Abstract

Graphene-based plasmonic sandwiches have received considerable research interest because of their intriguing optical, electronic and catalytic properties. The capability of tuning the distribution of plasmonic nanostructures is essential for exploring their intrinsic properties and potential applications. Herein, we report an ultraviolet (UV)/ozone-assisted approach to synthesizing gold nanoparticles/reduced graphene oxide/gold thin film (AuNPs/RGO/Au) plasmonic nano-sandwiches with easy and fine tunability of AuNPs at room temperature. The UV/ozone functionalization controls the activation of anchor sites for AuNPs on the GO scaffold without creating new defects on the basal plane. By simply varying the functionalization time, the loading density of AuNPs with an average size of ~ 17 nm is able to reach a value of over 500 μm−2, which is higher than previously reported values using other room-temperature methods. The AuNPs/RGO/Au plasmonic nano-sandwiches offer remarkable near-field enhancement with an enhancement factor of over 300 in the Raman signal of graphene, which is comparable with the highest reported values. The as-prepared AuNPs/RGO/Au nano-sandwiches can be used as sensitive surface-enhanced Raman spectroscopy substrates. This work demonstrates that oxygen-containing functional groups, which were commonly considered to have negative effects on graphene-based nanocomposites, can contribute to the successful synthesis of high-loading plasmonic nano-sandwiches.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Functionalizing graphene with metal nanoparticles (NPs) has been demonstrated as an effective way to broaden its range of applications [1,2,3,4,5,6,7]. Among them, graphene-based plasmonic nano-sandwiches, which consist of two layers of metal components with a layer of graphene or its derivatives intercalated between them, have drawn tremendous research interest in the field including optoelectronics [8,9,10], energy conversion/storage [11, 12] and sensing [13,14,15]. In practical applications, it is of critical importance to have the capability of tuning the size and loading density of metal NPs [16] during the fabrication stage, since it determines the performance of plasmonic nano-sandwiches [1, 17]. So far, a variety of high-throughput synthetic strategies has been proposed, which can be categorized into ex situ hybridization and in situ crystallization [18, 19]. The ex situ hybridization employs self-assembly of pre-synthesized metal NPs onto the surfaces of graphene oxide (GO) or reduced graphene oxide (RGO) in solutions. Although ex situ hybridization has good control over sizes and shapes of metal NPs, it has much less control over their loading density and distribution uniformity on the surfaces [20,21,22]. The in situ crystallization provides on-site growth or formation of metal NPs by chemical reduction or thermal evaporation, but the toxicity of reducing agents [23, 24] or the high temperature of thermal annealing [15, 25] triggers its incompatibility with flexible optoelectronics and thus limits the application scenarios.

Plasma technology has been demonstrated as an efficient approach to fabricating metal or alloy composites on various supports [26,27,28,29] at room temperature without introducing organic impurities or unwanted byproducts. Since the oxygen functional groups act as the nucleation sites of the metal NPs when GO is used as the support material [19, 30], the quantity control of these oxygenated groups holds the potential to achieve graphene-based plasmonic nano-sandwiches with high metal-NPs loadings.

Inspired by this idea, we report, in this paper, a synthetic strategy to fabricate gold nanoparticles/reduced graphene oxide/gold thin film (AuNPs/RGO/Au) plasmonic nano-sandwiches using a combination of UV/ozone functionalization and argon (Ar) plasma reduction. The large amount of additional oxygen-containing functional groups induced by UV/ozone treatment, which were generally associated with negative contributions, are now utilized to modulate the nucleation and growth processes of AuNPs on the surfaces of RGO and achieve high-loading plasmonic nano-sandwiches. The density of AuNPs with an average size of ~ 17 nm can reach a value of over 500 μm−2. The AuNPs/RGO/Au plasmonic nano-sandwiches offer significant near-field enhancement and effectively enhance Raman signals from graphene by over 300 fold. We further explored the applications of the as-prepared plasmonic nano-sandwiches as sensitive SERS substrates. Compared with the traditional plasma reduction method [31, 32], our strategy offers an effective solution to achieving much denser metal NPs, and at the same time significantly alleviates the etching effect of plasma.

Materials and methods

Reagents and materials

All reagents were of analytical grade and used as received without further purification. Graphite oxide powder was purchased from Jiangsu XFNANO Materials Tech Co., Ltd (Nanjing, China). Chloroauric acid (HAuCl4·3H2O, ≥ 99.9%) and Rhodamine 6G (R6G, 99%) were purchased from Aladdin reagent (Shanghai, China). Acetone and isopropanol (IPA) were supplied by Sinopharm Chemical Reagent Co., Ltd (Shanghai, China). Silicon (Si) wafers with a 300-nm-thick oxide layer (SiO2) were obtained from Suzhou Crystal Silicon Electronic & Technology Co., Ltd (Suzhou, China).

Preparation of HAuCl4/GO/Au thin film on the SiO2/Si wafer

A 50-nm-thick Au film was first deposited onto the SiO2/Si wafer by electron-beam evaporating using a Combinatorial Materials Science Platform (Kurt J. Lesker Company). The substrate was then cut into 1 × 1 cm wafers for further processing. A 0.5 mg mL−1 GO aqueous dispersion was prepared by sonicating GO powder (15 mg) in deionized water (30 ml) for 30 min. The Au film was firstly treated with UV/ozone (PSD Series, Digital UV Ozone system, Novascan Technologies, Inc) for 60 min to improve the hydrophilicity. Then, 50 μl GO aqueous solution was drop-casted onto the Au thin film, and the wafers were naturally dried overnight. The GO-coated Au thin film was again treated with UV/ozone for 30 min, 60 min, 90 min, 120 min, 150 min and 180 min, respectively. 118.149 mg chloroauric acid powder was dissolved in 30 ml IPA to make a 10 mM solution. A droplet of 10 μl HAuCl4 solution was drop-casted onto each UV/ozone-treated GO-coated Au thin film, and the solvent was evaporated in air.

