Abstract

Highly conductive poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) fiber has been developed as a more promising candidate compared with bulk and film to achieve wearable thermoelectric energy harvesting. Single-walled carbon nanotubes (SWCNTs) with nanostructures are considered as an effective conductive filter for the further improvement in the thermoelectric (TE) performance of PEDOT:PSS fibers. However, the previous research primarily focused on PEDOT:PSS/SWCNT films instead of fibers. In this study, PEDOT:PSS/SWCNT hybrid fibers were synthesized via gelation process, which presents a 30% enhancement of the electrical conductivity with negligible changes in Seebeck coefficient. Moreover, there was a significant increase in the Young’s modulus in accordance with the addition of an appropriate amount of SWCNTs. Thereafter, the as-prepared hybrid fibers were treated using ethylene glycol (EG) to further optimize the TE performance. Moreover, the influence of the treatment time and temperature was systematically investigated. The EG treatment resulted in a significant improvement in the electrical conductivity without a significant decrease in the Seebeck coefficient. Furthermore, the hybrid fibers were subject to EG treatment at elevated temperature, whose optimal power factor was approximately 30% higher than that of the EG-treated PEDOT:PSS/SWCNT fibers at 25 °C. This indicates that the solvent treatment at higher temperature improves the TE performance of hybrid fibers. The findings of this study can serve as a guide for the preparation of flexible and metal-free hybrid fiber with enhanced TE performance and Young’s modulus.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The extensive development of wearable electronic device facilitated the progress of self-powering textiles, which involved photovoltaic [1], triboelectric [2], electrochemical [3] and thermoelectric (TE) [4] energy generation and storage techniques. Compared with thin films and bulks, fiber-shaped materials can be widely used in wearable energy supplying techniques, primarily because they can be significantly integrated into common textiles with minimal impact on comfort and breathability [5, 6]. Moreover, TE materials can utilize the temperature gradient between the human body and environment to generate power for wearable electronic devices [7,8,9,10,11]. The TE performance of a semiconductive material is evaluated as ZT = σS2T/κ, where σ, S, T and κ represent the electrical conductivity, Seebeck coefficient, absolute temperature and thermal conductivity, respectively. For organic TE materials with inherently low thermal conductivity, the evaluation of their TE performance using the power factor (PF = σS2) is widely accepted as well.

As one of the most promising organic thermoelectric materials, commercially available poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) has been extensively researched due to its easy processability, high electrical conductivity and nontoxicity [12,13,14,15]. Due to its simple preparation process and structural advantages, the PEDOT:PSS-based hydrogel fiber has attracted significant research attention in many fields [16,17,18,19]. In a previous study, a TE fiber was synthesized from PEDOT:PSS via a sulfuric acid-assisted gelation process. The resultant PEDOT:PSS fiber was then treated with ethylene glycol to further increase its electrical conductivity in accordance with a slight decrease in its Seebeck coefficient, whose optimized σ, S and PF values were calculated as 175 S cm−1, 16 μV K−1 and 4.77 μW m−1 K−2, respectively [20]. The tensile properties the abovementioned PEDOT:PSS fibers, which are critical for wearable thermoelectric energy harvesting applications, were not presented. Furthermore, the TE performance of the fibers can be further optimized by introducing nanostructured materials with excellent TE performance to the organic matrix.

In recent years, metal-free hybrid TE materials have been extensively developed due to their great potential to fulfill both merits of each component, thus leading to enhanced TE performance. Furthermore, their excellent mechanical reliability allows them to be implemented in wearable application [21,22,23,24,25]. As a highly conductive filler, single-walled carbon nanotubes (SWCNTs) have been extensively employed to enhance the TE performance of PEDOT:PSS based on the carrier scattering effect [26,27,28,29]. The junctions in the hybrid semiconducting materials are critical to high TE performance material. When charge carriers are transported through these junctions, charge carriers with low energy are scattered by the energy barrier in the junctions, which would benefit the Seebeck coefficient [30]. Yu et al. reported that σ of the PEDOT:PSS/CNT composite was increased to 13500 S cm−1 with an almost constant S ranging from 27–47 μV K−1 in accordance with an increase in weight content of the CNTs from 35 to 60 wt % [31]. Moreover, the introduction of SWCNTs can also increase the Young’s modulus of polymer-based materials [32], which may be due to the strong π–π interaction between the PEDOT chains and SWCNTs. However, most of the previous studies were mainly focused on the PEDOT:PSS/SWCNT bulk or film. The thermoelectric and tensile properties of PEDOT:PSS/SWCNT fibers with respect to wearable thermoelectric energy harvesting applications should be considered. Moreover, EG post-treatment was verified as an effective method for the improvement in the TE performance of PEDOT:PSS-based materials due to the removal of insulating PSS chains from highly conductive PEDOT chains, thus inducing the enrichment of the conductive phase in the surface region [20, 27, 33]. The information presented above can serve as a basis for the realization of hybrid fibers with enhanced TE and tensile performance.

