Abstract

Protonic ceramic fuel cells (PCFCs) can use hydrogen and hydrocarbon fuels to generate electricity with good performance and anti-cooking resistance. Herein, a novel dual-phase perovskite oxide BaCe0.5Fe0.4Ni0.1O3-δ (BCFN) with BaCe0.5Fe0.5O3-δ (BCF) as one reference was synthesized, characterized and then evaluated as the symmetrical electrodes for PCFCs. Both BCF and BCFN can be self-assembled into an orthorhombic cerium-rich oxide phase and a cubic iron-rich oxide phase after calcined at 1000 °C and show good redox stability. BCFN shows much better electrical conductivity and lower area specific resistance than BCF. Applying BCF and BCFN as symmetrical electrodes for PCFCs with the BaZr0.1Ce0.7Y0.2O3-δ (BZCY) electrolyte supporting, the cell performance with BCFN symmetrical electrode is almost twice (141 mW·cm2 at 700 °C) than those with BCF symmetrical electrode, and the electrode polarization resistances are also reduced from 0.7 to 0.5 Ω·cm2 using humidified H2. The preliminary experimental results can demonstrate that dual-phase perovskite oxides with nanoparticle in situ precipitation are very promising symmetrical electrodes for protonic ceramic fuel cells.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Symmetrical solid oxide fuel cells (SSOFCs) possess a unique configuration by applying the same anode and cathode materials, which can greatly simplify the fabrication technology and improve the thermomechanical compatibility between each component [1,2,3,4]. More importantly, the carbon deposition and sulfur poisoning problems faced by the traditional Ni-based cermet anode can be eliminated by the utilization of SSOFCs configuration. Because the air and fuel gas flow can be reversed owing to the same electrode material, thus the carbon and sulfur particles can be removed [5, 6]. At present, the relatively mature SSOFCs usually use high temperature oxygen ion conductors YSZ or LSGM as electrolyte materials due to their good stability and mechanical property. However, their ionic conductivity is greatly limited at low temperature. For example, SSOFCs with YSZ electrolyte generally operate at over 800 °C in order to reduce the ohmic resistance [7,8,9].

With the aim to maintain the benefits of SSOFCs at reduced working temperature, symmetrical protonic ceramic fuel cells (PCFCs) have come into people’s attention [10, 11]. PCFCs using a proton conducting material as electrolyte and working at 500–700 °C, which have been regarded the one of the most suitable electrochemical devices for energy conversion owing to the high energy efficiency and low activation energy. Compared with the conventional oxygen ion conducting configuration, the production of PCFC (steam) is generated at the cathode side and will not dilute the fuel gas [12]. However, since there is no oxygen ion supplied to anode side of PCFC, excessive carbon monoxide may lead to carbon deposition when using hydrocarbon fuels [13, 14]. To overcome this problem, Duan et al. proposed the anti-coking mechanism of protonic nickel-based cermet anode under the action of hydrogen and oxygen ions, and achieved the outstanding durability at 600 °C in a variety of hydrocarbon fuels [15]. A large amount of steam is provided and participated the fuels reforming processes, as shown in Fig. 1. The mainly reactions occurred at the anode side of PCFC when using ethanol fuel can be expressed as follows:

The high temperature and exothermic oxidation at SOFC anode are not conducive to the forward water–gas shift (2) and will cause the accumulation of CO [16, 17]. Conversely, the low-temperature and endothermic nature of steam reforming in PCFC can further promote the conversion of CH3CH2OH to H2 due to the continuously removable proton from the anode (1) and thus not limited by thermodynamic equilibrium [18, 19]. In addition, the steam reformation reaction of PCFC at low temperature also contributes to the formation of a low CO/CO2 ratio, which hinders the forward progress of the Boudouard reaction and improves the coking tolerance [20].