Reduction of HAuCl4 and GO by Ar plasma

The Ar plasma reaction was implemented in a custom-made plasma system using a radio frequency inductively coupled plasma (ICP). The detailed configuration has been reported in our previous work [33]. The chamber was sequentially evacuated by mechanical and turbo molecular pumps to 1.0 × 10−3 Pa before the generation of Ar plasma. The flow rate of pure Ar was controlled at 100 standard cubic centimeter per minute (sccm) and Ar plasma was generated at 4.0 Pa with an ICP frequency of 13.56 MHz and a power supply of 88 W. The length of Ar plasma reduction was fixed at 15 min, which we found is the optimal condition to obtain small and dense AuNPs. Plasma serves as the dual “reducing agent” for GO and Au3+ [27]. The as-prepared AuNPs/RGO/Au nano-sandwiches with UV/ozone treatment time length of 30 min, 60 min, 90 min, 120 min, 150 min and 180 min was labeled as S1, S2, S3, S4, S5 and S6, respectively. For comparison, we also fabricated AuNPs/RGO/Au nano-sandwiches using pristine GO (corresponding to UV/ozone treatment for 0 min), which was labeled as S0.

Microscopic characterization of AuNPs/RGO/Au nano-sandwiches

The GO films before and after the UV/ozone treatment were characterized by X-ray photoelectron spectroscopy (XPS, PHI-5300, Ulvac Phi Inc.). For XPS analyses, 50 μl GO dispersion was drop-casted onto Au/SiO2/Si substrates that were firstly treated with UV/ozone for 60 min. The as-casted samples were dried overnight in air and treated with UV/ozone for 0 min, 60 min, 120 min and 180 min, respectively. XPS deconvolution processing was conducted on AugerScan software. The peak positions of non-oxygenated carbon (C–C/C=C), hydroxyl (C–O), carbonyl (C=O) and carboxyl (O–C=O) were fixed at 284.6 eV, 286.1 eV, 287.3 eV and 288.7 eV, respectively. The morphology of AuNPs/RGO/Au nano-sandwiches was characterized using a field emission scanning electron microscopy (FESEM, merlin compact, Carl Zeiss, Germany). The structure of AuNPs/RGO was analyzed using transmission electron microscopy (TEM, Tecnai G2 20-s-twin, FEI, America). To prepare the sample for the TEM characterization, 50 μl GO solution was drop-casted onto a fused silica substrate. Before the drop-casting process, the fused silica substrate was sequentially cleaned by sonication in bath of acetone, IPA and deionized water for 15 min each and the glass substrate was then treated with UV/ozone for 15 min to improve the surface hydrophilicity. The as-deposited sample was dried overnight in air at room temperature to form a GO film, followed by UV/ozone for 120 min. Then, 10 μl HAuCl4 solution was drop-casted onto the UV/ozone-treated GO film, and the identical Ar plasma reduction process was performed as described above. The AuNPs/RGO film separated from the substrate by immersing the as-prepared sample into an ethanol solution and was subsequently transferred onto a copper grid.

SERS measurements

Raman spectra were obtained using a Renishaw in Via Raman system with a 633 nm laser. The laser power was kept at 1.7 mW to avoid overheating. The accumulation time was set as 10 s. The numerical aperture was 0.5, and the objective was × 50. The parameters were identical for all measurements. For each sample, we recorded three Raman spectra in different positions and took the average values. To investigate the enhancement of Raman signal of graphene in the AuNPs/RGO/Au plasmonic nano-sandwiches, Raman spectra of GO spin-coated on SiO2/Si, GO spin-coated on Au/SiO2/Si and AuNPs/RGO/Au nano-sandwiches were recorded. For assessment of the performance of our AuNPs/RGO/Au plasmonic nano-sandwiches as SERS substrates, R6G was used as the standard probe molecule. Before the measurements, a droplet of 10 μl R6G solution was dropped onto each sample, and the solvent was evaporated in a vacuum oven at room temperature.

Raman analyses of GO film

To investigate the structural change of GO during the process of UV/ozone treatment, we conducted Raman analyses of GO films treated with UV/ozone for different time lengths. To avoid the depth-average effect during the Raman measurements, we prepared GO films by spin-coating the GO dispersion on Au/SiO2/Si substrates at 2000 rpm for 30 s. Prior to the spin-coating, the Au/SiO2/Si substrates were pre-treated with UV/ozone for 60 min. After the spin-coating the GO films were treated with UV/ozone for 0 min, 60 min, 120 min and 180 min, respectively.