In this study, PEDOT:PSS/SWCNT hybrid fibers were prepared via a gelation method. The TE and tensile properties of the hybrid fibers were comprehensively characterized. EG post-treatment was then employed, and its effect on the TE performance of the as-prepared hybrid fibers was systematically investigated. Changes in the micromorphology and chemical composition of the as-prepared fibers, as induced by EG post-treatment, were detected using scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS). The proposed hybrid fibers represent a novel scheme for the development of fiber-based TE energy harvesting system.

Experimental

Materials

The PEDOT:PSS aqueous solution (Clevios PH1000) was obtained from HC Stark. SWCNT dispersion in water (0.2 wt %, TUBALL™ BATT) was purchased from OCSiAl (www.ocsial.com). Sulfuric acid (H2SO4) was obtained from Xilong Chemical Co. Ltd. Anhydrous ethanol (EtOH) was obtained from Sinopharm Chemical Reagent Co., Ltd. Hydrazine hydrate (N2H4·H2O, 80%) and ethylene glycol (EG) were obtained from J&K Scientific Ltd. All the chemical agents were used as received.

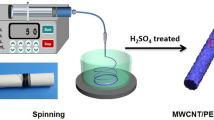

Fabrication of PEDOT:PSS/SWCNT hybrid fiber

The PEDOT:PSS hybrid fibers were synthesized mainly based on a method employed in a previous study [20]. In particular, 5 mL of PEDOT:PSS and SWCNT hybrid solution which contained 0.05 M H2SO4 was injected into a polytetrafluoroethylene tube mold (inner diameter = 1.0 mm) that was then set in an oven at a temperature of 90 °C for 3 h. To optimize the TE performance of as-prepared hybrid fibers, they were immersed in the EG solution for a given period of time. The as-prepared hybrid fibers were denoted as EGx-PEDOT:PSS/SWCNTy, where x and y represent the EG treatment temperature and weight content of the SWCNTs.

Measurement

The diameter and micromorphology of the as-prepared fibers were obtained using SEM (JSM-7500F; JEOL, Japan). The surface composition of the PEDOT:PSS fiber was detected using an Escalab 250Xi X-ray photoelectron spectroscope (XPS, Thermo Fisher Scientific, USA).

The tensile properties of the as-prepared hybrid fibers were determined using a tensile testing machine (ZQ-990LB). A 5 cm fiber was fixed on the test machine, which was then stretched at 1 mm min−1. A minimum of five tests were carried out for each sample. A standard four-point probe technique was employed to measure the electrical conductivity and the sheet resistance Rs of the fibers. The Rs was calculated as Rs = 2πrR/L, where L, R and r represent the length, resistance and the radius of fibers, respectively. S is estimated as S = −△V/△T, where △V and △T represent the temperature difference-induced voltage and the in-plane temperature gradient of fibers in the axial direction, respectively. The thermopower along the axial direction under the temperature gradient was measured using a data acquisition system (Keithley 2700), which was established with a heat resistor and controlled by regulated direct current.

Results and discussion

Based on a previous report [20], PEDOT:PSS fibers can be obtained when PEDOT:PSS and sulfuric acid hybrid solution was kept at 90 °C for 3 h. To further improve the TE performance, solution-processable SWCNTs were introduced into the PEDOT:PSS matrix. First, the effect of the SWCNTs weight content on the gelation of PEDOT:PSS, with the use of sulfuric acid, was investigated. The formation of the fibers can be attributed to the introduction of sulfuric acid, which eliminates a portion of PSS, thus leading to the enhancement of the hydrophobic attraction and π–π stacking interaction between PEDOT:PSS grains [16]. Additional SWCNT hindered the formation of the cross-linking network. As shown in Fig. 1, the continuity of hybrid fibers significantly decreased in accordance with an increase in the SWCNT weight content. The PEDOT:PSS cross-linking network was unable to bear the SWCNT overload and underwent breakage when the SWCNT weight content exceeded 70 wt %. Figure 2 presents the SEM images of the as-prepared hybrid fibers. The diameters of the PEDOT:PSS/SWCNT0.6, EG25-PEDOT:PSS/SWCNT0.6 and EG100-PEDOT:PSS/SWCNT0.6 hybrid fibers were calculated as 77.14 ± 4.81 μm, 66.11 ± 4.26 μm and 56.76 ± 2.77 μm, respectively. The diameters of hybrid fibers slightly decreased after EG treatment. Moreover, the surface of the hybrid fibers was relatively smooth. After EG treatment, more wrinkles were observed, which was in accordance with the findings of a previous study [34]. An assumption was made that the surface composite may be affected by the EG treatment.

