Abstract

Long afterglow material SrAl2O4: Eu2+, Dy3+ were synthesized by solution combustion method, and the effects of the concentration of H3BO3 on phases, micromorphology, photoluminescence properties, long afterglow properties and thermoluminescence glow curves of the phosphors were studied systematically. Phosphor with SrAl2O4 pure phase can be obtained when the concentration of H3BO3 is 2 mol%. The micromorphology of the phosphors changed a lot due to the varied amount of H3BO3, and nanoflower like phosphors was formed when the concentration of H3BO3 is 10 mol%. With the continue increasing of H3BO3, the nanoflower aggregate together to form irregular particles with a larger size and the petal gradually disappear while the luminescence intensity shows a linear increase. The decay curves and the Thermoluminescence glow curves were also measured, and the depth of traps were calculated. The results show that with the increasing concentration of H3BO3, the trap depth increasing gradually. However, the trap depth decrease gradually when the content of H3BO3 beyond 20 mol%, which caused by the diffusion of surplus B3+ in the interstitial sites.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Long afterglow luminescence materials can absorb light and stored the energy, and then show emission in dark place, so it have been widely studied. Alkaline earth aluminates have draw much attention due to the high luminescent brightness, long afterglow time, good chemical stability, and environmental friendliness [1–3].

One typical rare-earth doped alkaline earth aluminates is SrAl2O4: Eu2+, Dy3+ which emits a green light peaking at 512 nm due to the 5d–4f transition of Eu2+ ions [3–5]. The 5d–4f transition is associated with the change in electric dipole and the 5d excited state is affected by the crystal field effects, so the emission of Eu2+ is very strongly dependent on the host lattice and can occur from the ultraviolet to the red region of the electromagnetic spectrum [6]. Recently, many researchers focus on the introduction of new rare earth activators in the SrAl2O4 host and expect new luminescent properties [7–9], or expand the application of SrAl2O4: Eu2+, Dy3+ in other fields related with photoelectric [10]. H3BO3 was always added as flux [3–6] in the synthesis process of SrAl2O4: Eu2+, Dy3+, and it predicted that the addition of H3BO3 could decrease the temperature of solid-state reaction [11]. However, the influence of the additions of H3BO3 of SrAl2O4: Eu2+, Dy3+ is not clear completely, especially the mechanism of action.

In this paper, the effects of the concentration of H3BO3 on phases, micromorphology and luminescence properties of SrAl2O4: Eu2+, Dy3+ powders were studied systematically. All the samples show similar XRD patterns and photoluminescence properties, while the morphology and persistence properties are different. The trap depth and other parameters were calculated by thermoluminescence measurement which is important for discuss the relationship of energy trap and long afterglow characteristics.

2 Experimental procedure

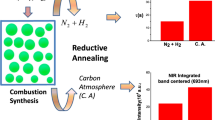

Sr(NO3)2 (99.9%), Al(NO3)3·9H2O (99.9%), Eu2O3 (99.99%) and Dy2O3 (99.99%) were used as the starting materials in a solution-combustion method. Sr(NO3)2, Al(NO3)3·9H2O and H3BO3 were dissolved in deionized water. Europium nitrate and dysprosium nitrate were obtained by dissolving Eu2O3 and Dy2O3 in dilute nitric acid. The above solutions were mixed according to the nominal composition of SrAl2O4: Eu0.01, Dy0.02. Urea [CO(NH2)2] was dissolved in deionized water and add to the solution. H3BO3 (99.9%) was used as flux, and it was also dissolved in deionized water, and add to the previous solution. The amount of H3BO3 is varied. For simplicity, the sample was named as S0, S2, S4, S6, S8, S10, S12, S14, S16, S18, S20, S22 and S24, according to the amount of H3BO3 is 0, 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22 and 24 mol%. The mixed solution was vigorously stirred for 1 h with slight heating, and then the precursor solution was poured into a crucible with a lid and introduced into a muffle furnace maintained at 600 °C. A spontaneous ignition occurred with a enormous swelling which lasted about 5 min, at last voluminous yellow-green phosphors was obtained.

The crystallization and phase identification of the sample was carried out by PANalytical X’pet pro MRD X-ray powder diffraction (XRD) with Cu Kα irradiation (λ = 1.5406 Å) at 40 kV tube voltage and 40 mA tube current. The morphologies of phosphors were observed by a Philips XL-30 scanning electron microscope (SEM). The photoluminescence (PL) spectra were measured by a Hitachi F-7000 fluorescence spectrophotometer. The decay curves were recorded by a GSZF-2A single-photon counter system (Tianjin Gangdong Sci.&Tech. Development Co. LTD). The thermoluminescence (TL) curves were measured using a FJ427A1 thermoluminescent dosimeter (Beijing Nuclear Instrument Factory). The heating rate was 1 K/s and the samples were excited by a UV light for 5 min.

