Abstract

BSCCO bulk samples have been prepared by solid-state reaction and ammonium nitrate precipitation methods with Bi1.65Pb0.35Sr2Ca2Cu3O10±y stoichiometry. Structural, mechanical and magnetic characterizations of the samples were performed by the X-ray powder diffraction (XRD), the scanning electron microscopy (SEM), Microhardness measurements, AC susceptibility measurements. The XRD patterns showed that the diffraction peaks for our samples belong to the two main phase, namely 2223 and 2212 of the BSCCO. In this study we have focused on microhardness measurements to investigate the mechanical properties. Vickers microhardness, Young’s modulus and yield strength values were calculated separately for all samples. In addition to these, we calculated the load independent hardness values of samples. Experimental results of hardness measurements were analyzed using the Meyer’s law, proportional sample resistance (PSR) model, Elastic–Plastic deformation model (EPD) and indentation induced cracking (IIC) model. The critical transition temperature, phase purity, lattice parameter, surface morphology and crystallinity of the prepared bulk samples were compared with each other.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Since the discovery of the Bi-based high-temperature ceramic superconductors; many researches have been carried out to characterize properties of the materials [1–11]. Preparation method, chemical doping, substitution, addition and diffusion play a very important role on critical superconducting parameters of the high-Tc superconductors. Enhancing the mechanical properties are significant goal of the studies in the field of Bi-based superconductors for their use in engineering applications. Especially practical applications are restricted because of brittleness of materials. The mechanical behavior of the BSCCO can be severely affected by defects, dislocation, twins, micro cracks and pores. To the best of our knowledge, previous studies mostly reported on the effects of mechanical properties of some materials substitution in BSCCO [12, 13].

The behavior of materials under mechanical loads is called as “mechanical properties”. The mechanical properties are mainly resulted from the bond strength between atoms. However, there is the effect of the inner structure of material (microstructure). So that it becomes possible to obtain different mechanical properties in the same material by changing the internal structure. In addition, hardness is the resistance against a solid object which is immersed in the surface of a material. Hardness values are a great important because these are directly related to strength of materials. It can be measured non-destructively. Hardness test is a test method which is relative values about the strength of the material. According to the geometry of indenter and size of the applied load, hardness testing methods are called as Brinell, Vickers and Rockwell hardness testing method.

We aimed to study the effects of different preparation methods on mechanical, structural and magnetic properties of BSCCO system with general formula Bi1.65Pb0.35Sr2Ca2Cu3O10±y. In this study, the samples were prepared by a conventional solid state method (SS) and ammonium nitrate precipitation method (AN).

2 Experimental

Superconducting samples with chemical composition Bi1.65Pb0.35Sr2Ca2Cu3Oy were prepared by solid state reaction method and ammonium nitrate precipitation methods from the powders of Bi2O3, PbO, SrCO3, CaCO3 and CuO with purities of more than 99.9 %. The powders were mixed in the appropriate amounts and ball-milled 3 h at 75 rpm. The milling procedure was maintained in a tungsten carbide jar together with tungsten carbide balls. The mixture was calcinated at 775 °C for 12 h. After the first calcination, the powders were grinded by using ball milling with same procedure. Then the mixture was calcinated at 810 °C for 24 h. Powders were pressed into pellets with 1 × 3 × 12 mm dimensions under the pressure of 5 tonnes. Pellets were annealed at 845 °C in air for 96 h. The furnace was heated to the annealing temperature with 1 °C/min heating rate. Then 1 °C/min rates were applied after the heat treatment. However, to obtain chemically homogenous mixture, appropriate amount of ammonium nitrate was added to the milled powders and heated at 250 °C for the ammonium nitrate precipitation methods. The other procedure is same for two methods. According to preparation methods, the pellets were called B and D for SS and AN, respectively.