Ni-based cermet are normally used as anode material for PCFCs. However, Ni-based anodes are prone to the carbon deposition reactions [13, 21]. Recently, perovskite oxide materials have been widely investigated to replace the conventional Ni-based anode owing to their good coking tolerance and good redox cycle stability [22]. However, the lack of metal active centers results in poor catalytic activity and larger anode polarization [23, 24]. BaFeO3-δ (BFO) is a promising parent oxide for SOFC cathodes [25, 26]. The transition metal Fe has variable oxidation and spin states, which potentially contribute high catalytic activity and strong resistance in cathode environment. Meanwhile, the large ionic radius and relatively low divalent state of Ba2+ is favorable toward the creation of more free lattice volume and oxygen vacancies for oxygen transport. Tao et al. have proposed a kind of multiphase composite cathode for PCFC [27]. The precursor BaCe0.5Fe0.5O3-δ (BCF) decomposes at high temperature into two uniformly dispersed and stable perovskite oxides: the main proton conductor phase BaCe0.85Fe0.15O3-δ (BCF8515) and the main electronic conductor phase BaCe0.15Fe0.85O3-δ (BCF). The transportation of protons and electrons in the two phases greatly increases the conductivity and enlarges the three phases boundary. Recently, Chen et al. found that the BCF ceramic membrane shows an extremely high hydrogen permeation flux [28]. Considering the good proton conductivity of iron-doped BaCeO3 system and the low coking tolerance of Ni-cermet anode, BaCe0.5Fe0.5O3-δ (BCF) was synthesized and evaluated as the symmetrical electrode material for PCFCs based on BaZr0.1Ce0.7Y0.2O3-δ (BZCY) electrolyte. In order to further enhance the catalytic activity, Ni was introduced to BCF (BaCe0.5Fe0.4Ni0.1O3-δ, BCFN). The electrochemical performance of the modified symmetrical electrode was systematically investigated.

Experimental

Powder synthesis

BaCe0.5Fe0.5O3-δ and BaCe0.5Fe0.4Ni0.1O3-δ powders were prepared by EDTA-citrate combustion method. Dissolving the stoichiometric proportion of (CH3COO)2Ba, Ce(NO3)3·6H2O, Fe(NO3)3·9H2O and Ni(NO3)2·6H2O in distilled water. Followed by adding nitric acid for combustion-supporting, citric acid and EDTA as complexing agent. Then the PH value was adjusted to 7 by ammonia. After stirring and heating in evaporating dish, the clear solution gradually became viscous gel and then self-sustaining combustion occurred, resulting in light yellow ash. The ashes were calcinated at 1000 °C for 3 h to obtain the pure phase of BCF and BCFN powders. The electrolyte powders of BZCY were also synthesized using the EDTA-citrate combustion method and calcined at 1000 °C for 3 h.

Cell fabrication

The calcined BZCY powders were milled with zirconia balls in ethanol for 12 h. After drying at 70 °C, the BZCY disks with a diameter of 15 mm were fabricated by dry-pressing technology and sintered at 1400 °C for 5 h to achieve densification. A proper amount of BCF or BCFN powder was mixed with 10% ethyl cellulose–terpineol to prepare electrode ink. Then both sides of the electrolyte disks were painted with the electrode ink. The assemblies were calcined at 1000 °C for 3 h to apply symmetrical cells. And the active area in cathode of the single cell is 0.2 cm2.

Characterization and cell measurement

The crystal structure of BCF and BCFN powders was characterized by X-ray diffraction (XRD, DX-2800 diffractometer). In order to compete the measurement of conductivity test, the rectangular BCF and BCFN samples (0.15 × 0.4 × 1.4 mm3) were pressed and then sintered at 1300 °C to achieve densification. The conductivity of electrode was measured by standard DC four-probe method on a digital multimeter (KEITHLEY 2000). The electrochemical performance of the cells was measured by AC impedance spectroscopy workstation (CHI604E, Shanghai Chenhua) with temperature range from 700 to 600 °C. Current density (I)–Voltage (V)–Powder density (P) curves of cells were measured on electrochemical workstation using humidified hydrogen as fuel with an intake flow of 40 mL·min−1. The frequency range of EIS was set to 1 MHz ~ 0.01 Hz with voltage amplitude of 10 mV. The long-term testing of single cells was set with a constant voltage of 0.7 V and recorded the data of running for 100 h. Significantly, the stability performance of the cells with BCFN electrodes was measured on another electrochemical workstation (ZenniumE, Germany) due to the damage on the original instrument. Field emission scanning electron microscopy (SEM) was performed to observe the cross-sectional morphology of single cells.

