Abstract

This paper presents experimental ductile fracture data for 2139-T8 aluminum alloy under various stress states for the ultimate purpose of probing the fracture envelope as a function of stress triaxiality and normalized Lode angle. A new ductile fracture model is also proposed and validated by experimental data, along with the evaluation of existing ductile fracture models. The data extracted from published literature on 2024-T351 aluminum alloy was also used as an additional experimental data set for validation. An extensive experimental program was implemented to produce data in a wide range of stress states, including tensile tests (with round smooth, round notched, and plate specimens), torsion, compression (with round smooth and round notched specimens), and shear-compression experiments (two different sizes). The combined effects of stress triaxiality and normalized Lode angle were used to define a 3D fracture envelope for fracture strain. A parallel finite element simulation (fine-tuned by the experimental results) has been performed for each experiment to evaluate the evolution of stress triaxiality and normalized Lode angle in the critical section of the specimens with complex geometries. Finally, these results were used to develop two fracture models whose predictions were compared with some of the existing models.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

Experimental and simulation data are available in the Table 2.

Code availability

No code has been used in analyzing the data. ABAQUS was used to simulate the experiments, which can be found at https://www.3ds.com/products-services/simulia/products/abaqus/.

References

The Aluminum Association Inc. (2006) Registration record series teal sheets—International alloy designations and chemical composition limits for wrought aluminum and wrought aluminum alloys. Arlington, VA

Cho A, Bes B (2006) Damage tolerance capability of an Al–Cu–Mg–Ag alloy (2139). Mater Sci Forum 519–521:603–608. https://doi.org/10.4028/www.scientific.net/msf.519-521.603

Bridgman PW (1952) Studies in large plastic flow and fracture with special emphasis on the effects of hydrostatic pressure, 1st edn. McGraw-Hill, New York

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35(2):363–371. https://doi.org/10.1115/1.3601204

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields∗. J Mech Phys Solids 17(3):201–217. https://doi.org/10.1016/0022-5096(69)90033-7

Roy G, Embury J, Edwards GM, Ashby M (1981) A model of ductile fracture based on the nucleation and growth of voids. Acta Metall 29(8):1509–1522. https://doi.org/10.1016/0001-6160(81)90185-1

Brozzo P, Deluca B, Rendina R (1972) A new method for the prediction of formability limits in metal sheets, sheet metal forming and formability. In: Proceedings of the seventh biennial conference of the international deep drawing research group, Amsterdam, Netherlands

Cockcroft MG, Latham DJ (1968) Ductility and the workability of metals. J Inst Met 96:33–39

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21(1):31–48. https://doi.org/10.1016/0013-7944(85)90052-9

Chaboche J (1981) Continuous damage mechanics—A tool to describe phenomena before crack initiation. Nucl Eng Des 64(2):233–247. https://doi.org/10.1016/0029-5493(81)90007-8

Lemaitre J (1996) A course on damage mechanics. Springer, Berlin

Lemaître J, Desmorat R, Sauzay M (2000) Anisotropic damage law of evolution. Eur J Mech A Solids 19(2):187–208. https://doi.org/10.1016/s0997-7538(00)00161-3

Wierzbicki T, Bao Y, Bai Y (2005) A new experimental technique for constructing a fracture envelope of metals under multi-axial loading. In: Casavant T (ed) Proceedings of the 2005 SEM annual conference & exposition on experimental and applied mechanics. Portland, Oregon, pp 1295–1303

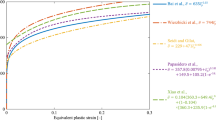

Wierzbicki T, Bao Y, Lee Y, Bai Y (2005) Calibration and evaluation of seven fracture models. Int J Mech Sci 47(4–5):719–743. https://doi.org/10.1016/j.ijmecsci.2005.03.003

Xue L, Wierzbicki T (2008) Ductile fracture initiation and propagation modeling using damage plasticity theory. Eng Fract Mech 75(11):3276–3293. https://doi.org/10.1016/j.engfracmech.2007.08.012

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and Lode dependence. Int J Plast 24(6):1071–1096. https://doi.org/10.1016/j.ijplas.2007.09.004

Mirone G, Corallo D (2010) A local viewpoint for evaluating the influence of stress triaxiality and Lode angle on ductile failure and hardening. Int J Plast 26(3):348–371. https://doi.org/10.1016/j.ijplas.2009.07.006