Our samples have been investigated by means of XRD, Microhardness, SEM and AC susceptibility measurements. XRD data were taken using a Rigaku D/Max-IIIC diffractometer with CuKα radiation in the range 2θ = 3–60 with a scan speed of 3 °/min and a step increment of 0.02. Vickers microhardness measurements are conducted at room temperature in air by using a digital microhardness tester (SHIMADZU HVM-2) to obtain information about the mechanical properties of the BSCCO samples prepared at different conditions. A rigid Vickers pyramidal indenter is applied for 10 s using different load in the range from 0.245 to 2.940 N and the diagonals of indentation are measured with an accuracy of ±0.1 µm. The Vickers microhardness measurements are performed with an average of 10 readings at different locations of sample surfaces to obtain reasonable mean values for each applied load. The microhardness measurements are analyzed by means of various models. Microstructure examinations were performed using a Jeol JSM-5300 SEM. Samples were prepared in the normal manner for SEM measurements, ground on 2,400 grit, and polished on 0.5 and 0.1 µm alumina lap wheels. The samples were coated with a thin layer of gold to avoid the charging effect for SEM examinations. Polished surfaces of the samples were investigated using a SEM. The susceptibility measurements were carried out by a commercial Lake Shore 7130-model ac susceptometer employing a mutual inductance coil system with a closed cycle refrigerator.

3 Results and discussion

XRD patterns, which demonstrate phase formations of the B and D of BSCCO samples annealed at 845 °C in air for 96 h are shown in Fig. 1. The detected major phases are Bi-2223 and Bi-2212, with the fraction of the latter being higher. Traces of non-superconducting Ca2PbO4 and one unknown phase is also detected in all samples. The relative volume fractions of the Bi-2223 and Bi-2212 phases in all the samples were estimated from the peak heights of the reflections belonging the same particular crystallographic plane, using the following well-known expressions [14, 15]:

Here IH(hkl) and IL(hkl) are the intensities of the (hkl) diffraction lines for Bi-2223 and Bi-2212 phases (Fig. 1). There is no effective differences in the volume fractions of the samples prepared by two methods. The lattice parameters of the samples were performed employing the least-squares method and using the data extracted from XRD measurements. The results are listed in Table 1. It is observed that D sample prepared by AN has higher peak intensity than B sample prepared by SS.

In this study, the Vickers hardness test is used. During the test, five different loads (0.245, 0.490, 0.980, 1.960, 2.940 N) are applied on the sample surface by the indenter with 10 s. Vickers hardness values are calculated using diagonal length of trace formed on the surface of the sample after removing the indenter by using Eq. 3.

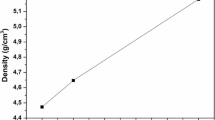

Materials exhibit two types behavior as ISE and RISE. While ISE is defined as hardness decreases with increasing applied load, RISE is defined as hardness increases with increasing applied load. The variation graph of hardness against the applied load is given in Fig. 2. As can be seen from the graph, hardness values increased with increasing the applied load to 0.245 N from 2.940 N. This means that the material shows RISE behavior. As well as applied load, hardness of material has been affected by the preparation method. Hardness of D sample is higher than B sample. Moreover, there is reached to plateau region around 1.5 N. A significant change in the hardness values was not observed over 2 N. The load dependent elastic modulus (E) and the yield strength (Y) values of material are calculated (Table 2). E and Y values increase with increasing the applied load.

There are models used in microhardness analysis of materials. The results obtained from these models are described below.

3.1 Meyer law

Meyer Law is the most fundamental law that is used to definition of mechanical behavior exhibited by material [16].

The n value is obtained from slope of InF-Ind graph (Fig. 3) determines the behavior of the material (ISE or RISE). If n is smaller than 2, the material exhibits ISE behavior. But this value is greater than 2, the material exhibits RISE behavior [17, 18]. In this study, n values are greater than 2 for the samples B and D (Table 3). According to these results, it is understood that both of the samples show RISE behavior.

3.2 PSR (proportional sample resistance) model

The load independent H PSR values are calculated using the β value that is obtained from slope of F/d–d graph (Fig. 4) is drawn using Eq. 5.

It can be seen that α value is defined as energy of cracks formed on the surface of the sample is negative for B and D (Table 3). The reason for this is materials that have RISE behavior. If the material has ISE behavior, α value is positive [19].

Hardness values are calculated according to PSR model are so far from plateau region or load dependent hardness values. This means that the PSR model is not suitable for the hardness analysis of materials produced in this study.