3 Results and discussion

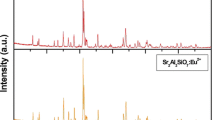

Figure 1 is the XRD patterns of the obtained samples. From Fig. 1, it can be found that the main phase of S0 sample is SrAl2O4, and Sr3Al2O6 which exist as a second phase also can be found in S0 sample. From the XRD pattern of S2 sample, it can be seen that the Sr3Al2O6 phase disappeared when a slightly H3BO3 was added. Furthermore, with the increasing of H3BO3, the sample phase remain as SrAl2O4. It can be concluded that the addition of H3BO3 is beneficial for obtain phosphors with SrAl2O4 pure phase.

Furthermore, the cell volumes of the phosphors were calculated, and the calculating results were show in Table 1. The relationship between cell volume and the concentration of H3BO3 was shown as Fig. 2. It is obvious that with the increasing of the content of H3BO3, the cell volume first linear decrease and then linear increases.

The relative strain ratios of the samples were calculated using analysis described by Williamson and Hall (W–H) method [12],

where ε is the strain developed in the sample, λ is the wavelength of the X-ray source, β is full width at half maximum height (FWHM). The strain are estimated from the slope of the line. The result was shown as Fig. 3. It can be seen that the strain first increasing during the increasing of H3BO3 content and achieve maximum when the concentration of H3BO3 is 18 mol%, and then it suddenly reduced to a lower value and begin another rising process when the content of H3BO3 is beyond 20 mol%. The decreasing trend of the cell volume and the first rising process of strain were results from the replacement of B3+ for Al3+, which would resulting in a decrease due to the ionic radius of B3+ (27 pm) is smaller than that of Al3+ (53.5 pm). When the substitution is adequate, surplus B3+ tend to diffused to the interstitial sites, which leads to an expansion of the lattice, so the cell volume show a increasing trend when the concentration of H3BO3 excess 18 mol%. When the substitution is adequate, surplus B3+ tend to diffused to the interstitial sites, which leads to an expansion of the lattice and increase the strain.

Flux always affects the micromorphology of the phosphors, so it is necessary to investigate the effect of H3BO3 to the microtopography of the obtained samples. Figure 4a–m show the SEM photos of the S0, S2, S4, S6, S8, S10, S12, S14, S16, S18, S20, S22 and S24 samples. Figure 4a reflects that the S0 sample show an irregular morphology with angularity and corners. Seen from Fig. 4b–e, the phosphors show a petal shape and the petal gather together as the content of H3BO3 is increasing. In particular, nanoflower was formed when the concentration of H3BO3 is 10 mol%. From Fig. 4g, h, it can be found that when the content of H3BO3 exceed 10 mol%, the nanoflower aggregate together to form irregular particles with a larger size and the petal gradually disappear. Figure 4i–m indicates that the particle grown larger with the continue increasing of H3BO3, while the surface become smooth. The reason for this phenomenon is that H3BO3 provides a low melting medium for the solid/liquid reaction to proceed.

In order to determine the effects of the content of H3BO3 to the photoluminescence properties of SrAl2O4: Eu, Dy, the emission spectra of the samples were recorded under a 360 nm excitation and shown as Fig. 5. All the samples show similar broad blue–green emission band peaking at 512 nm due to the 5d–4 f transition of Eu2+ions [4, 5], and no emission peaks can be found from Eu3+ ions [12–14]. It can be seen that the luminescence intensity of the S2 sample is almost the same as S0 sample. As the content of H3BO3 continues to increase, the luminescence intensity shows a linear increase. The reason for the enhancement is also due to the replacement of B3+ to Al3+. When part of Al3+ was substitute by B3+, the crystal is distorted due to the different ionic radius. The distortion may result in the easier 4f–5d transition of Eu2+, so the luminescence intensity becomes stronger. Meanwhile, H3BO3 is flux in the solid state reaction, so the increase of H3BO3 would be beneficial for the Eu2+ enter to the crystal lattice, and form the luminescent centers. Last but not least, the SEM photos also reflect that the particle size of phosphors become larger with the increasing of the H3BO3 content. The three behaviors enhance the emission intensity of the samples. However, when the H3BO3 content reached 20 mol%, the luminescence intensity decease a lot. Figure 6 clearly show the trend of the change. From Fig. 2, we know the B3+ trend to diffused the interstitial sites, when the H3BO3 content excess 18 mol%, and the cell volume increased due to the expansion of the lattice. The diffusion of the B3+in the grain boundary would cause more defects, which is negative for the luminescence.

