Abstract

A series of Sc-substituted In2Mo3O12 ceramics were synthesized by the chemical co-precipitation method. The results reveal that In3+ can be substituted by Sc3+ and form a single phase with high purity for all In2−xScxMo3O12 (x = 0, 0.3, 0.6, 0.9, 1.2 and 1.5) samples. The crystal structure of In2−xScxMo3O12 changes from monoclinic to orthorhombic symmetry with increasing Sc3+-content, confirmed by X-ray diffraction and Raman spectroscopy (Raman). With increasing concentration of A-site Sc3+ cations, the microstructure of In2−xScxMo3O12 becomes denser and the shape and size distribution of grains is more regular and uniform. The monoclinic-to-orthorhombic phase transition temperature of In2Mo3O12 is successfully decreased from 343 °C to room temperature via the substitution of In3+ by Sc3+. When x = 1.5, the occurrence of the monoclinic-to-orthorhombic phase transition for In0.5Sc1.5Mo3O12 solid solution is at around 7 °C. It has an average linear coefficient of thermal expansion of − 5.08 × 10−6 °C−1 in 25–600 °C. The phase transition results obtained by theoretical calculation using the framework of spin-polarized DFT accord well with the experimental evidences.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In general, most of the materials expand as the temperature rises, but some materials exhibit anomalous thermal expansion, which is called negative thermal expansion (NTE). Such materials contract as they are heated up and expand as they are cooled down. They have attracted extensive attention due to their special physical properties, which have potential applications in optical and microelectronic devices. Previous studies in A2Mo3O12 (A = trivalent main group metal or transition metal and M = W, Mo) reveal that many of them exhibit NTE [1,2,3,4,5,6]. When the A-site is occupied by Y3+, Ho3+, Tm3+, Er3+, Yb3+ and Lu3+, these A2Mo3O12 materials form hydrated polymorphs that display positive thermal expansion (PTE) at room temperature because they are highly hygroscopic in the air. The water that is incorporated into the crystal structure hinders the transverse vibrations of the A–O–M linkages, ultimately leading to the complete loss of NTE. Only when the absorbed water is volatilized by heating can these A2Mo3O12 materials exhibit strong NTE. This reversible hygroscopicity severely restricts any practical applications of such materials [7,8,9,10,11,12,13,14,15,16]. No hygroscopicity has been observed in A2Mo3O12 (A = Sc, Al, In, Cr, Fe) molybdates as well as Sc2W3O12 tungstate [3, 4, 17]. However, in the above cases, A2Mo3O12 materials exhibit PTE with a monoclinic structure at low temperature, and NTE behavior can only be observed in an orthorhombic structure at high temperature upon undergoing a phase transition from monoclinic to orthorhombic.

In2Mo3O12 exhibits very strong NTE in its orthorhombic phase, making it a promising candidate for tuning coefficients of thermal expansion (CTE) in composites. In2Mo3O12 undergoes the monoclinic-to-orthorhombic phase transition at 340 °C [4]. Its solid solution suffers, however, from destruction by thermal cracking caused by the occurrence of the phase transition throughout the working temperature.

The dependence of the phase transition temperature for A2(MO4)3 on the electronegativity of the A-site cation has been reported. For example, the electronegativity of Sc3+ is the lowest among the non-hygroscopic A-site cations in the A2M3O12 series. Accordingly, the phase transition temperatures of Sc2Mo3O12 and Sc2W3O12 are also lowest, at about − 95 °C and − 263 °C (or lower), respectively. In an attempt to stabilize the orthorhombic phase at room temperature, the A-site cation in In2Mo3O12 is partially substituted by low-electronegativity Sc3+ to suppress the undesirable phase transition. In previous work by our group, a new series of In2−xScxMo3O12 solid solutions synthesized by the solid-state method suffer from high energy consumption, incomplete reaction and low density [18]. It is well known that the chemical co-precipitation method can overcome these disadvantages of the solid-state method.

