Abstract

La3(BWO9):Tb3+ nanofibers were fabricated by an electrospinning process. The XRD patterns of the obtained fibers indicate that the incorporation of Tb3+ ions will not change the phase of La3(BWO9). The excitation spectrum monitored at 547 nm consists of excitation bands originating from 1T1 → 1A1 transition of O2− → W6+ in the WO6 group and 4f8 → 4f75d1/4f8 transitions of Tb3+. Upon the excitation at 362 nm, La3(BWO9):Tb3+ fibers show emission bands originating from the 5D4 → 7Fj (j = 6, 5, 4 and 3) transitions of Tb3+. The decay characteristics of La3BWO9:Tb3+nanofibers indicate that Tb3+ ions occupy one site in the host lattice.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The electricity consumption in domestic buildings occupies higher and higher percentage in whole electricity consumption. As a result, white light emitting diodes (WLEDs), having advantages of long lifetime, high luminescence efficiency, low power consumption and environment friendly characteristics, attract considerable research for solid-state lighting applications [1, 2]. In the fabrication of WLEDs, the combination of green and red emitting phosphors with a blue chip leads to the high color rendering and high efficiency [3]. Due to the intense and sharp luminescence originating from the f–f electronic transitions, rare earth ions are used widely as activators in phosphors. Among rare earth ions, Eu3+ [4–10] and Tb3+ [11–18] ions often act as activators to obtain red and green emissions. The green emission of Tb3+ mainly comes from the 5D4 → 7Fj (j = 6, 5, 4 and 3) transitions.

Borate and tungstate phosphors for WLED applications have attracted much attention because of the broad and intense ligand-to-metal charge transfer band in the ultraviolet or near ultraviolet region, which is expected to capture the emission from a GaN-based LED in this range [10]. The mixed-anion rare earth compounds in combination with borate and tungstate have been reported in WO3–Ln2O3–B2O3 system (Ln = rare earth ion), such as Gd4B2WO12 [19], Eu3BWO9 [20] and LaBWO6 [9]. In this work, we report on the luminescent properties of La3(BWO9):Tb3+ nanofibers fabricated by an electrospinning method. Nanofiber-phosphors have obvious advances owing to their anisotropy, large width-thickness ratio and length-diameter ratio, unique optical, electrical and magnetic properties [21]. Electrospinning technology has been extensively explored as a simple and versatile method for forming inorganic superfine nanofibers using polymer/inorganic composite as the precursor. The morphology of fine products fabricated by electrospinning can be controlled by adjusting experimental parameters, such as the precursor solution viscosity, the structure of spinneret, voltage and the distance between the spinneret and the collector.

2 Materials and methods

A series of La3(BWO9):xmol%Tb3+ (x = 2, 3, 4, 5 and 6) nanofibers were fabricated by an electrospinning process. La2O3 (99.99 %), Tb4O7 (99.99 %), H3BO3 (99.99 %), (NH4)10H2(W2O7)6 (99.95 %) were used as raw materials. Citric acid (99.5 %) and polyvinyl pyrrolidone (PVP, Mw = 90,000) were used as additives. All chemicals were used directly without further purification.

Spinning solution was prepared firstly for fabrication of La3(BWO9):Tb3+ nanofibers. In a typical preparation, 1.3 mmol of La2O3 and 0.1 mmol of Tb4O7 were dissolved into 10 mL of hot aqueous nitric acid solution to form the solution A. Then, 1 mmol of H3BO3 and 0.083 mmol of (NH4)10H2(W2O7)6 were dissolved into 10 mL of deionized water containing citric acid to form the solution B. The molar ratio of La + Tb to citric acid was kept at 1:2. Precursor solution was obtained by mixing solutions A and B under continuous stirring. Finally, 3.0 g of PVP was added to the precursor solution and mixed to form a homogeneous spinning solution. During the process of electrospinning, the spinning solution was loaded into a plastic syringe with a spinneret, and the angle between spinneret and horizon was fixed to 10° for fabricating nanofibers. A flat iron net was used as the collector putting about 18 cm away from the spinneret. The flow rate was kept at 0.5 mL/h. The voltage of direct current adjusted to 15 kV was applied between the spinneret and the collector to generate the stable continuous PVP-based composite nanofibers. The obtained fibers were dried in an oven at 120 °C for 2 h and then heated at 800 °C for 5 h.