The decay curves of the phosphors are recorded after 5 min irradiation of a UV light (λ = 360 nm). In order to study the effect of the varying content of H3BO3 to phosphors, the decay curves of S8, S12, S16, S20 and S24 were shown in Fig. 7, the insert is the decay curves between 0 and 30 s. All the decay curves contain a rapid-decaying process and a slow-decaying one, and the distinction of initial intensity is obvious. The afterglow characteristics were evaluated utilizing curve fitting as referred to Refs [15–17]. The decay curves were fitted using double exponential equation:

where I represents the phosphorescent intensity; I 1 and I 2 are two constants; t represents the time; τ 1 and τ 2 are decay constants which decide the decay rate for the rapid and the slow exponentially decay components. The fitting results of the parameters of τ 1 and τ 2 are listed in Table 2. It is obviously that the decay constants and the initial intensity of S20 is the maximum, indicating that S20 sample show the best decay characteristics.

Generally, the decay characteristic of SrAl2O4: Eu, Dy phosphor is determined by the energy trap created by Dy3+ [18]. The trap depth and trap concentrations are two important factors, which show greatly effect on the long afterglow properties. If the trap energy level is deeper and the trap density is larger, the long afterglow time will be longer. However, if the trap energy level is too deep, the long afterglow phenomenon will disappear for the energy is too high to obtain by thermal agitation. So, appropriate trap depth is crucial for a better afterglow characteristic. Thermoluminescence(TL) glow curve was always used to analysis the trap information [17, 19, 20]. In order to make a further research about the decay characteristics and trap level of our specimens, the thermoluminescence curves of S0, S8, S12, S16, S20 and S24 were detected and the curves are shown in Fig. 8.

Thermoluminescence glow curves were measured using a FJ-427Al thermoluminescent dosimeter by heating the irradiated samples from room temperatures to 200 °C. All the samples were irradiated by UV light, and the heating rate was controlled at 1 °C/s. From Fig. 8, we can see that the curve of S0 show no peak while S8, S12, S16, S20 and S24 samples show obviously peaks at 336 K, 352 K, 348 K, 354 K, and 357 K, respectively.

Generally, peak-shape method and the usual general order kinetics are used to describe TL curves. We can calculate the depth of traps and trap intensities according to the following equations [17, 20]:

where I(T) is the TL intensity, n 0 is the concentration of trapped charges at T = 0, k B the Boltzmann’s constant, β the heating rate(1 °C/s in this paper), E t the activation energy (or depth of the trap), s the frequency factor and l the order of kinetics. Parameters E t and n0 are the most important parameters that describe the physical properties of the traps generated by the auxiliary activators. The frequency factor is obtained by taking the derivative of Eq. (3) with respect to T and setting it to zero at the peak temperature. The activation energy E t (trap depth) and n 0 are calculated from the glow-peak parameters by the following equation [21]:

where ω is known as the shape parameter and defined as ω = δ + τ, with δ being the high-temperature half width and τ the low-temperature half width. The asymmetry parameter µg = δ/ω. Calculated trap densities and the trap depth are shown in Table 3. From Table 3, the trap depth in S8, S12, S16, S20 and S24 is 0.702 eV, 0.713 eV, 0.752 eV, 0.810 eV and 0.731 eV, respectively. It can be noted that with the increasing concentration of H3BO3, the trap depth increasing gradually. However, the trap depth decrease gradually when the content of H3BO3 beyond 20 mol%. The trap depth in S20 is the deepest one in our specimens, while the decay parameters of S20 are larger than the others in Table 2. Figure 9 show the variation trends between the energy trap depth and n 0 with the concentration of H3BO3. It can be clearly seen that when the content of H3BO3 exceed 20 mol%, both the trap depth and n 0 decreased. In strontium aluminates, the doped Dy3+ (0.0912 nm) usually replaces Sr2+ (0.118 nm) due to the similar ion radius and the lattice contraction was produced. However, when the B3+ concentration exceed 20 mol%, surplus B3+ will diffuse the interstitial sites, and induce lattice expansion, so it would have negative effects on generation of energy trap caused by Dy3+. The n 0 values of our samples are exhibited in Table 3, which show a same trend as the trap depth. However, n 0 is another factor which affects the afterglow characteristics, especially the initially luminescence intensity. The variation trend of n 0 values are also in good agreement with the trend of initially luminescence intensity which can be found in decay curves. It indicates that with increasing content of H3BO3, the initial afterglow intensity first increases and then decreases. In this work, the phosphor synthesized with 20 mol% H3BO3 shows the highest initial luminescence intensity.