This study is devoted to the preparation of a series of In2−xScxMo3O12 solid solutions with high density and the stabilization of the orthorhombic phase of In2Mo3O12 at room temperature or lower by tuning the content of Sc3+-substitution. In this paper, In2−xScxMo3O12 solid solutions are synthesized by the chemical co-precipitation method. The effects of Sc3+-substitution on its crystal structure, phase transition, micromorphology, density as well as negative thermal expansion of In2Mo3O12 have been studied. From the combined experimental results, the correlation between Sc3+-substitution and NTE as well as the phase transition temperature of In2Mo3O12 can be well established. In this work, to investigate the phase transfer process of In2−xScxMo3O12, the total energies of both monoclinic and orthorhombic phase In2−xScxMo3O12 with various doping atomic ratios of Sc3+ are also calculated using spin-polarized density functional theory.

Experimental details

The series of In2−xScxMo3O12 solid solutions were synthesized by the chemical co-precipitation method using commercially available In(NO3)3·xH2O, Sc(NO3)3·6H2O and (NH4)6Mo7O24·4H2O as raw materials. The starting reactants were weighed in stoichiometric amounts corresponding to In3+:Sc3+:Mo6+ molar ratios of 2:0:3, 1.7:0.3:3, 1.4:0.6:3, 1.1:0.9:3, 0.8:1.2:3 and 0.5:1.5:3 and dissolved in deionized water. The three solutions were mixed in a total volume of 25 ml of deionized water while stirring at 80 °C. The pH value of the solution was kept around 10, which was controlled by dripping in ammonia as needed. The corresponding slurries were stirred for 2 h and then dried at 90 °C. The obtained powder was pre-sintered at 500 °C, followed by cold isostatic pressing into pellets (7 mm in diameter), and finally sintered at 760 °C for 6 h in air.

The structural characterization was determined by the X-ray diffraction (XRD) technique, using a Shimadzu XRD-7000 with CuKα radiation. Data were collected with a scanning speed of 5°/min. Raman spectra were collected (Thermo Fisher, DXRxi) in the scanning range of 100–1200 cm−1 with a power of 0.2 mW using a laser with a wavelength of 532 nm. Elemental mapping was done by energy-dispersive X-ray spectroscopy (EDX) on a high-resolution transmission electron microscopy (HRTEM, FEI Tecnai F30 S-TWIN). X-ray photoelectron spectroscopy (XPS, Thermo Scientific, ESCALAB 250Xi) was used to study the valence state of all elements. The cross-sectional microstructure was characterized by scanning electron microscopy (SEM, TESCAN VEEGA3). Dilatometric studies were performed on pellets at a heating rate of 5 °C/min from room temperature to 600 °C using thermal mechanical analysis (TMA/SS, Seiko 6300). Differential scanning calorimetry (DSC) measurements were carried out using PerkinElmer DSC-8500, with the heating rate of 5 °C/min from room temperature to 350 °C.

Results and discussion

Crystal structure analysis

The crystal structure of the samples was determined by X-ray diffraction. The XRD patterns of as-synthesized In2−xScxMo3O12(0 ≤ x ≤ 1.5) heat-treated at different temperatures are shown in Fig. 1. As shown in Fig. 1a, the samples are crystallized during pre-sintering at 500 °C. The crystallization temperature is relatively lower compared to that of solid-state reaction method [18], which means that the chemical co-precipitation synthesis can cause good sinterability of samples. To improve the crystallinity and density, the sintering temperature was further increased to 760 °C and the corresponding XRD patterns are shown in Fig. 1b. All the diffraction peaks become stronger and sharper with no variation in positions, revealing that the crystallinity of the samples is improved with increased sintering temperature. For comparison, the reference pattern for monoclinic In2(MoO4)3 is also displayed. All In2−xScx(MoO4)3 ceramics with Sc3+-content (x) ranging from 0.3 to 1.2 appear to be a well-crystallized single phase with monoclinic In2(MoO4)3-type structure, and no impurity phases are detected. As the Sc3+-content (x) is increased to 1.5, In0.5Sc1.5Mo3O12 crystallizes in an orthorhombic Sc2(MoO4)3-type structure (space group Pbcn, JCPDS card No.21-1329), as marked by the disappearance of the diffraction peaks at 2θ = 25°–27.5° (Fig. 2).