Results and discussion

Functionalization of GO via UV/ozone treatment

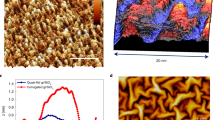

The XPS survey spectra of pristine GO film and GO films treated with UV/ozone for 60 min, 120 min and 180 min are shown in Fig. 1a, and the corresponding chemical composition is listed in Table 1. It can be seen that the ratios of C:O decreased as we prolonged UV/ozone treatment, indicating UV/ozone treatment will raise the oxidation degree of GO sheets. Figure 1b illustrates the high-resolution C1s spectra of GO treated with UV/ozone for 0 min (pristine), 60 min, 120 min and 180 min, respectively. The C1s spectrum of pristine GO can be deconvoluted into four components: non-oxygenated carbon (C–C/C=C), hydroxyl (C–O), carbonyl (C=O) and carboxyl (O–C=O) [34, 35], and the peak energies are calibrated by assigning the major C1s peak at 284.6 eV [36]. The changes of chemical bonding of GO during the UV/ozone treatment process are listed in Table 2, revealing that UV/ozone treatment can effectively increase the oxygen-containing functional groups on the GO basal plane. For UV/ozone-treated GO, it has been proposed that ozone molecules can be first physiosorbed on the graphene basal plane with a binding energy of 0.25 eV and then be dissociated into an epoxide group (C–O–C) and a separate oxygen molecule [37]. Since C–O–C bonds typically exhibit a binding energy of ~ 286 eV [38, 39] which is very close to that of C–O bonds and can lead to an almost utter overlap of these two components in the C1s spectrum, the overall percentage of C–O/C–O–C bonds slightly decreased during the first 60 min of UV/ozone treatment and then steadily increased with a much faster pace if the UV/ozone treatment continued. In addition, the content of O–C=O bonds grew progressively due to UV/ozone exposure, which agrees with previous studies [40, 41]. We believe that they were created mainly through the oxidation of C–O moieties into O–C=O moieties under the conditions of UV radiation and existence of ozone, which explains the fact that the C–O/C–O–C proportion decreased at first when the time length of UV/ozone treatment was 60 min or less. This also explains why the O–C=O proportion reached a plateau when the treatment time reached 120 min or above, while the C–O/C–O–C proportion did not: the formation of O–C=O moieties required the consumption of C–O moieties and the condition of UV/ozone, whereas the formation of C–O–C moieties only needed the latter.

Figure 1c demonstrates the Raman spectra of GO treated with UV/ozone for 0 min (pristine), 60 min, 120 min and 180 min. The four spectra exhibit a similar pattern: a D band centered at ~ 1350 cm−1 and a G band centered at ~ 1600 cm−1. The intensity ratio of D- and G-band (ID/IG) has been used as an indicator of degradation degree of crystallinity of graphitic materials and an increase in ID/IG means more defects on the GO basal plane [42,43,44]. The value of ID/IG of GO treated with UV/ozone for 0 min, 60 min, 120 min, 180 min was calculated to be 1.23 ± 0.03, 1.23 ± 0.03, 1.22 ± 0.02, 1.22 ± 0.03, respectively. This indicates the process of UV/ozone exposure did not create new defects in GO. Along with the findings of XPS analyses, we can conclude that the formation of oxygen functionalities during the UV/ozone treatment process preferentially occurred at the existing defective sites, that is to say, O–C=O moieties were formed at the former C–O sites and the formation of C–O–C moieties did not require breaking C=C/C–C bonds on the GO basal plane. Figure 1d summarizes the proposed reaction mechanism of GO with ozone under UV radiation.

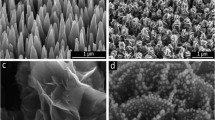

Morphology of AuNPs/RGO/Au nano-sandwiches

Figure 2a–g shows the SEM images of AuNPs/RGO/Au nano-sandwiches with UV/ozone treatment time increasing from 0 min to 180 min, and Fig. 2h summarizes the changes of particle size and density as a function of the UV/ozone treatment time. The average size of AuNPs on the top of AuNPs/RGO/Au nano-sandwiches was measured to be 20 ± 7 nm, 22 ± 6 nm, 19 ± 7 nm, 16 ± 5 nm, 17 ± 5 nm, 36 ± 17 nm, 78 ± 43 nm, respectively. The density of AuNPs on the surface of RGO with 0 min, 30 min, 60 min, 90 min, 120 min, 150 min and 180 min of UV/ozone treatment was 40 ± 11 μm−2, 61 ± 12 μm−2, 105 ± 12 μm−2, 272 ± 10 μm−2, 508 ± 9 μm−2, 293 ± 60 μm−2 and 143 ± 127 μm−2, respectively. It is evident that the density of AuNPs increased significantly as the treatment time increased from 0 to 120 min. Yet the density did not continue to rise but declined dramatically, and the particles tended to merge and exhibited island-like morphology when the treatment time reached 150 min or above (corresponding to S5 and S6). This indicates that when GO was treated with UV/ozone for a reasonable amount of time, the increased oxygen functional groups can adsorb gold ions through physisorption, electrostatic binding, or charge-transfer interactions [23] and then serve as nucleation sites for gold ions anchoring during the subsequent argon plasma reduction process [45]. However, the oxygen functional groups can become over-concentrated due to excessive UV/ozone treatment so that the spacing between Au nuclei is narrowed, which consequently leads to the aggregation of AuNPs and the island-like morphology.

FESEM images of AuNPs on the surface of RGO that were treated with UV/ozone for a 0 min, b 30 min, c 60 min, d 90 min, e 120 min, f 150 min and g 180 min, respectively. The scale bar is 200 nm. Size-distribution histograms of AuNPs are shown in the insets of (a–g). h The density and size of AuNPs as a function of UV/ozone treatment time

The change in particle size has an impact on the plasmonic properties of AuNPs/RGO/Au nano-sandwiches. We measured the reflection spectra of AuNPs/RGO/Au nano-sandwiches with UV/ozone treatment of 0 min, 60 min, 120 min and 180 min, respectively (corresponding to the sample of S0, S2, S4 and S6, respectively), and the peak was red-shifted with the increased of particle size (Fig. S1). The percentage of AuNPs covering each AuNPs/RGO/Au nano-sandwich is shown in Fig. S2 in the supporting information.

