Abstract

In this work, a PdAl/Au (20/30 nm) metal alloyed scheme was investigated for obtaining low resistance ohmic contacts to Mg-doped p-type GaN. The specific contact resistance (ρSCR) was determined using the circular-transmission-line pattern method between the metal contacts and p-type GaN by current–voltage (I–V) measurements. It is noted that the ρSCR of the as-deposited contact (1.23 × 10−2 Ω cm2) was enhanced upon rapid thermal annealing (RTA) at 600 °C (7.82 × 10−4 Ω cm2) for 1 min under N2 ambient. The effective Schottky barrier heights (SBHs) of the various annealed contacts were determined using the Norde and I–V methods. It is observed that the effective SBHs were dependent upon the RTA conditions. According to the X-ray diffraction and X-ray photoelectron spectroscopy results, the gallide-related phases were formed at the PdAl/Au/p-GaN interface such as Au7Ga2 and Ga3Pd5 upon RTA at 600 °C. These phases were responsible for obtaining low contact resistivity of the PdAl/Au contact. Atomic force microscopy results show that the surface morphology (root-mean-square, RMS) of the contact was reasonably smooth even after RTA at 600 °C with an RMS roughness of 0.714 nm. Observations indicate that the PdAl/Au metal alloyed contact was a suitable ohmic contact to p-type GaN for the development of commercially viable large-scale GaN-based microelectromechanical system applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Gallium nitride (GaN)-based microelectromechanical systems (MEMS) technology saw rapid developments in the last decade [1, 2]. GaN has good mechanical and chemical stability even at higher temperatures and also it has excellent piezoelectric properties, which makes it a strong candidate for MEMS applications regarding sensing and timing [3,4,5,6,7,8,9]. GaN can also be used in high-frequency and high power transistors because of its attractive properties of a high saturation velocity, high sheet carrier density, and high breakdown electric field [10, 11]. Remarkably, GaN is also quite suitable for satellite and radar communications compared to other semiconductors because it can easily handle electromagnetic frequencies and power levels.

For GaN-based MEMS technology, the metal contact is one of the most crucial parts for determining the device performance and reliability. Owing to the inherent characteristics of the p-type GaN layer, realizing low specific contact resistance (ρSCR) and a thermally high-stable ohmic contact at the same time is difficult. Various attempts have been made to minimize the ρSCR, which depends on the surface treatments [12, 13], metal deposition methods [14], and annealing techniques [15]. High work function metals (Pd, Au, Pt and Ni) and intermixing compounds have also been examined for ohmic contact formation with monolayer [13, 16], bilayer [12, 17], and multilayer [18, 19] metallization schemes. Many pioneering researchers have explored the fabrication of ohmic contacts on Mg-doped p-type GaN with various metallic schemes [20,21,22,23,24]. For example, Han et al. [20] fabricated low-resistance and transparent silver (Ag)/aluminum-doped oxide (AZO) films on Mg-doped GaN by using the electron-beam (EB) metal evaporation method. They obtained a ρSCR of 9.76 × 10−4 Ω cm2 at 600 °C under an air ambient, and the transmittance was over 80% for visible light. Belahsene et al. [21] investigated the interfacial microstructure, elemental diffusion, and electrical properties of a Pd/Au ohmic contact on p-type GaN. They found a ρSCR of 1.04 × 10−2 Ω cm2 at 800 °C in N2 ambient for 1 min. Oh et al. [22] fabricated silver nanowires (AgNWs) ohmic contacts on p-type GaN and they observed an excellent optical transmittance of 96.5% at 450 nm and ρSCR of ~10−3 Ω cm2. Zhao et al. [23] reported that the stable resistivity (~2 × 10−3 Ω cm2) of Ni/Au ohmic contact to p-GaN at a high temperature (450 °C) over 48 h. Gutierrez et al. [24] investigated the structural, chemical, and electrical characteristics of In+ ion-implanted Au/Ni, Au/Nb, and Au/W ohmic contacts on p-type GaN. They extracted a ρSCR value of 2.5 × 10−4 Ω cm2 from current–voltage (I–V) curves using the transmission-line method (TLM).