3.3 Elastic/plastic deformation (EPD) model

In the elastic plastic deformation (EPD) model, the type of the deformation formed in material is determined [20, 21]. d e value is point where the graph (Fig. 5) intercepts the y-axis is the coefficient of elastic deformation. If d e value is negative, elastic deformation is not observed in the material. There is only plastic deformation. If d e value is positive, there is elastic deformation as well as plastic deformation. In general, elastic deformation coefficient of materials that exhibit the ISE/RISE behavior is positive/negative.

As seen from Table 4, elastic deformation coefficient (d e ) is negative in both B and D. This means that the materials exhibit the RISE behavior. This case confirms the results obtained until now. Hardness values are calculated according to EPD model are so far from plateau region. So, EPD model is insufficient for the microhardness analysis.

3.4 Indentation-induced cracking (IIC) model

The IIC model is used in hardness analysis of materials that show RISE behavior [22–24]. According to this model, the applied test load is equilibrated by the total sample resistance in maximum depth. This resistance is composed of four components.

-

1.

Shift of the indenter or sample at the interface

-

2.

Elastic Deformation

-

3.

Plastic Deformation

-

4.

Cracks of sample

Hardness values are calculated using Eq. 9 in this model.

m value is determined from slope of In(F 5/3 /d 3 )–InH v graph (Fig. 6) is used to determination of behavior of material (ISE or RISE). If m is greater than 0.6 the material has a normal ISE behavior. But if m is less than 0.6, it has a RISE behavior [25, 26]. m values are 0.58 and 0.34 for B and D sample, respectively. So, materials have RISE character. Regression analysis of experimental data according to IIC Model is given in Table 5. Compared to the values are calculated using the other models, the microhardness values calculated from IIC model are quite similar to the microhardness values in the plateau region (Table 6). Therefore, IIC model is the most suitable model to use in the microhardness analysis.

Figure 7 shows surface micrographs of the prepared samples. It is observed that the microstructures of B and D samples exhibit a common feature of plate-like and strip-like grains, respectively. The grains are randomly distributed. Although the grain size of B is relatively bigger than the other sample, it may be said that D sample has comparatively denser surface structure. These surface structures are compatible with the microhardness results. As shown in Fig. 7, the sample D has less porosity from the B sample. Hardness is a measure of porosity. Smaller values of hardness are obtained where porosity is high. The results of the hardness values are consistent with the SEM measurements.

In Fig. 8, we have plotted the normalized ac susceptibility curves as a function of temperature at H ac = 640 A/m, frequency f = 125 Hz. Note that there exists two-step change to full diamagnetism in-phase component of the fundamental susceptibilities, χ′, of two samples. The first drop, near Tc, corresponds to 2223 phase; another drop at low temperatures indicates to 2212 phase. The out-of-phase component, χ′′, exhibits two peaks with decreasing temperature. T onsetc, value is given in Table 1.

4 Conclusion

Microhardness measurements were performed to determine the mechanical properties of the samples. In order to determine the most suitable model, Meyer’s law, PSR model, EPD model and IIC model were applied to hardness values of the samples. In addition to these structural properties were obtained with XRD and SEM measurement. Also the magnetic characterizations of the samples were performed AC susceptibility measurements. The following results are obtained;

-

Mechanical, structural and magnetic properties of the BSCCO superconductors with the measurements were determined to be strongly dependent on the fabrication methods.

-

According to the Vickers microhardness measurement, it is seen that the microhardness values of the samples that are produced in different methods are depend on the load applied.

-

The hardness of all samples increased with increasing applied loads. This behavior is referred to as RISE in the literature.

-

Also the sample prepared by ammonium nitrate precipitation method was found to be harder than the sample prepared by solid state reaction method.

-

IIC model is determined as the most successful model describing the mechanical properties of our samples.

-

The hardness results were confirmed by SEM and XRD measurements.

-

\({\text{T}}_{\text{c}}^{\text{onset}}\) values were obtained by the Ac susceptibility measurements.