To further characterize AuNPs and the elemental distributions of AuNPs/RGO nanocomposites after 120 min UV/ozone treatment (S4), TEM measurement was performed. Figure 3a shows the TEM image of AuNPs/RGO at low magnification. The AuNPs exhibited roughly spherical shape and were uniformly distributed on the RGO surface with a very high loading. The high-resolution TEM (HRTEM) image of a single AuNP is distinctly presented in Fig. 3b, where the lattice fringes can be clearly seen. The lattice spacing was measured to be 0.238 nm, which coincides well with Au (111) (JCPDS 04-0784). Electron energy loss spectroscopy (EELS) elemental mapping (Fig. 3c) and energy-dispersive X-ray spectroscopy (EDS) spectrum (Fig. 3d) further confirm the presence and uniform distribution of AuNPs on the RGO sheets.

Under the optimal condition (i.e., UV/ozone exposure of GO for 120 min), the AuNPs/RGO/Au plasmonic nano-sandwiches with an upper layer of high-density, good-dispersity and aggregation-free AuNPs were successfully prepared. More importantly, compared with other methods proposed previously for fabricating metal NP/graphene nanocomposites at room temperature (see Table 3), the strategy presented here offers a new route to achieving much denser metal NPs on graphene, while alleviate the etching effect of plasma at the same time, which is helpful in averting severe damage to graphene.

Enhanced SERS in AuNPs/RGO/Au

Enhancing the local electric field in graphene-based plasmonic nanostructures has been demonstrated as an effective way to improve the efficiency of various electro-optic processes [46], and graphene is an advantageous test bed for studying the mechanisms of optical response in plasmonic nanostructures [10, 47,48,49,50]. We performed Raman measurements for GO spin-coated on SiO2/Si, GO spin-coated on Au/SiO2/Si and AuNPs/RGO/Au nano-sandwiches and the spectra are shown in Fig. 4. The band intensities in pristine GO on SiO2/Si were rather weak with the intensity of G band being less than 200 counts. While the intensity of G band was slightly enhanced (ca. fourfold) on Au film, a remarkable enhancement of G band was observed in AuNPs/RGO/Au nano-sandwiches with the enhancement factor for G band exceeding 300. The significant enhancement can be attributed to the multiple plasmonic couplings including the AuNP–AuNP coupling and AuNP–Au film coupling constructed by intercalating RGO as a nano-spacer [13], and the satisfactory enhancement ratio is comparable to the highest ones observed in graphene-embedded plasmonic nanostructures reported to date [13, 15, 51,52,53]. Moreover, the strong multiple plasmonic couplings also contribute predominantly to the AuNPs/RGO/Au nano-sandwich system when used as a sensitive analyte-detection platform, which will be discussed below. Besides, compared with previous studies that achieved high-density plasmonic NPs through annealing metal thin film at high temperatures to gain ultrahigh enhancement of local electric field [15, 52, 53], our UV/ozone-assisted synthetic strategy shows its superiority by offering satisfactory enhancement with all the fabrication procedures being carried out at room temperature, which makes this strategy compatible with flexible optoelectronics.

SERS performance of AuNPs/RGO/Au nano-sandwiches

R6G, one of the widely used standard probe molecules for the evaluation of SERS properties, was chosen to assess the performance of our AuNPs/RGO/Au plasmonic nano-sandwiches as SERS substrates. The Raman spectra of R6G on substrate S0–S6 are presented in Fig. 5a. The strong Raman peaks at 611 cm−1, 771 cm−1, 1089 cm−1, 1124 cm−1, 1183 cm−1, 1309 cm−1, 1361 cm−1, 1508 cm−1, 1572 cm−1, 1597 cm−1 and 1648 cm−1 are in good agreement with the literature [54]. Figure 5b indicates the characteristic Raman shift peak intensity at 611 cm−1 as a function of UV/ozone treatment time. The intensity of Raman signal exhibits a clear volcano-type trend with the increase in treatment time, which matches with the trend of particle density. The overlap of these two curves is due to the positive correlation between the particle density and the number of “hot spots” [55, 56] for SERS. In order to evaluate the reproducibility of Raman spectra of R6G on our optimal sample, Raman measurements were performed at 20 randomly selected spots on the substrate S4, and the peak intensities at 611 cm−1 are shown in Fig. 5c. The relative standard deviation (RSD) of peak intensities centered at 611 cm−1 was calculated to be 6.1%, demonstrating high homogeneity of our plasmonic substrates and good reproducibility of Raman spectra. To assess the linear dependence of SERS signal intensity on the concentration of R6G molecules and the limit of detection of the substrate S4, a series of Raman spectra at different concentration were obtained. A broad range of linear response from 5 × 10−5 to 5 × 10−8 M with a detection limit of around 5 × 10−8 M was achieved (R2 = 0.9954) without the aid of digital mapping, as illustrated in Fig. 5d. Furthermore, the detection limit of R6G on the optimum AuNPs/RGO/Au nano-sandwich (S4) was compared with that on bare SiO2/Si, as shown in Fig. 5e, and a substantial enhancement of detection limit can be seen. The peak intensity of 611 cm−1 band of 5 × 10−8 M R6G on AuNPs/RGO/Au/SiO2/Si is 461 counts and the peak intensity of 611 cm−1 band of 1 × 10−3 M R6G on SiO2/Si is 352. We used the standard equation \( {\text{EF}} = \frac{{I_{\text{SERS}} }}{{I_{\text{bulk}} }} \times \frac{{N_{\text{bulk}} }}{{N_{\text{SERS}} }} \) [57] to calculate the enhancement factor (EF). ISERS and Ibulk are the peak intensity of 611 cm−1 band of 5 × 10−8 M R6G on the plasmonic substrate and 1 × 10−3 M R6G on the bare substrate, respectively, and NSERS and Nbulk are the number of R6G molecules excited by the Raman laser beam on the plasmonic and bare substrates, respectively. Since the laser power was fixed at 1.7 mW in all measurements, the activated volume was assumed to be identical, which means the value of \( \frac{{N_{\text{bulk}} }}{{N_{\text{SERS}} }} \) equals to that of \( \frac{{C_{\text{bulk}} }}{{C_{\text{SERS}} }} \). In our work, ISERS, Ibulk, Cbulk, CSERS equals to 461 counts, 352 counts, 1 × 10−3 M and 5 × 10−8 M, respectively, and the EF is therefore calculated to be 2.6 × 104. A comparison of the limit of detection (LOD) and EF of Rhodamine 6G on different graphene-based plasmonic nanostructures is listed in Table 4. The LOD in our work is comparable with the values reported in prior work, but the EF value is limited due to the following reasons. Firstly, the Raman laser wavelength does not match with the resonance wavelength of our plasmonic nano-sandwiches. Secondly, owing to overlap between bands of R6G and GO at ~ 1350 cm−1, we had to use 611 cm−1 band of R6G to determine the EF and LOD, which partially results in relatively lower EF and LOD [66]. Last but not least, because the plasmonic coupling between two metal layers decays as the number of graphene layer increases [53, 69], the use of few-layer RGO instead of single-layer RGO as the intercalation layer also leads to a decrease in EF.