4 Conclusions

SrAl2O4: Eu, Dy with different H3BO3 content were synthesized by a simple solution combustion. The slightly addition of H3BO3 is beneficial for obtain with SrAl2O4 pure phase phosphors. The morphology of prepared samples were different, and the nanoflower like phosphors were obtained when the amount of H3BO3 is 10 mol%. Excessive addition of H3BO3 leads to the growth of the particle size. The sample with 20 mol% H3BO3 show the best decay characteristics, because of the energy and concentration of trapped charges are the maximum. However, the decay characteristics and trap depth decreased when too much H3BO3 was added, the reason is that surplus B3+ in the interstitial sites have negative effects on generation of energy trap caused by Dy3+.

References

Y.N. Zhu, M.Q. Ge, Mater. Lett. 82 173–176 (2016)

J. Massera, M. Gaussiran, P. Gluchowski, M. Lastusaari, L. Hupa, L. Petit, J. Eur. Ceram. Soc. 35, 3863–3871 (2015)

H.L. Du, W.F. Shan, L.Y. Wang, D. Xu, H. Yin, Y.W. Chen, D.C. Guo, J. Lumin. 176, 272–277 (2016)

W. Xie, J. Quan, H.Y. Wu, L.X. Shao, C.W. Zou, J. Zhang, X.Y. Shi, Y.H. Wang, J. Alloy. Comp. 514, 97–102 (2012)

M. Nazarov, M.G. Brik, D. Spassky, B. Tsukerblat, J. Lumin. 182, 79–86 (2017)

B. Liu, M. Gu, X.L. Liu, S. Huang, C. Ni, J. Alloy. Comp. 509, 4300–4303 (2011)

L.K.S. deHerval, Y. TuncerArslanlar, M. Ayvacikli, F. Iikawa, J.A. Nobrega, P.S. Pizani, Y. GalvãoGobato, N. Can, M. Henini, M.P.F. deGodoy, J. Lumin. 163, 17–20 (2015)

H. Wang, X.P. Liang, K. Liu, Q.Q. Zhou, P. Chen, J. Wang, J.X. Li, Opt. Mater. 53, 94–100 (2016)

A.H. Wako, F.B. Dejene, H.C. Swart, Phys. B 480, 116–124 (2016)

Y.P. Tai, G.J. Zheng, H. Wang, J.T. Bai, J. Solid State Chem. 226, 250–254 (2015)

Y.J. Park, Y.J. Kim, Mater. Sci. Eng. B 146, 84–88 (2008)

S. Thakur, A.K. Gathania, Indian J. Phys. 89, 973–979 (2015)

S. Thakur, A.K. Gathania, J. Fluoresc. 25, 657–661 (2015)

S. Thakur, A. K. Gathania, J. Electron. Mater. 44, 3443–3449 (2015)

Z.X. Yuan, C.K. Chang, D.L. Mao, W.J. Ying, J. Alloy. Comp. 377, 268–271 (2004)

R. Chen, Y.H. Wang, Y.H. Hu, Z.F. Hu, C. Liu, J. Lumin. 128, 1180–1184 (2008)

W. Xie, Y.H. Wang, C.W. Zou, J. Quan, L.X. Shao, J. Alloy. Comp. 619, 244–247 (2015)

P. Dorenbos, J. Electrochem. Soc. 152, H107–H110 (2005)

S. Kumar, A.K. Gathania, A. Vij, R. Kumar, Ceram. Int. 42, 14511–14517 (2016)

T. Katsumata, S. Toyomane, A. Tonegawa, Y. Kanai, U. Kaneyama, J. Cryst. Growth 237–239, 361–366 (2002)

M.S. Jahan, D.W. Cooke, W.L. Hults, J.L. Smith, B.L. Bennett, M.A. Maez, J. Lumin. 47, 85–91 (1990)

Acknowledgements

The authors gratefully acknowledge financial support from Guangdong province science and technology plan project public welfare fund and ability construction project (2016A010103041), Program of Young Creative Talents in Universities of Guangdong (Natural Science, 2014KQNCX188), Doctoral Program of Lingnan Normal University (ZL1503), China Spark Program (2015GA780058), Natural Science Foundation of Guangdong Province (Nos. 2014A030307008, 2014A030307040, 2016A030313670) and Project for training high-level talents of “Yangfan Plan” in Guangdong Provence.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xie, W., Zou, C. & Xie, M. Effect of H3BO3 on phases, micromorphology and persistent luminescence properties of SrAl2O4: Eu2+, Dy3+ phosphors. J Mater Sci: Mater Electron 28, 6328–6334 (2017). https://doi.org/10.1007/s10854-016-6316-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6316-1