References

N. Ghanzanfari, A. Kılıç, A. Gencer, H. Özkan, Solid State Commun. 144, 210 (2007)

C. Terzioglu, M. Yilmazlar, O. Ozturk, E. Yanmaz, Phys. C 423, 119 (2005)

C. Terzioglu, O. Ozturk, A. Kilic, A. Gencer, I. Belenli, Phys. C 434, 153 (2006)

S.M. Khalil, J. Phys. Chem. Solids 64, 855 (2003)

A. Biju, R.P. Aloysius, U. Syamaprasad, Supercond. Sci. Technol. 18, 1454 (2005)

N. Udomkan, P. Vinotai, R. Suryanarayanan, N. Charoenthai, Supercond. Sci. Technol. 18, 1294 (2005)

K. Ozturk, S. Celik, U. Cevik, E. Yanmaz, J. Alloys Compds. 433, 46 (2007)

A. Biju, R.G. Abhilash Kumar, R.P. Aloysius, U. Syamaprasad, Phys. C 449, 109 (2006)

V.G. Prabitha, A. Biju, R.G. AbhilashKumar, P.M. Sarun, R.P. Aloysius, U. Syamaprasad, Physica C 433, 28 (2005)

M. Yilmazlar, O. Ozturk, O. Gorur, I. Belenli, C. Terzioglu, Supercond. Sci. Technol. 20, 365 (2007)

N. Güçlü, A. Kılıç, I.N. Askerzade, A. Gencer, Phys. Stat. Sol. 201, 995 (2004)

M. Yilmazlar, H.A. Cetinkara, M. Nursoy, O. Ozturk, C. Terzioglu, Phys. C 442, 106 (2006)

A. Tampieri, G. Celotti, S. Guicciardi, C. Melandri, Mater. Chem. Phys. 42, 188 (1995)

C.W. Chiu, R.L. Meng, L. Gao, Z.J. Huang, F. Chen, Y.Y. Xue, Nature 365, 323 (1993)

S.A. Halim, S.A. Khawaldeh, S.B. Mohammed, H. Azhan, Mater. Chem. Phys. 61, 251 (1999)

D. Tabor, The hardness and strength of metals. J. Inst. Met. 79, 1–18 (1951)

H. Koralay, A. Arslan, S. Cavdar, O. Ozturk, E. Asikuzun, A. Gunen, A.T. Tasci, J. Mater. Sci.: Mater. Electron. 24(11), 4270–4278 (2013)

O. Ozturk, M. Coskunyurek, E. Asikuzun, N. Soylu, A. Hancerliogullari, A. Varilci, C. Terzioglu, J. Mater. Sci.: Mater. Electron. 25(1), 444–453 (2014)

E. Asikuzun, O. Ozturk, H.A. Cetinkara, G. Yildirim, A. Varilci, M. Yılmazlar, C. Terzioglu, J. Mater. Sci.: Mater. Electron. 23, 1001–1010 (2012)

S.J. Bull, T.F. Page, E.H. Yoffe, Phil. Mag. Lett. 59, 281 (1989)

G.P. Upit, S.A. Varchenya, Phys. Status Solidi A 17, 831 (1966)

L. Arda, O. Ozturk, E. Asikuzun, S. Ataoglu, Powder Technol. 235, 479–484 (2013)

M. Tosun, S. Ataoglu, L. Arda, O. Ozturk, E. Asikuzun, D. Akcan, O. Cakiroglu, Mater. Sci. Eng., A 590, 416–422 (2014)

S. Safran, E. Asikuzun, E.S. Kilicarslan, A. Kilic, O. Ozturk, A. Gencer, J. Mater. Sci.: Mater. Electron. 25, 2737–2747 (2014)

R. Awad, A.I. Abou-Aly, M. Kamal, M. Anas, J. Supercond. Nov. Magn. 24, 1947–1956 (2011)

K. Sangwal, Mater. Chem. Phys. 63, 145–152 (2000)

Acknowledgments

This work has been supported by Turkish Research and Scientific Council (TUBITAK) under Grant contract No: 113F150. We also acknowledge The Republic of Turkey, Ministry of Development under the Project Number 2010K120520.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Safran, S., Kılıç, A., Kılıçarslan, E. et al. Mechanical, microstructural and magnetic properties of the bulk BSCCO superconductor prepared by two different methods. J Mater Sci: Mater Electron 26, 2622–2628 (2015). https://doi.org/10.1007/s10854-015-2733-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2733-9