a Raman spectra of R6G on S0, S1, S2, S3, S4, S5 and S6, respectively. b The change of characteristic Raman shift peak intensity at 611 cm−1 of R6G and density of AuNPs as a function of UV/ozone treatment time. c Variation of peak intensities of the 611 cm−1 bands in Raman spectra collected from 20 randomly selected spots on substrate S4. d The intensity of the Raman feature peak of the R6G at 611 cm−1 as a function of molecular concentration from 5 × 10−5 to 5 × 10−8 M using substrate S4. e Raman spectra of 1 × 10−3 M R6G on SiO2/Si and 5 × 10−8 M R6G on AuNPs/RGO/Au nano-sandwiches, respectively. f Raman spectra of 1 × 10−4 M R6G on a freshly substrate and an aged one stored under ambient conditions for 30 days. The symbol “blue solid circle” and “green solid square” denote characteristic Raman shift peaks of GO and SiO2

The stability performance is shown in Fig. 5f. We carried out Raman measurements of R6G on both a fresh substrate and an aged one stored under ambient conditions for 30 days. Compared with the Raman spectrum on the fresh substrate, the Raman spectrum on the aged one shows identical Raman fingerprint bands with an intensity loss at 611 cm−1 of only 3.7%. Since UV/ozone treatment induces epoxide formation on the basal plane of GO, we believe that the loss of stability is caused by restacking of RGO due to linking of discrete RGO layers by hydrogen bonding between oxygen atoms of epoxides and adsorbed water molecules from ambient air [70], which weakens the plasmonic coupling between Au film and AuNPs [53, 69].

Conclusions

In summary, we have developed a facile yet efficient approach to fabricating AuNPs/RGO/Au plasmonic nano-sandwiches with good tunability of AuNPs at room temperature with the aid of UV/ozone treatment. Combining the results from XPS and Raman analyses, we conclude that, the oxygen-functionalization of GO during the UV/ozone treatment process is ascribed to the formation of epoxide groups and oxidation of hydroxyl into carboxyl. Notably, the oxygen-containing functional groups, which were generally associated with negative contributions, were successfully utilized to readily tune the nucleation and growth processes of AuNPs on the surfaces of RGO. By optimizing UV/ozone treatment time length, the plasmonic nano-sandwiches with an upper layer of high-density, good-dispersity and aggregation-free AuNPs were successfully synthesized. The resultant AuNPs/RGO/Au plasmonic nano-sandwiches offer considerable near-field enhancement with a graphene Raman enhancement factor of over 300. The as-fabricated nano-sandwiches exhibit good performance when used as SERS substrates. It is expected that this work will not only offer an effective strategy for the synthesis of graphene-based plasmonic nanostructures in the field of flexible electronics, but also holds the potential to be extended to other areas that entail metal nanoparticle/RGO such as catalysis (e.g., hydrogen evolution reaction), fuel cells and actuators.

