Abstract

In this work, polycrystalline LaxBa1−xCoO3−δ (0 ≤ x ≤ 0.1) ceramic samples were prepared by conventional solid-state reaction process. La3+ doping effects on the crystal structures, densities, microstructures and thermosensitive characteristics of the LaxBa1−xCoO3−δ ceramics were investigated. The major phase presented in the sintered samples is a hexagonal perovskite BaCoO2.6 phase. The doping of La3+ reduces the quantity of voids and improves the densities of the LaxBa1−xCoO3−δ ceramics compared with La-free ceramic. The resistivities of the LaxBa1−xCoO3−δ ceramics decrease exponentially with increasing temperature in each of the range of 10–26 K and 26–100 K. The resistivities and B constants increase as the contents of La3+ increase in the LaxBa1−xCoO3−δ ceramics.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Negative temperature coefficient resistance are thermally sensitive resistors whose resistance decreases with increasing temperature, which have been used widely for temperature measurement because of various virtues, like high sensitivity, stable resistant, fast response, small volume and low cost [1]. As a general rule, resistivity and B constant usually are used to characterize the performance of NTC thermistors [2].The resistances of the NTC thermistors can be expressed by the Arrhenius Eq. (1) [3]:

where the R and R0 are electrical resistances at a certain temperature and the infinite temperature, respectively. Ea is the activation energy for electrical conduction and kB is the Boltzmann constant. The BT1/T2 constant can be expressed by the Eq. (2) [2]:

where the ρ1 and ρ2 are the resistivities at T1 and T2, respectively. Furthermore, Ea is defined by Eq. (3) [4]:

Recently years, cobalt oxides, such as SrCoOx, are currently attracting much research interest due to the semiconductor characteristics as a consequence of an orbital ordering, charge ordering and magnetic variation because of the electrons spin tend to align spontaneously or randomly in some regions at low temperature [5,6,7,8,9,10]. In our previous work, BaCoO3−δ ceramic materials were fabricated and demonstrated to be used as potential candidates for NTC thermistors at low temperature [11]. However, there are a few voids in the BaCoO3−δ ceramics, which may be the concentration of the stress leading to the ceramics breaking. Recently, some investigations reported that La3+ doping could improve the microstructures of the sintered ceramics, which are free from cracks in the ceramics [12].What’s more, the cobalt oxides doped by rare earth lanthanum are used popularly in domestic and industry, such as electrode materials and oxygen permeable materials, owing to a good electronic conductor with low electrical resistivity [13,14,15]. However, there are few reports about BaCoO3−δ ceramic materials doped by La3+ used for NTC thermistors of low temperature measurement. In this article, the effects of La3+ doping on the crystal structures, densities, microstructures and thermosensitive characteristics in the LaxBa1−xCoO3−δ ceramics were investigated.

2 Experimental procedure

The powders were prepared by conventional solid state reaction method. Starting material were high-purity oxide powders La2O3, Co2O3 and BaCO3, which were weighted in appropriate proportions, as shown in Table 1. They were wet-milled, dried, and calcined at 900 °C for 2 h. Then the calcined powders were wet-milled, dried again and pressed into green compacts under a uniaxial pressure of 20 MPa for 30 s and cold isostatic pressing at 300 MPa for 60 s. The pressed green compacts were sintered at 1050 °C for 2 h and furnace cooled. Then the sintered compacts were cut into wafers of 0.25 mm thick, printed with silver palladium paste in each side, heated at 835 °C for 20 min and cut into ceramic chips of 1 mm × 1 mm. At last, the chips were attached by tinned copper wires as electrodes and solidified by epoxy resin for electrical measurement.

The crystal structures of the samples were analyzed by an X-ray diffractimeter (XRD, BRUKERD2-ADVANCE; Germany) using Cu Kα (λ = 1.5418 Å) radiation in the angular range from 20° to 70° (2θ) at room temperature. The microstructures of the samples were investigated using a scanning electron microscope (SEM, Phenom pro; Netherlands). The density of the samples were obtained by the Archimedes method. The resistances of the prepared thermistors were measured by a system sourcemeter (Keithley 2612A, America). The low temperature ambient was supplied by a refrigerator (Model 22, Janis research company Inc., America).

