, when the a/b change from 0.88 to 1.136, the Curie temperature decrease from 167.1 to 133.2 °C. It is reasonable that the Curie temperature decreased with increasing PNN/PZT, because of the Curie temperature of PNN (−120 °C) are lower than both PT (490 °C) and PZ (230 °C).

3.5 Relaxation behavior of ceramics

Figure 7 is the inverse dielectric constant as a function of temperature for PZN–PNN–PZT ceramic at 10 kHz. For the normal ferroelectric, when the T > Tm, dielectric permittivity follows the Curie–Weiss law described by (1):

where Tcw is the Curie–Weiss temperature and C is the Curie–Weiss constant.

The degree of the deviation from the Curie–Weiss law is defined by ΔTm as formula (2) [17]:

where TB is denoted the beginning of temperature of the function that the dielectric constant comply with the Curie–Weiss law, Tm represents the temperature of dielectric constant maximum.

From the Table 1, it can be seen that with the increasing of a/b value, the value of ΔTm also gradually increase. It is indicated that degree of diffuse phase transition of PZN–PNN–PZT increased. The value of other parameters extracted from dielectric properties are listed in Table 1.

For relaxor ferroelectrics, in order to characteristic the relationship between the relative permittivity and temperature at the range of T > Tm can be described by an empirical expression:

where εm and Tm is the maximum dielectric constant and corresponding temperature respectively, C1 are assumed to be constant, The γ (1 ≤ γ≤2) is the expression of the degree of dielectric relaxation in the relaxor ferroelectric materials and can be extracted from the fitting of slope of ln(1/εr − 1/εm)/ln(T − Tm).When γ = 1, Eq. (3) describes a normal ferroelectric transition, while γ = 2, Eq. (3) corresponds to complete relaxor ferroelectrics with diffuse phase-transition behavior [18, 19]. Figure 8 shows that plot of ln(1/εr − 1/εm)/ln(T − Tm) at 1 MHz for ceramics and relationship between γ and Tc. It should also be noted that the γ decreases with the increase of a/b. The degree of dielectric relaxation γ reaches the minimum with a/b is 1.136, there is not existence of MPB in the ceramics, and electric properties are poor.

The value of γ of the prepared PZN–PNN–PZT ceramics was found to decrease from 1.8447 to 1.7944 with increasing of a/b, which confirms the occurrence of the diffuse phase transition behaviors decreases. And this suggested that appropriate adjustment of a/b can contribute to change of relaxation behaviors. In this study, no pyrochlore phase was observed and the grain sizes have an obvious variation as a function of the PNN/PZT; and when the relaxation behavior at minimum value (1.7944), the piezoelectric properties at lowest level (d33 = 650 pC/N). Further studies should be carried out to understand the relation between the degree of diffuseness and piezoelectric properties.

4 Conclusions

The PZN–PNN–PZT ceramics with ratios of PNN/PZT were 0.88, 1.00 and 1.136 have been fabricated by using a traditional solid-state reaction method. The effects of a/b on the phase structure, electric properties, Curie temperature and relaxation behavior of PZN–PNN–PZT were investigated in details. It was found that change of a/b induced a diffuse phase transformation and relaxation behavior in the samples of PZN–PNN–PZT system. Furthermore, the Curie temperature was deceased significantly with a/b increased. When γ value reaches at minimum value (1.7944), the ceramics with a/b = 1.136, there was not existence of MPB in ceramics, and electric properties also poor; When the ceramics with a/b was 1.00 exhibited an excellent electric properties as follows: d33 = 800 pC/N, kp = 0.63, εr ~ 6020, tan δ ~ 2.31 %, it was indicated that ceramics reached an optimization at the MPB, and a new MPB region has been found in PZN–PNN–PZT systems, which provided a foundation for further research on this. The PZN–PNN–PZT formulation was with high piezoelectric properties, such as piezoelectric constant, relative dielectric constant and acceptable other electric properties, which could be a potential candidate in various piezoelectric applications such as transducers and actuators.

References

S. Zhang, F. Yu, J. Am. Ceram. Soc. 94, 3153 (2011)

T. Stevenson, D.G. Martin, P.I. Cowin, A. Blumfield, A.J. Bell, T.P. Comyn, P.M. Weaver, J. Mater. Sci.: Mater. Electron. (2015). doi:10.1007/s10854-015-3629-4

T.N. Koltunowicz, J. Mater. Sci.: Mater. Electron. (2015). doi:10.1007/s10854-015-3236-4

Y. Guo, W. Ma, M. Wang, N. Chen, Mater. Lett. 159, 126 (2015)

Z. Li, L. Zhang, X. Yao, J. Mater. Res. 16, 834 (2001)

M. Kondo, M. Hida, M. Tsukada, K. Kurihara, N. Kamehara, J. Ceram. Soc. Jpn. 105, 719 (1997)

N. Vittayakorn, G. Rujijanagul, X. Tan, M.A. Marquardt, D.P. Cann, J. Appl. Phys. 96, 5103 (2004)

R.J. Cao, G.R. Li, J.T. Zeng, S.H. Zhao, L.Y. Zheng, Q.G. Yin, J. Am. Ceram. Soc. 93(3), 737 (2010)

R. Gupta, S. Verma, D. Singh, K. Singh, K.K. Bamzai, Appl. Ceram. 9(1), 5 (2015)

S. Wirunchit, P. Laoratanakul, N. Vittayakorn, J. Phys. D Appl. Phys. 41, 125406 (2008)

E.F. Alberta, A.S. Bhalla, Int. J. Inorg. Mater. 3, 987 (2001)

W.L. Ji, X.Y. He, X. Zeng, Ceram. Int. 41, 10387 (2015)

M.M. Nadoliisky, S.D. Toshey, T.K. Vasileva, Phys. Status Sol. 86(a), K145 (1984)

B.J. Fang, Q.B. Du, L.M. Zhou, Y.H. Shen, J. Wang, Eur. Phys. J. Appl. Phys. 51(01), 10301 (2010)

N. Pisitpipathsin, P. Kantha, K. Pengpat, G. Rujijanagul, Ceram. Int. 39, S35 (2013)

H.J. Fan, M.H. Kuok, S.C. Ng, N. Yasuda, H. Ohwa, M. Iwata, Y. Ishibashi, J. Appl. Phys. 91, 2262 (2002)

C. Lei, K. Chen, X. Zhang, J. Wang, Solid State Commun. 123, 445 (2002)

G. Ajai, D.C. Agrawal, J. Mater. Sci.: Mater. Electron. 10, 649 (1999)

T. Ravender, R.P. Tandon, V.K. Hans, Mater. Sci. Eng. B Solid 100, 47 (2003)

Acknowledgments

The authors acknowledge the support of the Science and Technology Department of Guizhou Province [Project Number: (2013) 3075 and (2012) 7010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, G., Chen, C., Zhang, J. et al. Effects of PNN/PZT ratios on phase structure, electric properties and relaxation behavior of PZN–PNN–PZT ceramics. J Mater Sci: Mater Electron 27, 3145–3151 (2016). https://doi.org/10.1007/s10854-015-4136-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4136-3