As the small differences between the monoclinic and orthorhombic crystal structures of In2−xScxMo3O12 can make them difficult to distinguish through XRD, Raman analysis was carried out to further characterize the different phases, and the results are depicted in Fig. 3. For x = 0, the recorded Raman spectrum of In2Mo3O12 agrees well with literature reports [19]. As seen in the spectrum, In2Mo3O12 presents strong Raman bands with some shoulders in the 970–1030 cm−1 and 790–970 cm−1 region that can be related to Mo–O symmetric and asymmetric stretching modes, respectively. In addition, the distinct peaks in the 300–400 cm−1 range originate from bending modes of the MoO4 tetrahedra and InO6 octahedra. Comparison of the spectra as a function of composition reveals that the three characteristic peaks located at 175, 862 and 994 cm−1 are gradually weakened with increasing Sc3+-content (x) and disappear completely around x = 1.5 (Fig. 3f). The Raman spectrum of In0.5Sc1.5Mo3O12 corresponds to the typical spectrum of orthorhombic Sc2Mo3O12 in exact accordance with literature data [19]. This observation suggests that the crystal structure of In0.5Sc1.5Mo3O12 has changed from monoclinic to orthorhombic symmetry at room temperature, in good agreement with the above XRD analysis.

To further confirm the successful synthesis of single-phased samples, EDX, STEM and XPS were performed on the In0.5Sc1.5Mo3O12 solid solution. In, Mo, O, Sc and C used for calibration are detected in In0.5Sc1.5Mo3O12 (Fig. 4a), and the corresponding high-resolution XPS spectra of the In 3d and Sc 2p are shown in Fig. 4b, c, respectively. Two peaks at the binding energy of 445 eV and 453 eV are assigned to In 3d5/2 and In 3d3/2 of trivalent indium. In addition, the two peaks with binding energies of 403 eV and 407 eV are attributed to Sc 2p3/2 and Sc 2p1/2, indicating the existence of trivalent scandium. The homogeneity of the elemental composition of In0.5Sc1.5Mo3O12 was further demonstrated through EDX analysis, as shown in Fig. 4d. No elements other than In, Mo, O, Sc and Cu are detected. The strong Cu signal originates from the copper net used to mount the sample. Moreover, as shown in Fig. 4e–i, the STEM image and elemental maps of a selected particle for In0.5Sc1.5Mo3O12 powder demonstrate that the four elements are uniformly distributed throughout the investigated region. Based on the above analysis, these results clearly confirm that In3+ is substituted by Sc3+ in In2Mo3O12 to form a single phase with high purity.

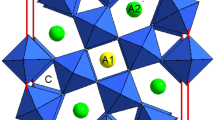

To better understand the crystal structure of In2−xScxMo3O12, the ball-and-stick model presentations are given in Fig. 5; In2Mo3O12 takes on a monoclinic structure (see Fig. 5a), while In0.5Sc1.5Mo3O12 adopts an orthorhombic structure at room temperature (see Fig. 5b), and the frameworks of both are composed of a network of InO6 (ScO6) octahedra and MoO4 tetrahedra. Mo6+ occupies the center of MoO4 tetrahedra. In3+ occupies the center of InO6 octahedra. With the increase in Sc3+-substitution content, Sc3+ gradually replaces In3+ and occupies the A-sites in the center of InO6 octahedra, which is shown in Fig. 5c. Sc3+-substitution leads to the change in crystal structure from monoclinic to orthorhombic symmetry.

Microstructure analysis

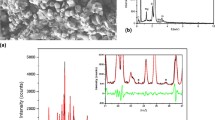

To reveal the relationship between the microstructure and substituted Sc3+-content (x), the typical cross-sectional morphologies of In2−xScxMo3O12 solid solutions are shown in Fig. 6. It is observed that all samples exhibit a dense microstructure without significant pores in contrast to the solid solutions synthesized by the solid-state method [18], indicating a great improvement in the density of solid solutions. In the case of pure In2Mo3O12, the average size of particles varies from 2 to 10 µm and the shapes of particles are not regular (Fig. 6a). Moreover, SEM micrographs clearly reveal the dependence of grain size, as well as the homogeneity of grain sizes, on Sc3+-content (x): The average grain size is gradually reduced and the uniformity of the grain size is improved with increasing Sc3+-content. For x = 1.2, the average grain size is reduced to 2–3 µm, and the microstructure morphology of In0.8Sc1.2Mo3O12 solid solution is clearly more regular with spherical shapes (Fig. 6e). For composition x = 1.5, In0.5Sc1.5Mo3O12 solid solution displays a uniform grain size distribution and the particle size is further reduced to 1 µm, as shown in Fig. 6f.