Generally, most researchers have extensively investigated on commonly used Ni/Au [25, 26] and Pd/Au [21, 27] ohmic contacts on p-GaN. However, the Ni/Au and Pd/Au metallization schemes exhibited high resistivity led to poor ohmic characteristics [21, 28]. In fact, the chemical stability of the metal/semiconductor interface can be well understood by using thermodynamic data associated with bulk compounds. In terms of thermodynamics, the low chemical reactivity between a metal and semiconductor can be addressed by selecting metallic compounds such as NiAl, PtAl, and PdAl with a large heat of formation [29, 30]. However, there has been only limited work on using PdAl metallic compound contacts with semiconductors. So far, the PdAl metallic compound has not been explored as an ohmic contact on Mg-doped p-type GaN. In the present study, we examined using a PdAl/Au metal alloyed ohmic contact to Mg-doped p-type GaN in order to obtain low resistance and thermal stability. In this work, a PdAl metal alloyed scheme was selected as the first layer because this metallic compound had an enormous heat of formation (∆H = −92 kJ/g atom) and Au as a second capping layer to protect the metallization scheme during the subsequent processing. The main purpose of this study was to find a low-contact-resistance PdAl/Au ohmic contact on Mg-doped p-type GaN for high-temperature GaN-based MEMS technology. The electrical and structural characteristics of PdAl/Au ohmic contacts on p-type GaN were investigated at various annealing temperatures by X-ray photon electron spectroscopy (XPS) and X-ray diffraction measurements. The ohmic contact formation mechanisms of PdAl/Au thin films on p-GaN are also discussed and described at various annealing temperatures.

2 Experimental methods

An epitaxial structure was grown on a c-plane sapphire substrate with the metal organic chemical vapor deposition system (MOCVD) technique. The grown GaN structure consisted of a nucleation layer from low-temperature deposition, a 1.5-µm-thick un-doped GaN layer, and a 0.2-µm-thick Mg-doped p-GaN layer (3–4 × 1017 cm−3). In order to obtain good ohmic contacts, contaminants and the removal of oxides on the semiconductor surface are very important prior to metal deposition. First, the p-type GaN layer was degreased by using an ultrasonic agitator with acetone, isopropyl alcohol (IPA) and deionized (DI) water for 5 min in each step and then dried with nitrogen (N2) gas. This degreased wafer was then immersed into a buffered-oxide-etch (BOE) chemical solution for 10 min to eliminate the native oxides followed by DI water. The wafer was then dried with N2 gas. The circular-transmission-line method (CTLM) patterned pads on the surface-treated p-GaN layer with a typical photolithography technique. Prior to metal deposition, the CTLM-patterned samples were immersed in the BOE solution for 30 s and promptly loaded into a high-vacuum electron-beam evaporation system. The contact metal schemes (PdAl/Au) (20/30 nm) consisting of a PdAl (90 wt% of Pd and 10 wt% of Al) metallic compound as the first layer and Au as the second layer were evaporated on the cleaned p-type GaN. Some of the contacts were annealed at temperatures ranging from 400 to 700 °C for 1 min in a RTA system under N2 atmosphere. I–V relationship was measured with a semiconductor type parameter analyzer (Keithley 4200 source measuring unit) to evaluate the contact resistance. X-ray photon electron spectroscopy (XPS) (Thermo-Fisher Scientific Inc., K-Alpha,) using monochromatized Al Kα radiation (1486.6 eV) was used to examine (at ultra high vacuum) the intermixing of the metals and p-type GaN before and after RTA. X-ray diffraction (XRD) (PANalytical) using Cu Kα radiation was used to characterize the interfacial chemical products between the PdAl/Au and p-type GaN layers. Atomic force microscopy (AFM) (XE-100 SPM Controller, Park Systems) was employed to characterize the surface morphology of the ohmic contacts before and after RTA.

