Abstract

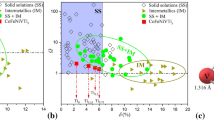

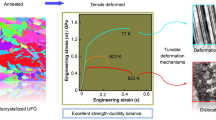

High-entropy alloys (HEAs) with a face-centered cubic (FCC) structure have recently received significant attention due to their outstanding ductility and fracture toughness. In this study, the effects of Ti addition and annealing on the microstructures and mechanical properties of CoCrFeMnNi HEAs were investigated. Two CoCrFeMnNiTix (x = 0 and 0.2, named Ti-0 and Ti-0.2) HEAs were prepared by arc melting, followed by homogenization, cold rolling and annealing at 800 °C and 900 °C, respectively, for 1 h. The microstructure evolution, crystallographic texture and mechanical properties were studied. It was found that the Ti-0 alloy exhibited a single-phase FCC solid solution, while Cr-rich σ phase and (Ni, Co)3Ti η phase precipitated in the Ti-0.2 alloy after annealing. With the precipitation of the hard yet brittle σ and η phases, the yield strength and hardness of Ti-0.2 alloy increased significantly but with the sacrifice in the tensile elongation. The contributions of intrinsic strength, solid solution, grain size and precipitation strengthenings to the tensile yield strength were calculated and compared with measurements. Both grain boundary strengthening and precipitation strengthening were the main strengthening mechanisms for the Ti-doped CoCrFeMnNi HEAs.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

Data will be made available upon reasonable request.

References

Cantor B, Chang ITH, Knight P, Vincent AJB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375–377:213–218. https://doi.org/10.1016/j.msea.2003.10.257

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448–511. https://doi.org/10.1016/j.actamat.2016.08.081

Tsai MH, Yeh JW (2014) High-entropy alloys: a critical review. Mater Res Lett 2:107–123. https://doi.org/10.1080/21663831.2014.912690

Gludovatz B, George EP, Ritchie RO (2015) Processing, microstructure and mechanical properties of the CrMnFeCoNi high-entropy alloy. JOM 67:2262–2270. https://doi.org/10.1007/s11837-015-1589-z

Li WD, Xie D, Li DY, Zhang Y, Gao YF, Liaw PK (2021) Mechanical behavior of high-entropy alloys. Prog Mater Sci 118:100777. https://doi.org/10.1016/j.pmatsci.2021.100777

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6:299–303. https://doi.org/10.1002/adem.200300567

Abuzaid W, Sehitoglu H (2017) Critical resolved shear stress for slip and twin nucleation in single crystalline FeNiCoCrMn high entropy alloy. Mater Charact 129:288–299. https://doi.org/10.1016/j.matchar.2017.05.014

Nohring WG, Curtin WA (2018) Cross-slip of long dislocations in FCC solid solutions. Acta Mater 158:95–117. https://doi.org/10.1016/j.actamat.2018.05.027

Kireeva IV, Chumlyakov YI, Pobedennaya ZV, Vyrodova AV, Kuksgauzen IV, Kuksgauzen DA (2018) Orientation and temperature dependence of a planar slip and twinning in single crystals of Al0.3CoCrFeNi high-entropy alloy. Mater Sci Eng A 737:47–60. https://doi.org/10.1016/j.msea.2018.09.025

Lin QY, Liu JP, An XH, Wang H, Zhang Y, Liao XZ (2018) Cryogenic-deformation-induced phase transformation in an FeCoCrNi high-entropy alloy. Mater Res Lett 6:236–243. https://doi.org/10.1080/21663831.2018.1434250

Stepanov N, Tikhonovsky M, Yurchenko N, Zyabkin D, Klimova M, Zherebtsov S, Efimov A, Salishchev G (2015) Effect of cryo-deformation on structure and properties of CoCrFeNiMn high-entropy alloy. Intermetallics 59:8–17. https://doi.org/10.1016/j.intermet.2014.12.004

Zaddach AJ, Scattergood RO, Koch CC (2015) Tensile properties of low-stacking fault energy high-entropy alloys. Mater Sci Eng A 636:373–378. https://doi.org/10.1016/j.msea.2015.03.109

