Abstract

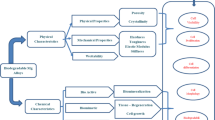

Materials with medical applications must show different properties and requirements, such as mimicking bones' structures and supporting bone tissue formation (osteogenesis) for implants. Magnesium (Mg) alloys as biodegradable materials have recently become outstanding biomaterials because of their desirable properties like being soluble within the body, having low density, exhibiting near-to-natural-bone Young module, and having after-corrosion-based products, which are not only biologically degradable but also non-toxic. In addition to the mentioned properties, the ability to stimulate new bone growth and more outstanding biocompatibility of Mg alloys than other ceramic-based, polymeric, and metallic biomaterials make Mg alloys one of the most favorable biomaterials for the next generation of orthopedic appliances and bioresorbable scaffolds. However, the rapid corrosion rate of Mg results in adverse outcomes such as hydrogen gas release (hydrogen built-up), mechanical integrity loss of the implant before the complete healing of the tissue (premature mechanical integrity disintegration), and weaker mechanical properties, which can limit their more comprehensive applications and restrict their ability in clinical bone restoration has become a challenge needing urgent action. The properties of Mg and its alloys, making them biomaterials and their applications, are introduced thoroughly in this study. At the same time, the most notable drawback of Mg, which is its rapid degradation rate, as well as Mg corrosion classification, its modeling approaches, and in vivo/in vitro testing methods, are fully described. Moreover, the relevant techniques to improve and boost its corrosion resistance, such as purification, adding alloying elements, surface coating, and Mg-based composites, are entirely presented.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A biomaterial is described by Agrawal [1] as “any material used to replace or restore the function of a body tissue and is continuously or intermittently in contact with body fluids”. However, this description does not include the materials used as dental or surgical tools because these devices are in contact with body fluids and are not used as a replacement for human body tissues. For biomaterials exposed to body fluids, there are more strict restrictions, such as being biocompatible, nontoxic, non-allergic, non-inflammatory, non-carcinogenic, and not irritating. Such materials should also exhibit unique physicomechanical features for body tissue replacement or augmentation and withstand the body’s environment [1,2,3].

Orthopedic implants have become a highly demanded market over the last two decades. Such markets were worth over US$94.1 billion in 2012 and grew to US$134.3 billion in 2017. Biomaterials can be categorized into five groups depending on their building materials: metals, composites, polymers, ceramics, and natural biomaterials. Metals (Fe-based, Stainless steel, Zn-based, Ti alloys, Co–Cr alloys, and Mg-based alloys) are mainly used for joint prostheses, medical devices, and load-bearing implants. Still, polymeric biomaterials (PEEK-cHAp) are commonly used in tissue engineering, for instance, for facial prostheses. Although both composites and ceramics can be utilized in the dentistry field and restorative materials, ceramics' poor fracture behavior limits their broader applications. Many other materials that can be used as biomaterials are derived from animals or plants. An example of such natural biomaterials is collagen [2,3,4].

Implants can also be classified into permanent long-term implants within the body and temporary short-term implants that must be removed after the injured part is recovered. Removing short-term implants requires post-surgery that will impose other clinical issues, such as medical cost, pain, and prolonged treatment time. Therefore, a new type of biomaterials known as biodegradable or bioabsorbable materials are required to address these issues [5, 6]. Practically, degradable biomaterials or biodegradable materials and implants can stay temporarily in the human body, supporting the healing process of the damaged tissue, and being dissolved and absorbed or consumed within the body without requiring surgery for the implant removal [7].

Each degradable biomaterial utilized as bone implants needs to provide exceptional properties such as adequate mechanical/tensile/compressive strength, corrosion resistance, fracture toughness, and elastic modulus close to those of natural bones [7, 8]. Such properties have appeared among some types of metallic materials such as Cr, Co, stainless steel, Ti, Mg, and their alloys rather than ceramics, polymers, and bioactive glasses [9]. In addition to the above mechanical properties of biomaterials, their degradability within the human body and the physiological environment during the healing process is of great importance. Such a biodegradation process will affect the tissues' healing time and influence the mechanical integrity and material loss of the replaced biomaterial-based parts during the degradation process [10]. An ideal biomaterial should also exhibit an acceptable level of corrosion resistance so that the concentration of corrosion products does not exceed the level of adequate absorption around body implants [7, 10, 11]. Biosafety and biocompatibility are essential factors that are required to be considered during the designing of biodegradable materials. As the bio-elements are gradually dissolved and absorbed in the body, they should not cause any toxicological issues [4, 8, 12,13,14,15,16].

According to the required properties for biomaterials, Mg alloys are one of the most promising biomaterials. The first application of Mg-based implants dates back to the 1930s for bone surgery. Since then, Mg alloys have been widely used in biomedical applications as materials for bone fixation, cardiovascular stents, and scaffolds for repairing bones. The densities of Mg alloys range between 1.74 and 2.0 g/cm3, which is very close to the density of human bone (1.75 g/cm3). On one side, Mg-based biomaterials are lighter than Ti and Al-based biomaterials; on the other side, Mg’s fracture toughness is much higher than the ceramics-based biomaterials [7, 17,18,19,20,21,22]. The young's modulus and compressive yield stress of Mg are close-to-natural bone (Young modulus for Mg and bone are 45 and 15–30 GPa, respectively) [2]. These properties enhance the stability of Mg-based implants while stimulating bone growth [7, 23, 24]. Moreover, Mg is a non-toxic, abundant element within the human body, which is essential to the body’s metabolism, and helpful in forming biological apatite [25]. Mg can stabilize the DNA and RNA structures by being a co-factor for many human body enzymes. More importantly, Mg and its alloys can entirely go under in vivo degradation within the body, which eliminates the need for a second surgery for their removal [2].

Although lots of the above advantages make Mg a promising biodegradable element, its high corrosion rate in the human body can negatively impact the tissue regeneration process and limit its wide application. Therefore, tuning the degradation rate of Mg-based biomaterials is of high importance [7, 26,27,28]. Understanding the nature of the Mg corrosion process, its classification and testing methods, and modeling it can help overcome the issue of fast corrosion of Mg. Therefore, this review paper focuses on Mg-based biomaterials, the issue of Mg corrosion, and the strategies used to overcome this problem.

Mg corrosion as a biomaterial

Despite some other traditional biomedical materials, like Ti and stainless steel, that Tafel theory defines their corrosion mechanism, the corrosion mechanism of Mg-based biomaterials is complex and needs to be understood entirely. The Tafel equation/theory is an equation in electrochemical kinetics related to the rate of an electrochemical reaction to the overpotential. This theory says that the values of cathodic and anodic partial reaction potentials (the amount of work energy required to leave a unit of electric charge from a reference point to another specific point in an electric field) become equal at the corrosion potential of Ecorr (the characteristic of metal and nonmetal surfaces to lose electrons in the presence of an electrolyte) [29, 30].

Contrary to the Tafel theory, for metals like Mg with highly active corrosion, a rise in the corrosion's potential cause to increases in both anodic and cathodic partial reaction potentials. This is introduced as the Negative Difference Effect (NDE). This phenomenon occurs when the potential of the Mg electrode is more positive, which increases the rate of Mg + formation. So, the hydrogen evolution rate rises instead of decreasing with increased Mg anodic polarization. Therefore, the rate of hydrogen evolution increases instead of falling off, with increasing anodic polarization of the magnesium [29, 31, 32].

Figure 1 and Eq. 1 show how Mg corrosion occurs in aqueous media including SBFs.

The following reactions explain the corrosion of Mg in an aqueous environment:

Mg corrosion in an aqueous media begins with an anodic reaction with Mg losing two electrons. Since electrons during a chemical reaction are neither generated nor destroyed, water (H2O) absorbs the electrons to produce hydrogen gases and hydroxide ions according to the cathodic reaction. Therefore, gas cavities are caused after this step, and the tissue surrounding the environment's pH increases. In the following product reaction, Magnesium hydroxide (Mg(OH)2) as a protective film forms on the Mg surface and prevents it from further ions' migration. As observed in the general reaction equation, each atom of Mg yields one molecule of H2 [19, 33, 34].

Since an alkaline pH shift around the corroded surface is another issue for the Mg-based implants, developing strategies for increasing the Mg and its alloy's corrosion resistance seems essential [29].

Mg corrosion classification

There are three main classifications of Mg and its alloys corrosion [36]:

-

i.