3 Results and discussion

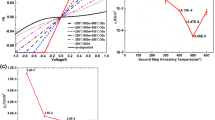

Figure 1 shows a schematic prototype of the investigated PdAl/Au metal alloyed ohmic contacts on p-type GaN. The inside circle radius was 100 μm, and the arrangement between the inside and outside circle radii was varied from 5 to 30 μm. Figure 2 shows the I–V curves of the PdAl/Au metal alloyed contacts on p-type GaN as a function of RTA. These were measured between the ohmic pads with a spacing of 5 µm. The inset in Fig. 2 shows an optical surface image of the PdAl/Au metal alloyed ohmic contacts on p-type GaN with the CTLM pattern. The as-deposited PdAl/Au/GaN ohmic contact showed nonlinear I–V behavior. However, as the temperature increased the I–V linearity improved after annealing at 600 °C and then prominently degraded upon annealing at 700 °C. As shown in Fig. 3, the measured ρSCR was 1.23 × 10−2 Ω cm2 for the as-deposited sample. For the samples RTA at 400, 500, 600, and 700 °C, the estimated ρSCR were 1.86 × 10−3, 1.03 × 10−3, 7.82 × 10−4, and 1.31 × 10−2 Ω cm2, respectively. Upon RTA at 600 °C, the ohmic contact exhibited as low as ρSCR, as noticeable from the I–V curves. According to these results, the variation in the ρSCR was found to be a function of RTA. The ρSCR gradually decreased as the RTA temperature increased up to 600 °C. However, further increasing the RTA temperature (above 600 °C) degraded the ρSCR. The reduced value of the ρSCR was obtained at 600 °C, which suggests that this is the optimal annealing temperature for the PdAl/Au metal alloyed contacts on p-type GaN. The ρSCR started to degrade when the sample was RTA at 700 °C (Fig. 3). This may be due to the possible effects of the degraded contact surface and the deterioration of the interface contacts, which was attributed to intermixing heavily between the PdAl/Au metal alloyed layers and GaN and/or the disorder of the GaN crystalline structure [31].

In order to elucidate the effective Schottky barrier heights (SBHs) of the PdAl/Au ohmic contacts at various RTA, the Norde method [32] was employed. The plot of F(V) versus V for the PdAl/Au ohmic contact at different RTA as shown in Fig. 4, from which the minimum value of F(V) and it corresponding voltage Vmin were determined. Using these values the effective SBH is determined at different RTA. Measurements showed that the effective SBH values were 0.37, 0.32, 0.31, 0.30, and 0.36 eV for as-deposited, 400, 500, 600 and 700 °C contacts, respectively. Calculations indicate that the effective SBH was reduced upon RTA at 600 °C and then slightly increased after RTA at 700 °C, (as noticed from I–V curves of the PdAl/Au ohmic contacts). The I–V method was also used to compare the effective SBHs of the PdAl/Au ohmic contacts [33, 34]. Figure 5 shows a plot of I/[1 − exp (−qV/kT)] versus V for the before and after RTA at 700 °C contacts. The extracted effective SBHs were 0.37 eV for as-deposited, 0.32 eV for 400 °C, 0.31 eV for 500 °C, 0.30 eV for 600 °C, and 0.35 eV for 700 °C contacts, respectively. These values were comparable with those obtained by the Norde method. The obtained values of ρSCR and SBHs of the PdAl/Au metal alloyed contacts as a function of RTA are shown in Table 1. The variation in the ρSCR and SBHs of the PdAl/Au metal alloyed contacts as a function of RTA will be discussed by XPS and XRD measurements.

XPS measurements were used in order to describe the interfacial chemical reactions between the PdAl/Au metal alloyed and p-type GaN layers. Figure 6 shows the XPS depth profiles of the PdAl/Au metal alloyed ohmic contacts before and after RTA at 600 °C. Figure 6a shows the depth profile of before RTA PdAl/Au metal alloyed ohmic contact. The individual layers of PdAl metallic compound and Au layers were well-defined. However, there was an interface region between the PdAl metallic compound and GaN films. This indicates a possible reaction between PdAl metallic compound and GaN during the deposition time in electron beam evaporation. It was noted that a little amount of metallic Ga out-diffused into the PdAl metal compound layer, resulting in the formation of the Ga–Pd interfacial phases at the interface, in addition, a little amount of Al out-diffused through the Au layer. For the contact RTA at 600 °C, as shown in Fig. 6b, it was observed the interface region was changed, where large amounts of Pd and Au metals were in-diffused to the GaN films compared to the before RTA sample. Moreover, a little amount of metallic Ga-layer was out-diffused into the surface. This indicates that a chemical reaction happened between the metals and metallic Ga content, which indicates the interfacial metallic gallide-phases were formed at the interface. There was no clear proof for nitrogen out-diffused into the PdAl/Au metal alloyed layers. This indicates that the interface chemical layers that formed on the GaN surface region may have prevented the out-diffusion of nitrogen, which determines the performance of a p-type ohmic contact.