Figure 3a, b and c presents the S2p XPS of the PEDOT:PSS/SWCNT0.6, EG25-PEDOT:PSS/SWCNT0.6 and EG100-PEDOT:PSS/SWCNT0.6 fibers, for an accurate determination of the chemical structure. In general, the doublet at 166–170 eV can be attributed to the sulfur atom from the sulfonate group in PSS, and the doublet at 162–166 eV can be attributed to the sulfur atom from the thiophene group in PEDOT [35]. The ratio between PEDOT and PSS of the PEDOT:PSS/SWCNT0.6, EG25-PEDOT:PSS/SWCNT0.6 and EG100-PEDOT:PSS/SWCNT0.6 fiber was quantified as 1:1.77, 1:1.56 and 1:1.39, respectively. After the EG treatment, the insulative PSS molecules were readily removed from the surface region of the hybrid fibers, which can be mainly attributed to the weakening of the Coulombic force between the PEDOT and PSS chains, as induced by the EG screen effect [36]. Moreover, compared with the hybrid fibers subject to EG treatment at 25 °C, the PEDOT/PSS ratio of the EG100-PEDOT:PSS/SWCNT0.6 fibers decreased further. This indicates that the organic solvent treatment at an elevated temperature promotes the phase separation of PSS from PEDOT chains, thus resulting in the further enhancement of the electrical conductivity.

The representative strain–stress curves of the PEDOT:PSS/SWCNT hybrid fibers are shown in Fig. 4. All the hybrid fibers exhibited bilinear strain–stress curves, thus indicating linear strain-hardening characteristics [37]. The bilinear curves represent two sequential deformations during the stretching process. The first linear curve indicates the elastic behavior, and the second linear curve indicates plastic behavior when subject to additional stress. The bilinear behavior can be described by a simple Prandtl–Reuss elasto-plastic model, where H (H = (σm−σy)/D), σm, σy and D represent the classical linear hardening parameter, final tensile stress, yield stress and plastic strain, respectively. All the tensile properties of the hybrid fibers are listed in Table 1. The introduction of SWCNT promotes the Young’s modulus of the PEDOT:PSS fibers from 0.8 to 1.6 when the SWCNTs weight content reached 20 wt %, which can be attributed to the intrinsic high stiffness of the SWCNTs [38, 39]. With a further increase in the SWCNTs loading, the SWCNTs were not homogeneously dispersed in the PEDOT:PSS matrix and aggregation occurred. Consequently, the Young’s modulus, fracture strain and σm were decreased. It should be noted that the Young’s modulus of polymer-based materials is inversely proportional to the relative humidity (RH) [40]. Tensile tests were conducted on samples under 65% RH. A higher Young’s modulus was obtained under a lower RH. Moreover, the Young’s modulus values of the PEDOT:PSS-based materials are listed in Table 2. The hybrid fibers synthesized in this study demonstrate a relative low Young’s modulus when compared with previous reports.

The TE performance characteristics of the PEDOT:PSS/SWCNT fibers are presented in Fig. 5. Hybrid fibers were obtained when the SWCNTs weight content was below 65 wt %. When SWCNTs weight content was higher than 65 wt %, the hybrid fibers were excessively weak; thus, they could not be extracted from EtOH, which was mainly because the PEDOT:PSS network lacked the strength to bear the excessive SWCNTs content. The TE performance of the hybrid fibers remained almost constant when the SWCNTs weight content was less than 50 wt %. With an increase in the SWCNTs weight content, σ of the hybrid fibers increased from 58.6 to 76.3 S cm−1 and then decreased significantly to 37.3 S cm−1. The increase in electrical conductivity can be mainly attributed to (1) the intrinsic higher electrical conductivity of the SWCNTs with a highly conductive π-conjugated path for the transport of charge carriers (78.9 S cm−1) [47] and the (2) filling of the junctions between the SWCNTs by PEDOT:PSS, thus decreasing the resistance of the junctions [26, 31].