Galvanic corrosion

Before defining galvanic corrosion, explaining the term “Noble Metal” is better. Noble metals are metals resistant to oxidation and corrosion in moist air (unlike many base metals). In contrast to noble metals, some less noble ones are less corrosion-resistant, and Mg is amongst the least noble metals. The galvanic corrosion phenomenon occurs when the two least noble metals with non-similar electrochemical voltages are in contact with each other in a conductive medium. In summary, galvanic corrosion is an electrochemical process in which one metal start to corrode preferentially when it is in electrical contact with another, in the presence of an electrolyte.Therefore, the reason behind this corrosion is the difference between in-contact metal's different electrode potentials.

Different alloying elements can affect the properties of Mg's corrosion, and more information can be found in [37]. Figure 2a, b show the Mg internal and external corrosion schematic.

Figure 2 Schematic of a internal corrosion and b external corrosion. Adapted with permission from reference [36]. Copyright [2020], [MDPI]

-

ii.

Pitting corrosion

The second most conventional class of Mg corrosion is pitting corrosion, a random and severely localized corrosion on the Mg-based alloys' surface. After immersion of Mg-based alloy in an aqueous medium, the passive protective layer of the alloy's surface breaks (de passivation), and shallow pits appear on the metal surface, called pitting corrosion. In other words, Pitting corrosion is a shape of enormously localized corrosion that randomly introduces small holes in Mg.

Theoretically, a neighborhood mobile that ends in the initiation of a pit may be because of an extraordinary anodic site surrounded through an everyday surface, which acts as a cathode, or through the presence of an odd cathodic website online surrounded via a typical floor wherein a pit will have disappeared due to corrosion [36]. In step with Frankel [38], who evaluated pitting corrosion, it develops in 3 successive steps: (a) nucleation (initiation) by the breakdown of the passive film defensive the metallic floor from oxidation (de passivation) for Mg, this layer is Mg(OH)2, (b) increase of metastable pits ((developing as much as the micron scale and then re-passivating), and (c) the boom of larger and stable pits. Figure 3 shows the schematic of pitting corrosion of Mg.

Figure 3 Schematic of Mg pitting corrosion. Adapted with permission from reference [36]. Copyright [2020], [MDPI]

-

iii.

Filiform corrosion

Filiform corrosion is another common (as common as pitting corrosion) corrosion type for Mg and its alloys. It usually coincides with pitting corrosion. It originates from corrosion pits and spreads forward along the active area. It grows by the movement of active corrosive cells through the surface of the metal. Based on scientific reports, this type of corrosion is generally seen under the Mg alloys' protecting coating and anodic oxide layer. Thus, pure Mg with no coatings does not undergo filiform corrosion [40].

-

iV.

Stress Corrosion Cracking (SCC)

Mg alloys and pure Mg have shown they are susceptible to stress corrosion cracking. This type of corrosion depends on different factors, such as the level of the applied force and stress, the alloying elements and their composition, and the surrounding environment. More information regarding the influential factors of Mg' SCC and its two categories [Intragranular stress corrosion cracking (IGSCC) and Transgranular stress corrosion cracking (TGSCC)] can be found in [41, 42]. The former category of the Mg's SCC, IGSCC, is caused by dissolutions that are continuous (a sort of corrosion due forces on the granular boundaries of a metal), and the latter, TGSCC, is caused by cleavage cracks/fractures that are discontinuous (a form of localized corrosion that takes place along cracks or faults throughout the crystals in different metals), shown in Fig. 4 [36]. However, in general, IGSCC is hypothesized into 3 categories. The first is a preferential attack when the \(\alpha\) phase (matrix) is attacked, and the grain boundaries near the cathodic region begin to corrode, leading to tiny surface cracks. Such cracks grow under applied stress. The second category is the occurrence of galvanic corrosion because of the strains leading to the rupture of the passive/protective film and exposing the anodic parts, which results in accelerated corrosion. The third is that IGSCC is initiated because of tunneling, a kind of tubular pitting corrosion. For TGSCC, two modes are reported. The first one is the cleavage fracture that happens due to electrochemical and mechanical effects, which are the initiator of cleavage cracks and their growth. The second one is hydrogen embrittlement due to hydrogen evolution which results in cracks embrittlement and their propagation [41, 43].

Mg corrosion modeling

There are two basic modeling methods to model Mg’s corrosion mechanism. One is the phenomenological approach by which corrosion defects that are externally visual on the metal's surface, including cracks and picks and general corrosion, can be modeled. The basic theory behind this modeling method is the continuum damage one. Another modeling method is physical modeling, primarily used for modeling the implant's uniform corrosion or studying the localized pit growth of tiny samples. Combining the two mentioned modeling methods leads to the creation of the Cellular Automata Corrosion modeling method. Although, to date, this technique has not been studied for corrosion modeling of biodegradable materials, it has the potential to be used for this purpose in the future [36, 45].

Pidaparti et al. [46] employed this method for modeling pitting corrosion that occurred on aircraft made out of Al on a 2D grid. Di Caprio et al. [47] also used a 2D cellular automata model for modeling the combination of pitting and uniform corrosion of metals. The model was the function of 4 parameters, including the one which represents the diffused corrosion side products ratio to the surface standstill portion, the other parameter is the representative of metal corrosion kinetics, the next is λ parameter which is used to distinguish the two corrosion type regions based on their corrosion rates (uniform corrosion region with lower corrosion rate, and the bottom region for pitting corrosion with higher corrosion rate). The last one is \(\varepsilon\), which modulates the corrosion rates in two regions. By keeping the two first parameters constant and tweaking the third and fourth parameters, a model was developed that gave the results which effectively matched the results obtained from experimental work. After the success of this 2D cellular automata model, Di Caprio et al. [48] also expanded it to a 3D one and used it for modeling the intergranular and transgranular corrosion.

-

i.

Phenomenological modeling

As mentioned earlier, this method is based on continuum damage theory. Based on the damage concept, which was first introduced by Lemaitre et al. [49], the discontinuities of the internal geometry (mass loss) over time can be used to calculate the defects and effective stress. Therefore, they introduced a scalar field of D that ranges between 0 and 1 and uses the damage evolution equation to show the status of internal geometry. That is to say, 0 is for the material with no damaged element, and 1 is for the completely damaged component. Based on this concept, researchers could model the damaged materials according to the corrosion types and the materials' characteristics. This modeling of Mg's corrosion can be achieved by modeling the uniform corrosion resulting from the micro-galvanic cells distributed uniformly. It can be modeled using phenomenological modeling technique as well as modeling inevitably pitting corrosion of Mg and its alloys and stress corrosion cracking using the damage evolution theory [49, 50]. More information can be found in [36].

-

ii.

Physical modeling

Despite the excellent match between the experimental data and what resulted from the phenomenological modeling approach, the failure of this method in capturing other aspects of corrosion, such as the interaction among Mg’s dissolving ions, the formation of corrosion products, and dissolution, led to the introduction of physical modeling method. For physical modeling of Mg corrosion becomes achievable, three subcategories of modeling should be considered. The first one is the activation-controlled modeling, which is the function of the potential difference between the material, which is anodic, and the surrounding solution leading to a faster movement of Mg ions than the transformation of Mg into Mg(OH)2 because of an utterly electrochemical reaction, Eq. 2. This modeling method uses the FE method for solving a Laplace formula [36, 51].

$${\text{Mg}} + {\text{2H}}_{{2}} {\text{O}} \to {\text{Mg}}\left( {{\text{OH}}} \right)_{{2}} + {\text{H}}_{{2}}$$(2)

Another sub-modeling approach is transport-controlled modeling. Although corrosion begins at the very early phase with the activation effect, which is the result of the applied potential, corrosion is independent of this effect in the long term, and increasing the voltage does not increase the current anymore. The reason is that after a period of time, passive corrosion products will precipitate on the material's surface and prevent the migration of Mg ions to the surface of the surrounding solution. Moreover, based on the in vivo scenario, the layers of the tissues surrounding the implant prevent the voltage difference from increasing and then reduce the effect of the voltage difference. As a result of the reduced voltage difference effect, species need to flow through the corroded surface and layers deposited on the surface, such as tissue cells or coatings. Therefore, the process of corrosion is considered a transport-controlled one [36, 52].

The next one is coating effect modeling. In order to limit and control the rate of degradation of Mg used as biomaterial inside the human body, Mg is usually coated, alloyed, or goes under mechanical processes. Some coating techniques for enhancing the corrosion resistance of Mg-based biomaterials will be introduced in "Improving the mechanical properties of Mg and it alloys as biomaterials" Section. For modeling the coating effect, the coating is modeled by the diffusivity reduction at the boundaries of the implant using the diffusion equation. This equation is defined as a parabolic partial differential equation and, in physics, describes the macroscopic behavior of micro-particles in Brownian motion (the random motion of particles suspended in a medium, such as liquid or a gas) resulting from the random movements and collisions of the particles. Bajger et al. [51] introduced the equation below, Eq. 3, to calculate the effective diffusivity by considering the product of corrosion is a porous medium [36].