Li WD, Liaw PK, Gao YF (2018) Fracture resistance of high entropy alloys: a review. Intermetallics 99:69–83. https://doi.org/10.1016/j.intermet.2018.05.013

Brechtl J, Feng R, Liaw PK, Beausir B, Jaber H, Lebedkina T, Lebyodkin M (2023) Mesoscopic-scale complexity in macroscopically-uniform plastic flow of an Al0.3CoCrFeNi high-entropy alloy. Acta Mater 242:118445. https://doi.org/10.1016/j.actamat.2022.118445

Wang XD, Bai WL, Zhang Z, Wang ZB, Ren XC (2023) Enhanced fatigue resistance of a face-centered-cubic single-phase AlCoCrFeNi high-entropy alloy through planar deformation characteristic. Mater Sci Eng A 862:144499. https://doi.org/10.1016/j.msea.2022.144499

Yoosefan F, Ashrafi A, Vaghefi SMM (2024) Corrosion and tribological behavior of CoCrFeMoNi high-entropy alloys as a potential vascular implant material. J Alloy Compd 976:172964. https://doi.org/10.1016/j.jallcom.2023.172964

Zhang Y (2023) High-Entropy materials : advances and applications. CRC Press, Boca Raton. https://doi.org/10.1201/9781003319986

Wang C, Li TH, Liao YC, Li CL, Jang JSC, Hsueh CH (2019) Hardness and strength enhancements of CoCrFeMnNi high-entropy alloy with Nd doping. Mater Sci Eng A 764:138192. https://doi.org/10.1016/j.msea.2019.138192

Stepanov ND, Shaysultanov DG, Salishchev GA, Tikhonovsky MA, Oleynik EE, Tortika AS, Senkov ON (2015) Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J Alloy Compd 628:170–185. https://doi.org/10.1016/j.jallcom.2014.12.157

Qin G, Chen RR, Zheng HT, Fang HZ, Wang L, Su YQ, Guo JJ, Fu HZ (2019) Strengthening FCC-CoCrFeMnNi high entropy alloys by Mo addition. J Mater Sci Technol 35:578–583. https://doi.org/10.1016/j.jmst.2018.10.009

Chen RR, Qin G, Zheng HT, Wang L, Su YQ, Chiu YL, Ding HS, Guo JJ, Fu HZ (2018) Composition design of high entropy alloys using the valence electron concentration to balance strength and ductility. Acta Mater 144:129–137. https://doi.org/10.1016/j.actamat.2017.10.058

Campari EG, Casagrande A, Colombini E, Gualtieri ML, Veronesi P (2021) The effect of Zr addition on melting temperature, microstructure, recrystallization and mechanical properties of a Cantor high entropy alloy. Materials 14:5994. https://doi.org/10.3390/ma14205994

Zhuang YX, Zhang XL, Gu XY (2018) Effect of molybdenum on phases, microstructure and mechanical properties of Al0.5CoCrFeMoxNi high entropy alloys. J Alloy Compd 743:514–522. https://doi.org/10.1016/j.jallcom.2018.02.003

Zhang MD, Zhang LJ, Liaw PK, Li G, Liu RP (2018) Effect of Nb content on thermal stability, mechanical and corrosion behaviors of hypoeutectic CoCrFeNiNbx high-entropy alloys. J Mater Res 33:3276–3286. https://doi.org/10.1557/jmr.2018.103

Song R, Ponge D, Raabe D (2005) Improvement of the work hardening rate of ultrafine grained steels through second phase particles. Scripta Mater 52:1075–1080. https://doi.org/10.1016/j.scriptamat.2005.02.016

Guo LY, Lu YC, Hsueh CH (2023) Effects of Erbium addition on microstructure and mechanical properties of CoCrNi medium entropy alloy. J Mater Eng Perform. https://doi.org/10.1007/s11665-023-08317-2

Lin YS, Lu YC, Hsueh CH (2023) Strengthening of CoCrNi medium entropy alloy with gadolinium additions. Vacuum 211:111969. https://doi.org/10.1016/j.vacuum.2023.111969