The Seebeck coefficient of the SWCNTs (13.6 μV K−1) was relatively lower than that of PEDOT:PSS fibers (17.3 μV K−1). Moreover, the Seebeck coefficient of the hybrid fibers did not decrease significantly upon mixture with the SWCNTs, which was possibly due to the energy filtering effect. In particular, the work functions of the PEDOT:PSS and SWCNT were different, i.e., the Fermi level that represents the average kinetic energy of the charge carriers in the two semiconducting materials was different. When the two components were in contact with each other, interfacial barriers were formed due to band bending, which could preferentially scatter low-energy carriers and allow for the passage of high-energy carrier [48,49,50,51]. The variation in the TE performance of the hybrid fibers with respect to the SWCNTs content was in agreement with the findings of previous reports [47, 52].

When the SWCNTs weight content was greater than 60 wt %, σ and S decreased simultaneously. It should be noted that the PEDOT:PSS matrix cannot contain a significant amount of SWCNTs, and an excessive amount SWCNTs severely impacts the continuity of the conductive network. In general, the optimal power factor of the hybrid fibers was 2.22 μW m−1 K−2, which was 24 and 53% higher than those of the PEDOT:PSS fibers and SWCNTs, respectively, when the SWCNTs weight content was 60 wt %.

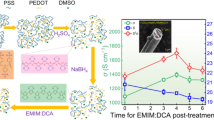

The insulating nature of the PSS chains in the hybrid fibers limits the charge carrier transport between conductive PEDOT chains. Post-treatment with polar solvents [53], such as H2SO4 [54], dimethyl sulfoxide (DMSO) [55,56,57] and EG [58], is widely considered as an efficient method for the removal of PSS and the promotion of charge carrier transport in the hybrid fibers. Figure 6 presents the TE performance of the hybrid fibers subject to EG treatment for several minutes at 25 °C. Due to the immersion treatment processing, the sheet resistance decreased, whereas the electrical conductivity significantly increased, which was mainly due to the partial removal of the insulating PSS chains in the surface region of hybrid fibers as confirmed by XPS results. This resulted in the enrichment of conductive PEDOT chains. Moreover, slight changes were observed in the Seebeck coefficient of the hybrid fiber. The optimal power factor of this hybrid fiber reached 5.57 μW m−1 K−2 after EG treatment for 45 min, which was higher than that of the untreated PEDOT:PSS/SWCNT0.6 fibers by a factor of approximately 1.5.

The treatment temperature was assumed to have an effect on the TE performance of the PEDOT:PSS/SWCNT hybrid fibers. First, the hybrid fibers were subject to EG treatment under a series of elevated temperatures. As shown in Fig. 7a, the EG treatment at higher temperature improved the TE performance of the hybrid fiber. Thereafter, the TE performance of the hybrid fibers subject to EG treatment at 100 °C for varying durations was systematically investigated. As shown in Fig. 7b, the variation trend of the electrical conductivity and Seebeck coefficient of hybrid fibers was the same as that presented in Fig. 6; thus indicating that EG treatment at an elevated temperature may further facilitate the removal of insulating PSS chains, as previously confirmed by XPS results. The optimal power factor of the hybrid fiber reached 7.23 μW m−1 K−2 after EG treatment at 100 °C for 45 min, which was approximately 30% higher than that of EG25-PEDOT:PSS/SWCNT0.6.

Table 3 presents a summary of the TE performance of the PEDOT:PSS/SWCNT hybrid materials. The electrical conductivity of the pristine PEDOT:PSS fibers was found to be significantly lower than that of the films. The significant decrease in electrical conductivity can be attributed to the abundance of insulating PSS chains within the hydrogel fibers when compared with that of the thin films. The cause for the formation of the PEDOT:PSS hydrogel is the enhanced hydrophobic interaction between PEDOT:PSS grains in addition to the π–π stacking interaction between the PEDOT chains, as induced by sulfuric acid [16]. In this self-assembly process, many insulating PSS chains may be wrapped within and on the surface regions of the fibers. Moreover, EG treatment can only remove the PSS chains in the surface regions. The remaining PSS chains within the fibers then limit the charge carrier transport. It should be noted that the electrical conductivity of the PEDOT:PSS fibers without any treatment mainly ranged from 0.4 to 74 S cm−1, when prepared via a wet spinning technique [43, 59] or gelation [16, 20], which was relatively lower than that of the films. In particular, PSS chains allow for the solution to exhibit suitable processability; however, an excess of PSS chains leads to a decrease in the electrical conductivity. Hence, further research is required on the effective regulation of the amount of PSS chains necessary to balance the solution processability (also referred to as ‘spinnability’ for spinning dope) and electrical conductivity for the PEDOT:PSS-based fibers. Furthermore, according to the SWCNT dispersion formula, polyvinylpyrrolidone (PVP) was added to provide the SWCNTs with suitable dispersity in aqueous solutions, which severely deteriorated the charge transport between the PEDOT chains and SWCNTs [60].