\({D}_{c}^{e}\) is the effective diffusivity of particle c, \(\epsilon\) and \(\tau\) are porosity and tortuosity of the assumed Mg(OH)2 layer and \({D}_{\mathrm{c}}\) is defined as diffusivity of zero corrosion film thickness, that is called free diffusivity. Tortuosity is an intrinsic property of a porous material usually defined as the ratio of actual flow path length to the straight distance between the ends of the flow path [36, 53].

Magnesium corrosion testing methods

For experimental studies, as well as validating and calibrating the corrosion modeling methods, there should be some testing practices for biodegradable metals, especially Mg. The most common and critical experimental practices are summarized below:

-

i.

In vitro testing.

This testing method refers to experimental practices performed in an environment outside the living body. Such an environment is designed as it can simulate the physiological conditions of the human body. For in vitro testing of degradation/corrosion or the toxicity of a biomaterial, a simulated body fluid, such as Hanks’ balanced salt solution (HBSS), is typically used. This solution consists of a balanced mixture of inorganic salts found in the living human body. This kind of testing can also be divided into polarized and un-polarized testing. Each of these testing methods can be split into some other sub-testing ways [36, 54].

Un-polarized testing methods are:

-

1.

Measuring the mass loss (ML): It is a straightforward testing method to evaluate the corrosion rate of a biodegradable material. This method is based on measuring the initial and after-corrosion mass of the samples. First, the sample's mass is measured, then samples are put into an SBF, and after the corrosion occurs, the samples are removed, and their final mass is measured.

Finally, the ML is calculated by Eq. 4:

$${\text{ML}} = \frac{{m_{{\text{i}}} - m_{{\text{f}}} }}{A}$$(4)While mi is the initial mass of the sample, mf is the final mass of the corroded sample, and A is the area that is exposed to SBF [54, 55].

Some advantages reported for this method include its low cost, easy setup, and accurate and well-defined measured data. In contrast to these advantages, this method suffers some limitations, including not providing information related to the mechanism of corrosion and time-dependent corrosion. Multiple samples are also needed to be tested for reliable results [56]. Xu et al. [57] used a physiological saline solution (0.9% NaCl at a pH of 7) as the HBSS solution, and Mg samples were put in it for 30 days. The coated (with steam oxidation and micro-arc oxidation) and uncoated samples' degradation was measured by monitoring the crack propagation. In another study, Yfantis et al. [58], submerging Mg in a neutral pH saline solution, determined the degradation rate by the theory mass loss at the end of 22 days of the testing. The degradation rate results via this method were then compared to another study to the rate established employing an electrochemical corrosion test. They observed that the corrosion rate estimated from the electrochemical corrosion test was 3 to 5 times higher than that computed using ML.

-

2.

Measuring the hydrogen evolution: Since the development of hydrogen gas results from Mg degradation in an aqueous medium, measuring hydrogen evolution is another way of evaluating the corrosion rate. Based on Eq. 2, an interaction between water and 1 mol of Mg results in 1 mol of hydrogen gas. However, because of the difficulties in calculating and capturing all the evolved hydrogen and appropriate adjustment of atmospheric pressure, etc., this method is not as liable as the ML one. Below is the equation used to measure the change between the corroded and non-corroded sample's weight according to the volume of the hydrogen gas that evolved during the degradation.

$$\Delta W=\frac{1\cdot 085{V}_{H}}{{P}_{atm}}$$(5)\(\Delta W\) (mg) is the difference between the weights of corroded and non-corroded Mg sample, VH is the volume of evolved H2 (ml), and Patm is the atmospheric pressure (atm) [36, 59].

Despite some advantages of this low-cost corrosion measurement technique, like providing real-time measuring and monitoring of the corrosion, allowing the alkalization degree measurement, and giving results that are not affected by the corrosion side products, there are some disadvantages associated with this method. Disadvantages of the method include needing multiple samples for accurate results, not having an easy setup, and needing many different considerations, making this method irreproducible compared to other testing methods [56].

-

3.

Measuring the pH number: Mg degradation in aqueous solutions causes an increase in the pH number. Therefore, measuring an increase in the pH may also give some insights into the degradation rates of different metals. However, this method cannot be reliable due to the fact that a pH number equal to 7.4 is essential physiologically for simulating the in vivo environment for Mg corrosion behavior assessment [36, 60]. Like two other previously introduced methods, this technique is also inexpensive. It is straightforward to perform the test and can be used continuously. On the other hand, there are some shortcomings reported for this method. The method needs changes in pH values that are forbidden during in vitro tests and can lead to unrealistic results [56].

Polarized (Electrochemical) testing methods are

-

1.

PotentioDynamic Polarization (PDP): This is the most common polarized testing method for evaluating the samples' degradation rate. This testing method starts with putting samples into an open circuit potential (OCP) with a fully or near to fully steady state. After establishing the OCP, there will be an applied voltage between the Mg and the metal electrode that has been inserted. At first, there will be more negative or cathodic voltage as compared to the OCP value, but in the following steps, there will be a more positive (anodic) shift in the voltage. After about 5 min of testing, some information, such as corrosion potential (Ecorr), the reaction between Mg with both cathodic and anodic voltages, and the density of corrosion current (icorr). By using Faraday’s law, the corrosion rate can be calculated as below:

$${\text{CR}} = 0.00327\frac{{EW \cdot \left( {i_{{{\text{corr}}}} } \right)}}{\rho }$$(6)$${\text{EW}} = \sum \frac{{f_{i} \cdot a_{i} }}{{n_{i} }}$$(7)In these equations, CR is the rate of corrosion (mm/year), and as mentioned above icorr and Ecorr are corrosion current density (μA/cm2) and corrosion potential. (g/cm3) is the density and EW, which is equivalent weight is used for alloys, and are the mass fraction, atomic weight, and the valence electrons number of element i, respectively [36, 61]. A good point of this method is that samples can be used several times as long as they are cleaned from the corrosion products. Moreover, the method’s setup and sample preparation is relatively easy. In contrast, it needs special equipment, considered as its weak point. The method is destructive for Mg alloys since the samples need re-polishing. Converting the test data to the corrosion rate is difficult as it requires different assumptions. Moreover, the PDP method can also affect and change the surface of the sample leading to unrealistic results [56].

-

2.

Electrochemical Impedance Spectroscopy (EIS): This technique uses the response of received frequency from AC polarization and polarizing low-value voltages with different frequencies transmitted in a cyclic pattern between the anodic and cathode peaks. The results are the information regarding the impedance of a subjected to polarization surface. The surface impedance is given as the ratio of the voltage to current, and it has a direct and indirect relation with resistance and corrosion rate, respectively. Therefore, it can be considered an indicator of the degradation rate. Some advantages of this method are: that it is non-destructive for Mg in SBF, one sample can be used several times without reworking it, samples preparation and test setup is approximately easy, it provides real-time measurements of corrosion, employing EIS also provides reliable and repeatable estimations of Mg alloys instantaneous corrosion rate, and finally, it can study the corrosion behavior of high-impedance systems, such as coatings [62]. This method, however, has some main disadvantages, such as difficulties of low-frequency measurement, not providing information regarding anodic/cathodic contributions, difficulties with choosing the most appropriate circuit for analyzing the data and needing previous knowledge of Tafel theory and slopes for converting test data to corrosion rate. It is also susceptible to corrosion that occurs over time [56, 63,64,65,66]. This method is mainly used for measuring the corrosion of the Mg’s coatings. By calculating the B constant for a particular system using Tafel theory, based on Eq. 8, polarization resistance Rp can be calculated by Eq. 9.

$$B=\frac{{b}_{a} \cdot {b}_{c}}{2 \cdot 3({b}_{a}+{b}_{c})}$$(8)$${R}_{p}=\frac{B}{{i}_{corr}}$$(9)\({b}_{a}\) and \({b}_{c}\)are anodic and cathode reactions, respectively [36, 67, 68].

-

ii.