Results and discussion

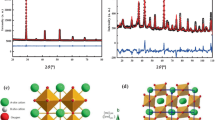

Figure 2a shows the XRD patterns of the pre-calcined BCF and BCFN powders. It can be seen that the prepared precursor powders decomposed into a dual-phase compound which consists of an orthorhombic perovskite phase and a cubic perovskite phase after calcining at high temperature, as Tao et al. reported [27]. In addition, the characteristic peaks of corresponding crystal planes of BCF are clearly observed in BCFN samples. This indicates that the substitution of Ni at the B-site does not affect the formation of the dual-phase compound. Typical (110) peak of BCF which originally observed at 30.75° shifts to a higher angle (30.79°) in BCFN owing to the shrinkage of the crystal cell, further illustrating the replacement of iron ions by nickel ions with a smaller radius [29]. The chemical compatibility of BCF and BCFN electrode with BZCY electrolyte was examined after calcined in air for 5 h under a certain temperature gradient. As shown in Fig. 2a, all the peaks assigned to the perovskite phase corresponding to original electrode materials and BZCY, demonstrating good chemical compatibility. It also indicates that cerium in BZCY would not affect the self-assembly behavior of electrode in the cell structure with BaCO3-based perovskite oxide as both electrode material and electrolyte material. The TEM image shown in Fig. 2b confirms the phase structure of BCFN. The characteristic lattice fringe spacing of the (110) crystal plane of BCFN is 2.93 Å, related to the cubic perovskite structure. The spacing of (211) planes is 3.12 Å, corresponding to the orthorhombic perovskite structure.

a XRD patterns of BCF and BCFN powder calcined at 1000 °C for 3 h and the chemical compatibility between BZCY electrolyte; b The typical HR-TEM images of the as-prepared BCFN sample; XRD patterns of as-synthesized c BCF and d BCFN powder calcined at 1000 °C in air and reduced at different temperature in humidified H2

The phase structure of BCF and BCFN powders treated in humidified H2 was also investigated by the XRD technology. As shown in Fig. 2c, BCF without Ni doping still exhibits only orthorhombic and cubic phases after being reduced at 700 °C for 5 h, which shows excellent redox stability. However, after substituting the Fe sites with fewer Ni ions, the perovskite phase was effectively weakened in Fig. 2d. Moreover, when the reduction temperature reached 650 °C, the additional Fe–Ni alloy peaks appear between 42° and 45° from the XRD patterns of BCFN [30]. It indicates that the in situ formation of Fe–Ni alloy will occur when the operation temperature is higher than 650 °C in H2. These exsoluted alloy particles will inevitably improve the catalytic activity of the anode in a reducing atmosphere, thus affecting the electrochemical performance of the electrode and even the single cell [31,32,33].

Figure 3a shows the electrical conductivity of BCF and BCFN tested from 300 to 800 °C in air. The conductivity shows an upward tendency with the increase of temperature and reaches the maximum value at 550 °C. Then, it becomes to decrease with the further increasing temperature, which has a fairly consistence with the reported results of B-site doped BaFeO3 [34, 35]. The increase of conductivity below 550 °C is attributed to the thermally activated process of small polaron hopping, and the temperature increase significantly promotes the conductivity of BCFN. However, by further increasing the temperature, the formation of oxygen vacancies will accelerate and thus the concentration of electron holes will reduce. Simultaneously, the reduction of high-valent iron ions driven by high temperature will lead to a decrease in carrier concentration [34]. The defect reaction as follows:

By comparing the data in Fig. 3a, it can be seen that the substitution of Ni significantly improved the conductivity. The conductivity of BCFN is about 1.68 S·cm−1 at 550 °C, while BCF is only 0.98 S cm−1 at the same temperature. The low-valence metal nickel doping inhibits the reduction of iron ions and the generation of oxygen vacancies, and at the same time increases the concentration of electron hole, which leads to the improvement of conductivity:

As shown in Fig. 3b, the conductivity of BCF and BCFN in humidified H2 (3% H2O) was also recorded. Unlike the results measured in air, the conductivity of these two samples under hydrogen increases with increasing temperature, showing a thermally activated semiconducting behavior [36]. It is noteworthy that the conductivity in hydrogen atmosphere is much lower than that of air, the conductivities of BCFN at 600 °C are 0.32 S.cm−1 in H2 but 1.62 S.cm−1 in air. This is due to the concomitant reduction of some higher valence cations to lower valence cations to maintain charge neutrality resulted in a decrease in the charge carrier concentration [37]. Similarly, the conductivity in H2 is also greatly improved by replacing part of Fe with Ni. At 550 °C, the conductivity of BCFN is 0.25 S·cm−1, which is almost 50% higher than that of undoped BCF (0.17 S·cm−1).

