Abstract

A low temperature co-fired ceramic (LTCC) was fabricated at 910 °C /2 h from the powder mixture of Li2Zn3Ti4O12, TiO2 and a B2O3–La2O3–MgO–TiO2 glass (BLMT), and the influence of TiO2 on microstructure and dielectric properties of the composite was investigated in the composition range (wt%) of 20BLMT–(80 − x)Li2Zn3Ti4O12–xTiO2 (x = 0, 2.5, 5, 7.5, 9 and 10). The results showed that all samples consisted of Li2Zn3Ti4O12, TiO2, LaBO3 and LaMgB5O10 phase. And LaBO3, LaMgB5O10 and a small amounts of TiO2 were crystallized from BLMT glass during sintering process. As x increases, dielectric constant and temperature coefficient of resonance frequency of the composites demonstrated gradually increase, whereas the quality factor of the sample of x = 0 wt% was about 41,500 GHz and the ones maintained stable at a high level of 49,000–51,000 GHz for other samples. The composite with x = 9 wt% had an optimal microwave dielectric properties with the dielectric constant of 20.2, quality factor of 50,000 GHz and temperature coefficient of resonant frequency of − 0.33 ppm/°C.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For meeting the requirements of miniaturization, integration and high reliability of electronic devices, low-temperature co-fired ceramics (LTCC) technology has played an increasingly significant role in the development to Internet of Things, the Tactile Internet (5th generation wireless systems), electronic warfare, satellite broadcasting and intelligent transport systems [1, 2]. The ideal LTCC materials owe several features such as low sintering temperature (below 950 °C), an appropriate dielectric constant (εr), high quality factor (Q × f) and a near-zero temperature coefficient of resonant frequency (|τf| ≤ 10 ppm/°C) [3]. Unfortunately, most of the dielectric ceramics with good microwave dielectric properties cannot be used for LTCC application due to the sintering temperatures above 1000 °C. Therefore, lowering the sintering temperature as well as maintaining an excellent dielectric properties simultaneously is the key to promote the LTCC materials.

Li2Zn3Ti4O12 is a new member of the Li2O–ZnO–TiO2 ternary microwave dielectric ceramics with the middle-εr (20.6), high Q × f value (106,700 GHz) and large negative τf (− 48 ppm/°C), and the sintering temperature of it is around 1075 °C [4]. Obviously, the sintering temperature and τf value are a huge barrier for it to be further applied in LTCC technology. In order to realize Li2Zn3Ti4O12 ceramics for LTCC applications, low-melting sintering aids such as BaCu(B2O5) and Li2O–ZnO–B2O3 glass for lowering the sintering temperature and a positive τf-tailoring material (e.g., TiO2 + 465 ppm/°C, Li2TiO3 + 20.3 ppm/°C) for modifying to near-zero τf value are used simultaneously [4,5,6,7]. It can be found from our previous works that B2O3–La2O3–MgO–TiO2 (BLMT) glass is a promising candidate due to its low transformation temperature (644 °C) [8, 9]. In addition, TiO2 is chosen as the positive τf-tailoring material in this study. In this paper, a series of LTCC composites based on 20BLMT–(80 − x)Li2Zn3Ti4O12–xTiO2 (x = 0, 2.5, 5, 7.5, 9 and 10, in wt%) are fabricated, meanwhile the effects of the TiO2 on the crystallization and microwave dielectric properties of the material are investigated.

2 Experimental

Glass of 42.9B2O3–17.1La2O3–25.7MgO–14.3TiO2 in mol% was prepared by traditional glass melting method [8, 9]. The BLMT glass powder was obtained after the quenched glass was planetary-milled in aluminum jar with ethyl alcohol and ZrO2 balls for 2 h, and then dried and screened through a 200-mesh sieve. Li2CO3, ZnO and TiO2 were weighted according to the stoichiometry of Li2Zn3Ti4O12 and mixed in a Nylon tank using ethyl alcohol and ZrO2 balls by planetary ball mill for 2 h. The mixture was dried and calcined at 900 °C for 8 h to form Li2Zn3Ti4O12 phase. Then the BLMT glass powder, calcined Li2Zn3Ti4O12 powder and TiO2 powder were weighed with the ratio of 20BLMT–(80 − x)Li2Zn3Ti4O12–xTiO2 (x = 0, 2.5, 5, 7.5, 9 and 10) and planetary-milled with ZrO2 balls and ethyl alcohol for 2 h. After drying, the mixture was granulated by adding 8 wt% poly(vinyl butyral) solution for getting the uniformity particle size and good fluidity power. Preformed pellets of 15 mm in diameter and 7–8 mm in height were obtained from the powder using a cylindrical steel mold, and then were pressed at 2 MPa by hydraulic pressing, followed by sintering between 790 and 920 °C for 2 h in air at a heating rate of 5 °C/min.