The variation in electrical resistance of the optimal hybrid fibers with respect to the bending angle was investigated. As shown in Fig. 8a, there were negligible changes in the electrical conductivity after bending at an angle of 300°. Thereafter, the fiber was subject to approximately 1000 bend-and-release cycles at an angle of 300°. As shown in Fig. 8b, the fibers exhibited slight differences in electrical conductivity before and after 1000 bend-and-release cycles at an angle of 300°. The experimental results demonstrated the good mechanical reliability of the hybrid fibers.

Conclusions

In summary, the development of PEDOT:PSS/SWCNT hybrid fibers with enhanced TE and tensile performance was realized. First, the PEDOT:PSS/SWCNT hybrid fibers were fabricated via the injection of PEDOT:PSS and SWCNT homogeneous dispersion with 0.05 M H2SO4 into a tube mold. It should be noted that hybrid fibers were not obtained when the SWCNT weight content exceeded 65 wt %. The Young’s modulus was increased from 0.8 GPa to 1.6 GPa when the SWCNTs weight content reached 20 wt %. Compared with the power factor of the PEDOT:PSS fibers, that of the hybrid fibers was calculated as 2.22 μW m−1 K−2, which was 24% higher than that of PEDOT:PSS fibers. Thereafter, EG post-treatment was employed to further optimize the TE performance of the hybrid fibers, thus resulting in a significant enhancement of the electrical conductivity with negligible changes in the Seebeck coefficient. This resulted in an increase in the power factor by approximately 2.5 to a value of 5.57 μW m−1 K−2. This was primarily because the EG treatment facilitated the separation of the insulating PSS chains from the highly conductive PEDOT chains in the surface region of the hybrid fibers. Moreover, EG treatment at elevated temperature could further improve the TE performance of the hybrid fibers, whose power factor was 7.23 μW m−1 K−2, indicating that solvent treatment under higher temperature is a more effective method for the improvement in the TE performance of hybrid fibers. The findings of this study can serve as a guide for the preparation of PEDOT:PSS-based fiber with enhanced TE performance.

References

Peng M, Dong B, Zou D (2018) Three dimensional photovoltaic fibers for wearable energy harvesting and conversion. J Energy Chem. 27:611–621

Dong K, Peng X, Wang ZL (2019) Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv Mater 32:1902549. https://doi.org/10.1002/adma.201902549

Zhai S, Karahan HE, Wang C, Pei Z, Wei L, Chen Y (2019) 1D supercapacitors for emerging electronics: current status and future directions. Adv Mater 32:1902387. https://doi.org/10.1002/adma.201902387

Li C, Jiang F, Liu C, Liu P, Xu J (2019) Present and future thermoelectric materials toward wearable energy harvesting. Appl Mater Today 15:543–557

Zhang L, Lin S, Hua T, Huang B, Liu S, Tao X (2017) Fiber-based thermoelectric generators: materials, device structures, fabrication, characterization, and applications. Adv Energy Mater 8:1700524. https://doi.org/10.1002/aenm.201700524

Jia Y, Shen L, Liu J, Zhou W, Du Y, Xu J, Liu C, Zhang G, Zhang Z, Jiang F (2019) An efficient PEDOT-coated textile for wearable thermoelectric generators and strain sensors. J Mater Chem C 7:3496–3502

Shi J, Liu S, Zhang L, Yang B, Shu L, Yang Y, Ren M, Wang Y, Chen J, Chen W, Chai Y, Tao X (2019) Smart textile‐integrated microelectronic systems for wearable applications. Adv Mater 32:1901958. https://doi.org/10.1002/adma.201901958

Zhang Y, Park SJ (2019) Flexible organic thermoelectric materials and devices for wearable green energy harvesting. Polymers 11:909–927

Lin Y, Liu J, Wang X, Xu J, Liu P, Nie G, Liu C, Jiang F (2019). An integral p-n connected all-graphene fiber boosting wearable thermoelectric energy harvesting. Compos Commun 16:79–83