Chan SN, Hsueh CH (2022) Effects of La addition on the microstructure and mechanical properties of CoCrNi medium entropy alloy. J Alloy Compd 894:162401. https://doi.org/10.1016/j.jallcom.2021.162401

Hong XW, Hsueh CH (2022) Effects of yttrium addition on microstructures and mechanical properties of CoCrNi medium entropy alloy. Intermetallics 140:107405. https://doi.org/10.1016/j.intermet.2021.107405

Lee D, Agustianingrum MP, Park N, Tsuji N (2019) Synergistic effect by Al addition in improving mechanical performance of CoCrNi medium-entropy alloy. J Alloy Compd 800:372–378. https://doi.org/10.1016/j.jallcom.2019.06.005

Chang H, Zhang TW, Ma SG, Zhao D, Xiong RL, Wang T, Li ZQ, Wang ZH (2021) Novel Si-added CrCoNi medium entropy alloys achieving the breakthrough of strength-ductility trade-off. Mater Design 197:109202. https://doi.org/10.1016/j.matdes.2020.109202

Chang RB, Fang W, Bai X, Xia CQ, Zhang X, Yu HY, Liu BX, Yin FX (2019) Effects of tungsten additions on the microstructure and mechanical properties of CoCrNi medium entropy alloys. J Alloy Compd 790:732–743. https://doi.org/10.1016/j.jallcom.2019.03.235

Cui P, Ma YM, Zhang LJ, Zhang MD, Fan JT, Dong WQ, Yu PF, Li G, Liu RP (2018) Effect of Ti on microstructures and mechanical properties of high entropy alloys based on CoFeMnNi system. Mater Sci Eng A 737:198–204. https://doi.org/10.1016/j.msea.2018.09.050

Shun TT, Chang LY, Shiu MH (2012) Microstructures and mechanical properties of multiprincipal component CoCrFeNiTix alloys. Mater Sci Eng A 556:170–174. https://doi.org/10.1016/j.msea.2012.06.075

Ye XC, Wang T, Xu ZY, Liu C, Wu HH, Zhao GW, Fang D (2020) Effect of Ti content on microstructure and mechanical properties of CuCoFeNi high-entropy alloys. Int J Miner Metall 27:1326–1331. https://doi.org/10.1007/s12613-020-2024-1

Shahmir H, Nili-Ahmadabadi M, Shafiee A, Andrzejczuk M, Lewandowska M, Langdon TG (2018) Effect of Ti on phase stability and strengthening mechanisms of a nanocrystalline CoCrFeMnNi high-entropy alloy. Mater Sci Eng A 725:196–206. https://doi.org/10.1016/j.msea.2018.04.014

Qin G, Li ZB, Chen RR, Zheng HT, Fan CL, Wang L, Su YQ, Ding HS, Guo JJ, Fu HZ (2019) CoCrFeMnNi high-entropy alloys reinforced with Laves phase by adding Nb and Ti elements. J Mater Res 34:1011–1020. https://doi.org/10.1557/jmr.2018.468

Yamanaka S, Ikeda K, Miura S (2021) The effect of titanium and silicon addition on phase equilibrium and mechanical properties of CoCrFeMnNi-based high entropy alloy. J Mater Res 36:2056–2070. https://doi.org/10.1557/s43578-021-00251-0

Zamani MR, Mirzadeh H, Malekan M, Weissensteiner I, Roostaei M (2023) Unveiling the strengthening mechanisms of as-cast micro-alloyed CrMnFeCoNi high-entropy alloys. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2023.170443

Eissmann N, Mühle U, Gaitzsch U, Walther G, Weissgärber T, Kieback B (2021) Precipitation hardening of high entropy alloy CoCrFeMnNi containing titanium. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2020.157610

Chen YH, Liu WK, Wang HW, Xie JL, Zhang TM, Yin LM, Huang YD (2022) Effect of Ti content on the microstructure and properties of CoCrFeNiMnTi high entropy alloy. Entropy. https://doi.org/10.3390/e24020241

Mizushima S, Ichishima I (1966) The nature of the metallic bond. III Proc Jpn Acad 42:913–918. https://doi.org/10.2183/pjab1945.42.913