The impedance spectrum obtained is fitted by an equivalent circuit L-R1 (R2-CPE1) (R3-CPE2). Each arc describes a process that leads to the impedance. R1 is the ohmic resistance consist of electrolyte and other cell components. R2 represents the resistance at high frequency that probably correlated with the transfer of oxygen ions through the electrode/electrolyte interface. R3 is the resistance at low frequency that may related to the surface oxygen exchange of the electrode [38, 39]. For the convenience of comparison, the ohmic resistance (Ro) of the Nyquist plots is reduced to zero to observe the difference between polarized resistance arcs. Shown in Fig. 4a, the area specific resistance (ASR) of BCFN at 700 °C is 0.067 Ω·cm2 and that of BCF is 0.18 Ω·cm2, demonstrating that the oxygen reduction reaction (ORR) performance is enhanced by doping Ni at Fe site. A similar phenomenon was also observed at lower test temperatures. The BCFN in this work exhibited much outperforming ASR values than other proton conducting cobalt-free cathodes, such as La0.5Sr1.5MnO4+δ- La0.5Sr0.5MnO3-δ based on BZCY electrolyte (0.34 Ω·cm2 at 700 °C) [40], Pr1.7Ca0.3NiO4+δ-BaCe0.5Zr0.3Y0.2O3-δ with BaCe0.5Zr0.3Y0.2O3-δ electrolyte (0.28 Ω·cm2 at 700 °C) [39]. It is also lower than some novel Co contained cathodes, such as SrCo0.4Fe0.15Zr0.05O3-δ with BaZr0.1Ce0.7Y0.1Yb0.1O3-δ electrolyte (0.07 Ω·cm2 at 700 °C) [41]. It may due to Ni doping which enhances the conductivity and reduces the charge transfer resistance. The Rp of BCF and BCFN in humidified hydrogen (3% H2O) was also studied. The results show that BCFN has a lower Rp in all temperature ranges, with recorded values of 0.50, 1.09 and 2.69 Ω·cm2 from 700 to 600 °C, respectively. The decrease in Rp of BCFN indicates that the electrocatalytic oxidation ability can also be improved due to the doping of Ni.

Figure 5a–b shows the ASR value of BCF and BCFN from 700 to 600 °C. The change of ASR value with temperature can be intuitively observed. Figure 5c–d shows the Arrhenius plots of the BCF and BCFN in air. The activation energy (Ea) of BCF and BCFN is similar in air. However, the Ea for BCFN cathode is about 1.2 eV in H2, which is much lower than that of BCF (1.5 eV). The data indicated that BCFN electrode has lower potential barriers of reaction and can achieve higher performance at lower temperatures.

Figure 6a shows the voltage–current density characteristics of BZCY-supported symmetrical cells with BCF electrodes tested using wet H2 (3% H2O) as fuel with an intake flow of 40 mL·min−1 and air as oxidation from 700 to 600 °C. The open circuit voltage (OCV) with BCFN is 1.085 V at 700 °C, which is slightly improved than BCF (1.076 V) at same temperature. These values are close to the theoretical voltage due to the highly density of BZCY electrolyte. Peak power densities (Pmax) of 82.7, 60.1 and 28.3 mW·cm−2 at 700, 650 and 600 °C were obtained from single cell with BCF electrode, respectively. As shown in Fig. 6b, corresponding Pmax of single cells with BCFN electrode reached 141, 81.6 and 42.2 mW·cm−2 at 700, 650 and 600 °C, respectively, which is almost twice than those with BCF symmetrical electrode. The long-term testing of single cells with BCF and BCFN symmetrical electrode were also measured in H2 for 100 h as shown in Fig. 6c–d. It can be clearly seen that the current density of both BCF and BCFN cells under test condition for 100 h without obvious degradation, indicating the promising application of BCF and BCFN electrodes in proton conducting SSOFCs. Notably, the abrupt change of the curve at around 60 h in Fig. 6c is due to the split of fuels that change the flow rate into the anode chamber. And the whole system tended to be stable after 7 h.

