Abstract

In this paper, the wettability of lead-free solders on substrates with fluxes was studied based on reflow process and Taguchi method. Effects of different control factors, including solder materials, fluxes, substrate materials and atmosphere on the wettability of the lead-free solder joints were examined and calculated. Moreover, the effect of rare earth Eu on the wetting of SnAgCu solder was investigated, the effect mechanism was analyzed too. The wettability optimal design in the lead-free solders system has the combination of the SnAgCu-0.04Eu solder, RMA flux, Au/Ni/Cu substrate, and vacuum atmosphere. Moreover, the flux is the most important factor among the control factors in the wettability system.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the toxicity of Pb, the restriction of Pb use in the industrial fields has been strongly promoted because of the environmental protection on water resources [1, 2], which has stimulated substantial research and development efforts to discover substitute, lead-free solders for electronic applications [3]. These years, the investigation of lead-free solders has become an important research aspect in electronic industry, SnAgCu, SnAg, SnZn, SnCu etc. have been studied to replace the SnPb solder, moreover, the SnAgCu solder have be proposed as the most promising alternative [4], because of its good soldering and wetting behavior on several substrate materials such as Cu, Ag, Au, Ni and respective alloys [5]. However, the poor wettability of SnAgCu solders can be found comparing with traditional SnPb solder used in electronic device [6].

In order to improve the wettability of SnAgCu solders, rare earth elements were selected by many researchers to enhance the wettability [7–9], and it is demonstrated that the addition of rare earth is an effective way. Gao et al. [10] found that the wettability was improved by adding small amount of rare earth Nd, and an optimal wettability was achieved when the Nd content is 0.05 wt%. Shi et al. [11] reported that when Er content was less than 0.25 wt%, the spreading area of SnAgCu increased as Er increase. The spreading area of SnAgCu solder given a 13.3 % increase after soldering when the content of Yb was 0.05 wt% [12]. The wettability of SnAgCu shows obvious relationship with additives, however, the atmospheres, fluxes and substrates can also influence the wettability of lead-free solders. Until now, no literature reported the influence order of these control factors.

Taguchi method was proposed as an effective way to optimize the parameters of electronic packaging. Lau [13] used the gray-based Taguchi method to optimize the thermal stress of a solder joint and cooling rate of a ball grid array package, and found that the approach can greatly improve in reducing soldering defects and enhances solutions to lead-free reliability issues. Wei finds [14] that the fatigue life after optimal design by Taguchi method has 3.43 folds on the fatigue life over the original design in QFN device. Zhang [15] researches the thermo-mechanical reliability of lead-free solder joints in WLCSP assembly subjected to an accelerated thermal cyclic loading based on finite element simulation and Taguchi method, and the solder materials was demonstrated to be the most important factor among the control factors in the WLCSP assembly.

In this paper, Taguchi method was utilized to analyze the effect of control factors on the wettability of lead-free solders. Four control factors contains solder materials, fluxes, substrates and atmospheres of soldering. Moreover, the effect mechanism of rare earth Eu on the wettability of SnAgCu was discussed.

2 Experimental

The SnAgCu, SnAgCu-0.04Eu and SnAgCu-0.1Eu solders were prepared from the pure Sn, Sn-Cu alloy, Sn-Ag alloy, and Sn-Eu alloys. All the raw materials for SnAgCu base solders were melted in a ceramic crucible, and melted at 550 ± 1 °C for 40 min. And the mechanical stirring was needed to homogenize the solder alloy. In order to protect the solder for oxidation during the melting, KCl + LiCl (1.3:1) were used over the surface of liquid solder. Then the molten alloys were chilled and cast ingots in a mold and solidified by nominally air-cooling. At last for stabilizing the microstructure of the solder alloys, all solder specimens were heated and treated at 125 °C for an hour.

0.2 g solder was placed on substrates (4 × 4 × 1 mm) with fluxes, and then was heated with 245 °C reflow soldering process. And all the samples were cooled in the furnace. Figure 1 shows a schematic drawing of the measured spreading area of the SnAgCu solders on substrate. The spreading area can be used to analyze the wettibility of lead-free solders. The parameter can be measured by ImageJ software, and the data was estimated with five samples.

3 Results and discussion

In order to optimize the control factors of the wettability of lead-free solders, the Taguchi method was utilized in the optimization. In 1980, Taguchi’s introduction of robust design to several major American industries, including AT & T, Ford and Xerox, resulted in significant quality improvements in product and manufacturing process design [16]. Taguchi method uses two effective tools, which are orthogonal array and S/N ration [17]. The idea of orthogonal arrays is to get the statistic information and robust process conditions during shorter time by using fewer analyses. With the consideration of control factors and their levels, the L9 (34) orthogonal array is to be applied in wettability testing of spreading area (s). The smaller-the-better is one of the three quality characteristic types (Nominal-the-best, smaller-the better, and larger-the-better), and used to analyze the data of the wettability, where the smaller quality characteristic is the better; in other words, the value of its optimum function is zero. A metric which identifies conditions to help minimize variation has to be implemented, for this purpose, the signal-to-noise ratio (S/N ratio) measured with dB is used [18]. The signal-to-noise (S/N) objective function for the quality characteristic of smaller-the-better type was computed as shown in Eq. (1):

where r is the total number of measurements, y i is the ith measurement data, and S/N is the signal-to-noise ration in decibel.