3 Results and discussion

3.1 X-ray diffraction

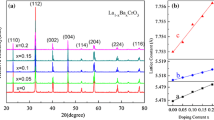

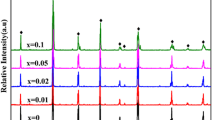

As shown in Fig. 1, the XRD patterns of the LaxBa1−xCoO3−δ (0 ≤ x ≤ 0.1) ceramics indicate that the major phase of the samples is a hexagonal perovskite BaCoO2.6 (JCPDS No: 71-2453) phase. It could be seen that the peaks of the La-doped ceramics shift dramatically toward to lower angles with respect to the La-free ceramic. It may be due to that at first La3+ doping causes the lattice distortion and expand the lattice parameters [16]. What’s more, the peaks of the La-doped ceramics shift higher angle as the contents of the La3+ increase. It may be attributed to that according to the Bragg equation 2dsinθ = nλ, the radius of La3+ (0.1032 nm) is smaller than the radius of Ba2+ (0.1350 nm), so the crystalline interplanar spacing decreases and then the diffraction angle θ increases. All of these can also be seen from the lattice parameter of the ceramic samples in Table 2.

3.2 SEM

As depicted in Fig. 2, the SEM images of LaxBa1−xCoO3−δ (0 ≤ x ≤ 0.1) ceramics show that there are fewer voids in the La-doped ceramics than the La-free ceramic, which can also be seen from the densities of the ceramics in Table 3. All the relative densities of the La-doped ceramics are larger than the relative density of the La-free ceramic. This may be the reason that the La-doped ceramics are not easier to break up than the La-free ceramics. Because fewer voids could be the concentration of the stress in the La-doped ceramics than the La-free ceramic. So the doping of La in the ceramics could improve the densities and the mechanical strength of the ceramic samples. What’s more, in the present work, when x = 0.025, there are fewest voids in the ceramic sample, and whose relative density is also the highest (96.62%) among the ceramic samples.

3.3 NTC electrical properties

The ρ-T curves and the lnρ-1/T curves of the samples are shown in Fig. 3a, b, respectively. As shown in Fig. 3a, it is obviously that the resistivities decrease exponentially as temperature increases in each of the range of 10–26 K (range I) and the range of 26–100 K(range II), i.e., obeying the well known exponential law described by Eq. (1) in each of the range. In addtion, as shown in the Fig. 3b, these samples operate the approximate linear relationship between lnρ and 1/T over each of the range I and range II, indicative of NTC thermistor characteristics. The reason of the resistivities decreasing exponentially as temperature increases only in the internal of each of the range I and the range II could be seen in our previous work [11].

The ρ15 K, ρ30 K, B15 K/25 K, B30 K/50 K constant, Ea15 K/25 K and Ea30 K/50 K of the samples are shown in Table 4. In the range I, the values of the ρ15 K, B15 K/25 K constant and Ea15K/25K of the LaxBa1−xCoO3−δ ceramics are in the range of 4.06 × 103–6.610 × 104 Ω cm, 34.46–62.45 K, and 2.97 × 10−3–5.38 × 10−3 eV, respectively. In the range II, the values of the ρ30 K, B30 K/50 K constant and Ea30 K/50 K of the LaxBa1−xCoO3−δ ceramics are in the range of 8.0 × 102–3.66 × 103 Ω cm, 134.43–188.39 K, and 1.163 × 10−2–1.620 × 10−2 eV, respectively. These results show that the electrical properties of the NTC thermistors can be tuned to desired values by changing the content of La3+ doped in the ceramics.

Figure 4 shows the ρ15 K, ρ30 K, B15 K/25 K and B30K/50K constant of the LaxBa1−xCoO3−δ ceramics as a function of the content of La3+ doped in the ceramics. From Fig. 4 and Table 4, it can be seen that the value of the ρ15 K, ρ30 K, B15 K/25 K and B30K/50K of the LaxBa1−xCoO3−δ ceramics increase as the contents of La doped in the ceramics increase. On the one hand, the electrical conduction in these ceramics may be due to the electron jumps between Co3+ and Co4+ ions [8, 17,18,19]. On the other hand, the quantities of Co3+/Co4+ pairs decrease because the valance of La3+ is higher than the valance of Ba2+, which make the hopping more difficult, increase the B constant and the resistivity of the ceramic samples [20, 21].