X-ray diffraction analysis (XRD, D8 ADVANCE, Bruker, Germany) was using to identify the crystalline phases of samples. The backscattered electron (BSE) micrograph and element-distribution mapping (EDM) of sample was examined by field emission scanning electron microscope (FESEM, Magellan 400, FEI, USA). The bulk density was measured applying the Archimedes method. The dielectric properties of the samples with the diameter of 12 mm and the height of 6 mm were collected by the Hakki–Coleman dielectric resonator method in the TE011 mode using an Agilent E8363A PNA series network analyzer in frequency range of 1–20 GHz. The τf value was gauged by using the temperature test cabinet (VTL7003, Vötsch, Germany) according to the following equation:

where ƒ85 and ƒ25 represent the resonant frequencies at 85 and 25 °C, respectively.

3 Results and discussion

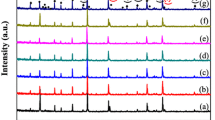

Figure 1 shows XRD patterns of the composites sintered at 910 °C for 2 h. The sample with x = 0 wt% consists of Li2Zn3Ti4O12 (JCPDS no. 44-1038), LaBO3 (JCPDS file no. 12-0762), LaMgB5O10 (JCPDS no. 35-0120) and very small amounts of TiO2 (JCPDS file no. 21-1276). According to our previous work [8, 9], LaBO3, LaMgB5O10 and TiO2 phase are crystallized from the BLMT glass. However, it can be easily seen that the peak intensity of TiO2 enhances as x increases from 2.5 to 10 wt% compared to that of composite with x = 0 wt%. It means the positive τf-tailoring material TiO2 does not chemically react with the BLMT glass or Li2Zn3Ti4O12ceramic, which is a great advantage to modify the τf value of the composite to near-zero.

The BSE micrograph and ESM of the composite with x = 9 wt% sintered at 910 °C for 2 h are showed in Fig. 2. It can be found from Fig. 2a that the composite exhibits compact microstructure with grain sizes in the range 3–10 μm and seems to be composed of two kinds of phases which are present in gray and white. However, EDM reveals that there are more than two phases, in which the Li element belongs to the ultralight elements so that it cannot be detected by EDM [10]. It also can be easily seen from Fig. 2b, c that the most area of gray grains has a composition rich in Zn and Ti element corresponding to Li2Zn3Ti4O12 phase, yet some small gray grains (white arrows) are richer in Ti element than other gray grains and no other element is detected in these grains beside Ti element, suggesting that these grains belong to the TiO2 phase. It is notable that some gray grains enrichment in Mg maybe correspond to MgLaB5O10 phase as shown in Fig. 2e. The area of white grains has a composition rich La and B element as shown in Fig. 2d, f, which is consistent with the composition of LaBO3 phase. The results indicate that four phases co-exist in the sample, which is agree with the discussion in previous XRD analysis shown in Fig. 1.

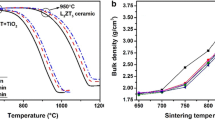

Figure 3a–c demonstrates the bulk density, dielectric constant, and Q × f value of BLMT–Li2Zn3Ti4O12–TiO2 composite as functions of sintering temperature. The bulk density of sintered samples increases, and then slightly declines after reaching a maximum with increasing the sintering temperatures as shown in Fig. 3a. The maximum density is obtained at 900 °C for composite with x = 0 wt%, and the maximum density are achieved at 910 °C for composites with x = 2.5–10 wt%, which indicates that all composite can be densified sintering below 950 °C. It can be easily seen from Fig. 3b, c that the change in the εr and Q × f value is attributed to the variation in sintering temperature and x value during sintering. Obviously, the εr of the composites have the tendency of increasing with the increasing sintering temperature owing to the densification of composites. The εr of composites sintered at the optimum sintering temperature could be adjusted to the range of 17–21 with the increasing of x from 0 to 10 wt% due to the increase of higher-εr TiO2 (108) phases. The Q × f value of the composites is not only related to the phase composition but also closely associated with imperfections such as porosity and grains size [10,11,12,13]. In this case, the increasing Q × f value of the composites with the increasing sintering temperature is still influenced by the densification of composites. The Q × f value of composites sintered at the optimum sintering temperature first increases from 41,500 to 49,000 GHz with the x increasing from 0 to 2.5 wt%, and then maintain stable at a high level of 49,000–51,000 GHz as the x further increases to 10 wt%.