In the wettability testing, the r = 5 and y = 1/s, so the \(\frac{{\sum\nolimits_{i = 1}^{r} {y_{i}^{2} } }}{r} = \frac{{\sum\nolimits_{i = 1}^{5} {\left( {1/s_{i} } \right)_{{}}^{2} } }}{5}\), therefore, the Eq. (1) can be described as

The four selected control factors and their levels applied in this study are tabulated in Table 1. These control factors contain solder materials, fluxes, substrates and atmospheres. And the control factors all show three levels. SnAgCu, SnAgCu-0.04Eu and SnAgCu-0.1Eu solder materials were selected in this paper, which can be used to analyze the effect of rare earth Eu on the wettability of SnAgCu solder.

In order to obtain the optimal parameters of the wettability of lead-free solders, the main experiment is carried out to analyze the control factors and levels. Table 2 shows the 1/s (spreading areas: s) and the S/N ration for each experiment cells on the L9(34) orthogonal array. It is found that with the variation of solder materials, fluxes, substrates and atmospheres, the 1/s and S/N ratio change significantly. The smaller value of 1/s demonstrated the better wettability of lead-free solders. And the evaluation of lead-free solders is based on the quality factor 1/s.

The S/N ratio response diagram of the four control factors is shown in Fig. 2, magnitudes of the control factors response and ranks are summarized in Table 3. According to the S/N response diagram, the effect of four factors is different, the contribution degree of the four factors is Factor B(fluxes) > Factor D (Atmospheres) > Factor A (solder materials) > Factor C (Substrates), the most important factor is the fluxes, which demonstrates that the wettability of the lead-free solders in the system can be influenced by many factor, not only solder materials, we should enhance the wettability of lead-free solders based on the optimal design. In this analysis, the optimization of fluxes can prevent the oxidation of solder, and boost the liquidity. Cheng et al. [19] and Wang et al. [20] also demonstrated the active effect of fluxes. And the optimal parameters match is A2B3C3D3, namely the optimal design in the wettability of lead-free solder system has the combination of the SnAgCu-0.04Eu, RMA flux, Au/Ni/Cu substrate, and vacuum atmosphere. Moreover, it is imperative to illustrate that when the levels are varied, the optimal set of the control factors and rank then change obviously. Wang [21, 22] also found the superiority of Au/Ni/Cu substrate, and demonstrated that the wettability of solder on Au/Ni/Cu substrates can improved obviously in laser soldering.

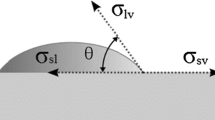

With the analyze of wettability optimization design, it is found that the wettability of lead-free solders can be controlled with many factors, so in the application of lead-free solders in electronic packaging field, many factors should be taken into consideration to improve the wettability of solders. Moreover, it is found 0.04 wt%Eu can improve the wettability of SnAgCu solder, which can be attributed to the higher affinity Sn of rare earths [23], Eu can react with Sn to form EuSn3 particles, and precipitate form the molten solder, especially for the nucleation of particles at the triple point of gay-liquid–solid system, when the particles exist at the triple point, the balance among the gas, liquid and solid will be broken, the fluidity of solders will be improved, therefore, the wettability can be enhanced obviously.

4 Conclusion

An L9(34) orthogonal array with Taguchi method was used to analyze the wettability optimization, It is found that the flux is the most important factor among all control factors, and the optimal design in the wettability system has the combination of the SnAgCu-0.04Eu solder, RMA flux, Au/Ni/Cu substrate, and vacuum atmosphere.

References

K. Suganuma, K. Niihara, T. Shoutoku, Y. Nakamura, Wetting and interface microstructure between Sn-Zn binary alloys and Cu[J]. J. Mater. Res. 13(10), 2859–2865 (1998)

L. Zhang, K.N. Tu, Structure and properties of lead-free solders bearing micro and nano particles[J]. Mater Sci Eng R Rep 82, 1–32 (2014)

K. Suganuma, Advances in lead-free electronics soldering[J]. Curr. Opin. Solid State Mater. Sci. 5(1), 55–64 (2001)

L. Zhang, J.H. Cui, J.G. Han, C.W. He, Y.H. Guo, J.M. Yuan, Finite element analysis of SnAgCu (Zn Co, Fe) lead-free solder joints for electronic packaging[J]. Int. J. Nonlinear Sci. Numer. Simul. 15(3–4), 197–206 (2014)

L. Zhang, J.G. Han, Y.H. Guo, C.W. He, Effect of rare earth Ce on the fatigue life of SnAgCu solder joints in WLCSP device using FEM and experiments[J]. Mater. Sci. Eng. A 597, 219–224 (2014)