Shown in Fig. 7a–b is the AC impedance spectroscopy of the single cells with BCF and BCFN symmetrical electrodes. The intercept of the spectrum at high frequency and low frequency represents ohmic resistance (Ro) and total resistance (Rt), respectively. The difference between Rt and Ro represents Rp. As shown in Fig. 7a, the Rp of the cell with BCF electrode was 0.7, 1.7, 4.9 Ω·cm2 at 700, 650 and 600 °C, respectively. And as expected, BCFN exhibited relatively low Rp over the test temperature range with recorded values of 0.5, 1.3 and 3.2 Ω·cm2 at 700, 650 and 600 °C in Fig. 7b, respectively. It indicates that BCFN is a promising cathode material for proton conducting SSOFCs.

The relaxation time distribution (DRT) method was applied to further elaborate the polarization process of BCFN electrode under SOFC mode, as shown in Fig. 7c. Each deconvolution peak reflects one certain electrochemical process based on the high resolution of DRT method. It has been established that the P1 peak is related to the gas diffusion in porous anode. While P2 and P3 peak are corresponding to the oxygen reduction process and incorporation of O2− in the electrolyte lattice, respectively. The diffusion of protons to the electrolyte surface in anode can be represented by P4 [42, 43]. By lowering the test temperature, the rate limiting steps P1-P4 show different trends. The P1, P2 peaks approach the low frequency regions and the P4 peak moves toward high frequencies. In addition, a new polarization peak Padd shows when the temperature drops to 650 °C. The Padd peak represents the hydrogen adsorption/ dissociation process and proton formation reaction on anode [44, 45]. As shown in Fig. 7d, the calculated resistance value of each part at different temperature is expressed as percentages. Obviously, P2 and P3 impedance account for the main proportion of total impedance at 700 °C. As the temperature decreases, the peaks of P2 and P3 gradually separate and the ratio of P2 to P3 increases significantly indicating that the process of oxygen reduction becomes the rate limiting step at lower temperature. As described above, the DRT results reveal that the cathode reaction make a great contribution to the total polarization resistance, which provides a new perspective for further study on the mechanism of proton conducting SSOFC.

The cross-sectional SEM of BCF and BCFN cells after test is shown in Fig. 8. The dense BZCY electrolyte layer is in good contact with the porous electrode layer. And both the BCF and BCFN cathode present a porous structure with inseparably connected particles, which is consistent with the stable ASR value. In addition, BCFN has a smaller grains and finer microstructure than BCF, which is helpful for surface catalytic reaction and ion transport in the electrode. Figure 9 shows the SEM image of the BCFN anode morphology after 100 h of long-term testing. Obviously, plentiful nanoparticles precipitated on the surface of the BCFN anode, and did not destroy the continuous three-dimensional network. According to Fig. 6d, the performance of fuel cell is slightly improved in the first 40 h due to in situ formation of nanoscale particles. Combined with the XRD results in Fig. 2d, it seems that an in situ process of Fe–Ni alloy nanoparticles formation occurs on the BCFN anode. Most of the particles are uniformly dispersed and remain the size of 40 nm although some agglomeration can be seen.

Conclusions

In summary, self-assembled cubic-orthorhombic perovskite nanocomposites with the precursor composition of BaCe0.5Fe0.5O3-δ and BaCe0.5Fe0.4Ni0.1O3-δ were prepared and investigated as symmetrical electrodes for PCFC. The transportation of protons and electrons in the two phases greatly increases the conductivity and enlarges the three phases boundary. The BaCeO3-based electrode and electrolyte materials show good chemical compatibility, which is also the basis for stable long-term operation of the cell. In addition, BCFN shows much better electrical conductivity and lower area specific resistance than BCF, resulting from the partial substitution of Fe with Ni. BCFN exhibits remarkable catalytic activity in air, the ASR of symmetrical cells is only 0.067 Ω·cm−2 at 700 °C. The single cell with BCFN electrode achieves the peak power outputs of 141 mW·cm−2 at 700 °C in H2, which is almost twice than those with BCF symmetrical electrode. The preliminary experimental results can demonstrate that dual-phase perovskite oxides are very promising symmetrical electrodes for protonic ceramic fuel cells.