Hsieh CC, Wu W (2012) Overview of intermetallic Sigma (σ) phase precipitation in stainless steels. ISRN Metall 2012:732471. https://doi.org/10.5402/2012/732471

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46:2817–2829. https://doi.org/10.2320/matertrans.46.2817

Cai YC, Zhu LS, Cui Y, Shan MD, Li HJ, Xin Y, Han J (2021) Fracture and wear mechanisms of FeMnCrNiCo + x(TiC) composite high-entropy alloy cladding layers. Appl Surf Sci 543:148794. https://doi.org/10.1016/j.apsusc.2020.148794

Du LF, Yang SM, Zhang P, Du HL (2018) Pinning effect of different shape second-phase particles on grain growth in polycrystalline: numerical and analytical investigations. Compos Interface 25:357–368. https://doi.org/10.1080/09276440.2018.1439625

Yang X, Zhao ZY, Bai PK, Du WB, Wang SW (2022) EBSD investigation on the microstructure of Ti48Al2Cr2Nb alloy hot isostatic pressing formed by selective laser melting (SLM). Mater Lett 309:131334. https://doi.org/10.1016/j.matlet.2021.131334

Liu G, Wang C, Han ZH, Miao XL, Liu XW, Yang X, Wang ZJ, Zhang GJ (2022) Serrated flow stress and nano-precipitation in (CoCrFeNi)94Ti2Al4 high entropy alloy. Intermetallics 141:107429. https://doi.org/10.1016/j.intermet.2021.107429

Li ZY, Fu LM, Peng J, Zheng H, Ji XB, Sun YL, Ma S, Shan AD (2020) Improving mechanical properties of an FCC high-entropy alloy by γ’ and B2 precipitates strengthening. Mater Charact 159:109989. https://doi.org/10.1016/j.matchar.2019.109989

Klimova MV, Shaysultanov DG, Zherebtsov SV, Stepanov ND (2019) Effect of second phase particles on mechanical properties and grain growth in a CoCrFeMnNi high entropy alloy. Mater Sci Eng A 748:228–235. https://doi.org/10.1016/j.msea.2019.01.112

Klimova MV, Shaysultanov DG, Chernichenko RS, Sanin VN, Stepanov ND, Zherebtsov SV, Belyakov AN (2019) Recrystallized microstructures and mechanical properties of a C-containing CoCrFeNiMn-type high-entropy alloy. Mater Sci Eng A 740–741:201–210. https://doi.org/10.1016/j.msea.2018.09.113

Maier-Kiener V, Schuh B, George EP, Clemens H, Hohenwarter A (2017) Nanoindentation testing as a powerful screening tool for assessing phase stability of nanocrystalline high-entropy alloys. Mater Design 115:479–485. https://doi.org/10.1016/j.matdes.2016.11.055

Zhao YY, Chen HW, Lu ZP, Nieh TG (2018) Thermal stability and coarsening of coherent particles in a precipitation-hardened (NiCoFeCr)94Ti2Al4 high-entropy alloy. Acta Mater 147:184–194. https://doi.org/10.1016/j.actamat.2018.01.049

Zhang LJ, Yu PF, Fan JT, Zhang MD, Zhang CZ, Cui HZ, Li G (2020) Investigating the micro and nanomechanical properties of CoCrFeNi-Cx high-entropy alloys containing eutectic carbides. Mater Sci Eng A 796:140065. https://doi.org/10.1016/j.msea.2020.140065

Kim SJ, Lee CG, Lee TH, Oh CS (2003) Effect of Cu, Cr and Ni on mechanical properties of 0.15 wt.% C TRIP-aided cold rolled steels. Scripta Mater 48:539–544. https://doi.org/10.1016/S1359-6462(02)00477-3

Yan FK, Tao NR, Lu K (2014) Tensile ductility of nanotwinned austenitic grains in an austenitic steel. Scripta Mater 84–85:31–34. https://doi.org/10.1016/j.scriptamat.2014.04.008