C.Y. Ho, J.G. Duh, Wetting kinetics and wettability enhancement of Pad added electrolytic Ni surface with molten Sn-3.0Ag-0.5Cu solder[J]. Mater. Lett. 92, 278–280 (2013)

C.M.L. Wu, D.Q. Yu, C.M.T. Law, L. Wang, Properties of lead-free solder alloys with rare earth element additions[J]. Mater. Sci. Eng. R Rep. 44(1), 1–44 (2004)

L. Zhang, C.W. He, Y.H. Guo, J.G. Han, Y.W. Zhang, X.Y. Wang, Development of SnAg-based lead-free solders in electronics packaging[J]. Microelectron. Reliab. 52(3), 559–578 (2012)

L. Zhang, S.B. Xue, L.L. Gao, G. Zeng, Z. Sheng, Y. Chen, S.L. Yu, Effects of rare earths on properties and microstructures of lead-free solder alloys[J]. J. Mater. Sci. Mater. Electron. 20(8), 685–694 (2009)

L.L. Gao, S.B. Xue, L. Zhang, Z. Sheng, G. Zeng, F. Ji, Effects of trace rare earth Nd addition on microstructure and properties of SnAgCu solder[J]. J. Mater. Sci. Mater. Electron. 21(7), 643–648 (2010)

Y.W. Shi, J. Tian, H. Hao, Z.D. Xia, Y.P. Lei, F. Guo, Effects of small amount addition of rare earth Er on microstructure and property of SnAgCu solder[J]. J. Alloys Compd. 453(1–2), 180–184 (2008)

L. Zhang, X.Y. Fan, Y.H. Guo, C.W. He, Properties enhancement of SnAgCu solders containing rare earth Yb[J]. Mater. Des. 57, 646–651 (2014)

C.S. Lau, M.Z. Abdullah, F.C. Ani, Optimization modeling of the cooling stage of reflow soldering process for ball grid array package using the gray-based Taguchi method[J]. Microelectron. Reliab. 52(6), 1143–1152 (2012)

Wu W., Qin F., Gao C., Zhu W.H. Thermal fatigue life optimization of QFN package based on Taguchi methods[C].13th International conference on electronic packaging technology and high density packaging, pp. 1128–1132 2012

L. Zhang, L. Sun, J.G. Han, Y.H. Guo, Reliability of lead-free solder joints in WLCSP device with finite element simulation and Taguchi method[J]. Int. J. Nonlinear Sci. Numer. Simul. 15(6), 405–410 (2014)

M.H.C. Li, S.M. Hong, Optimal parameter design for chip-on-film technology using the Taguchi method[J]. Int. J. Adv. Manuf. Technol. 25(1–2), 145–153 (2005)

W.R. Jong, H.C. Tsai, H.T. Chang, S.H. Peng, The effects of temperature cyclic loading on lead-free solder joints of wafer level chip scale package by Taguchi method[J]. J. Electron. Packag. 130(1), 011001 (2008)

A. Mertol, Application of the Taguchi method on the robust design of molded 225 plastic ball grid array packages[J]. IEEE Trans. Compon. Packag. Manuf. Technol. 18(4), 734–743 (1995)

F.J. Cheng, F. Gao, J.Y. Zhang, W.S. Jin, X. Xiao, Tensile properties and wettability of SAC0307 and SAC105 low Ag lead-free solder alloys[J]. J. Mater. Sci. 46(10), 3424–3429 (2011)

H. Wang, S.B. Xue, W.X. Chen, J.X. Wang, Effects of different fluxes on the characteristics of Sn-Zn solders[J]. Trans. China Weld. Inst. 30(1), 5–8 (2008)

J.X. Wang, S.B. Xue, Z.J. Han, N. Wang, S.L. Yu, Effects of temperature and coatings on wettability of Sn-Cu-Ni lead-free solder[J]. Trans. China Weld. Inst. 27(10), 53–56 (2006)

J.X. Wang, S.B. Xue, D.S. Fang, J.L. Ju, Z.J. Han, L.H. Yao, Effect of diode-laser parameters on shear force of micro-joints soldered with Sn-Ag-Cu lead-free solder on Au/Ni/Cu pad[J]. Trans. Nonferrous Met. Soc. China 16, 1374–1378 (2006)

L. Zhang, J.G. Han, C.W. He, Y.H. Guo, Microstructures and properties of SnZn lead-free solder joints bearing La for electronic packaging[J]. IEEE Trans. Electron Devices 59(12), 3269–3272 (2012)

Acknowledgments

The present work was carried out with the support of the Natural Science Foundation of China(51475220); Natural Science Foundation of Jiangsu Province (BK2012144) and the Natural Science Foundation of the Higher Education Institutions of Jiangsu Province (12KJB460005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Sun, L., Han, Jg. et al. Wettability optimization analysis of lead-free solders with Taguchi method. J Mater Sci: Mater Electron 26, 2605–2608 (2015). https://doi.org/10.1007/s10854-015-2730-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-2730-z