References

Bian L, Duan C, Wang L, Zhu L, O’Hayre R, Chou K-C (2018) Electrochemical performance and stability of La0.5Sr0.5Fe0.9Nb0.1O3-δ symmetric electrode for solid oxide fuel cells. J Power Sources 399:398–405

Ruiz-Morales JC, Canales-Vázquez J, Ballesteros-Pérez B, Peña-Martínez J, Marrero-López D, Irvine JTS, Núñez P (2007) LSCM–(YSZ–CGO) composites as improved symmetrical electrodes for solid oxide fuel cells. J Eur Ceram Soc 27(13):4223–4227

Vázquez S, Basbus J, Soldati AL, Napolitano F, Serquis A, Suescun L (2015) Effect of the symmetric cell preparation temperature on the activity of Ba0.5Sr0.5Fe0.8Cu0.2O3-δ as cathode for intermediate temperature solid oxide fuel cells. J Power Sources 274:318–323

Zheng Y, Zhang C, Ran R, Cai R, Shao Z, Farrusseng D (2009) A new symmetric solid-oxide fuel cell with La0.8Sr0.2Sc0.2Mn0.8O3-δ perovskite oxide as both the anode and cathode. Acta Mater 57(4):1165–1175

Liu Q, Dong X, Xiao G, Zhao F, Chen F (2010) A novel electrode material for symmetrical SOFCs. Adv Mater 22(48):5478–5482

Su C, Wang W, Liu M, Tadé MO, Shao Z (2015) Progress and prospects in symmetrical solid oxide fuel cells with two identical electrodes. Adv Energy Mater 5(14):1500188

Wachsman ED, Lee KT (2011) Lowering the temperature of solid oxide fuel cells. Science 334(6058):935–939

Ling Y, Yu J, Lin B, Zhang X, Zhao L, Liu X (2011) A cobalt-free Sm0.5Sr0.5Fe0.8Cu0.2O3-δ–Ce0.8Sm0.2O2-δ composite cathode for proton-conducting solid oxide fuel cells. J Power Sources 198(5):2631–2634

Ling Y, Chen H, Niu J, Wang F, Zhao L, Ou X, Nakamur T, Amezawa K (2016) Bismuth and indium co-doping strategy for developing stable and efficient barium zirconate-based proton conductors for high-performance H-SOFCs. J Eur Ceram Soc 36(14):3423–3431

Fabbri E, Bi L, Pergolesi D, Traversa E (2012) Towards the next generation of solid oxide fuel cells operating below 600 °C with chemically stable proton-conducting electrolytes. Adv Mater 24(2):195–208

An H, Lee H-W, Kim B-K, Son J-W, Yoon KJ, Kim H, Shin D, Ji H-I, Lee J-H (2018) A 5 × 5 cm2 protonic ceramic fuel cell with a power density of 1.3 W·cm–2 at 600 °C. Nat Energy 3(10):870–875

Duan C, Kee R, Zhu H, Sullivan N, Zhu L, Bian L, Jennings D, O’Hayre R (2019) Highly efficient reversible protonic ceramic electrochemical cells for power generation and fuel production. Nat Energy 4(3):230–240

Wei K, Wang X, Zhu H, Liu H, Wang S, Chen F, Zhou F, Ling Y (2021) Clean and stable conversion of oxygen-bearing low-concentration coal mine gas by solid oxide fuel cells with an additional reforming layer. J Power Sources 506:230208

Wei T, Qiu P, Jia L, Tan Y, Yang X, Sun S, Chen F, Li J (2020) Power and carbon monoxide co-production by a proton-conducting solid oxide fuel cell with La0.6Sr0.2Cr0.85Ni0.15O3-δ for on-cell dry reforming of CH4 by CO2. J Mater Chem A 8(19):9806–9812

Duan C, Kee RJ, Zhu H, Karakaya C, Chen Y, Ricote S, Jarry A, Crumlin EJ, Hook D, Braun R, Sullivan NP, O’Hayre R (2018) Highly durable, coking and sulfur tolerant, fuel-flexible protonic ceramic fuel cells. Nature 557(7704):217–222

Chen T, Wang WG, Miao H, Li T, Xu C (2011) Evaluation of carbon deposition behavior on the nickel/yttrium-stabilized zirconia anode-supported fuel cell fueled with simulated syngas. J Power Sources 196(5):2461–2468