In vivo testing

Another type of corrosion testing method is in vivo testing, which is based on implanting the samples in a natural living body to record their real reactions. For this type of testing, the model organisms are usually rats, mice, and rabbits. After inserting Mg-based biomedical samples in the mentioned animals' bodies, a micro CT scan or X-ray is used to monitor the degradation. Until now, there has not been a recorded relationship between the results of in vivo and in vitro testing methods. Because the former is performed in a real environment and the latter in a simulated solution. A study was done by Xu et al. [57] using in vivo testing on three groups of rats with 5 rats in each group, using the implants made out of 1. Mg, 2. Mg with Sodium montmorillonite, and 3. Mg with an MMVT/brovine serum albumin (BSA) soating showed that uncoated Mg samples had the most degradation and the least bone growth after 12 weeks. The group of Mg-SO showed slightly less degradation and more bone growth. However, the most significant bone growth volume and the most negligible degradation amount belong to the Mg- micro-arc oxidation (MAO) group. Since the animal body is not entirely similar to humans, in vivo testing cannot perfectly gives 100% accurate results. Therefore, the results provide approximate values until the tests are conducted in human clinical trials [1, 36, 69].

Tailoring Mg corrosion rate

In addition to the negative impacts of fast corrosion of Mg and its alloys, introduced previously, an alkaline pH shift around the corroded surface is another issue for Mg-based implants. Therefore, it is essential to develop strategies for increasing the Mg and its alloy's corrosion resistance [70].

Some methods, such as coating/surface modification or adding alloying elements, are among the key strategies in tailoring the Mg corrosion rate. These strategies involve chemical conversion coatings and adding small elements for alloying Mg. In some cases using Severe Plastic Deformation (SPD) methods can also be used to modify the metal microstructure to improve its mechanical properties and corrosion resistance [17, 29, 71, 72].

Surface modifying coating methods

Due to Mg alloys’ low corrosion resistance, different surface coatings have been introduced to improve their bio-stability during in vitro contact in SBF and in vivo exposure to Cl ion-rich Extracellular Fluid (ECF) [29]. Some surface modifying/coating methods used for Mg-based medical devices are but not limited to:

-

i.

Plasma electrolytic oxidation (PEO) is an electrochemical surface treatment method known as micro-arc oxidation (MAO). It is a high-voltage electrochemical process that generates a plasma discharge in the metal-electrolyte interface to convert the substrate surface into a dense, hard ceramic oxide layer. This method does not damage the substrate by thermal expansion [29]. MAO-coated AZ31Mg alloys are one of the most exciting coatings for Mg-based implants, which have recently been studied and investigated by many researchers regarding their effective parameters on the coating properties and the role of added elements (additives) and post-treatments on the residual stresses and rate of corrosion [7]. Figure 5 shows the schematic of this method.

Figure 5 Schematic of MAO method. Adapted with permission from reference [73]. Copyright [2009], [Elsevier]

Gu et al. [74] studied the corrosion behavior of micro-arc oxidation coated AZ31in SBF for almost 28 days. Coatings were prepared in the Sodium Phosphate (Na3PO4) electrolyte at different concentrations of 20, 30, and 40 g/L. Based on the results, HA (Hydroxyapatite) was generated on the corroded samples' surface, which is considered an acceptable biocompatible material. It was shown that optimizing electrolyte concentrations could enhance the coated Mg alloy's corrosion resistance. It was also concluded that a corrosion product layer formed on the surface during the first days of immersion in SBF could then enhance the corrosion resistance in the following days of the test.

-

ii.

Galvanic Anodization is a method of transferring the surface of a non-ferrous metal into a corrosion-resistant, decorative, non-conductive oxide. It is commonly used for Al alloys but can also be applied to other types of metals, such as Ti and Mg [29, 75,76,77]. More information regarding surface modification of Mg using anodization can be found in reference [77], a chapter with the title of “surface modification of Magnesium and its alloys using anodization for orthopedic implant applications”.

-

iii.

Hydrothermal surface modifying coating of a hydroxyapatite layer on Biodegradable magnesium is a practical method to improve corrosion resistance [29]. More information regarding hydroxyapatite can be found in Sect. 4.2. Magnesium hydroxide coating as can offer a long-term protection layer against in vivo/vitro corrosion [29, 78]. Figure 6 shows the different between Mg samples: bare Mg samples and HA-coated Mg samples after 2, 4, 6, 8, and 12 weeks after being implanted.

Figure 6 The difference between the corrosion of coated and bare Mg, after 2, 4, 6, 8, and 12 weeks of implantation. Adapted with permission from reference [79]. Copyright [2014], [Elsevier]

It is clear from this figure that at all times, the HA-coated Mg sample was less attacked by corrosion than the bare Mg sample, which experienced severe corrosion attacks.

-

iv.

Physical Vapor Deposition (PVD) is a widely used method for generating thin films and surface coatings. It is defined as a process in which the material is converted from a condensed phase to a vapor one and then back in the shape of a thin condensed layer [78].

-

v.

Electrophoretic Deposition (EPD) is a widely used and economical method for coating various materials, especially for bio applications. Its most important advantage is creating dense and uniform diverse coatings for biomedical applications. This method is widely used to improve mechanical properties, wear and corrosion resistances, biocompatibility and bioactivity of Mg and its alloys [78].

-

vi.

Electrochemical Deposition (ECD) is similar to EPD. However, in this method, unlike EPD, a chemical bonding method take places in ECD [80].

-

vii.

Pulsed Laser Deposition (PLD) belongs to the group of PVD techniques that uses a laser a laser with high energy concentration to vaporize the different materials. This process is employed where and when other methods have been problematic or have failed to make the deposition [81].

-

viii.

Radio-frequency Magnetron sputtering (r.f.MS) is defined as a physical deposition technique that creates thin, dense, and well-adherent coatings with desired chemistry and crystallinity. Radio-frequency Magnetron sputtering CaP coatings have been commonly used for Ti and its alloys. Recently, there have been some reports regarding using it for Mg and its alloys in the field of biomedical applications [82].

-

ix.

Sol–gel coatings are commonly coated on metallic materials to enhance some of their chemical and mechanical properties due to the structural control at a molecular level. Such coatings have also been one of the methods of eliminating the application of chromates to make conversion coatings or additives for anodizing baths due to health issues for the human body. Recently Sol–gel coatings have been coated on Mg and its alloys to prevent them from corrosion and to enhance their low wear and scratch resistance [83, 84].

-

x.

Other less commonly used coating techniques are cold gas dynamic spraying (CGDS), electrospinning, laser cladding, etc. [29].

Bio-coatings

Calcium phosphate (CaP) coatings

CaP biologically is naturally found in different biological organ, such as teeth and bone. Two inorganic components of biological apatites (CaP) and organic components comprise water and collagen from the bone structure [85, 86].

Calcium phosphates (CaPs), which come in different phases, are one of the most appropriate candidates for being used as Mg-based implant coatings. The beneficial characteristics of CaPs are summarized below [87,88,89]:

-

i.

Similar composition to that of the human bone mineral components.

-

ii.

Bioactivity.

-

iii.

Osteoconductivity for bone/tissue ingrowth.

-

iv.

Strong bonding between the host tissue and CaPs biomaterials.

-

v.

Enhancing bone formation ability.

CaP phases used as bio-coatings are but are not limited to:

vi. Hydroxyapatite is one of the widely used and studied phases of CaPs as bio-coatings (Ca10(PO4)6(OH)2, HA). Although HA could establish itself as a promising coating for improvement of the Mg corrosion scaffolds resistance due to its outstanding biocompatibility and bioactivity as well as close to natural bone properties, its high brittleness and low strength limit its wider use, especially its load-bearing applications. Several techniques are used to deposit HA on metals, such as sol–gel, sputtering, and electrophoretic processes. But due to Mg's poor heat resistance and high-temperature treatment needed during the coating processes, such methods are not appropriate, as mentioned above. Therefore, electrochemical deposition is a useful and practical technique for applying HA on an Mg scaffold. This method does not need high deposition temperature and can deposit uniform coating with controllable thickness and chemical composition on the Mg scaffolds. HA microstructure and its morphology can be controlled via electrolyte and electrochemical potential to improve osteoconductivity and biocompatibility. If the HA coating is loose, the host tissue healing process will be accelerated due to easier bone ingrowth and infiltration. However, despite many benefits of HA coating, in vivo tests have shown that in comparison to other Caps phases, it has slower resorption rates; in other words, it has poor biodegradability [85, 88, 90].

Based on Figure 7, the first day after implantation, the uncoated implant's surface was covered with a small crack network structure, which confirmed degradation due to the corrosion. Fast degradation impaired mechanical parameters and leads to overproduction of hydrogen gas. At the same time, HA-coated alloy has shown a smooth surface without cracks [91].