The τf value of the composites sintered at their optimum temperatures are shown in Fig. 3d. It is clear that the τf valve increases from − 50 to + 11 ppm/°C with x increasing from 0 to 10 wt%. The τf for composites is well known to be influenced by the composition and their relative contents [14, 15]. As discussed about the XRD results in Fig. 1, it is easily found that the τf increases owing to the increasing of TiO2 (+ 456 ppm/°C). Besides, it also can be found that the τf value of composites seems to be linear with the x value. Based on the experimental data in Fig. 3d, the linear regression equation of τf on the x value with Adj. R2 = 0.95443 are obtained by the Origin software:

It means that the τf can be precisely adjusted by adding the suitable content of TiO2, and when τf of composite is zero, the x is 9.037 wt%, which indicates that the τf value of composites is mainly influenced by the phase composition and their relative contents in composites. On the whole, the promising microwave dielectric properties of εr = 20.2, Q × f = 50,000 GHz, and τf = − 0.33 ppm/°C can be obtained when the x is equal to 9 wt%. Table 1 shows that the dielectric properties of composite in our paper compare with recently reported Li2Zn3Ti4O12 LTCC materials, which indicates that the 20BLMT–71Li2Zn3Ti4O12–9TiO2 (in wt%) material displays excellent microwave dielectric properties.

4 Conclusions

In this study, the 20BLMT–(80 − x)Li2Zn3Ti4O12–xTiO2 (x = 0, 2.5, 5, 7.5, 9 and 10, in wt%) composites system has been fabricated and investigated. The results indicate that all composites are made up of Li2Zn3Ti4O12, TiO2, LaBO3 and LaMgB5O10 phases. And BLMT glass crystallizes forming LaBO3, LaMgB5O10 and very small amounts of TiO2 phase during sintering process. All composites can be sintered at 910 °C. Corresponding to the increase of x in system, the εr and τf value of composites augment as well, whereas the Q × f value of the composite with x = 0 wt% is about 41,500 GHz and that of the composites with x = 2.5–10 wt% maintain stable at a high level of 49,000–51,000 GHz. Optimized microwave dielectric properties of composites with x = 9 wt% are obtained by sintering at 910 °C/2 h with: εr = 20.2, Q × f = 50,000 GHz, and τf = − 0.33 ppm/°C.

References

Y. Imanaka, Multilayered low temperature cofired ceramics (LTCC) technology. (Springer, Tokyo, 2005)

M.T. Sebastian, H. Wang, H. Jantunen, Curr. Opin. Solid. State Mater. Sci. 20, 151–170 (2016)

M.T. Sebastian, R. Ubic, H. Jantunen, Int. Mater. Rev. 60, 392–412 (2015)

H.F. Zhou, X.B. Liu, X.L. Chen, L. Fang, Y.L. Wang, J. Eur. Ceram. Soc. 32, 261–265 (2012)

A. Sayyadi-Shahraki, E. Taheri-Nassaj, S.A. Hassanzadeh-Tabrizi, H. Barzegar-Bafrooei, J. Mater. Sci. 25, 355–360 (2014)

X.B. Liu, H.F. Zhou, X.L. Chen, L. Fang, J. Alloy. Compd. 515, 22–25 (2012)

Y. Wu, D. Zhou, J. Guo, L.X. Pang, J. Mater. Sci. 24, 1505–1510 (2013)

H.S. Ren, M.Z. Dang, H.J. Wang, T.Y. Xie, S.H. Jiang, H.X. Lin, L. Luo, Mater. Lett. 210, 113–116 (2018)

H.S. Ren, X.G. Yao, T.Y. Xie, M.Z. Dang, H.Y. Peng, S.H. Jiang, H.X. Lin, L. Luo, J. Mater. Sci. 28, 18646–18655 (2017)

Y. Lv, R.Z. Zuo, Y. Cheng, C. Zhang, J. Am. Ceram. Soc. 96, 3862–3867 (2013)

T.W. Zhang, R.Z. Zuo, C. Zhang, Mater. Res. Bull. 68, 109–114 (2015)

L. Yuan, H.J. Wang, H.X. Lin, W. Li, X.W. Li, J.L. Shi, Ceram. Int. 40, 2109–2113 (2014)

K. Zhang, L. Yuan, Y.P. Fu, C. Yuan, W. Li, J. Mater. Sci. 26, 6526–6531 (2015)

K.X. Song, S. Wu, P. Liu, H.X. Lin, Z.H. Ying, P. Zheng, W.T. Su, J.X. Deng, L. Zheng, H.B. Qin, J. Alloy. Compd. 628, 57–62 (2015)

J.B. Song, K.X. Song, J.S. Wei, H.X. Lin, J. Wu, J.M. Xu, W.T. Su, Z.Q. Cheng, J. Am. Ceram. Soc. 101, 244–251 (2018)

T.W. Zhang, R.Z. Zuo, Y. Wang, J. Mater. Sci. 25, 5570–5575 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ren, H., Peng, H., Xie, T. et al. Investigation of Li2Zn3Ti4O12-based temperature stable dielectric ceramics for LTCC applications. J Mater Sci: Mater Electron 29, 9033–9037 (2018). https://doi.org/10.1007/s10854-018-8928-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-8928-0