Authayanun S, Arpornwichanop A, Paengjuntuek W, Assabumrungrat S (2010) Thermodynamic study of hydrogen production from crude glycerol autothermal reforming for fuel cell applications. Int J Hydrogen Energ 35(13):6617–6623

Steil MC, Nobrega SD, Georges S, Gelin P, Uhlenbruck S, Fonseca FC (2017) Durable direct ethanol anode-supported solid oxide fuel cell. Appl Energ 199:180–186

Song W, Ma Z, Yang Y, Zhang S, Ou X, Ling Y (2020) Characterization and polarization DRT analysis of direct ethanol solid oxide fuel cells using low fuel partial pressures. Int J Hydrogen Energ 45(28):14480–14490

Duan C, Tong J, Shang M, Nikodemski S, Sanders M, Ricote S, Almansoori A, O’Hayre R (2015) Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 349(6254):1321–1326

Hua B, Yan N, Li M, Zhang YQ, Sun YF, Li J, Etsell T, Sarkar P, Chuang K, Luo JL (2016) Novel layered solid oxide fuel cells with multiple-twinned Ni0.8Co0.2 nanoparticles: the key to thermally independent CO2 utilization and power-chemical cogeneration. Energ Environ Sci 9(1):207–215

Hibino T, Hashimoto A, Suzuki M, Sano M (2002) A solid oxide fuel cell using Y-doped BaCeO3 with Pd-Loaded FeO anode and Ba0.5Pr0.5CoO3 cathode at low temperatures. J Electrochem Soc 149(11):A1503–A1508

Nasani N, Wang Z-J, Willinger MG, Yaremchenko AA, Fagg DP (2014) In-situ redox cycling behaviour of Ni–BaZr0.85Y0.15O3−δ cermet anodes for protonic ceramic fuel cells. Int J Hydrogen Energ 39(34):19780–19788

An H, Shin D, Ji HI (2019) Effect of nickel addition on sintering behavior and electrical conductivity of BaCe0.35Zr0.5Y0.15O3-δ. J Kor Ceram Soc 56(1):91–97

Watenabe K, Yuasa M, Kida T, Teraoka Y, Yamazoe N, Shimanoe K (2010) High-performance oxygen-permeable membranes with an asymmetric structure using Ba0.95La0.05FeO3−δ perovskite-type oxide. Adv Mater 22(21):2367–2370

Chen C, Baiyee ZM, Ciucci F (2015) Unraveling the effect of la A-site substitution on oxygen ion diffusion and oxygen catalysis in perovskite BaFeO3 by data-mining molecular dynamics and density functional theory. Phys Chem Chem Phys 17(37):24011–24019

Tao Z, Bi L, Zhu Z, Liu W (2009) Novel cobalt-free cathode materials BaCexFe1-xO3-δ for proton-conducting solid oxide fuel cells. J Power Sources 194(2):801–804

Cheng S, Wang Y, Zhuang L, Xue J, Wei Y, Feldhoff A, Caro J, Wang H (2016) A dual-phase ceramic membrane with extremely high H2 permeation flux prepared by autoseparation of a ceramic precursor. Angewandte Chemie - Int Ed 55(36):10895–10898

Zhong M, Feng Q, Yuan C, Liu X, Zhu B, Meng L, Zhou C, Xu J, Wang J, Rao G (2021) Photocurrent density and electrical properties of Bi0.5Na0.5TiO3-BaNi0.5Nb0.5O3 ceramics. J Adv Ceram. https://doi.org/10.1007/s40145-021-0497-7

Du Z, Zhao H, Yi S, Xia Q, Gong Y, Zhang Y, Cheng X, Li Y, Gu L, Świerczek K (2016) High-performance anode material Sr2FeMo0.65Ni0.35O6−δ with In situ exsolved nanoparticle catalyst. ACS Nano 10(9):8660–8669

Adijanto L, Padmanabhan VB, Kungas R, Gorte RJ, Vohs JM (2012) Transition metal-doped rare earth vanadates: a regenerable catalytic material for SOFC anodes. J Mater Chem 22(22):11396–11402