To attempt to investigate the effect of substituted Sc3+-content (x) on the relative densities of In2−xScxMo3O12 solid solutions, Archimedes’ method was performed on all samples. It can be found that the relative densities for In2−xScxMo3O12 slightly increase with the increase in Sc3+-content (x), which is consistent with the SEM observations. Furthermore, the average relative densities of In2−xScxMo3O12 solid solutions were found to be about 93% (Fig. 7). Obviously, compared with samples prepared by the solid-state method [18], it can be generalized that the microstructure of In2−xScxMo3O12 solid solutions becomes denser without raising the temperature through use of the chemical co-precipitation method.

Phase transition and thermal expansion studies

The thermal expansion behavior of In2−xScxMo3O12 (0 ≤ x ≤ 1.5) solid solutions is shown in Fig. 8. The abrupt change in the slope of the thermal expansion curves for In2Mo3O12 can be attributed to the structural phase transition. This means that In2Mo3O12 maintains the monoclinic structure up to 334 °C, exhibiting positive thermal expansion with a CTE of 10.48 × 10−6 °C−1. The material then undergoes a phase transition in the 334–355 °C temperature range, above which In2Mo3O12 crystallizes in an orthorhombic structure and exhibits strong NTE with a CTE of − 8.36 × 10−6 °C−1 from 360 to 600 °C. Similarly, to unsubstituted In2Mo3O12, all In2−xScxMo3O12 solid solutions follow the same trend, except for In0.5Sc1.5Mo3O12. It is worth noting that we have not found any changes in the slope of the curve for In0.5Sc1.5Mo3O12, which shows NTE throughout the testing temperature range. It can be seen that the onset of the phase transition temperature of In2−xScxMo3O12 solid solutions shifts from 334 °C to a temperature of 75 °C as the Sc3+-content increases progressively from x = 0 to x = 1.2. In addition, A-site substitution with Sc3+ not only dramatically decreases the phase transition temperature of In2Mo3O12, but also gradually narrows the transition range, which is correlated with the electronegativity of the cation. Owning to the lower electronegativity of Sc3+ (1.36) compared to that of In3+ (1.78), the reduction in the average A-site electronegativity of (In2−xScx)3+ as Sc3+-content increases results in increased effective negative charges on the oxygens, and accordingly stronger O–O repulsion, which ultimately results in suppressing the phase transition temperature of In2−xScxMo3O12 to a lower temperature.

The average linear thermal expansion coefficients of the measured In2−xScxMo3O12 solid solutions over the corresponding testing temperature range are summarized in Table 1. In0.5Sc1.5Mo3O12 has an average linear CTE of − 5.08 × 10−6 °C−1 throughout the testing temperature range.

In order to shed more light on the precise phase transition temperature of In2−xScxMo3O12 solid solutions, differential scanning calorimetry was employed to further characterize the samples, and the results are shown in Fig. 9. The DSC curve of In2Mo3O12 (Fig. 9a) displays a sharp endothermic peak at 343 °C. We attribute the appearance of this peak to the structural change associated with the monoclinic-to-orthorhombic phase transition. It can be seen that the observed endothermic peak progressively shifts to lower temperatures as the content of Sc3+-substitution increases gradually from x = 0.3 to x = 1.2. As shown in Fig. 9f, the endothermic peak disappears in the testing temperature range in the case of x = 1.5, revealing that the phase transition temperature of In0.5Sc1.5Mo3O12 has been reduced below room temperature. The phase transition temperatures of all In2−xScxMo3O12 solid solutions determined by DSC and TMA are summarized in Table 2 and show good consistency. The correlation between the variation in phase transition temperature and Sc3+-content (x) is established in Fig. 10, which can be used to estimate the phase transition temperature of In2−xScxMo3O12 solid solutions with different contents of Sc3+-substitution. For instance, Sc2Mo3O12 experiences the phase transition at about − 104.2 °C, which is consistent with the reported data. It could be inferred that the occurrence of the phase transition for In0.5Sc1.5Mo3O12 is at about 7 °C.