XRD analysis was performed to investigate the interfacial phases formed between the PdAl/Au metals and GaN films before and after RTA at 600 °C. Figure 7a shows the XRD plot of the before RTA sample. The plot reveals the characteristic peaks of GaN (002) (004) and Au (111). In addition to the characteristic peaks, there were extra peaks which were identified as Al3Pd5 (021) and Ga3Pd5 (042). The diffraction peak Ga3Pd5 (042) indicates the feasible formation of metal alloyed Ga–Pd phases, as estimated from the XPS depth profiles. When the sample was RTA at 600 °C (Fig. 7b), extra peaks were identified compared to the before RTA. These peaks were identified as Au7Ga2 (205), Ga3Pd5 (541) which correspond to the metal alloyed Ga–Au and Ga–Pd phases as expected from XPS depth profile results (Fig. 6).

Further, to distinguish the chemical bonding interfacial states of metallic Ga, XPS analysis was carried out before and after RTA at 600 °C. Figure 8a shows a typical wide XPS survey spectrum, wherein all the core level and Auger features have assigned to electronic transitions in Ga, N and O. Fig. 8b, c show the Ga 2p and N 1s core-level energy spectra obtained from the PdAl/Au/p-type GaN interface before and after RTA at 600 °C. For the RTA sample (Fig. 8b), the metallic Ga 2p core-level shows clearly shifted toward the lower binding energy side as compared to the before RTA sample. The metallic Ga 2p core level was an interface that experienced a shift of about 0.37 eV compared to the before RTA sample, which indicates that the surface Fermi level shifted towards the valence band edge [35]. In other words, the impact of RTA on the ρSCR of the PdAl/Au metal alloyed contacts on p-type GaN may be described as a reduction in the effective SBH (i.e., reduction in band bending) from the surface Fermi level shift towards the valence band edge, as shown in Fig. 8b (shift of the metallic Ga 2p core level).The surface Fermi level shift may have been caused by increased Ga vacancies that acted like acceptors in p-GaN, which increased the carrier (acceptor) concentration near the p-GaN surface region of the RTA sample. One more reason, the metallic Ga 2p peak intensity shifts indicate a change of energy band bending due to N 1s (Fig. 8c) core level peak. The N 1s peak shows a similar shift behavior to that of the metallic Ga 2p maximum intensity peak [5]. Figure 9a, b shows the energy level band diagrams of PdAl/Au metal alloyed contacts on p-GaN before and after RTA. It is clearly represented (Fig. 9b), a reduction in the effective SBH for the RTA at 600 °C contact.

Atomic force microscopy (AFM) was used to examine the surface morphology of the PdAl/Au metal alloyed ohmic contact on p-type GaN. Figure 10 shows the AFM surface morphological images of the contacts before and after RTA at 600 °C. For the before RTA sample, the surface morphology was fairly smooth with a root-mean-square (RMS) roughness of 0.987 nm, as shown in Fig. 10a. For the sample RTA at 600 °C, the surface morphology of the PdAl/Au was slightly lower with a RMS roughness of 0.714 nm (Fig. 10b) compared with that of the before RTA. As a result, the surface roughness of the PdAl/Au metal alloyed contacts was fairly low, even though RTA at 600 °C, which means that no surface defects and structural deformation were caused.

The interfacial products and interface chemical reactions between metal/semiconductor interface is known to play a vital role in the electrical behavior of contact. Based on the electrical and structural data, the relationship between a low ρSCR of the PdAl/Au metal alloyed contact on p-type GaN and the RTA temperature may be described as follows. First, the enhancement can be associated to the shift of surface Fermi level, as noted from the low-energy shift of the Ga 2p core level (Fig. 8b), resulting in a decrease in the surface barrier height. The shift of the surface Fermi level may be due to an increase in carrier concentration near the GaN surface region. Second, the XPS and XRD data revealed the metal alloyed interfacial phases were formed at metallic/GaN interface such as Ga–Pd and Ga–Au. The formation of metal-alloyed gallide phases generates deep acceptor-like metallic Ga vacancies on the p-type GaN surface [35]. Hence, the enhance in acceptor carrier concentration near the surface of p-type GaN, led to the better electrical properties of the PdAl/Au metal alloyed contacts after RTA at 600 °C. Similar characteristic results were also observed in the other metal contacts [36,37,38].