SEM images of the surface of a, c HA–Mg coatings and b, d Mg-alloys b, d after 1 and 5 days of implantation in bone tissue. Adapted with permission from reference [91]. Copyright [2018], [MDPI]

vii. Tricalcium phosphate (Ca3(PO4)2, TCP) is another phase of CaP used as coating material. Like the HA coating, TCP one shows good bioactivity and biocompatibility. But TCP biodegradability rate is much higher than that of the HA, and it exhibits poor mechanical properties and lower cracks growth propagation resistance. It is found in two phases -TCP and -TCP. The former occurs at temperatures higher than 1250 °C, while the latter is dominant at slightly lower temperatures of 900–1100 °C. -TCP has a hexagonal crystal structure, slow degradation rate, and exhibits better osteoimmunomodulatory characteristics, which evoke the immune system response and consequently accelerate the healing process. In some studies, cell proliferation of human, mouse, and rat osteoblast cells was shown in the presence of this type of coating. According to some investigations, TCP coatings could also prevent infections of ovine cancellous bone defects during the healing process. Some studies also have confirmed the effectiveness of HA and TCP combination [85, 88, 91, 92]. Figure 8 compares the degradation of oxide-coated and TCP one of a Mg scaffold in a rat.

Compressive strength and modulus of elasticity for different Mg-Zn-based alloys. Adapted with permission from reference [124]. Copyright [2016], [Institute of Metals and Technology]

viii. Calcium phosphate dehydrates (CaHPO4.2H2O, CPD, brushite) are the next CaP phase with monoclinic crystals and higher solubility than other phases. It is a cost-effective coating that can be easily applied and deposited on metallic surfaces. However, since it is less stable than HA, it is more often used as a precursor to the HA phase. Since crystal modification of HA is more challenging to obtain than CPD, in most cases, CPD crystal size is modified via homogenous precipitation and then converted to the HA coating. Moreover, when an environment pH exceeds 6–7, the CPD phase becomes unstable and changes into the HA phase. The CPD phase can also be used as an initial component of bone cement. In vivo and in vitro tests of this phase have confirmed its biocompatibility without causing inflammation or infection [85, 88, 94].

ix. Anhydrous calcium phosphate (CaHPO4, ADCP, monetite) is also classified as one of the CaPs phases with triclinic crystals, which is stable at high temperatures and low levels of 4 to 5. Although there are few studies on this phase, some experimental investigations have shown that at higher pH levels of 6–7, this phase becomes unstable and then is converted to a more thermodynamically favorable HA. Based on the number of Ca and P ions released over a period of time, it was confirmed that the ADCP solubility is slightly lower than that of DCP. It is noteworthy to mention here that the more the number of the Ca and P released ions is, the better the osseointegration and osteogenesis will be. Some recent investigations indicate acceptably adherence, differentiation, and spread of human cells on 3D printed ADCP implant after 14–21 days in culture. Another study in which ADCP bone cement was used in a rabbit femoral region confirmed this CaP phase biocompatibility and its osteoconductivity after 21 days [85, 95].

x. Octacalcium phosphate (Ca8H2(PO4)65H2O, OCP) with triclinic structured crystals present in alternating hydrated and apatite layers is the most stable phase at physiological temperatures and pHs. This phase is somehow observed between the HA phase and bone-like apatite. It is experimentally shown that HA cannot be obtained directly from the solution and needs an intermediary stage, which is mostly OCP. OCP has the ability to be converted to bone-like apatite when exposed to an acidic solution and is considered a precursor for the mineralization of bones. Therefore, this phase is established itself as one of the best medical coatings as it can be converted to bone-like apatite in an after-surgical acidic solution and avoid inflammatory. In vitro investigations have confirmed OCP's excellent biocompatibility with less inflammatory reactions as compared to other CaPs phases [85, 96, 97].

xi. And finally, Fluorapatite (Ca10(PO4)6F2, FA), is another CaP phase characterized by several excellent attractive properties, such as biocompatibility, bioactivity, better stability, and antibacterial behavior with high hardness values. FA is a bone and tooth nonorganic substitution material that is used for repair and replacement. In properties such as high chemical and crystal structure stability and low degradation rate, FA outperforms HA. Moreover, FA is able to release fluoride at an under-control rate which is beneficial in stimulating bone formation. The mineral phase of hard tissue includes low but significant portions of fluorine ions, some of which have been replaced with OH− groups in the apatite structure. Examinations have revealed that substitution of OH− with F− could improve mechanical strength, lessen dissolution rates and boost its stability in biological environments. According to some studies, by increasing the levels of F−, hardness, elastic modulus, density, and fracture toughness of FA could be improved [98].

Other bio-ceramic coatings

Some other ceramic coatings can also effectively slow down the degradation rate of Mg alloys. Using Plasma-immersion ion implantation (PIII), a technique of extracting the accelerated ions from the plasma by applying a or pure and targeting them into a suitable or with a semiconductor placed over it, Lin et al. [99] coated ZK60 Mg alloy with a multifunctional TiO2—based nano layer. The in vitro study of the TiO2/MgO layer showed that it increased the corrosion resistance of the implant by controlling the corrosion rate. In vivo tests also indicated that the integrity of the implant as 94% of its volume was maintained after eight weeks of implantation. The improved antimicrobial activity and osteoconductivity of the coated Mg alloy were also reported. Xiong et al. [100] introduced a novel bio-coating of bioactive Ca, Sr/P-containing silk fibroin on the surface of Mg alloy to enhance its corrosion resistance, osteocompatibility, and bone formation and growth.

Alloying elements

Due to Mg's high chemical activity, any impurity or alloying element in its pure or intermetallic form/phase can increase the corrosion rate [101, 102]. Therefore, as found by Song [59], purification can significantly decrease the corrosion rate of pure Mg. Some harmful impurities to the Mg are Fe, Ni, and Cu. If these impurities amount exceeds the tolerance limit, the corrosion rate will remarkably increase [103,104,105]. The manufacturing method and heat treatment for pure Mg can also affect the corrosion rate. For example, forging or rolling can lead to grain refinement, producing higher corrosion-resistant pure Mg. Heat treatment, however, might have both negative and positive effects, as Ren et al. reported an increase in the corrosion resistance of the as forged pure Mg after 10 h of heat treatment at 773 K, while Kuwahara et al. [106] found that the corrosion resistance of 3N-Mg decreased after 25 h of heat treatment at 803 K. Despite the effect of purification and heat treatment, pure Mg's corrosion resistance is still high, and its mechanical properties are low to be used as a biomedical material. Therefore, besides coatings that can protect the Mg-based implants from the effects of the human body environment, alloying Mg with other biocompatible and some metabolically essential elements to the human body and modifying the microstructure of the surface can protect Mg-based implants from in vivo corrosion [20, 107,108,109].

To improve its corrosion behavior, the alloying elements added to Mg must show two main characteristics. First, they must react with Mg so intermetallic phases can be formed, dissolved within the Mg matrix, or distributed along the grain boundaries. Therefore, various degradation rates and varying microstructures can be earned. And the second characteristic of alloying elements is the biocompatibility of the resultant Mg alloy's released ions [110].

The most widely used Mg alloys with biomedical applications are:

-

i.

Mg–Zn-based alloys: Zn is another widely found nutritionally necessary element in the human body and is one of the typical alloying elements in Mg alloys with a 6.2 wt% limitation of solubility. It can effectively enhance Mg’s mechanical properties [107, 111]. Various types of Mg–Zn-based alloys are as follows:

-

1.

Mg–Zn binary alloys: One of these Mg–Zn-based binary alloys is Mg–6Zn which was investigated as a biodegradable alloy by Zhang et al. [112]. The alloy's galvanic corrosion is avoided and shows acceptable mechanical properties concerning biomedical applications. The alloy's in vitro biocompatibility is another reason why this alloy is suitable to be used as a biodegradable material. Biochemical measurements and viscera studies confirmed that Mg-Zn degradation within the body does not harm and affect the critical organs [107, 113, 114].

-

2.

Mg–Zn–Zr, as well as Mg–Zn–Y and Mg–Zn–Zr–Y, are other types of Mg-Zn-based alloys. Adding Y (with 8.0 wt% solubility in Mg) into the Mg-based alloys increases the matrix solubility by enabling the harmful elements to be dissolved into the matrix and decreasing the corrosion rate. Zr is another alloying element commonly used as Mg alloys grain refiner. This element also exhibits well in vivo/vitro biocompatibility. The effect of Y content on Mg–Zn–Y alloy’s tensile strength and corrosion resistance was also studied by Zhang et al. [113]. Based on their results, adding Y content increased the tensile property and elongation. The mass loss of Mg–5.6Zn–0.55Zr–0.9Y was about 1.7% in Gao et al. study after 2424 h in SBF, while for Mg–5.4Zn–0.55Zr, this mass loss was about 3.1% [107].

-

3.

