Abstract

We have examined the effect of re-pelletization on structural, mechanical and superconducting properties of high temperature superconducting (HTS) bulk samples using Bi1.85Pb0.35Sr2Ca2Cu3Oy stoichiometry. Conventional solid state reaction method is used for preparation of three different bulk samples. XRD measurement of the samples shows that a high percentage of high-T c phase is determined. Superconducting critical transition temperature of the samples have been obtained from the curves of ρ-T and χ-T. Vickers micro-hardness are also calculated for all samples. Re-pelletization has a positive effect on structural, mechanical and superconducting properties of bulk samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Many effort have been spent to develop the properties of the materials, since the discovery of the HTS ceramics [1–10]. Many parameters such as preparation method, pressure, diffusion, substitution, addition, chemical doping, etc. play a very important role on critical superconducting parameters of the high-T c superconductors. Fradina et al., Tepe et al. and Kocabas et al. [11–13] studied the effect of pressure on superconducting and structural properties of BSCCO bulk samples. They obtained that the quality of structural and electrical properties of BSCCO samples strongly depends on the pressure, which has an optimum value of around 400 MPa. In addition, the results of the work by Mune et al. [14] have shown that the porosity and the volume of the extra phases in the samples decrease with increasing compaction pressure. Intra-granular properties of these samples are very similar but their intergranular properties are found to be quite different. In conclusion, it is found that J c (B) dependence are very sensitive with pressure.

The brittleness of HTS bulk samples usually restricts the technological applications. Dislocations, ordering defects, pores, twins, micro cracks etc. affect the strength and plasticity of HTS samples. Therefore, for technological applications and better efficiency, it is necessary to develop the mechanical properties of BSCCO. In this respect, to get information about deformation and strength of the materials, hardness tests which is related to composition and structure of the materials, are necessary and useful. So that, hardness tests play a very important role for mechanical characterization of a material. To estimate the hardness values of HTS samples, several methods such as Vickers, Knopp, Rockwell and Brinnel can be used. The most commonly used method is Vickers microhardness test for estimation of the mechanical properties. Different HTS superconductors have been investigated for mechanical properties for several years [15, 16].

In our previous work microstructural, mechanical, electric and magnetic properties of bulk BSCCO superconductor depending on annealing time and preparation method have been studied. It is observed that properties of BSCCO superconductors strongly depend on annealing time and preparation method [17, 18]. Higher annealing time yields while reducing volume fraction associated with the extra phases, increases the high-T c phase. To obtain high-T c phase, solid state reaction method (SS) has better performance than ammonium nitrate precipitation method (AN). However, samples prepared by AN is harder than the SS sample. According to these works, the annealing parameter and preparation method are determined 120 h (h) at 845 °C [17, 18], respectively. In this study, effect of pelletization have been investigated on structural, mechanical and superconducting properties of BSCCO bulk samples which annealed 120 h at 845 °C.

2 Experimental procedure

Conventional solid state reaction method have been used for preparation of superconducting bulk samples using some oxides and carbonates. Five different starting powders, Bi2O3, PbO, SrCO3, CaCO3 and CuO, are mixed to obtain chemical composition of Bi1.85Pb0.35Sr2Ca2Cu3Oy. The purities of powders is chosen more than 99.9 % for better quality of composition. Precursor powders are well mixed and milled mechanically using ball-milling machine for 3 h at 75 rpm. These final mixture in powder form is heat treated twice at 775 °C for 12 h and at 810 °C for 24 h in crucible made from 0.5 mm thick silver plate. The powders are ground after each calcination with same procedure by using ball milling. After final calcination, the heat-treated powder is milled again in a mortar with pestle for homogenization and is pressed into pellets of 13 mm in diameter under pressure of 400 MPa. All prepared samples are annealed totally 120 h at 845 °C. Annealing procedure is given in [16] detailed. According to intermediate pelletization, three different samples called as S40-40-40, S60-60 and S120 are kept for 40 h + 40 h + 40 h, 60 h + 60 h and 120 h at this temperature, respectively. S40-40-40 and S60-60 samples are annealed three and two times for 40 and 60 h, respectively. The means of 40 h + 40 h + 40 h is that three annealing procedure is applied for 40 h. After each annealing time, 40 h, the samples are milled with mortar, re-pressed and sintered in same conditions. Similar procedure is also applied to S60-60 sample.

Our samples have been investigated by means of XRD, ρ-T, AC susceptibility, and microhardness measurements to provide information about the microstructural, mechanical and superconducting properties of the BSCCO samples. XRD data are taken using a Rigaku D/Max-IIIC diffractometer with CuKα radiation in the range 2θ = 3°–60° with a scan speed of 3°/min and a step increment of 0.02. The ac susceptibility measurements are carried out by a commercial Lake Shore 7130-model ac susceptometer employing a mutual inductance coil system with a closed cycle refrigerator. A closed cycle cryostat, Cryodine CTI-Cryogenics, is used in the temperature range of 60–140 K for dc resistivity measurements. The electrical resistance measurement are determined on the sample with the four-probe method. The electrical contacts are made with silver paint on rectangular bars, which resistance being of the order of 0.1 Ω or lower. Digital microhardness tester, SHIMADZU HVM-2, is used for Vickers microhardness measurements. The hardness measurements are taken at room temperature in air atmosphere with an average of 10 readings. The different loads from 0.245 to 2.940 N is applied with a rigid Vickers pyramidal indenter for 10 s. To obtain moderate values for each applied load, each measurement are performed at different locations of sample surfaces. The trace of the indentation are obtained with an accuracy of ±0.1 μm.