4 Conclusions

In the present work, LaxBa1−xCoO3−δ (0 ≤ x ≤ 0.1) ceramic materials were prepared by conventional solid state reaction. The major phase in the ceramic samples is a hexagonal perovskite BaCoO2.6 phase. The quantity of voids of the ceramics are fewest when x = 0.025, whose relative density is the highest (96.62%). The resistivity of the prepared LaxBa1−xCoO3−δ (0 ≤ x ≤ 0.1) ceramics decreases exponentially as temperature increases in each of the range of 10–26 K and 26–100 K, respectively. In addition, the resistivities and B constants increase as the contents of La3+ doped in the ceramics increase. LaxBa1−xCoNiO3−δ ceramics could be applied as potential candidates for NTC thermistors in a low temperature range from 10 to 100 K.

References

A. Feteira, J. Am. Ceram. Soc. 92, 967 (2009)

K. Park, J.K. Lee, J. Alloys Compd. 475, 513 (2009)

P. Fau, J.P. Bonino, J.J. Demai, J. Rousse. Appl. Surf. Sci. 319, 65 (1993)

K. Park, Mater. Sci. Eng. B 104, 9 (2003)

K. Yamaura, H. Zandbergen, K. Abe, R. Cava, J. Solid State Chem. 96, 146 (1999)

P.M. Botta, V. Pardo, C.d..l.. Callec, D. Baldomir, J.A. Alonsoc, J. Rivas Magn. Mater. 316, e670 (2007)

C. Martin, A. Maignan, D. Pelloquin, N. Nguyen, B. Raveau, Appl. Phys. Lett. 71, 1421 (1997)

A. Maignan, S. Hébert, D. Pelloquin, V. Pralong, J. Solid State Chem. 179, 1852 (2006)

K. Yamaura, R. J. Cava, Solid State Commun. 115, 301 (2000)

M. Kauffmann, O. Mentré, A. Legris, S. Hébert, Chem. Mater. 20, 1741 (2008)

Z. Hu, H. Zhang, J. Wang, L. Chen, X. Xie, X. Liu, J. Mater. Sci. Mater. Electron 28, 6239 (2017)

J. Yao, J. Wang, Q. Zhao, A. Chang, Int. J. Appl. Ceram. Technol. 10, E106 (2013)

I. Maurin, P. Barboux, Y. Lassailly, J.P. Boilot, F. Villain, P. Dordor, J. Solid State Chem. 160, 123 (2001)

Y. Hao, W. Ma, Y. Qu, T. Xu, J. Electroceram. 15, 251 (2005)

V.A. Cherepanov, L.Y. Gavrilova, E.A. Filonova, M.V. Trifonova, V. I. Voronin, Mater. Res. Bull. 34, 983 (1999)

F. Prado, Solid State Ion. 167, 147 (2004)

H. Taguchi, M. Shimada, M. Koizumi, J. Solid State Chem. 29, 221 (1979)

H. Taguchi, M. Shimada, M. Koizumi, Mater. Res. Bull. 15, 165 (1980)

C. Zener, Phys. Rev. 81, 440 (1951)

F. Cheng, J. Wang, H. Zhang, A. Chang, W. Kong, B. Zhang., J. Mater. Sci. Mater. Electron. 26, 1374 (2014)

H. Taguchi, M. Shimada, M. Koizumi, Mater. Res. Bull. 13, 1225 (1978)

Acknowledgements

This work was supported by West Light Foundation of Chinese Academy of Science (No. XBBS201314).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Hu, Z., Wang, J., Xie, X. et al. Effects of La3+ doping on the crystal structures, densities, microstructures and thermosensitive characteristics of the LaxBa1−xCoO3−δ (0 ≤ x ≤ 0.1) ceramics for low temperature NTC resistances. J Mater Sci: Mater Electron 28, 17606–17610 (2017). https://doi.org/10.1007/s10854-017-7698-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7698-4