Lan X, Wang T, Liu C, Liu P, Xu J, Liu X, Du Y, Jiang F (2019) A high performance all-organic thermoelectric fiber generator towards promising wearable electron. Compos Sci Technol 182:107767. https://doi.org/10.1016/j.compscitech.2019.107767

Li X, Wang T, Jiang F, Liu J, Liu P, Liu G, Xu J, Liu C, Jiang Q (2019) Optimizing thermoelectric performance of MoS2 films by spontaneous noble metal nanoparticles decoration. J. Alloys Compd. 781:744–750

Fan X, Nie W, Tsai H, Wang N, Huang H, Cheng Y, Wen R, Ma L, Yan F, Xia Y (2019) PEDOT: PSS for flexible and stretchable electronics: modifications, strategies, and applications. Adv Sci 6:1900813. https://doi.org/10.1002/advs.201900813

Ni D, Song H, Chen Y, Cai K (2019) Free-standing highly conducting PEDOT films for flexible thermoelectric generator. Energy 170:53–61

Xue Z, Chen S, Gao N, Xue Y, Lu B, Watson OA, Zang L, Xu J (2019) Polymer Reviews. https://doi.org/10.1080/15583724.2019.1673404

Wang X, Meng F, Tang H, Gao Z, Li S, Jiang F, Xu J (2017) An effective dual-solvent treatment for improving the thermoelectric property of PEDOT: PSS with white graphene. J Mater Sci 52:9806–9818. https://doi.org/10.1007/s10853-017-1166-7

Yao B, Wang H, Zhou Q, Wu M, Zhang M, Li C, Shi G (2017) Ultrahigh‐conductivity polymer hydrogels with arbitrary structures. Adv Mater 29:1700974

Zhao Y, Wang K, Li S, Zhang P, Shen Y, Fu Y, Zhang Y, Zhou J, Wang C (2018) Polydimethylsiloxane (PDMS)-based flexible optical electrodes with conductive composite hydrogels integrated probe for optogenetics. J Biomed Nanotechnol 14:1099–1106

Cao S, Tong X, Dai K, Xu Q (2019) A super-stretchable and tough functionalized boron nitride/PEDOT: PSS/poly (N-isopropylacrylamide) hydrogel with self-healing, adhesion, conductive and photothermal activity. J Mater Chem A 7:8204–8209

Lu B, Yuk H, Lin S, Jian N, Qu K, Xu J, Zhao X (2019) Pure PEDOT: PSS hydrogels. Nat Commun 10:1043

Liu J, Jia YH, Jiang QL, Jiang FX, Li CC, Wang XD, Liu P, Liu PP, Hu F, Du YK, Xu JK (2018) Highly conductive hydrogel polymer fibers toward promising wearable thermoelectric energy harvesting. ACS Appl Mater Interfaces 10:44033–44040

Cheng X, Wang L, Wang X, Chen G (2018) Flexible films of poly (3, 4-ethylenedioxythiophene): Poly (styrenesulfonate)/SnS nanobelt thermoelectric composites. Compos Sci Technol 155:247–251

Xiong J, Jiang F, Shi H, Xu J, Liu C, Zhou W, Jiang Q, Zhu Z, Hu Y (2015) Liquid exfoliated graphene as dopant for improving the thermoelectric power factor of conductive PEDOT: PSS nanofilm with hydrazine treatment. ACS Appl Mater Interfaces 7:14917–14925

Ni D, Song H, Chen Y, Cai K (2020) Significantly enhanced thermoelectric performance of flexible PEDOT nanowire film via coating Te nanostructures. J Materiomics. https://doi.org/10.1016/j.jmat.2019.07.001

Jiang F, Xiong J, Zhou W, Liu C, Wang L, Zhao F, Liu H, Xu J (2016) Use of organic solvent-assisted exfoliated MoS 2 for optimizing the thermoelectric performance of flexible PEDOT: PSS thin films. J Mater Chem A 4:5265–5273

Mahakul PC, Sa K, Das B, Subramaniam BVRS, Saha S, Moharana B, Raiguru J, Dash S, Mukherjee J, Mahanandia P (2017) Preparation and characterization of PEDOT: PSS/reduced graphene oxide–carbon nanotubes hybrid composites for transparent electrode applications. J Mater Sci 52:5696–5707

