Abstract

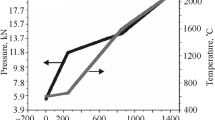

To reduce the sintering temperature of liquid-phase sintered conductive SiC ceramics, the SiC nanopowder with Sc2O3 additives was intentionally oxidized by heat treatment in air to enhance the SiO2 content coated on SiC surfaces moderately. Taking advantage of the lower eutectic temperature (1660 °C) between SiO2 and Sc2O3, conductive SiC ceramics were successfully sintered at 1700 °C. The effects of sintering temperature (1700–1900 °C), holding time (1–10 min), and additive content (1–7 wt.%) on microstructural, mechanical, and electrical properties were systematically investigated. The phase composition of as-received SiC ceramics contained Sc–Si–O–C–N and doped β-SiC, without apparent phase transformation of β-SiC to α-SiC. The Vickers hardness, elastic modulus, and fracture toughness of SiC ceramics varied within the ranges of 18.08–22.29 GPa, 269.12–391.16 GPa, and 4.09–7.86 MPa m1/2, respectively. The electrical resistivity of conductive SiC ceramics obtained under different process conditions varied in a small range (1–10 Ω cm). Meanwhile, the low-temperature sintering, phase formation, and evolution mechanisms of electrical properties were discussed in detail.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Guo F, Chen X, Cheng G et al (2022) Microstructural and mechanical evolution of SiCf/SiC composites in wet oxygen atmosphere above 1000 °C. Ceram Int 48:8473–8480

Snead LL, Nozawa T, Ferraris M et al (2011) Silicon carbide composites as fusion power reactor structural materials. J Nucl Mater 417:330–339

Song S, Lu B, Gao Z et al (2019) Microstructural development and factors affecting the performance of a reaction-bonded silicon carbide composite. Ceram Int 45:17987–17995

Talwar DN, Sherbondy JC (1995) Thermal expansion coefficient of 3C-SiC. Appl Phys Lett 67:3301–3303

He K, Shen R, Hao L et al (2022) Advances in nanostructured silicon carbide photocatalysts. Acta Phys-Chim Sin 38:2201021. https://doi.org/10.3866/PKU.WHXB202201021

Zhu DD, Yan JF, Jin YL et al (2024) Pressure-induced excellent corrosion resistance of Ti-45Al-8Nb alloy. Mater Lett 355:135446

Zhou XB, Yu T, Xu J et al (2022) Ultrafast low-temperature near-seamless joining of Cf/SiC using a sacrificial Pr3Si2C2 filler via electric current field-assisted sintering technique. J Eur Ceram Soc 42:6865–6875

Yu T, Xu J, Zhou XB et al (2022) Near-seamless joining of Cf/SiC composites using Y3Si2C2 via electric field-assisted sintering technique. J Adv Ceram 11:1196–1207

Li HX, Shen WJ, Yang FQ et al (2022) Microstructural, electrical, and mechanical properties of conductive SiC ceramics fabricated by spark plasma sintering. Int J Appl Ceram Tec 19:3376–3391

Burk AA Jr, O’Loughlin MJ, Siergiej RR et al (1999) SiC and GaN wide bandgap semic-onductor materials and devices. Solid State Electron 43:1459–1464

Takeda Y, Nakamura K, Maeda K et al (1987) Effects of elemental additives on electrical resistivity of silicon carbide ceramics. J Am Ceram Soc 70:266–267

Hua A, Wei F, Pan DS et al (2017) Wide-band microwave absorption by in situ tailoring morphology and optimized N-doping in nano-SiC. Appl Phys Lett 111:223105

Sciti D, Silvestroni L, Balbo A et al (2006) High-strength and-toughness electroconductive SiC-based composites. Adv Eng Mater 8:997–1001

Kim KJ, Lim KY, Kim YW (2011) Effective nitrogen doping for fabricating highly conductive β-SiC ceramics. J Am Cera Soc 94:3216–3219

Zhao TT, Gu H, Wang XH et al (2021) Revealing correlation of core rim structures, defects and stacking-faults in SiC ceramics by integrated scanning electron microscopy. J Eur Ceram Soc 41:204–212

Noviyanto A, Han SW, Yu HW et al (2013) Rare-earth nitrate additives for the sintering of silicon carbide. J Eur Ceram Soc 33:2915–2923