References

Zhao Y, Zhu Y (2015) Graphene-based hybrid films for plasmonic sensing. Nanoscale 7(35):14561–14576

Dou S, Tao L, Wang R, El Hankari S, Chen R, Wang S (2018) Plasma-assisted synthesis and surface modification of electrode materials for renewable energy. Adv Mater 30(21):1705850

Das S, Pandey D, Thomas J, Roy T (2019) The role of graphene and other 2D materials in solar photovoltaics. Adv Mater 31(1):1802722

Wu J, Lu Y, Feng S, Wu Z, Lin S, Hao Z, Yao T, Li X, Zhu H, Lin S (2018) The interaction between quantum dots and graphene: the applications in graphene-based solar cells and photodetectors. Adv Funct Mater 28(50):1804712

Xu G-R, Hui J-J, Huang T, Chen Y, Lee J-M (2015) Platinum nanocuboids supported on reduced graphene oxide as efficient electrocatalyst for the hydrogen evolution reaction. J Power Sources 285:393–399

Yu X, Kuai L, Geng B (2012) CeO2/rGO/Pt sandwich nanostructure: rGO-enhanced electron transmission between metal oxide and metal nanoparticles for anodic methanol oxidation of direct methanol fuel cells. Nanoscale 4(18):5738–5743

Lu L, Liu J, Hu Y, Zhang Y, Chen W (2013) Graphene-stabilized silver nanoparticle electrochemical electrode for actuator design. Adv Mater 25(9):1270–1274

Echtermeyer TJ, Britnell L, Jasnos PK, Lombardo A, Gorbachev RV, Grigorenko AN, Geim AK, Ferrari AC, Novoselov KS (2011) Strong plasmonic enhancement of photovoltage in graphene. Nat Commun 2:458

Chen Z, Li X, Wang J, Tao L, Long M, Liang SJ, Ang LK, Shu C, Tsang HK, Xu JB (2017) Synergistic effects of plasmonics and electron trapping in graphene short-wave infrared photodetectors with ultrahigh responsivity. ACS Nano 11(1):430–437

Xu G, Liu J, Wang Q, Hui R, Chen Z, Maroni VA, Wu J (2012) Plasmonic graphene transparent conductors. Adv Mater 24(10):OP71–OP76

Zhang PY, Song T, Wang TT, Zeng HP (2018) Plasmonic Cu nanoparticle on reduced graphene oxide nanosheet support: an efficient photocatalyst for improvement of near-infrared photocatalytic H2 evolution. Appl Catal B-Environ 225:172–179

Kirubasankar B, Murugadoss V, Lin J, Ding T, Dong MY, Liu H, Zhang JX, Li TX, Wang N, Guo ZH, Angaiah S (2018) In situ grown nickel selenide on graphene nanohybrid electrodes for high energy density asymmetric supercapacitors. Nanoscale 10(43):20414–20425

Li X, Choy WCH, Ren X, Zhang D, Lu H (2014) Highly intensified surface enhanced Raman scattering by using monolayer graphene as the nanospacer of metal film-metal nanoparticle coupling system. Adv Funct Mater 24(21):3114–3122

Lee KJ, Kim D, Jang BC, Kim D-J, Park H, Jung DY, Hong W, Kim TK, Choi Y-K, Choi S-Y (2016) Multilayer graphene with a rippled structure as a spacer for improving plasmonic coupling. Adv Funct Mater 26(28):5093–5101

Zhan Z, Liu L, Wang W, Cao Z, Martinelli A, Wang E, Cao Y, Chen J, Yurgens A, Sun J (2016) Ultrahigh surface-enhanced raman scattering of graphene from Au/Graphene/Au sandwiched structures with subnanometer gap. Adv Opt Mater 4(12):2021–2027

Koppens FH, Chang DE, Garcia de Abajo FJ (2011) Graphene plasmonics: a platform for strong light-matter interactions. Nano Lett 11(8):3370–3377

Grigorenko AN, Polini M, Novoselov KS (2012) Graphene plasmonics. Nat Photonics 6(11):749–758

Huang X, Qi X, Boey F, Zhang H (2012) Graphene-based composites. Chem Soc Rev 41(2):666–686

Singh V, Joung D, Zhai L, Das S, Khondaker SI, Seal S (2011) Graphene based materials: past, present and future. Prog Mater Sci 56(8):1178–1271

Huang J, Zhang L, Chen B, Ji N, Chen F, Zhang Y, Zhang Z (2010) Nanocomposites of size-controlled gold nanoparticles and graphene oxide: formation and applications in SERS and catalysis. Nanoscale 2(12):2733–2738

Li Y, Yang J, Zhou Y, Zhao N, Zeng W, Wang W (2017) Fabrication of gold nanoparticles/graphene oxide films with surface-enhanced Raman scattering activity by a simple electrostatic self-assembly method. Colloid Surf A 512:93–100

Wu J, Xu Y, Xu P, Pan Z, Chen S, Shen Q, Zhan L, Zhang Y, Ni W (2015) Surface-enhanced raman scattering from AgNP-graphene-AgNP sandwiched nanostructures. Nanoscale 7(41):17529–17537

Muszynski R, Seger B, Kamat PV (2008) Decorating graphene sheets with gold nanoparticles. J Phys Chem C 112(14):5263–5266

Lee S, Lee MH, Shin H-J, Choi D (2013) Control of density and LSPR of Au nanoparticles on graphene. Nanotechnology 24(27):275702

Zhou H, Qiu C, Liu Z, Yang H, Hu L, Liu J, Yang H, Gu C, Sun L (2010) Thickness-dependent morphologies of gold on n-layer graphenes. J Am Chem Soc 132(3):944–946

Takahashi S, Chiba H, Kato T, Endo S, Hayashi T, Todoroki N, Wadayama T (2015) Oxygen reduction reaction activity and structural stability of Pt–Au nanoparticles prepared by arc-plasma deposition. Phys Chem Chem Phys 17(28):18638–18644

Yang C, Yu Y, Xie YJ, Zhang D, Zeng P, Dong YR, Yang BL, Liang RQ, Ou QR, Zhang SY (2019) One-step synthesis of size-tunable gold nanoparticles/reduced graphene oxide nanocomposites using argon plasma and their applications in sensing and catalysis. Appl Surf Sci 473:83–90