Kim D, Kim Y, Choi K, Grunlan JC, Yu C (2010) Improved thermoelectric behavior of nanotube-filled polymer composites with poly (3, 4-ethylenedioxythiophene) poly (styrenesulfonate). ACS Nano 4:513–523

Lee W, Kang YH, Lee JY, Jang K-S, Cho SY (2016) Improving the thermoelectric power factor of CNT/PEDOT: PSS nanocomposite films by ethylene glycol treatment. RSC Adv 6:53339–53344

Song H, Qiu Y, Wang Y, Cai K, Li D, Deng Y, He J (2017) Polymer/carbon nanotube composite materials for flexible thermoelectric power generator. Compos Sci Technol 153:71–83

Yoo D, Kim J, Lee SH, Cho W, Choi HH, Kim FS, Kim JH (2015) Effects of one-and two-dimensional carbon hybridization of PEDOT: PSS on the power factor of polymer thermoelectric energy conversion devices. J Mater Chem A 3:6526–6533

Wang X, Wang H, Liu B (2018) Carbon nanotube-based organic thermoelectric materials for energy harvesting. Polymers 10:1196–1218

Yu C, Choi K, Yin L, Grunlan JC (2011) Light-weight flexible carbon nanotube based organic composites with large thermoelectric power factors. ACS Nano 5:7885–7892

Gojny F, Wichmann M, Fiedler B, Schulte K (2005) Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites–a comparative study. Compos Sci Technol 65:2300–2313

Ouyang J, Xu Q, Chu C-W, Yang Y, Li G, Shinar J (2004) On the mechanism of conductivity enhancement in poly (3, 4-ethylenedioxythiophene): poly (styrene sulfonate) film through solvent treatment. Polymer 45:8443–8450

Mengistie DA, Chen CH, Boopathi KM, Pranoto FW, Li LJ, Chu CW (2015) Enhanced thermoelectric performance of PEDOT: PSS flexible bulky papers by treatment with secondary dopants. ACS Appl Mater Interfaces 7:94–100

Kim GH, Shao L, Zhang K, Pipe KP (2013) Engineered doping of organic semiconductors for enhanced thermoelectric efficiency. Nat Mater 12:719–723

Lee CS, Kim JY, Lee DE, Koo YK, Joo J, Han S, Beag YW, Koh SK (2003) Organic based flexible speaker through enhanced conductivity of PEDOT/PSS with various solvents. Synth Met 135–136:13–14

Ladevèze P, Pelle J-P (2005) Mastering calculations in linear and nonlinear mechanics. Springer, New York

Treacy MMJ, Ebbesen TW, Gibson JM (1996) Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 381:678–680

Lourie O, Wagner HD (1998) Transmission electron microscopy observations of fracture of single-wall carbon nanotubes under axial tension. Appl Phys Lett 73:3527–3529

Lang U, Dual J (2007) Key Eng Mater 345–346:1189–1192

Zhou J, Li EQ, Li R, Xu X, Ventura IA, Moussawi A, Anjum DH, Hedhili MN, Smilgies D-M, Lubineau G, Thoroddsen ST (2015) Semi-metallic, strong and stretchable wet-spun conjugated polymer microfibers. J Mater Chem C 3:2528–2538

Jalili R, Razal JM, Wallace GG (2012) Exploiting high quality PEDOT: PSS–SWNT composite formulations for wet-spinning multifunctional fibers. J Mater Chem 22(48):25174–25182

Okuzaki H, Harashina Y, Yan H (2009) Highly conductive PEDOT/PSS microfibers fabricated by wet-spinning and dip-treatment in ethylene glycol. Eur Polym J 45:256–261

Greco F, Zucca A, Taccola S, Menciassi A, Fujie T, Haniuda H, Takeoka S, Dario P, Mattoli V (2011) Ultra-thin conductive free-standing PEDOT/PSS nanofilms. Soft Matter 7:10642–10650

Seyedin MZ, Razal JM, Innis PC, Wallace GG (2014) Strain‐responsive polyurethane/PEDOT: PSS elastomeric composite fibers with high electrical conductivity. Adv Funct Mater 24:2957–2966

Zhou J, Fukawa T, Shirai H, Kimura M (2010) Anisotropic motion of electroactive papers coated with PEDOT/PSS. Macromol Mater Eng 295:671–675

Moriarty GP, De S, King PJ, Khan U, Via M, King JA, Coleman JN, Grunlan JC (2013) Thermoelectric behavior of organic thin film nanocomposites. J Polym Sci, Part B: Polym Phys 51:119–123