The X-ray powder diffraction (XRD) measurements were carried out on a Rigaku-Dmax 2500 diffractometer using Cu Kα radiation (λ = 0.15405 nm). The morphology and structure of the samples were inspected by an FESEM-4800 field emission scanning electron microscope (SEM, Hitachi). The luminescence was performed on a HitachiF-7000 spectrophotometer equipped with a 150 W xenon lamp as the excitation source. The decay curves were obtained from a Lecroy Wave Runner 6100 digital oscilloscope (1 GHz) using a tunable laser (pulse width = 4 ns, gate = 50 ns) as excitation source (Continuum Suncite OPO).

3 Results and discussion

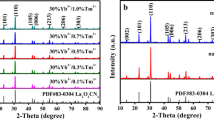

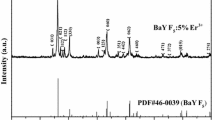

The phase of La3(BWO9):xmol%Tb3+ (x = 2, 3, 4, 5 and 6) after the heating at 800 °C are confirmed by XRD patterns. La3(BWO9) crystallizes in a hexagonal structure with the P63 space group. W atoms in the structure are surrounded by six oxygen atoms, forming a trigonal-prismatic coordination, which shares edges with three rare-earth polyhedrons. La atoms adopt ninefold coordination, of which six O atoms are derived from three WO6 groups by sharing one edge with a WO6 trigonal prism and the other three O atoms from BO3 groups. LaO9 polyhedrons connect each other by sharing the corner O atoms of WO6 and BO3 groups, forming the framework of La3BWO9. As shown in Fig. 1, the XRD patterns of all samples are identical and match well with that of the pure La3BWO9 with a hexagonal structure (JCPDS No. 77-1040). No other impurity peaks can be detected. These results suggest that Tb3+ ions have doped into the La3BWO9 host lattice entirely and form the complete solid solution. Due to the same valence state and similar ionic radii, Tb3+ ions will substitute La3+ ions in La3BWO9. The diffraction peaks of these samples are broadened remarkably, which reveals their nanocrystalline structure. The average crystallite sizes of samples can be calculated by the Scherrer equation:

where D is the average grain size, K = 0.9 is a characteristic for spherical objects, λ is the X-ray wavelength, θ and β are the diffraction angel and full-width at half-maximum of an observed peak. On the basis of diffraction peak of (201), the average grain sizes are calculated to be about 20 nm.

To show the morphology and size of the samples, the SEM images are obtained. Figure 2 shows the SEM images of La3(BWO9):5 mol%Tb3+ after the heating at 800 °C. As shown in Fig. 2a, a large number of uniform fibers with diameters about 150 nm are obtained. The enlarged SEM image (Fig. 2b) shows that these fibers are rough and comprised of nanoparticles with sizes about 20 nm. The rough surface is induced by the removal of the residual organic solvent and PVP, plus the agglomeration of nanoparticles to form nanofibers during the electrospinning and heating processes. All samples have the same morphology and size. The morphology and diameter of the electrospun samples depend on the intrinsic properties of the solution and the operational conditions. In order to obtain fibers with perfect uniform morphology, the key is searching a balance point of various electrospinning parameters, such as the volume ratio of deionized water to citric acid, the weight percentage of PVP, the spinning rate, the strength of the electric field, and the distance between the spinneret and the collector.