Adding Mn and creating Mg–Zn–Mn alloy: Mn has no toxic effect and plays a critical role in activating multiple enzyme systems. It does not affect the mechanical properties of Mg alloy but significantly improves its resistance to corrosion. According to Zhang et al. [113] study about the effect of Zn amount on properties of Mg–Zn–Mn, by increasing its content from 0 to 3 wt%, the grain size significantly decreases from 12 to 4, and though the mechanical properties enhance remarkably. However, higher content of Zn leads to a significant reduction in elongation because the grains stop decreasing, and therefore the tensile strength cannot be improved more. Based on their study, the best amount of Zn bringing the best anti-corrosion property was 1 wt%. Zhang et al. selected Zn and Mn to study the biocompatibility, mechanical and microstructural properties, and corrosion resistance of Mg–Zn–Mn alloy. Adding Zn alongside the extrusion could significantly refine the grain size of the extruded and as-cast Mg, consequently improving strength and elongation. Zn also accelerates the passive-film formation that can protect Mg against SBF. Although the results showed acceptable cytocompatibility/cytological compatibility (the property of not being harmful to a cell) and no cell toxicity, Mg alloy brought hemolysis to the human blood system. Therefore, surface modification is highly recommended to improve the Mg alloy's blood compatibility [107, 115, 116].

-

4.

Another type of Mg–Zn-based alloy is Mg–Zn–Ca. Having medium content of Zn, which is about 4 wt%, this alloy exhibits the best mechanical properties compared to other types of this alloy family. This alloy’s corrosion resistance reduces as the content of Zn increases. Sun et al. [117] investigated the properties of as-extruded one of the Mg–Zn-based alloys: Mg–4Zn–0.2Ca. According to their results, although after about 30 days of immersion in Simulated Body Fluid (SBF), some properties of the alloy, such as yield and the ultimate tensile strength, elongation, and elastic modulus, decreased, their values were still adequate for bone fixing [107, 118].

-

5.

Both AZ91D and AZ31 are typical examples of Mg–Al–Zn alloys. Adding Al not only results in the modification of the mechanical properties but also can increase corrosion resistance. However, due to the generation of the Mg17 Al12 phase, the increases in the al content in Mg–Zn–Al alloying system can decrease the corrosion resistance; higher Al content in the human body is also harmful to the neurons and osteoblasts [119, 120]. Therefore, there is a need for a carefully controlled Al amount in the Mg-based implant, and compared to other types of Mg alloys, AZ31 has a low content of Al. It is believed to be one of the most appropriate biomedical materials [7, 113, 121,122,123].

Figure 8 shows the differences between the ultimate compressive strength (UCS) and modulus of elasticity (E) for some Mg–Zn-based alloys.

-

ii.

Mg-Si-based alloys are also considered as other types of Mg alloys. The average daily intake of Si for animal-based and plant-based diets ranges between 20 to 50mg, and a small quantity of Si is essential for mammals. It is reported to be necessary for bone growth and connective tissue development. However, because of the coarse grains of Mg2Si, Si solubility in Mg is limited, and the ductility of Mg–1Si is low [125]. Therefore, as introduced by Zhang et al., adding Ca or Zn can lead to refinement and modification of the Mg2Si morphology and, ultimately, improve corrosion resistance and other mechanical characteristics. According to the Zhang et al. [126] study, adding Ca enhances the resistance of Mg–Si to corrosion. However, there was no sign of improvement in elongation and strength of the alloy. By adding Zn, about 1.6 wt%, into Mg–0.6Si, not only the morphology of the Mg2Si was modified, but also its mechanical properties of it, such as tensile strength, corrosion resistance, and elongation, were enhanced [107].

-

iii.

Mg–Sr-based alloys are defined as a group of Mg alloys that uses Strontium. Similar to Ca and Mg, Sr is included in the group of IIA in the periodic table and therefore exhibits similar mechanical, biological, and chemical properties. Most of the Sr in the human body, which is about 140 mg, is stored in the bones and has an effect on stimulating bone growth and formation. It is used as a treatment to increase the mass of the bones and decrease the occurrence of fractures. The results of Gu et al. [60] study showed that alloying Mg with Sr improves the strength of the alloy and reduces the corrosion rate [107, 127].

-

iv.

Mg–Ca–based alloys: Ca is another non-toxic element for the human body, and the simultaneous release of Ca and Mg ions is beneficial for healing bone tissue. Mg is also essential for incorporating Ca into the bone. Therefore, some researchers' attention has been drawn to the Mg–Ca alloying system. Bita et al. [128], for instance, studied the biodegradability of a Mg0.8Ca alloy using immersion tests in various simulated biological mediums. The latter is a widely used basal medium supporting many mammalian cells' growths. Although their results confirmed that Mg-0.8Ca could be a promising biomedical material, they suggested that the alloy's biodegradable rate needs to be enhanced and improved via various strategies, such as coating. Ca also is considered to be beneficial for refining the Mg alloys grains. There is a Ca solubility limitation of 1.34% in Mg, and Mg-Ca alloys mainly include (Mg) and Mg2Ca phase, and by increasing the Ca content more significant number of coarse Mg2Ca phase precipitates around the grain boundaries, which then weakens the as-cast Mg–Ca alloy’s mechanical properties, ductility, and corrosion resistance. The grains are refined by hot rolling/extrusion, and smaller Mg2Ca phase particles enhance the mechanical properties and resistance of Mg–Ca alloy to corrosion [107, 129].

-

v.

Some rare earth elements, classified as Mg–RE-based alloys, are used in Mg alloying and can strengthen and improve corrosion resistance. These elements are Y, La, Sc, Ce, Nd, Pr, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, and Pm. Based on Feyerabend et al. recommendation, if the higher solid solubility of RE elements is the case, Gd and Dy are better than Y. If low solubility is requested, Eu, Nd, and Pr are more suitable. La and Ce are classified to be highly cytotoxic. Some of the widely investigated Mg–RE-based alloys in the field of biomedical usage are Mg–Y, Mg–Gd, and WE43, and among them, WE43 has shown better mechanical properties and corrosion resistance [125, 130, 131]. However, Zhang et al. introduced MG-Nd–Zn–Zr alloy, which showed better properties than WE43 [132,133,134,135].

Improving the mechanical properties of Mg and it alloys as biomaterials

As discussed in previous sections and based on their biomedical applications, Mg and its alloys used as biomaterials must meet favorable mechanical properties under different loadings. Therefore, improving their mechanical characteristics, besides their corrosion resistance, is of great importance.

The methods introduced earlier for improving the corrosion resistance of Mg and its alloys for biomedical applications, such as using coatings and alloying elements, can also be used for enhancing the mechanical properties of Mg-based biomaterials. In addition to those methods, two other approaches can be employed to get better mechanical properties and are briefly discussed in the following.

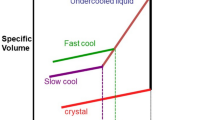

Heat treatment

Heat treatment is another method that can be utilized to improve the properties of materials, especially their mechanical behavior. It belongs to a group of industrial, thermal, and metalworking processes that can change materials', specifically metals’ properties. Heat treatment is used to either make the metal stronger or more malleable, more resistant to abrasion, or more ductile by refining and modifying its microstructure. Therefore, fine-grain and second-phase strengthening are two purposes of using the heat treatment method that can be done by influencing the grain size and its distribution or orientation and the second-phase distribution. It can then change the mechanical characteristics of Mg alloys directly or indirectly. Common heat treatments for Mg and its alloys-based biomaterials are (i). solid solution heat treatment (T4), (ii) aging or precipitation heat treatment (T5), (iii) annealing and (iv) solid solution + ageing heat treatment (T6). Heat treatment is typically an efficient, functional method of improving the mechanical, microstructural, and biodegradable behavior of Mg and its alloys. Heat treatment will influence the microstructure and the second-phase distribution, which in turn, directly and indirectly, affects the mechanical characteristics of Mg alloys [2].

Plastic deformation

When Mg and its alloys undergo plastic deformation processing, their dislocation densities increase, and grains are refined. As the dislocation density rises (the resistance to dislocation movement), Mg and its alloys are strengthened. The most widely used plastic deformation used to improve the mechanical properties of Mg and its alloys are extrusion, rolling, drawing, and forging [136].Moreover, as mentioned earlier, Mg and its alloys are considered suitable options for biomedical applications due to their low density and the young module close to that of the natural bone. However, besides the base material, here Mg, which should be biodegradable and have low density and appropriate mechanical properties, making porous implants with specific open-cell interconnected porous structures would also lead to increased bone cell ingrowth capacity and transportation pathways for body fluids. Therefore, porous bioabsorbable Mg and Mg alloy scaffolds offer new solutions in the field of bio-implants [137].