Jin HY, Ishiyama M, Qiao GJ et al (2008) Plasma active sintering of silicon carbide. Mat Sci Eng A Struct 483–84:270–273

Kim KJ, Jang SH, Kim YW et al (2016) Conductive SiC ceramics fabricated by spark p-lasma sintering. Ceram Int 42:17892–17896

Wing ZN (2017) TiN modified SiC with enhanced strength and electrical properties. J Eur Ceram Soc 37:1373–1378

Kim YW, Lim KY, Kim KJ (2012) Electrical resistivity of silicon carbide ceramics sintered with 1 wt.% aluminum nitride and rare earth oxide. J Eur Ceram Soc 32:4427–4434

Zhang N, Ru HQ, Cai QK et al (2008) The influence of the molar ratio of Al2O3 to Y2O3 on sintering behavior and the mechanical properties of a SiC-Al2O3-Y2O3 ceramic composite. Mat Sci Eng A Struct 486:262–266

Baud S, Thévenot F, Pisch A et al (2003) High temperature sintering of SiC with oxide additives: I. Analysis in the SiC-Al2O3 and SiC-Al2O3-Y2O3 systems. J Eur Ceram Soc 23:1–8

Gil GY, Yoon DH (2011) Densification of SiCf/SiC composites by electrophoretic infiltration combined with ultrasonication. J Ceram Process Res 12:371–375

Ishikawa T, Kohtoku Y, KUMAGAWA K, et al (1998) High-strength alkali-resistant sintered SiC fibre stable to 2200 °C. Nature 391:773–775

Noviyanto A, Yoon DH (2013) Rare-earth oxide additives for the sintering of silicon carbide. Diam Relat Mater 38:124–130

Bahrami A, Pech-Canul MI, Gutierrez CA et al (2015) Wetting and reaction characteristics of crystalline and amorphous SiO2 derived rice-husk ash and SiO2/SiC substrates with Al-Si-Mg alloys. Appl Surf Sci 357:1104–1113

Barin I (1989) Thermochemical data of pure substance, VCH, New York, pp 21–31. https://doi.org/10.1002/9783527619825

Barin I (1989) Thermochemical data of pure substance, VCH, New York, pp 33–34 https://doi.org/10.1002/9783527619825

Feng D, Ren Q, Ru H et al (2019) Effect of oxygen content on the sintering behaviour and mechanical properties of SiC ceramics. Ceram Int 45:23984–23992

Jia Q, Zhang H, Li S et al (2007) Effect of particle size on oxidation of silicon carb-ide powders. Ceram Int 33:309–313

Vaben R, Stöver D (1994) Oxidation of ultrafine (Si-) SiC powders. J Mater Sci 29:3791–3796

Majumdar P, Singh SB, Chakraborty M et al (2008) Elastic modulus of biomedical titanium alloys by nano-indentation and ultrasonic techniques—a comparative study. Mat Sci Eng A Struct 489:419–425

Laugier MT (1987) New formula for indentation toughness in ceramics. J Mater Sci Lett 6:355–356. https://doi.org/10.1007/BF01729352

Anstis GR, Chantikul P, Lawn BR et al (1981) A critical evaluation of indentation techniques for measuring fracture toughness. I. Direct crack measurements. J Am Ceram Soc 64:533–538

Kim YH, Kim YW, Kim KJ et al (2019) Electrically conductive SiC ceramics processed by pressureless sintering. Int J Appl Ceram Tec 16:843–849

Grosso D, Sermon PA et al (2000) Scandium oxide nanoparticles produced from sol-gel chemistry. J Mater Chem C 10:359–363. https://doi.org/10.1039/A906000F

King SW, Bielefeld J, French M et al (2011) Mass and bond density measurements for PECVD a-SiCx: H thin films using Fourier transform-infrared spectroscopy. J Non Cryst Solids 357:3602–3615

Zhang Y, Sun W, Li Z (2008) Infrared spectroscopy study of structural nature of geopolymeric products. J Wuhan Univ Technol 23:522–527

Pujar VV, Cawley JD (1995) Effect of stacking faults on the X-ray diffraction profiles of beta-SiC powders. J Am Ceram Soc 78:774–782

Dubey RS, Rajesh YBRD, More MA (2015) Synthesis and characterization of SiO2 nanoparticles via sol-gel method for industrial applications. Mater Today Proc 2:3575–3579