Figure 3 shows the excitation and emission spectra of La3(BWO9):5 mol%Tb3+ nanofibers. The excitation spectrum consists of two parts by monitoring the emission at 547 nm. The broad band maximized at 296 nm is ascribed to charge transfer from the ligand to the metal, derived from the 1T1 → 1A1 transition of O2− → W6+ in the WO6 group [10] and the 4f8 → 4f75d1 transition of Tb3+ ions [22]. Those excitation bands in the range of 300-400 nm come from the 4f8 → 4f8 transitions from the ground 7F6 level to excited 2S+1LJ of Tb3+ ions [23]. There is a weakness of the interconfigurational 4f8 → 4f75d1 transition comparing to the 4f8 → 4f8 transitions although the former is parity allowed and thus usually much stronger, because that the 4fn → 4fn−15d1 transitions within the conduction band will lose the superior intensity as has been shown for the Ce3+-doped Y3Al5O12 single crystals [24]. Upon the excitation at 362 nm, four typical emission peaks at 489, 547, 589 and 623 nm originating from 5D4 → 7Fj (j = 6, 5, 4 and 3) transitions of Tb3+ ions can be observed. Among them, the green emission band at 547 nm originating from the 5D4 → 7F5 transition is strongest.

The dependence of emission intensity on Tb3+ doping concentration is shown in Fig. 4. Upon the excitation of 362 nm, La3(BWO9):xmol%Tb3+ (x = 2, 3, 4, 5 and 6) nanofibers show emission bands originating from 5D4 → 7Fj (j = 6, 5, 4 and 3) transitions of Tb3+ ions and the increasing concentrations of Tb3+ ions bring no obvious alteration in the shapes of emission spectra. The almost complete absence of emission bands originating from 5D3 → 7Fj transitions means that the emission from the 5D3 level is quenched and the excitation energy ends to the 5D4 level instead. The weakness of the 4f8 → 4f75d1 transitions in the excitation spectrum offers a plausible explanation for the absence of 5D3 emission: the 5D3 level locates in the conduction band of La3BWO9, and the 5D3 emissions are quenched to the lowest emitting level, 5D4, via the conduction band. The emission intensity increases with the increasing concentrations of Tb3+ and reaches the maxima for La3(BWO9):5 mol%Tb3+, then decreases with the further increase of Tb3+ concentration. The increases of emission intensity with the increasing concentrations of Tb3+ is attributed to a large number of luminescent centers up to a critical concentration, beyond which a decrease in the emission intensity occurs due to the concentration quenching effect. Quenching can originate from efficient energy transfer among the dopant ions, because of the matching of their energy levels, followed by the eventual energy transfer from the dopant ions to a defect where non-radioactive decay occurs. The occurrence of nonradiative energy transfer may be caused by exchange interaction, radiation reabsorption, or multipole–multipole interaction [25]. The exchange interaction is a short-distance interaction and the typical critical distance is about 5 Å. The critical transfer distance (Rc) can be calculated by the formula of

where X is the critical concentration of Tb3+, V is the volume of the unit cell, and N is the number of available sites of the dopant in the unit cell. For La3BWO9:Tb3+nanofibers, V = 371.05 Å, X = 0.05 and N = 6, the critical transfer distance of Tb3+ in La3BWO9 is calculated to be 13.32 Å. And the mechanism of radiation reabsorption comes into effect only when there is a broad overlap of the emission spectrum of the sensitizer and the excitation spectrum of the activator. Since the critical transfer distance is larger than 5 Å and there is no overlap between the excitation and emission spectra of La3BWO9:Tb3+, the energy transfer process should be controlled by the multipole–multipole interaction.

To obtain additional information on the luminescent properties of the Tb3+ ions in La3(BWO9) host, the decay curves of the Tb3+ emission at 547 nm corresponding to the 5D4 → 7F5 transition upon 362 nm excitation for La3(BWO9):xmol%Tb3+ nanofibers are measured, as shown in Fig. 5. All of curves demonstrate almost perfect single-exponential function:

where I is the emission intensity at time of t, A is a constant, t is the time, τ is the decay time. This suggests that Tb3+ ions occupy one site in the host lattice. The decay times for La3(BWO9):xmol%Tb3+ (x = 2, 3, 4, 5 and 6) are 2.896, 2.821, 2.608, 2.448, 2.365 and 2.290 ms, respectively.