He M, Ge J, Lin Z, Feng X, Wang X, Lu H, Yang Y, Qiu F (2012) Thermopower enhancement in conducting polymer nanocomposites via carrier energy scattering at the organic–inorganic semiconductor interface. Energy Environ Sci 5:8351–8358

Coates NE, Yee SK, McCulloch B, See KC, Majumdar A, Segalman RA, Urban JJ (2013) Effect of interfacial properties on polymer–nanocrystal thermoelectric transport. Adv Mater 25:1629–1633

Kumar P, Zaia EW, Yildirim E, Repaka DVM, Yang SW, Urban JJ, Hippalgaonkar K (2018) Polymer morphology and interfacial charge transfer dominate over energy-dependent scattering in organic-inorganic thermoelectrics. Nat Commun 9:5347. https://doi.org/10.1002/aelm.201500017

Lan X, Liu C, Wang T, Hou J, Xu J, Tan R, Nie G, Jiang F(2019) Effect of functional groups on the thermoelectric performance of carbon nanotubes. J Electron Mater 182:107767. https://doi.org/10.1002/aelm.201500017

Yu C, Kim Y, Kim D, Grunlan J (2008) Thermoelectric behavior of segregated-network polymer nanocomposites. Nano Lett 8:4428–4432

Shi H, Liu CC, Jiang QL, Xu JK (2015) Effective approaches to improve the electrical conductivity of PEDOT: PSS: a review. Adv Electron Mater 1:1500017. https://doi.org/10.1002/aelm.201500017

Li X, Liu C, Zhou W, Duan X, Du Y, Xu J, Li C, Liu J, Jia Y, Liu P, Jiang Q, Luo C, Liu C, Jiang F (2019) Roles of polyethylenimine ethoxylated in efficiently tuning the thermoelectric performance of poly(3,4-ethylenedioxythiophene)-rich nanocrystal films. ACS Appl Mater Interfaces 11:8138–8147

Wang X, Liu P, Jiang Q, Zhou W, Xu J, Liu J, Jia Y, Duan X, Liu Y, Du Y, Jiang F (2018) Efficient DMSO-vapor annealing for enhancing thermoelectric performance of PEDOT: PSS-based aerogel. ACS Appl Mater Interfaces 11:2408–2417

Lim K, Jung S, Lee S, Heo J, Park J, Kang J-W, Kang Y-C, Kim D-G (2014) The enhancement of electrical and optical properties of PEDOT: PSS using one-step dynamic etching for flexible application. Org Electron 15:1849–1855

Zhang L, Harima Y, Imae I (2017) Highly improved thermoelectric performances of PEDOT: PSS/SWCNT composites by solvent treatment. Org Electron 51:304–307

Yan H, Jo T, Okuzaki H (2009) Highly conductive and transparent poly (3, 4-ethylenedioxythiophene)/poly (4-styrenesulfonate)(PEDOT/PSS) thin films. Polym J 41:1028–1029

Jalili R, Razal JM, Innis PC, Wallace GG (2011) One‐step wet‐spinning process of poly (3, 4‐ethylenedioxythiophene): poly (styrenesulfonate) fibers and the origin of higher electrical conductivity. Adv Funct Mater 21:3363–3370

Jiang Q, Lan X, Liu C, Shi H, Zhu Z, Zhao F, Xu J, Jiang F (2018) High-performance hybrid organic thermoelectric SWNTs/PEDOT: PSS thin-films for energy harvesting. Mater Chem Front 2:679–685

Song H, Liu C, Xu J, Jiang Q, Shi H (2013) Fabrication of a layered nanostructure PEDOT: PSS/SWCNTs composite and its thermoelectric performance. RSC Adv 3(4):22065–22071

Kim J-Y, Lee W, Kang YH, Cho SY, Jang K-S (2018) Wet-spinning and post-treatment of CNT/PEDOT: PSS composites for use in organic fiber-based thermoelectric generators. Carbon 133:293–299

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51762018 and 51863009), the Innovation-Driven ‘‘5511′’ Project of Jiangxi Province (20165BCB18016), the Natural Science Foundation of Jiangxi Province (20181ACB20010) and the Open Fund of the State Key Laboratory of Luminescent Materials and Devices (South China University of Technology, 2019-skllmd-01).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Zhu, Z., Zhou, W. et al. Flexible metal-free hybrid hydrogel thermoelectric fibers. J Mater Sci 55, 8376–8387 (2020). https://doi.org/10.1007/s10853-020-04382-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04382-3