Madsen BD, Kobsiriphat W, Wang Y, Marks LD, Barnett SA (2007) Nucleation of nanometer-scale electrocatalyst particles in solid oxide fuel cell anodes. J Power Sources 166(1):64–67

Neagu D, Oh TS, Miller DN, Menard H, Bukhari SM, Gamble SR, Gorte RJ, Vohs JM, Irvine JTS (2015) Nano-socketed nickel particles with enhanced coking resistance grown in situ by redox exsolution. Nat Commun 6:8120

Dong F, Ni M, He W, Chen Y, Yang G, Chen D, Shao Z (2016) An efficient electrocatalyst as cathode material for solid oxide fuel cells: BaFe0.95Sn0.05O3−δ. J Power Sources 326:459–465

Dong F, Chen Y, Chen D, Shao Z (2014) Surprisingly high activity for oxygen reduction reaction of selected oxides lacking long oxygen-ion diffusion paths at intermediate temperatures: a case study of cobalt-free BaFeO3-δ. Acs Appl Mater Inter 6(14):11180–11189

Niu B, Jin F, Feng T, Zhang L, Zhang Y, He T (2018) A-site deficient (La0.6Sr0.4)(1-x)Co0.2Fe0.6Nb0.2O3-δ symmetrical electrode materials for solid oxide fuel cells. Electrochim Acta 270:174–182

Markov AA, Patrakeev MV, Savinskaya OA, Nemudry AP, Leonidov IA, Leonidova ON, Kozhevnikov VL (2008) Oxygen nonstoichiometry and high-temperature transport in SrFe1−xWxO3−δ. Solid State Ionics 179(1):99–103

Li P, Yang W, Tian C, Zhao W, Lü Z, Xie Z, Wang C-A (2021) Electrochemical performance of La2NiO4+δ-Ce0.55La0.45O2−δ as a promising bifunctional oxygen electrode for reversible solid oxide cells. J Adv Ceram 10(2):328–337

Escudero MJ, Aguadero A, Alonso JA, Daza L (2007) A kinetic study of oxygen reduction reaction on La2NiO4 cathodes by means of impedance spectroscopy. J Electroanal Chem 611(1):107–116

Adler SB (1998) Mechanism and kinetics of oxygen reduction on porous La1−xSrxCoO3−δ electrodes. Solid State Ionics 111(1):125–134

Hou J, Wang Q, Li J, Lu Y, Wang L, Fu XZ, Luo JL (2020) Rational design of an in-situ co-assembly nanocomposite cathode La0.5Sr1.5MnO4+δ-La0.5Sr0.5MnO3-δ for lower-temperature proton-conducting solid oxide fuel cells. J Power Sources 466:228240

Shi N, Su F, Huan D, Xie Y, Lin J, Tan W, Peng R, Xia C, Chen C, Lu Y (2017) Performance and DRT analysis of P-SOFCs fabricated using new phase inversion combined tape casting technology. J Mater Chem A 5(37):19664–19671

Xia J, Wang C, Wang X, Bi L, Zhang Y (2020) A perspective on DRT applications for the analysis of solid oxide cell electrodes. Electrochim Acta 349:136328

Wang X, Ma Z, Zhang T, Kang J, Ou X, Feng P, Wang S, Zhou F, Ling Y (2018) Charge-transfer modeling and polarization DRT analysis of proton ceramics fuel cells based on mixed conductive electrolyte with the modified anode-electrolyte interface. Acs Appl Mater Inter 10(41):35047–35059

Yang Y, Bao H, Ni H, Ou X, Wang S, Lin B, Feng P, Ling Y (2021) A novel facile strategy to suppress Sr segregation for high-entropy stabilized La0.8Sr0.2MnO3-delta cathode. J Power Sources 482:228959

Acknowledgements

This work was supported by the Ministry of Science and Technology of China (No. 2021YFE0100200), Pakistan Science Foundation (PSF) Project (No. PSF/CRP/18thProtocol (01)), National Natural Science Foundation of China (No. 51806241), China Postdoctoral Science Foundation (No. 2018M632416 and No.2019T120481).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Mark Bissett.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ni, H., Yang, Y., Tian, Y. et al. Novel dual-phase symmetrical electrode materials for protonic ceramic fuel cells. J Mater Sci 56, 19651–19662 (2021). https://doi.org/10.1007/s10853-021-06531-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06531-8