4 Conclusion

In summary, we systematically investigated the PdAl/Au (20/30 nm) metal alloyed scheme for the fabrication of ohmic contacts on Mg-doped p-type GaN. The electrical characteristics showed that the ohmic contact performance was enhanced with RTA compared with that of the before RTA. Explicitly, the specific contact resistance (ρSCR) was obtained as low as 7.82 × 10−4 Ω cm2 with the RTA at 600 °C for 1 min in an N2 ambient. The effective SBHs calculated by the modified Norde and I–V methods and the values were in good agreement with each other. The XPS and XRD results revealed that the formation of the metal alloyed Ga–Pd and Ga–Au interfacial phases, which were responsible for reducing the ρSCR after RTA at 600 °C. The AFM results indicated that the surface roughness of the ohmic contact was fairly smooth even after RTA at 600 °C. These results indicate that PdAl/Au metal alloyed contacts can be useful ohmic contacts on p-type GaN for the fabrication of high-temperature GaN-based MEMS device applications.

References

M.R. Zadeh, V.J. Gokhale, A. Ansari, M. Faucher, D. Theron, Y. Cordier, L. Buchaillot, J. Microelectromech. Syst. 23, 1252–1271 (2014)

E. Sillero, D.L. Romero, A. Bengoechea, M.A.S. Garcia, F. Calle, Phys. Stat. Sol. C 5, 1974–1976 (2008)

R. Szweda, Gallium Nitride and Related Wide Band Gap Materials and Devices, 2nd edn. (Elsevier Science, New York, 2000)

M.S.P. Reddy, B.-J. Kim, J.-S. Jang, Opt. Express 22, 908–915 (2014)

M.S.P. Reddy, H. Park, S.-M. Kim, S.-H. Jang, J.-S. Jang, J. Mater. Chem. C 3, 8873–8880 (2015)

M.S.P. Reddy, P.T. Puneetha, Y.-W. Lee, S.-H. Jeong, C. Park, Polym. Test 59, 107–112 (2017)

V. Cimalla, J. Pezoldt, O. Ambacher, J. Phys. D 40, 6389–6434 (2007)

S. Davies, T.S. Huang, M.H. Gass, A.J. Papworth, T.B. Joyce, P.R. Chalker, Appl. Phys. Lett. 84, 2566–2568 (2004)

Z. Yang, R.N. Wang, S. Jia, D. Wang, B. Zhang, K.M. Lau, K.J. Chen, Appl. Phys. Lett. 88, 041913 (2006)

S.J. Pearton, F. Ren, A.P. Zhang, K.P. Lee, Mater. Sci. Eng. R30, 55–212 (2000)

H.-S. Kang, M.S.P. Reddy, D.-S. Kim, K.-W. Kim, J.-B. Ha, Y.-S. Lee, H.-C. Choi, J.-H. Lee, J. Phys. D 46, 155101 (2013)

J.-S. Jang, S.-J. Park, T.-Y. Seong, J. Appl. Phys. 88, 5490–5492 (2000)

J.-S. Jang, T.-Y. Seong, Appl. Phys. Lett. 76, 2743–2745 (2000)

G. Greco, F. Iucolano, F. Roccaforte, Appl. Surf. Sci. 383, 324–345 (2016)

V. Rajagopal Reddy, S.-H. Kim, J.-O. Song, T.-Y. Seong, Solid-State Electron 48, 1563–1568 (2004)

H.-W. Jang, C.-M. Jeon, J.-L. Lee, Phys. Stat. Sol. C 0, 227–230 (2002)

J.K. Ho, C.S. Jong, C.C. Chiu, C.N. Huang, K.K. Shih, L.C. Chen, F.R. Chen, J.J. Kai, J. Appl. Phys. Lett. 86, 4491–4497 (1999)