Porous Mg scaffolds exhibit great potential for being used as a bone substitute, as changing the implant from a solid structure to a porous one can reduce density and make it much closer to that of natural bone. Interconnected pores can also make bone cell ingrowth easier. By controlling the fabrication procedure of porous Mg structures and their porosity, it is also possible to control the structure's strength and strengthen it to be used as an implant [137]. For instance, Yang et al. [138] could increase the yield strength of porous Mg from 8.69 to 27.11 MPa, by decreasing its porosity from 71.1 to 53% using melt-foaming method.

However, porosity is like a double-edged sword. When it is low, it leads to osteogenesis stimulation, whereas when it is high, it results in more significant bone formation. Therefore, high porosity is preferred for more significant osteogenesis and bone ingrowth, but this percentage of porosity will negatively affect the mechanical properties and increase the degradation rate of scaffolds. Thus it is vital to balance the porosity and mechanical properties. Moreover, the number and interconnected pores also remarkably affect the yield strength and Young’s modulus of porous structures [137].

Current and future biomedical applications of Mg and its alloys

As mentioned earlier, the main advantage of Mg over other conventional metals used in biomedical applications is its biodegradability, which eliminates additional surgery for implant removal after completely healing the tissue. Figure 9 compares the degradability of the pin made of Stainless Steel and the screw made of Mg alloy.

A difference between the degradability of a pin made out of Stainless steel and a screw made out of Mg. Adapted with permission from reference [139]. Copyright [2016], [PNAS]

According to Fig. 9, the Mg-based screw started to degrade progressively after it was implanted, while the SS-based pin remained approximately unchanged even 12 months after its implantation [139, 140]. It is reported that the Mg–Ca–Zn-based screw was replaced completely by the generation of new bone within 1 year of implantation [139, 140]. Therefore, Mg can be used for:

-

i.

Orthopedic implant devices Using biomaterials for orthopedic implant devices is one of their significant application. Mg-based implants can replace weight-bearing joints, such as the hip and knees, or some other movable joints, like the shoulder, elbow, and ankle.

-

ii.

Cardiovascular applications The body's cardiovascular or circulatory system consists of the heart and blood vessels responsible for circulating blood. Heart valves and arteries are the main parts of this system that are susceptible to causing problems and can be replaced by artificial bio-implants.

-

iii.

Ophthalmics applications The eye's tissues can suffer from different disorders, resulting in partial vision loss and blindness. The problems within this body system can also be resolved using biomaterials.

-

iv.

Dental applications Bacterially controlled diseases might readily destroy not only the teeth but also the supporting gum tissues. Cavities, demineralization, and teeth dissolution, which cause bacteria to be trapped on the teeth' surface, can lead to extensive tooth loss. Another application of biomaterials is filling the cavities or replacing the entire tooth and its segments.

-

v.

Wound healing applications Implanted biomaterials, such as Mg-based one, which is also one of the essential materials for human body metabolism, can help to stimulate bone and tissue growth.

-

vi.

Drug delivery system Delivering drugs to the targeted tissue is one of the newly emerged fields of using biomaterials. This area needs more study and attempts to incorporate drug reservoirs into biomaterials-based agents for sustained and controlled drug release [88, 141,142,143,144].

Conclusion

Mg and its alloys are the most recently studied materials for developing biodegradable implants due to their inherent properties as desirable mechanical characteristics, near-to-natural-bone young modulus, nontoxicity, biodegradability, biocompatibility, and osteopromotive characteristics. Using Mg as a biomaterial is but not limited to physically replacing hard and soft body tissues that are destroyed or damaged. Mg-based biomaterials can be used either as orthopedic devices or for dental applications, wound healing, and drug delivery systems considered one of the fastest-growing fields of biomaterials applications. Despite their favorable degradability in simulated body fluid, the high corrosion rate of Mg and its alloys is a significant challenge limiting their wider biomedical applications. This paper reviews the corrosion behavior of Mg and its alloys, especially when used as biomaterials. Mg corrosion classification, modeling, and in vivo/in vitro testing methods are briefly discussed, and the solutions for overcoming the rapid corrosion rate of Mg-based biomaterials are introduced.

Although several findings described in this study confirm using Mg and its alloys in clinics to treat illnesses and as implants, because of the complex stress state, plate and screw systems have only been tried in animals, and there is still a lack of enough information regarding in vivo/in vitro testing of Mg. Therefore, more attention should be paid to using different techniques for improving biodegradability, and mechanical properties, such as strength, formability, fracture toughness, fatigue life, corrosion resistance, and other properties of Mg and its alloys as biomaterials.

Data and code availability

Not Applicable

References

Agrawal CM (1998) Reconstructing the human body using biomaterials. JOM 50(1):31–35

Nasr Azadani M et al (2022) A review of current challenges and prospects of magnesium and its alloy for bone implant applications. Prog Biomater 11(1):1–26

Wang X (2013) Overview on biocompatibilities of implantable biomaterials. In: Lazinica R (ed) Advances in biomaterials science and biomedical applications in biomedicine, pp 111–155

Farag MM (2023) Recent trends on biomaterials for tissue regeneration applications: review. J Mater Sci 58(2):527–558

Vahidgolpayegani A et al (2017) Production methods and characterization of porous Mg and Mg alloys for biomedical applications, pp 25–82

Liu S et al (2023) A review of the different fabrication techniques of porous Mg structures considering the effect of manufacturing parameters on corrosion rate and mechanical properties in the bio application. J Mater Sci 58:6556–6579

Zhang L, Zhang J, Chen C-F (2014) Advances in microarc oxidation coated AZ31 Mg alloys for biomedical applications. Corros Sci 91:7–28

Niinomi M (2002) Recent metallic materials for biomedical applications. Metall Mater Trans A 33(3):477–486

Niinomi M, Nakai M, Hieda J (2012) Development of new metallic alloys for biomedical applications. Acta Biomater 8(11):3888–3903

Gu X-N, Zheng Y-F (2010) A review on magnesium alloys as biodegradable materials. Front Mater Sci Chin 4(2):111–115

Hermawan H, Dubé D, Mantovani D (2010) Developments in metallic biodegradable stents. Acta Biomater 6(5):1693–1697

Kuroda D et al (2005) Development of new Ti–Fe–Ta and Ti–Fe–Ta–Zr system alloys for biomedical applications. Mater Trans 46:1532–1539

Ahmadkhaniha D et al (2018) Effect of high-pressure torsion on microstructure, mechanical properties and corrosion resistance of cast pure Mg. J Mater Sci 53(24):16585–16597

Miura K et al (2011) The bone tissue compatibility of a new Ti–Nb–Sn alloy with a low Young’s modulus. Acta Biomater 7:2320–2326

Zhou Y-L, Niinomi M, Akahori T (2008) Changes in mechanical properties of Ti alloys in relation to alloying additions of Ta and Hf. Mater Sci Eng A Struct Mater Prop Microstruct Process 483:153–156

Ikeda M et al (2009) Isothermal aging behavior of beta titanium-manganese alloys. Mater Trans 50:2737–2743

Ahmadi M et al (2022) Review of selective laser melting of magnesium alloys: advantages, microstructure and mechanical characterizations, defects, challenges, and applications. J Market Res 19:1537–1562

Stanciu L, Díaz Amaya S (2022) Biodegradable materials for medical applications, pp 307–346

Eivani AR et al (2021) Applying multi-pass friction stir processing to refine the microstructure and enhance the strength, ductility and corrosion resistance of WE43 magnesium alloy. J Market Res 12:1946–1957

Witte F et al (2008) Degradable biomaterials based on magnesium corrosion. Curr Opin Solid State Mater Sci 12(5):63–72

Witte F (2010) The history of biodegradable magnesium implants: a review. Acta Biomater 6(5):1680–1692

Radha R, Sreekanth D (2017) Insight of magnesium alloys and composites for orthopedic implant applications–a review. J Magnes Alloys 5(3):286–312

Tsn SN, Park IS, Lee MH (2014) Strategies to improve the corrosion resistance of microarc oxidation (MAO) coated magnesium alloys for degradable implants: prospects and challenges. Prog Mater Sci 60:1–71

Nagels J, Stokdijk M, Rozing PM (2003) Stress shielding and bone resorption in shoulder arthroplasty. J Shoulder Elbow Surg 12(1):35–39

Xu T et al (2019) Overview of advancement and development trend on magnesium alloy. J Magnes Alloys 7(3):536–544

Hartwig A (2001) Role of magnesium in genomic stability. Mut Res Fundam Mol Mech Mutagen 475(1):113–121