Theoretical calculation analysis

To analyze the structural stability of the In2−xScxMo3O12, the total energy of both monoclinic and orthorhombic phase In2−xScxMo3O12 is calculated by the framework of spin-polarized DFT as implemented in the Vienna Ab initio Simulation Package (VASP) [20, 21]. The exchange–correlation potentials were treated by the generalized gradient approximation (GGA) parameterized by Perdew, Burke and Ernzerhof (PBE) [22]. The interaction between valence electrons and ion cores was described by the projected augmented wave (PAW) method [23]. The monoclinic and orthorhombic phases of In2−xScxMo3O12 were modeled as a periodic slab by setting the lattice parameters as a = 16.34 Å/19.32 Å, b = 9.55 Å/13.23 Å and c = 18.76 Å/9.47 Å, respectively. The Monkhorst–Pack grid of 1 × 2 × 1 and 1 × 1 × 2 was used for the geometry optimization. A 400 eV kinetic energy cutoff was chosen for plane-wave basis set, and conjugated gradient (CG) atomic optimization was performed with a criterion of convergence of 0.01 eV/Å.

To address the phase transfer process of In2−xScxMo3O12, we compared the stabilities of the monoclinic and orthorhombic phase In2−xScxMo3O12 by displacing In atom with Sc atoms, at the ratios (R = Sc:In) of 0:6, 2:14, 4:12, 6:10, 8:8, 10:6, 12:4, 14:2 and 16:0, respectively (see Fig. 11a). Our results indicate that very close energies are found for these two phases at various doping ratios. This may be explained by the small difference in the two crystal structure. Normal XRD cannot tell the difference between monoclinic and orthorhombic phase of In2Mo3O12 [4]. Only the XRD results obtained using a synchrotron facility can distinctly reveal the difference of the two structures. Figure 11b shows the energy difference (\( \Delta E \)) between the monoclinic and orthorhombic phase In2−xScxMo3O12 with the same doping atomic ratio of Sc, and the \( \Delta E \) is calculated as:

A careful examination manifested that the energy profile of two phases crosses at around R = 12:4, which can be clearly seen in Fig. 11b. When R < 12:4, ΔE < 0, indicating the In2−xScxMo3O12 has stable monoclinic phase, while an orthorhombic phase is energetically favored once R ≥ 12:4. In other words, it means that the In2−xScxMo3O12 (x < 1.5) crystallizes in a monoclinic In2Mo3O12-type symmetry, and when x ≥ 1.5, the In2−xScxMo3O12 shows an orthorhombic Sc2Mo3O12-type symmetry. These theoretical results accord well with our experimental evidences.

Conclusions

For the first time, single-phased In2−xScxMo3O12 solid solutions (x = 0, 0.3, 0.6, 0.9, 1.2 and 1.5) were synthesized by the chemical co-precipitation method. Sc3+-substitution gave rise to a change in the crystal structure of In2Mo3O12. In2−xScxMo3O12 adopts monoclinic In2Mo3O12-type symmetry for x ≤ 1.2 and transforms to orthorhombic Sc2Mo3O12-type symmetry in the case of x = 1.5. Meanwhile, the co-precipitation synthesis leads to better densification and sinterability in the above samples. The microstructure of In2−xScxMo3O12 becomes denser with fine grain shape and narrow size distribution influenced by the increase in Sc3+-content. Furthermore, Sc3+-substitution at A-site of In2Mo3O12 can effectively shift the phase transition temperature to below room temperature. The phase transition temperature of In0.5Sc1.5Mo3O12 is around 7 °C and shows stable negative thermal expansion. The corresponding average CTE of In0.5Sc1.5Mo3O12 ceramics is − 5.08 × 10−6 °C−1 from 25 to 600 °C. The calculation results obtained using spin-polarized density functional theory agree well with the experimental results. When R < 12:4, the In2−xScxMo3O12 has stable monoclinic phase, while an orthorhombic phase is energetically favored once R ≥ 12:4.