H.K. Cho, T. Hossain, J.W. Bae, I. Adesida, Solid-State Electron 49, 774–778 (2005)

L.F. Voss, L. Stafford, R. Khanna, B.P. Gila, C.R. Abernathy, S.J. Pearton, F. Ren, I.I. Kravchenko, Appl. Phys. Lett. 90, 212107 (2007)

T. Han, T. Wang, X.W. GaN, H. Wu, Y. Shi, J. C. Liu, Korean. Phys. Soc. 65, 62–65 (2014)

S. Belahsene, G. Patriarche, D. Troadec, S. Sundaram, A. Ougazzden, A. Martinez, A. Ramdane, J. Vac. Sci. Technol. B 33, 010603 (2015)

M. Oh, W.-Y. Jin, H.-J. Jeong, M.-S. Jeong, J.-W. Kang, H. Kim, Sci. Rep. 5, 13483 (2015)

S. Zhao, H. Mcfavilen, S. Wang, F.A. Ponce, C. Arena, S. Goodnick, S. Chowdhury, J. Electron. Mater. 45, 2087–2091 (2016)

C.A.H. Gutierrez, Y. Kudriavtsev, E. Mota, A.G. Hernandez, A.E. Echavarria, V.S. Resendiz, Y.L.C. Moreno, M.L. Lopez, Nucl. Instrum. Methods Phys. Res. B 388, 35–40 (2016)

D. Qiao, L.S. Yu, S.S. Lau, J.Y. Lin, H.X. Jiang, T.E. Haynes, J. Appl. Phys. 88, 4196–4200 (2000)

J.K. Kim, J.H. Je, J.L. Lee, Y.J. Park, B.T. Lee, J. Electrochem. Soc. 147, 4645–4651 (2000)

J.-K. Kim, J.-L. Lee, J.-W. Lee, H.-E. Shin, Y.-J. Park, T. Kim, Appl. Phys. Lett. 73, 2953–2955 (1998)

L.-C. Chen, F.R. Chen, J.J. Kai, L. Chang, J.K. Ho, C.-S. Jong, C.C. Chiu, C.-N. Huang, C.-Y. Chen, K.-K. Shih, J. Appl. Phys. 86, 3826–3832 (1999)

T.S. Huang, J.G. Pang, J. Appl. Phys. 78, 5739–5744 (1995)

R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleiser, K.K. Kelley, Selected values of the thermodynamic properties of binary alloys (ASM, Materials Park, OH, 1973)

V. Rajagopal Reddy, Mater. Chem. Phys. 93, 286–290 (2005)

H. Norde, J. Appl. Phys. 50, 5052–5053 (1979)

T. Mori, T. Kozawa, T. Ohwaki, Y. Taga, S. Nagai, S. Yamasaki, S. Asami, N. Shibata, M. Koike, Appl. Phys. Lett. 69, 3537–3539 (1996)

E.H. Rhoderick, R.H. Williams, Metal-Semiconductor Contacts. (Clarendon, Oxford, 1988)

J. Sun, K.A. Rickert, J.M. Redwing, A.B. Ellis, F.J. Himpsel, T.F. Kuech, Appl. Phys. Lett. 76, 415–417 (2000)

V. Rajagopal Reddy, N.R. Reddy, C.-J. Choi, Solid-State Electron 49, 1213–1216 (2005)

J.-S. Jang, S.-J. Park, T.-Y. Seong, Appl. Phys. Lett. 76, 2898–2900 (2000)

V. Rajagopal Reddy, S.-H. Kim, J.-O. Song, T.-Y. Seong, Semicond. Sci. Technol. 18, 541–544 (2003)

Acknowledgements

This study was supported partially by the Energy technology development program of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) which is funded by the Ministry of Trade, Industry and Energy, Republic of Korea (No. 20153010130320).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puneetha, P.T., Reddy, M.S.P., Lee, YW. et al. Electrical and interface properties of PdAl/Au metal alloyed ohmic contacts on p-type GaN for high-temperature MEMS devices. J Mater Sci: Mater Electron 28, 16903–16909 (2017). https://doi.org/10.1007/s10854-017-7609-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-7609-8