Wang Q, Song M, Chen C, Hu W, Wang X (2012) Plasma synthesis of surface-functionalized graphene-based platinum nanoparticles: highly active electrocatalysts as electrodes for direct methanol fuel cells. ChemPlusChem 77(6):432–436

Su N, Hu X, Zhang J, Huang H, Cheng J, Yu J, Ge C (2017) Plasma-induced synthesis of Pt nanoparticles supported on TiO2 nanotubes for enhanced methanol electro-oxidation. Appl Surf Sci 399:403–410

Gong X, Liu G, Li Y, Yu DYW, Teoh WY (2016) Functionalized-graphene composites: fabrication and applications in sustainable energy and environment. Chem Mater 28(22):8082–8118

Ma Y, Fang S, Wang Q (2017) The tunable plasma synthesis of Pt-reduced graphene oxide nanocomposites. AIP Adv 7(6):065118

Wang Q, Zuo X, Wang X (2014) Preparation of graphene supported Pt nanoparticles by a plasma approach and their application for methanol electro-oxidation: a comparison with chemical reduction. Dalton Trans 43(34):12961–12966

Yang C, Gong J, Zeng P, Yang X, Liang R, Ou Q, Zhang S (2018) Fast room-temperature reduction of graphene oxide by methane/argon plasma for flexible electronics. Appl Surf Sci 452:481–486

Paredes JI, Villar-Rodil S, Solis-Fernandez P, Martinez-Alonso A, Tascon JM (2009) Atomic force and scanning tunneling microscopy imaging of graphene nanosheets derived from graphite oxide. Langmuir 25(10):5957–5968

Singh G, Botcha VD, Sutar DS, Narayanam PK, Talwar SS, Srinivasa RS, Major SS (2014) Near room temperature reduction of graphene oxide Langmuir–Blodgett monolayers by hydrogen plasma. Phys Chem Chem Phys 16(23):11708–11718

Palchan I, Crespin M, Estrade-Szwarckopf H, Rousseau B (1989) Graphite fluorides: an XPS study of a new type of C–F bonding. Chem Phys Lett 157(4):321–327

Lee G, Lee B, Kim J, Cho K (2009) Ozone adsorption on graphene: Ab initio study and experimental validation. J Phys Chem C 113(32):14225–14229

Lee B, Park S-Y, Kim H-C, Cho K, Vogel EM, Kim MJ, Wallace RM, Kim J (2008) Conformal Al2O3 dielectric layer deposited by atomic layer deposition for graphene-based nanoelectronics. Appl Phys Lett 92(20):203102

Checa M, Figueredo M, Aguinaco A, Beltran FJ (2019) Graphene oxide/titania photocatalytic ozonation of primidone in a visible LED photoreactor. J Hazard Mater 369:70–78

Huh S, Park J, Kim YS, Kim KS, Hong BH, Nam J-M (2011) UV/ozone-oxidized large-scale graphene platform with large chemical enhancement in surface-enhanced Raman scattering. ACS Nano 5(12):9799–9806

Kwon KC, Dong WJ, Jung GH, Ham J, Lee J-L, Kim SY (2013) Extension of stability in organic photovoltaic cells using UV/ozone-treated graphene sheets. Sol Energy Mater Sol Cells 109:148–154

Lucchese MM, Stavale F, Ferreira EHM, Vilani C, Moutinho MVO, Capaz RB, Achete CA, Jorio A (2010) Quantifying ion-induced defects and Raman relaxation length in graphene. Carbon 48(5):1592–1597

Cancado LG, Jorio A, Ferreira EH, Stavale F, Achete CA, Capaz RB, Moutinho MV, Lombardo A, Kulmala TS, Ferrari AC (2011) Quantifying defects in graphene via Raman spectroscopy at different excitation energies. Nano Lett 11(8):3190–3196

Jorio A, Lucchese MM, Stavale F, Ferreira EH, Moutinho MV, Capaz RB, Achete CA (2010) Raman study of ion-induced defects in N-layer graphene. J Phys: Condens Matter 22(33):334204

Xu W, Wang X, Zhou Q, Meng B, Zhao J, Qiu J, Gogotsi Y (2012) Low-temperature plasma-assisted preparation of graphene supported palladium nanoparticles with high hydrodesulfurization activity. J Mater Chem 22(29):14363–14368

Schedin F, Lidorikis E, Lombardo A, Kravets VG, Geim AK, Grigorenko AN, Novoselov KS, Ferrari AC (2010) Surface-enhanced Raman spectroscopy of graphene. ACS Nano 4(10):5617–5626

Tian H, Chen H-Y, Gao B, Yu S, Liang J, Yang Y, Xie D, Kang J, Ren T-L, Zhang Y, Wong HSP (2013) Monitoring oxygen movement by Raman spectroscopy of resistive random access memory with a graphene-inserted electrode. Nano Lett 13(2):651–657

Ling X, Xie L, Fang Y, Xu H, Zhang H, Kong J, Dresselhaus MS, Zhang J, Liu Z (2010) Can graphene be used as a substrate for Raman enhancement? Nano Lett 10(2):553–561

Thrall ES, Crowther AC, Yu Z, Brus LE (2012) R6G on graphene: high Raman detection sensitivity, yet decreased Raman cross-section. Nano Lett 12(3):1571–1577