Okuma T (2001) Magnesium and bone strength. Nutrition 17(7–8):679–680

Saris NE et al (2000) Magnesium. An update on physiological, clinical and analytical aspects. Clin Chim Acta 294(1):1–26

Heimann RB (2021) Magnesium alloys for biomedical application: advanced corrosion control through surface coating. Surf Coat Technol 405:126521

Mei D et al (2020) Selecting medium for corrosion testing of bioabsorbable magnesium and other metals–a critical review. Corros Sci 171:108722

Thomaz TR et al (2010) The negative difference effect of magnesium and of the AZ91 alloy in chloride and stannate-containing solutions. Corros Sci 52:2235–2243

Persaud-Sharma D, McGoron A (2012) Biodegradable magnesium alloys: a review of material development and applications. J Biomim Biomater Tissue Eng 12:25–39

Li T et al (2021) Improved corrosion resistance of Mg alloy by a green phosphating: insights into pre-activation, temperature, and growth mechanism. J Mater Sci 56(1):828–843

Amukarimi S, Mozafari M (2022) Biodegradable Magnesium biomaterials-road to the clinic. Bioengineering 9(3):107

Bita A, Antoniac I, Ion C (2016) Potential use of Mg–Ca alloys for orthopedic applications. UPB Sci Bull Ser B Chem Mater Sci 78:173–184

Abdallah M et al (2020) Corrosion modeling of magnesium and its alloys for biomedical applications: review. Corros Mater Degrad 1:219–248

Song GL, Atrens A (1999) Corrosion mechanisms of magnesium alloys. Adv Eng Mater 1(1):11–33

Frankel G (1998) Pitting corrosion of metals: a review of the critical factors. J Electrochem Soc 145(6):2186

Veleva L, Fernández-Olaya MG, Feliu S (2018) Initial stages of AZ31B magnesium alloy degradation in ringer’s solution: interpretation of EIS, mass loss, hydrogen evolution data and scanning electron microscopy observations. Metals 8(11):933

Rong-Chang Z et al (2018) Chapter 3 Corrosion types of magnesium alloys. In: Tomasz T, Wojciech B, Mariusz K (eds) Magnesium alloys. IntechOpen, Rijeka

Winzer N et al (2005) A critical review of the stress corrosion cracking (SCC) of magnesium alloys. Adv Eng Mater 7(8):659–693

Winzer N et al (2007) Stress corrosion cracking in magnesium alloys: characterization and prevention. JOM 59(8):49–53

Abdalla M et al (2020) Corrosion modeling of magnesium and its alloys for biomedical applications. Corros Mater Degrad 1(2):11

Yoon I-S et al (2019) Corrosion protection method and performance for prestressing strands. HERON 64(1/2):39

Duddu R (2014) Numerical modeling of corrosion pit propagation using the combined extended finite element and level set method. Comput Mech 54:613–627

Pidaparti R, Fang L, Palakal M (2008) Computational simulation of multi-pit corrosion process in materials. Comput Mater Sci 41:255–265

di Caprio D et al (2011) Morphology of corroded surfaces: contribution of cellular automaton modelling. Corros Sci 53(1):418–425

Caprio D et al (2016) 3D cellular automata simulations of intra and intergranular corrosion. Corros Sci 112:438–450

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture

Amerinatanzi A et al (2018) Predicting the biodegradation of magnesium alloy implants: modeling, parameter identification, and validation. Bioengineering 5:105

Bajger P et al (2017) Mathematical modelling of the degradation behaviour of biodegradable metals. Biomech Model Mechanobiol 16:227–238

Scheiner S, Hellmich C (2007) Stable pitting corrosion of stainless steel as diffusion-controlled dissolution process with a sharp moving electrode boundary. Corros Sci 49:319–346

Ghanbarian B et al (2013) Tortuosity in porous media: a critical review. Soil Sci Soc Am J 77:1461

Kirkland N, Birbilis N, Staiger M (2011) Assessing the corrosion of biodegradable magnesium implants: a critical review of current methodologies and their limitations. Acta Biomater 8:925–936

Hou L et al (2014) In vitro and in vivo studies on biodegradable magnesium alloy. Prog Nat Sci Mater Int 24(5):466–471

Kirkland NT, Birbilis N, Staiger MP (2012) Assessing the corrosion of biodegradable magnesium implants: a critical review of current methodologies and their limitations. Acta Biomater 8(3):925–936

Xu H et al (2020) Degradability and biocompatibility of magnesium-MAO: the consistency and contradiction between in-vitro and in-vivo outcomes. Arab J Chem 13(1):2795–2805

Yfantis C et al (2006) In vitro corrosion behavior of new magnesium alloys for bone regeneration. In: Proceedings of the 4th WSEAS international conference on environment, ecosystems and development. Venice, Italy

Song G (2007) Control of biodegradation of biocompatable magnesium alloys. Corros Sci 49(4):1696–1701

Gu X et al (2012) In vitro and in vivo studies on a Mg–Sr binary alloy system developed as a new kind of biodegradable metal. Acta Biomater 8:2360–2374

Shi W et al (2021) A multi-dimensional non-uniform corrosion model for bioabsorbable metallic vascular stents. Acta Biomater 131:572–580

Tkacz J et al (2016) Comparison of electrochemical methods for the evaluation of cast AZ91 magnesium alloy. Materials 9:925

Feliu S Jr (2020) Electrochemical impedance spectroscopy for the measurement of the corrosion rate of magnesium alloys: brief review and challenges. Metals 10(6):775

Esmaily M et al (2017) Fundamentals and advances in magnesium alloy corrosion. Prog Mater Sci 89:92–193

Song G (2005) Recent progress in corrosion and protection of magnesium alloys. Adv Eng Mater 7(7):563–586

Shi Z, Liu M, Atrens A (2010) Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation. Corros Sci 52(2):579–588

De Oliveira LA et al (2021) Influence of anodization on the fatigue and corrosion-fatigue behaviors of the AZ31B magnesium alloy. Metals 11:1573

Tan L et al (2013) Biodegradable materials for bone repairs: a review. J Mater Sci Technol 29(6):503–513

Bütev Öcal E et al (2019) Comparison of the short and long-term degradation behaviors of as-cast pure Mg, AZ91 and WE43 alloys. Mater Chem Phys 241:122350

Eivani AR et al (2023) The effect of multi-pass friction stir processing on microstructure, mechanical properties, and corrosion behavior of WE43-nHA bio-composite. J Market Res 22:776–794

Pahlavani M et al (2021) The role of thickness on the fracture behavior of Al/Mg–Li/Al composite processed by cold roll bonding. Mater Sci Eng A 824:141851

Yang J et al (2023) Microstructural understanding of the oxidation and inter-diffusion behavior of Cr-coated Alloy 800H in supercritical water. Corros Sci 211:110910

Paital S, Dahotre N (2009) Calcium phosphate coatings for bio-implant applications: materials, performance factors, and methodologies. Mater Sci Eng R Rep Mat Sci Eng R 66:1–70

Bandopadhyay S et al (2013) Long-term corrosion inhibition mechanism of microarc oxidation coated AZ31 Mg alloys for biomedical applications. Mater Des 46:66–75

Kosaba T, Muto I, Sugawara Y (2021) Effect of anodizing on galvanic corrosion resistance of Al coupled to Fe or type 430 stainless steel in diluted synthetic seawater. Corros Sci 179:109145

Li JF et al (2006) Preparation and galvanic anodizing of a Mg–Li alloy. Mater Sci Eng A 433(1):233–240

Hamouda MM, Chan Hee P, Cheol Sang K (2017) Chapter 8 surface modification of magnesium and its alloys using anodization for orthopedic implant application. In: Mahmood A (ed) Magnesium alloys. IntechOpen, Rijeka

Rane AV et al (2018) Chapter 5 - methods for synthesis of nanoparticles and fabrication of nanocomposites. In: Mohan Bhagyaraj S et al (eds) Synthesis of inorganic nanomaterials. Woodhead Publishingn, New Delhi, pp 121–139

Dorozhkin S (2014) Calcium orthophosphate coatings on magnesium and its biodegradable alloys. Acta Biomater 10:2919–2934

Augello C, Liu H (2015) Surface modification of magnesium by functional polymer coatings for neural applications. In: Surface modification of magnesium and its alloys for biomedical applications. Elsevier, pp 335–353

Sanka RVSP et al (2019) Metal oxide based nanomaterials and their polymer nanocomposites, pp 123–144

Surmeneva MA et al (2015) Ultrathin film coating of hydroxyapatite (HA) on a magnesium–calcium alloy using RF magnetron sputtering for bioimplant applications. Mater Lett 152:280–282

García Rodríguez S et al (2021) Coating of Mg alloys and composites