Bai Y, Wierzbicki T (2009) Application of extended Mohr–Coulomb criterion to ductile fracture. Int J Fract 161(1):1–20. https://doi.org/10.1007/s10704-009-9422-8

Mohr D, Marcadet SJ (2015) Micromechanically-motivated phenomenological Hosford–Coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int J Solids Struct 67–68:40–55. https://doi.org/10.1016/j.ijsolstr.2015.02.024

Lou Y, Chen L, Clausmeyer T, Tekkaya AE, Yoon JW (2017) Modeling of ductile fracture from shear to balanced biaxial tension for sheet metals. Int J Solids Struct 112:169–184. https://doi.org/10.1016/j.ijsolstr.2016.11.034

Šebek F, Petruška J, Kubík P (2018) Lode dependent plasticity coupled with nonlinear damage accumulation for ductile fracture of aluminum alloy. Mater Des 137:90–107. https://doi.org/10.1016/j.matdes.2017.09.064

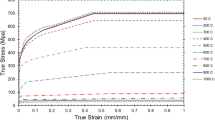

Vural M, Caro J (2009) Experimental analysis and constitutive modeling for the newly developed 2139-T8 alloy. Mater Sci Eng A 520(1–2):56–65. https://doi.org/10.1016/j.msea.2009.05.026

American Society for Testing and Materials (2016) ASTM Standard E8/E8M-16a: test methods for tension testing of metallic materials. https://doi.org/10.1520/E0008_E0008M-16A

Adams CM Jr (1967) Effective ductility in castings and weldments. In: American Society for Metals (ed) Chapter 6, pp 179–197

Rittel D, Lee S, Ravichandran G (2002) A shear-compression specimen for large strain testing. Exp Mech 42(1):58–64. https://doi.org/10.1007/bf02411052

Vural M, Molinari A, Bhattacharyya N (2010) Analysis of slot orientation in shear-compression specimen (SCS). Exp Mech 51(3):263–273. https://doi.org/10.1007/s11340-010-9363-1

Kudo H, Aoi K (1967) Effect of compression test conditions upon fracturing of medium carbon steel. J Japanese Soc Technol Plast 18:17–27

Hollomon JH (1945) Tensile deformation. Met Technol, 268–290

Wilkins ML, Streit R, Reaugh JE (1980c) Cumulative-strain-damage model of ductile fracture: simulation and prediction of engineering fracture tests. https://doi.org/10.2172/6628920

Kamoulakos A, Culière P, Araki T (2003) Prediction of ductile metal rupture with the E-W model in PAM-CRASH. SAE Technical Paper Series. https://doi.org/10.4271/2003-01-2799

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46(1):81–98. https://doi.org/10.1016/j.ijmecsci.2004.02.006

Bao Y (2003) Prediction of ductile crack formation in uncracked bodies. PhD Dissertation, Department of Mechanical Engineering, MIT, U.S.A.

Bai Y (2008) Effect of loading history on necking and fracture. PhD Dissertation, Department of Mechanical Engineering, MIT, U.S.A.

Acknowledgements

Not applicable.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflicts of interest

No conflicts of interest exist.

Ethical approval

Not Applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Calculating stress triaxiality and normalized Lode angle for shear compression specimens with \(\alpha =35.26^\circ \) in the elastic region based on Vural et al. [26].

-

(a)

Shear Compression, Large Gage Width (\(w=t\))

The stress field of shear compression specimen with \(w=t\) has the following form

where \({\sigma }_{zz}=0\) and \({\sigma }_{xx}={\sigma }_{yy}/2\), and since there is no traction along the sides of the gauge section

Therefore,

Also, the deviatoric stress tensor,

-

(b)

Shear Compression, Small Gage Width (\(w<<t\))

In the gauge section of the shear compression specimen with \(w<<t\), the strain tensor has the state of simple shear

And like the previous case, there is no traction along the sides of the gauge section

Therefore,

Also, the deviatoric stress tensor,

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nia, M., Vural, M. Effect of stress triaxiality and normalized Lode angle on ductile fracture of aluminum 2139-T8. J Mater Sci 59, 2155–2178 (2024). https://doi.org/10.1007/s10853-023-09279-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09279-5