Kravets VG, Schedin F, Jalil R, Britnell L, Novoselov KS, Grigorenko AN (2012) Surface hydrogenation and optics of a graphene sheet transferred onto a plasmonic nanoarray. J Phys Chem C 116(6):3882–3887

Wang P, Zhang W, Liang O, Pantoja M, Katzer J, Schroeder T, Xie YH (2012) Giant optical response from graphene–plasmonic system. ACS Nano 6(7):6244–6249

Xu W, Xiao J, Chen Y, Chen Y, Ling X, Zhang J (2013) Graphene-veiled gold substrate for surface-enhanced Raman spectroscopy. Adv Mater 25(6):928–933

Zhao Y, Li X, Du Y, Chen G, Qu Y, Jiang J, Zhu Y (2014) Strong light-matter interactions in sub-nanometer gaps defined by monolayer graphene: toward highly sensitive SERS substrates. Nanoscale 6(19):11112–11120

Lu R, Konzelmann A, Xu F, Gong Y, Liu J, Liu Q, Xin M, Hui R, Wu JZ (2015) High sensitivity surface enhanced Raman spectroscopy of R6G on in situ fabricated Au nanoparticle/graphene plasmonic substrates. Carbon 86:78–85

Schlucker S (2014) Surface-enhanced Raman spectroscopy: concepts and chemical applications. Angew Chem Int Ed 53(19):4756–4795

Xu H, Aizpurua J, Käll M, Apell P (2000) Electromagnetic contributions to single-molecule sensitivity in surface-enhanced Raman scattering. Phys Rev E 62(3):4318–4324

Wustholz KL, Brosseau CL, Casadio F, Van Duyne RP (2009) Surface-enhanced Raman spectroscopy of dyes: from single molecules to the artists’ canvas. Phys Chem Chem Phys 11(34):7350–7359

Lu G, Li H, Liusman C, Yin Z, Wu S, Zhang H (2011) Surface enhanced Raman scattering of Ag or Au nanoparticle-decorated reduced graphene oxide for detection of aromatic molecules. Chem Sci 2(9):1817–1821

Li SK, Yan YX, Wang JL, Yu SH (2013) Bio-inspired in situ growth of monolayer silver nanoparticles on graphene oxide paper as multifunctional substrate. Nanoscale 5(24):12616–12623

Du Y, Zhao Y, Qu Y, Chen C-H, Chen C-M, Chuang C-H, Zhu Y (2014) Enhanced light–matter interaction of graphene–gold nanoparticle hybrid films for high-performance SERS detection. J Mater Chem C 2(23):4683–4691

Fan W, Lee YH, Pedireddy S, Zhang Q, Liu T, Ling XY (2014) Graphene oxide and shape-controlled silver nanoparticle hybrids for ultrasensitive single-particle surface-enhanced Raman scattering (SERS) sensing. Nanoscale 6(9):4843–4851

Gong T, Zhu Y, Zhang J, Ren W, Quan J, Wang N (2015) Study on surface-enhanced Raman scattering substrates structured with hybrid Ag nanoparticles and few-layer graphene. Carbon 87:385–394

Cao X, Yan S, Cheng Y, Wang J, Zhu Y, Sun B, Xiao Z (2016) Cysteine-modified Graphene/Gold nanorod composites toward rhodamine 6G detection by surface-enhanced Raman scattering. J Nanosci Nanotechnol 16(7):6697–6704

Goul R, Das S, Liu Q, Xin M, Lu R, Hui R, Wu JZ (2017) Quantitative analysis of surface enhanced Raman spectroscopy of Rhodamine 6G using a composite graphene and plasmonic Au nanoparticle substrate. Carbon 111:386–392

Liang X, Liang B, Pan Z, Lang X, Zhang Y, Wang G, Yin P, Guo L (2015) Tuning plasmonic and chemical enhancement for SERS detection on graphene-based Au hybrids. Nanoscale 7(47):20188–20196

Chen W, Gui X, Zheng Y, Liang B, Lin Z, Zhao C, Chen H, Chen Z, Li X, Tang Z (2017) Synergistic effects of wrinkled graphene and plasmonics in stretchable hybrid platform for surface-enhanced Raman spectroscopy. Adv Opt Mater 5(6):1600715

Ghopry SA, Alamri M, Goul R, Cook B, Sadeghi SM, Gutha RR, Sakidja R, Wu JZ (2020) Au Nanoparticle/WS2 Nanodome/Graphene van der Waals heterostructure substrates for surface-enhanced Raman spectroscopy. ACS Appl Nano Mater 3(3):2354–2363

Sivashanmugan K, Nguyen V-H, Nguyen B-S (2020) Tailoring a novel Au nanodot arrays on graphene substrate for a highly active surface-enhanced Raman scattering (SERS). Mater Lett 271:127807

Zhao Y, Yang D, Li X, Liu Y, Hu X, Zhou D, Lu Y (2017) Toward highly sensitive surface-enhanced Raman scattering: the design of a 3D hybrid system with monolayer graphene sandwiched between silver nanohole arrays and gold nanoparticles. Nanoscale 9(3):1087–1096

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39(1):228–240

Acknowledgements

The authors would like to thank Dr. Yi Wan from Fudan University for the kind assistance for Raman measurements. This work was supported by the National Natural Science Foundation of China (51677031, 11975081, 61705042).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Pedro Camargo.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhang, D., Du, Y., Yang, C. et al. Tuning plasmonic nanostructures in graphene-based nano-sandwiches using ultraviolet/ozone functionalization. J Mater Sci 56, 1359–1372 (2021). https://doi.org/10.1007/s10853-020-05376-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05376-x