3 Results and discussion

One of the aim in this study is to determine the effect of intermediate pelletization, phases and impurities which may occur next to the main phase, on structural properties of the BSCCO superconductor. In this respect, XRD pattern is measured after every annealing time (40 h), then the intermediate sample is milled with mortar, re-pressed and sintered in same conditions for S40 series of samples. S40, S40-40 and S40-40-40 sample are annealed 40, 80 and 120 h at 845 °C, respectively. Similar procedure is also applied to S60 series. S60 and S60-60 sample are annealed 60 and 120 h at 845 °C, respectively. XRD patterns of S40, S60 and S120 series of samples are given in Fig. 1a–c, respectively. The annealing time are shown inside of the figure at the different curves. High-T c (Bi-2223) and low-T c (Bi-2212) peaks are detected in all samples. The formation of high-T c phases, the sharpening of reflections and the disappearance of non-superconducting phases tends to increase for all samples with increasing of annealing time. Traces of non-superconducting phases, Ca2PbO4 at 2θ = 19.3° and CuO phase at 2θ = 38.8°, are also detected in all samples. It indicates that it is not easy to obtain a single-phase material with a conventional solid state reaction method. The intensities of the most visible peaks H(0010) and H(0012) are sharpening and rising, and the peaks of low-T c phase, especially L(115) and (117) which is the characteristic peaks of low-T c phase, almost disappeared with increasing of annealing time. It can also be seen from XRD patterns that S40-40-40 has more smooth curves than S60-60 and S120. It can most probably be due to the effect of re-pelletization.

The relative volume fractions of the low-T c and high-T c phases are calculated with peak intensities of the reflections which belongs to same crystallographic plane by using Eqs. 1 and 2 [19, 20]:

Here I L (hkl) and I H (hkl) are the intensities of the (hkl) diffraction lines for low-T c and high-T c phases. Additionally, the lattice parameter for low-T c and high-T c phases are determined by using Whatfor program. The results obtained from Whatfor program are listed in Table 1. When performing the calculation, non-superconducting phases which percentage are smaller than 1 % are not taken into account, about 18 peaks are used for the lattice parameters.

S40-40-40 samples have the highest volume fraction of high-T c phase compared the samples which annealed totally 120 h. It is understood that intermediate pressing played a positive role for formation of high-T c phase. The lattice parameters value, a = b, remains almost constant, while c parameters increase with re-pressing for high-T c phase.

Figure 2 illustrates the normalized ac susceptibility curves of totally 120 h annealed samples as a function of temperature at H ac = 80A/m, frequency f = 125 Hz. The diamagnetic transition in fundamental susceptibility shows a typical single-step transition for S40-40-40 and S60-60 samples. However, two-step change to superconducting transition is observed to in-phase component of the fundamental susceptibility of S120 sample. Two step transition indicates weak links in the sample while the onset transition temperature is intra-grain property. The first decrease, near T c , indicates to 2223 phase; another fall at low temperatures shows to 2212 phase. Onset transition temperature, T c , values and transition width, ΔT, of the samples are determined from Fig. 2 by using an onset and 10–90 % criterion, respectively. We observe that all final samples have almost the same onset for critical temperatures of around 110 K. ΔT values found from this figure are 12, 9 and 8 K for S120, S60-60 and S40-40-40, respectively. From this data, we can say that the ac susceptibility curves becomes sharper with re-pelletization. From the data plotted, one would anticipate that re-pelletization affects the inter-grain connectivity. χı–T curves are saturated below 90 K for all samples, it suggests that the whole volume is superconducting below this temperature.

The electrical resistance behavior of samples as a function of temperature are given in Fig. 3 in the range of 70–140 K. As shown in the Fig. 3, ρ-T behaviors of both samples are similar. Both samples exhibited a metallic-like character in the normal state. For the sample, which re-pelletized two times, the resistance are lower than S120 above the superconducting transition. Only one single step of transition of the superconducting state is observed in the samples. The resistance of temperature goes down to zero depending on the effect of the pelletization at 104 and 109 K for S120 and S40-40-40, respectively. S40-40-40 have higher critical transition temperature than S120. ΔT values found from this Fig. 3 are 10 and 5 K for S120 and S40-40-40, respectively. From this data, it is seen that inter-grain connectivity is better for re-pelletized sample.