References

Evans JSO, Mary TA, Sleight AW (1998) Negative thermal expansion in Sc2(WO4)3. Solid State Chem 137:148–160

Evans JSO, Mary TA (2000) Structural phase transitions and negative thermal expansion in Sc2Mo3O12. Int J Inorg Mater 2:143–151

Evans JSO, Mary TA, Sleight AW (1997) Negative thermal expansion in a large molybdate and tungstate family. Solid State Chem 133:580–583

Marinkovic BA, Ari M, Jardim PM et al (2010) In2Mo3O12: a low negative thermal expansion compound. Thermochim Acta 499:48–53

Liu HF, Zhang ZP, Ma J et al (2015) Effect of isovalent substitution on phase transition and negative thermal expansion of In2−xScxW3O12 ceramics. Ceram Int 41:9873–9877

Sumithra S, Umarji AM (2004) Role of crystal structure on the thermal expansion of Ln2W3O12 (Ln = La, Nd, Dy, Y, Er and Yb). Solid State Sci 6:1313–1319

Xiao XL, Wu MM, Peng J et al (2008) Negative thermal expansion of Yb2Mo3O12 and Lu2Mo3O12[C]. Key Eng Mater 368:1662–1664

Sumithra S, Tyagi AK, Umarji AM (2005) Negative thermal expansion in Er2W3O12 and Yb2W3O12 by high temperature X-ray diffraction. Mater Sci Eng B 116:14–18

Xiao XL, Cheng YZ, Peng J et al (2008) Thermal expansion properties of A2(MO4)3 (A = Ho and Tm; M = W and Mo). Solid State Sci 10:321–325

Forster PM, Yokochi A, Sleight AW (1998) Enhanced negative thermal expansion in Lu2W3O12. Solid State Chem 140:157–158

Liu HF, Zhang W, Zhang ZP et al (2009) Synthesis and negative thermal expansion properties of solid solutions Yb2−xLaxW3O12 (0 ≤ x ≤ 2). Ceram Int 35:2951–2956

Cheng YZ, Xiao XL, Liu XF et al (2013) Study of the structures and thermal expansion properties of solid solutions Yb2−xDyxW3O12 (0 ≤ x ≤ 1.5 and 1.8 ≤ x ≤ 2.0). Phys B Condens Matter 411:173–177

Cheng YZ, Wu MM, Peng J et al (2007) Structures, thermal expansion properties and phase transitions of ErxFe2−xMo3O12 (0.0 ≤ x ≤ 2.0). Solid State Sci 9:693–698

Wu MM, Peng J, Cheng YZ et al (2007) Thermal expansion in solid solution Er2−xSmxW3O12. Mater Sci Eng B 137:144–148

Vinet P, Rose JH, Ferrante J et al (1989) Universal features of the equation of state of solids. J Phys Condens Matter 1:1941–1963

Wu MM, Peng J, Yong Z et al (2012) Thermal expansion properties of Lu2−x FexMo3O12. Chin Phys B 21:346–351

Tyagi AK, Achary SN, Mathews MD (2002) Phase transition and negative thermal expansion in A2Mo3O12 system (A = Fe3+, Cr3+ and Al3+). J Alloy Compd 339:207–210

Zhang ZP, Yang L, Zhu Q et al (2017) Phase transition and negative thermal expansion properties in isovalently substituted In2−xScxMo3O12 ceramics. Ceram Int 43:12013–12017

Maczka M, Hermanowicz K, Hanuza J (2005) Phase transition and vibrational properties of A2(BO4)3 compounds (A = Sc, In; B = Mo, W). J Mol Struct 744:283–288

Kresse G, Hafner J (1993) Ab initio molecular dynamics for open-shell transition metals. Phys Rev B 48:13115–13118

Kresse G, Furthmüller J (1996) Efficiency of ab initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci 6:15–50

Perdew JP, Burke K, Ernzerhof M (1996) Generalized gradient approximation made simple. Phys Rev Lett 77:3865–3868

Blochl PE (1994) Projector augmented-wave method. Phys Rev B 50:17953–17979

Acknowledgements

This work was supported by the National Natural Science Foundation of China [Grant Numbers 51602280, 51102207], Qing Lan Project of Jiangsu Province, University Natural Science Research Foundation of Jiangsu Province [Grant Number 14KJB430025] and Guangling College of Yangzhou University Natural Science Research Foundation [Grant Number ZKZD17001]. Thanks to Prof. Cora Lind for her suggestion and revision on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Wang, Y., Sun, W. et al. Phase transition temperature and negative thermal expansion of Sc-substituted In2(MoO4)3 ceramics. J Mater Sci 55, 5730–5740 (2020). https://doi.org/10.1007/s10853-020-04441-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04441-9