Yadav D, Bura N, Bhoriya A et al (2021) Estimation of anharmonic parameters of nano-crystalline Sc2O3 and Nd2O3. Mater Today Commun 29:102759

Malinge A, Coupé A, Le PY et al (2012) Pressureless sintering of beta silicon carbide nanoparticles. J Eur Ceram Soc 32:4393–4400

Liu WL, Li Q, Yang XL et al (2020) Synthesis and characterization of N-Doped SiC powder with enhanced photocatalytic and photoelectrochemical performance. Catalysts 10:769

Jin HB, Cao MS, Zhou W et al (2010) Microwave synthesis of Al-doped SiC powders and study of their dielectric propertie. Mater Res Bull 45:247–250

Castillo-Rodriguez M, Munoz A, Dominguez RA (2006) Effect of atmosphere and sintering time on the microstructure and mechanical properties at high temperatures of α-SiC sintered with liquid phase Y2O3-Al2O3. J Eur Ceram Soc 26:2397–2405

Malik R, Kim HM, Kim YW et al (2018) Grain-growth-induced high electrical conductiv-ity in SiC-BN composites. Ceram Int 44:16394–16399

Seo YK, Kim YW, Kim KJ et al (2016) Electrically conductive SiC-BN composites. J Eur Ceram Soc 36:3879–3887

Cho TY, Kim YW, Kim KJ (2016) Thermal, electrical, and mechanical properties of pres-sureless sintered silicon carbide ceramics with yttria-scandia-aluminum nitride. J Eur Ceram Soc 36:2659–2665

Jang SH, Kim YW, Kim KJ (2016) Effects of Y2O3-RE2O3 (RE = Sm, Gd, Lu) additives on electrical and mechanical properties of SiC ceramics containing Ti2CN. J Eur Ceram Soc 36:2997–3003

Li Z, Bradt RC et al (1986) Thermal expansion of the cubic (3C) polytype of SiC. J Mater Sci 21:4366–4368

Kim SH, Fisher CAJ, Nagashima N et al (2023) Self-healing behavior of Sc2Si2O7/SiC composites for environmental barrier coatings. Ceram Int 49:24268–24275

Kim KJ, Cho TY, Kim YW et al (2015) Electrical and thermal properties of silicon carb-ide-boron nitride composites prepared without sintering additives. J Eur Ceram Soc 35:4423–4429

Rezapour A, Balak Z (2020) Fracture toughness and hardness investigation in ZrB2-SiC-ZrC composite. Mater Chem Phys 241:122284

Yagi H, Yanagitani T, Numazawa T et al (2007) The physical properties of transparent Y3Al5O12 elastic modulus at high temperature and thermal conductivity at low temperature. Ceram Int 33:711–714

Kim KJ, Malik R, Park J et al (2020) Effects of M2O3-Y2O3 (M=Sc and Al) additives on electrical conductivity of hot-pressed SiC ceramics. Ceram Int 46:5454–5458

Suzuki Y, Morgan PED, Niihara K (1998) Improvement in mechanical properties of powder-processed MoSi2 by the addition of Sc2O3 and Y2O3. J Am Ceram Soc 81:3141–3149

Liu EK, Zhu BS, Luo JS (2017) The physics of semiconductors. Publishing House of Electronics industry, Beijing

Acknowledgements

The authors appreciate the financial support from the National Natural Science Foundation of China (Grant numbers: 52005445, 52175368, 52375391, and 52105162), Natural Science Foundation of Zhejiang Province (Grant number: LQ21E050018), China Postdoctoral Science Foundation (Grant number: 2022M712820), and China National Nuclear Corporation Young Talent Scientific Research Project (JT233).

Author information

Authors and Affiliations

Contributions

HL contributed to formal analysis, methodology, and writing—original draft. FY, ZL, and WS contributed to investigation. LW, HH, and JY contributed to writing—review and editing. YW and YZ contributed to resource. CL contributed to data curation. YL contributed to formal analysis.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Yang, F., Luo, Z. et al. Low-temperature fabrication of conductive SiC ceramics using SiO2-coated SiC nanopowder with Sc2O3 additive by spark plasma sintering. J Mater Sci 59, 15149–15167 (2024). https://doi.org/10.1007/s10853-024-10086-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-10086-9