Tasan CC, Diehl M, Yan D, Bechtold M, Roters F, Schemmann L, Zheng C, Peranio N, Ponge D, Koyama M, Tsuzaki K, Raabe D (2015) An overview of dual-phase steels: advances in microstructure-oriented processing and micromechanically guided design. Annu Rev Mater Res 45:391–431. https://doi.org/10.1146/annurev-matsci-070214-021103

Daoud HM, Manzoni A, Völkl R, Wanderka N, Glatzel U (2013) Microstructure and tensile behavior of Al8Co17Cr17Cu8Fe17Ni33 (at.%) high-entropy alloys. JOM 65:1805–1814. https://doi.org/10.1007/s11837-013-0756-3

Daoud HM, Manzoni AM, Wanderka N, Glatzel U (2015) High-temperature tensile strength of Al10Co25Cr8Fe15Ni36Ti6 compositionally complex alloy (high-entropy alloy). JOM 67:2271–2277. https://doi.org/10.1007/s11837-015-1484-7

Huo W, Zhou H, Fang F, Xie Z, Jiang J (2017) Microstructure and mechanical properties of CoCrFeNiZrx eutectic high-entropy alloys. Mater Design 134:226–233. https://doi.org/10.1016/j.matdes.2017.08.030

Li P, Wang A, Liu CT (2017) A ductile high entropy alloy with attractive magnetic properties. J Alloy Compd 694:55–60. https://doi.org/10.1016/j.jallcom.2016.09.186

Kang J, Park N, Kim J-K, Park JH (2021) Role of recrystallization and second phases on mechanical properties of (CoCrFeMnNi)95.2Al3.2Ti1.6 high entropy alloy. Mater Sci Eng A 814:141249. https://doi.org/10.1016/j.msea.2021.141249

Jiao ZB, Luan JH, Liu CT (2016) Strategies for improving ductility of ordered intermetallics. Prog Nat Sci-Mater Int 26:1–12. https://doi.org/10.1016/j.pnsc.2016.01.014

Tsai MH, Yuan H, Cheng GM, Xu WZ, Jian WWW, Chuang MH, Juan CC, Yeh AC, Lin SJ, Zhu YT (2013) Significant hardening due to the formation of a sigma phase matrix in a high entropy alloy. Intermetallics 33:81–86. https://doi.org/10.1016/j.intermet.2012.09.022

Zhao YL, Yang T, Zhu JH, Chen D, Yang Y, Hu A, Liu CT, Kai JJ (2018) Development of high-strength Co-free high-entropy alloys hardened by nanosized precipitates. Scripta Mater 148:51–55. https://doi.org/10.1016/j.scriptamat.2018.01.028

Otto F, Dlouhy A, Somsen C, Bei H, Eggeler G, George EP (2013) The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater 61:5743–5755. https://doi.org/10.1016/j.actamat.2013.06.018

Fleischer RL (1963) Substitutional solution hardening. Acta Metall 11:203–209. https://doi.org/10.1016/0001-6160(63)90213-X

Taylor GI (1934) The mechanism of plastic deformation of crystals. Part I.—theoretical. Proc R Soc A 145:362–387. https://doi.org/10.1098/rspa.1934.0106

Chang WC, Hsueh CH (2023) Strengthening of CoCrNi medium entropy alloy with Ti additions. Intermetallics 163:108072. https://doi.org/10.1016/j.intermet.2023.108072

Zhang Z, Chen DL (2006) Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: a model for predicting their yield strength. Scripta Mater 54:1321–1326. https://doi.org/10.1016/j.scriptamat.2005.12.017

Acknowledgements

This work was supported by the National Science and Technology Council, Taiwan under Contract no. NSTC 112-2221-E-002-083.

Author information

Authors and Affiliations

Contributions

Pei-Yu Chen involved in conceptualization, methodology, investigation, and writing—original draft; Chun-Hway Hsueh involved in supervision, writing—review and editing, and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, PY., Hsueh, CH. Effects of Ti addition and annealing on microstructure and mechanical properties of CoCrFeMnNi high-entropy alloy. J Mater Sci 59, 10526–10540 (2024). https://doi.org/10.1007/s10853-024-09790-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09790-3