4 Conclusion

La3BWO9:Tb3+nanofibers have been fabricated via an electrospinning process. The phase structure, size and morphology and luminescent properties have been studied as a function of Tb3+ concentration. The results suggest that the Tb3+ concentration in La3BWO9 host will not change the phase structure and morphology of La3BWO9:Tb3+nanofibers, but has obvious influence on the luminescent properties. The emission intensity increases with the increasing concentrations of Tb3+ and reaches the maximum for La3(BWO9):5 mol%Tb3+, then decreases with the further increase of Tb3+ concentration because of the concentration quenching effect. The decay characteristics of La3BWO9:Tb3+nanofibers indicate that Tb3+ ions occupy one site in the host lattice.

References

S. Tonzani, Nature 459, 312 (2009)

S. Pimputkar, J.S. Speck, S.P. Denbaars, S. Nakamura, Nat. Photonics 3, 180 (2009)

P. Falcaro, S. Furukawa, Angew. Chem. Int. Ed. 51, 8431 (2012)

Z. Zhang, L. Liu, S. Song, J. Zhang, D. Wang, Curr. Appl. Phys. 15, 248 (2015)

X. Lu, J. Mater. Sci. Mater. Electron. 25, 952 (2014)

Y. Yang, X. Wang, B. Liu, Nano 9, 1450008 (2014)

G. Chen, F. Wang, W. Ji, Y. Liu, X. Zhang, Superlattices Microstruct. 90, 30 (2016)

Y. Yang, Mater. Sci. Eng. B 178, 807 (2013)

Z. Liu, X. Wang, W. Xu, Z. Xia, Superlattices Microstruct. 89, 259 (2016)

J. Huang, B. Hou, H. Ling, J. Liu, X. Yu, Inorg. Chem. 53, 9541 (2014)

Y. Liu, X. Yue, K. Cai, H. Deng, M. Zhang, Energy 93, 1412 (2015)

B. Li, H. Zhang, A. Lan, H. Tang, Chem. Phys. Lett. 636, 22 (2015)

T. Grzyb, M. Runowski, A. Szczeszak, S. Lis, J. Phys. Chem. 116, 17188 (2012)

Y. Tian, Y. Fang, B. Tian, C. Cui, P. Huang, L. Wang, H. Jia, B. Chen, J. Mater. Sci. 50, 6060 (2015)

X. Zhang, X. Zhang, Z. Zhao, J. Chaudhuri, J. Mater. Sci. 50, 251 (2015)

F.-C. Lu, L.-J. Bai, T. Lu, W. Dang, Z.-P. Yang, P. Li, J. Am. Ceram. Soc. 98, 867 (2015)

M. Srinivas, B. Appa Rao, M. Vithal, P. Raghava Rao, Luminescence 28, 597 (2013)

Y. Zhang, V. Vijayaragavan, G.K. Das, K. Bhakoo, T.T.Y. Tan, Eur. J. Inorg. Chem. 12, 2044 (2012)

R. Zhu, Y. Huang, H.J. Seo, J. Am. Ceram. Soc. 94, 3380 (2011)

R. Zhu, Y. Huang, H.J. Seo, J. Electrochem. Soc. 157, H1116 (2010)

W. Ma, W. Yu, X. Dong, J. Wang, G. Liu, Chem. Eng. J. 244, 531 (2014)

C. Qin, L. Qin, G. Chen, T. Lin, Mater. Lett. 106, 436 (2013)

L.C.V. Rodrigues, H.F. Brito, J. Hölsä, R. Stefani, M.C.F.C. Felinto, M. Lastusaari, T. Laamanen, L.A.O. Nunes, J. Phys. Chem. C 116, 11232 (2012)

T. Tomiki, H. Akamine, M. Gushiken, Y. Kinjoh, M. Miyazato, T. Miyazato, N. Toyokawa, M. Hiraoka, N. Hirata, Y. Ganaha, T. Futemma, J. Phys. Soc. Jpn. 60, 2437 (1991)

L.G. Van Uitert, J. Electrochem. Soc. 114, 1048 (1967)

Acknowledgments

The work is supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miao, Y., Wang, P., Guan, H. et al. Electrospinning fabrication and luminescence of La3(BWO9):Tb3+ nanofibers. J Mater Sci: Mater Electron 27, 10798–10802 (2016). https://doi.org/10.1007/s10854-016-5185-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5185-y