In this study, Vickers micro-hardness measurements are used for mechanical characterization of prepared samples. In Vickers micro-hardness measurement, a small diamond terminal which has a pyramidal geometry is applied to the surface of sample. The trace of the indentation that be occurred after measurement on the surface is measured with microscope and then hardness value is calculated. In order to calculate Vickers hardness values with trace of the indentation formed on the sample are used with following expressions:

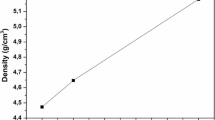

Here F and d are the applied load and length of the traces. Materials show two types of behavior as RISE and ISE. RISE behavior is described as hardness of the material increases with rising applied load. However, ISE behavior is described opposite of the RISE as hardness of the sample decreases with increasing load. The graph of hardness versus applied load and calculated microhardness values are given in Fig. 4 and Table 2, respectively. As can be seen from the graph and the table, length of the traces and hardness values rise with increasing the applied load from 0.245 to 2.940 N. It means that RISE behavior is observed to prepared samples. As well as hardness of material, applied load has been affected from the re-pelletization. Hardness of the samples have been increased with re-pelletization. It can be interpreted that more dense and less porous structure is formed with the effect of pelletization.

Three times pelletized sample, S-40-40-40, have the highest hardness values among the samples. There is no significant change in the hardness values above to 2 N. In addition, hardness values is attained to plateau region around 1.5 N.

In conclusion, pelletization between the heat treatment plays a very important role on structural, magnetic, electrical and mechanical properties of bulk superconducting BSCCO samples. We observe that formation of the high-T c phase, critical superconducting transition temperature and hardness of the samples have been increased with re-pelletization. In this respect, S40-40-40 is given the most positive results among the samples. The connection between grains have strengthened and the holes, it may occur in the boundary zone, have reduced with re-pelletization. In general, porosity is decreased and denser structure is obtained. The results of the hardness values also support this idea.

References

N. Ghanzanfari, A. Kılıç, A. Gencer, H. Özkan, Solid State Commun. 144, 210 (2007)

S.M. Khalil, J. Phys. Chem. Solids 64, 855 (2003)

C. Terzioglu, O. Ozturk, A. Kilic, A. Gencer, I. Belenli, Phys. C 434, 153 (2006)

A. Biju, R.P. Aloysius, U. Syamaprasad, Supercond. Sci. Technol. 18, 1454 (2005)

H. Maeda, Y. Tanaka, M. Fukutomi, T. Asano, Jpn. Appl. Phys. Lett. 27, L209 (1988)

M. Yilmazlar, O. Ozturk, O. Gorur, I. Belenli, C. Terzioglu, Supercond. Sci. Technol. 20, 365 (2007)

I. Hamadneh, A. Agil, A.K. Yahya, S.A. Halim, Phys. C 463, 207 (2007)

N. Udomkan, P. Vinotai, R. Suryanarayanan, N. Charoenthai, Supercond. Sci. Technol. 18, 1294 (2005)

H.B. Huang, G.F. de la Fuente, A. Sotelo, M.T. Ruiz, A. Larrea, L.A. Angurel, R. Navarro, Solid State Ion. 63, 889 (1993)

V.G. Prabitha, A. Biju, R.G. AbhilashKumar, P.M. Sarun, R.P. Aloysius, U. Syamaprasad, Phys. C 433, 28 (2005)

I.A. Fradina, A.F. Alekseev, T.J. Gridasova, V.V. Morozov, D.O. Jurchenko, Phys. C 311, 81 (1999)

M. Tepe, I. Avcı, D. Abukay, Status Sol. (a) 198(2), 420 (2003)

K. Kocabaş, M. Gökçe, M. Çiftçioğlu, Ö. Bilgili, J. Supercond. Nov. Magn. 23, 397 (2010)

P. Mune, E. Govea-Alcaide, R.F. Jardim, Phys. C 384, 491 (2003)

O. Ozturk, E. Asikuzun, S. Kaya, M. Erdem, S. Safran, A. Kilic, C. Terzioglu, J. Supercond. Nov. Magn. 28, 1943 (2015)

E. Asikuzun, A. Donmez, L. Arda, O. Cakiroglu, O. Ozturk, D. Akcan, M. Tosun, S. Ataoglu, C. Terzioglu, Ceram. Inter. 41, 6326 (2015)

S. Safran, E. Kılıçarslan, H. Ozturk, M. Alp, M. Akdogan, E. Asikuzun, O. Ozturk, A. Kılıç, Phys. B 472, 34 (2015)

S. Safran, A. Kılıç, E. Kılıçarslan, H. Ozturk, M. Alp, E. Asıkuzun, O. Ozturk, J. Mater. Sci.: Mater. Electron. 26, 2622 (2015)

S.A. Halim, S.A. Khawaldeh, S.B. Mohammed, H. Azhan, Mater. Chem. Phys. 61, 251 (1999)

C.W. Chiu, R.L. Meng, L. Gao, Z.J. Huang, F. Chen, Y.Y. Xue, Nature 365, 323 (1993)

Acknowledgments

This work is supported by Turkish Research and Scientific Council (TUBITAK) and The Republic of Turkey, Ministry of Development [Grant Numbers 113F150 and 2010K120520].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Safran, S., Kılıç, A. & Ozturk, O. Effect of re-pelletization on structural, mechanical and superconducting properties of BSCCO superconductors. J Mater Sci: Mater Electron 28, 1799–1803 (2017). https://doi.org/10.1007/s10854-016-5728-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5728-2