Abstract

The flower-like Co3O4 particles with three-dimensional structure have been achieved by inheriting the flower-like framework of β-Co(OH)2 particles fabricated by a facile solvothermal method without any surfactant. The obtained Co3O4 microflower, which was composed of large amounts of self-assembled porous ultrathin nanosheets, exhibited excellent electrochemical performances in terms of high specific capacity and good cycle stability when being evaluated as anode materials for lithium-ion battery. Specifically, a high reversible capacity of above 1100 mA h g−1 was achieved after 50 cycles at the current density of 296 mA g−1. Hierarchical flower-like structure with mesoporous was considered as providing more active sites for Li+ insertion and paths for transport of Li+, which led to faster lithium-ion diffusion. Co3O4 porous flower-like nanostructures possessed significant potential application in energy storage systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

On account of the merits of high energy density and long cycle life, lithium-ion batteries (abbreviated as LIB’s) are widely applied as power supply in various electronic devices [1, 2]. In order to realize higher power density and longer life span, numerous efforts have been taken to develop novel and high-performance electrode materials [3,4,5,6]. One significant aspect to promote performances of batteries is synthesizing functional nanomaterials with controlled size and shape as electrode materials [7, 8].

Meanwhile, spinel cobalt oxide (Co3O4) has been extensively investigated as anode material in LIB’s, due to its high theoretic capacity (890 mA h g−1) [9]. As a result of its relative abundance and facile synthesis, Co3O4 is especially attractive for energy storage systems. However, the large volume variation of Co3O4 structure during the lithium uptake/release process severely reduces the stability and longevity of LIB’s [10]. Different morphologies of Co3O4 nanostructures have been synthesized and researched, aimed at overcoming these drawbacks in their performances in LIB’s [11]. Nanocages [12], nanotubes [13], hollow nanostructures [14, 27,28,29] and so forth have been developed through different preparation methods, and their performances as anode materials have been researched systematically.

Recently, hierarchical flower-like microsphere with porous structure has attracted great attention after being prepared successfully. The three-dimensional hierarchical structure possessing large specific surface area offer more active sites for accessibility of the electrolyte and the fast ion diffusion in redox reactions [32, 34]. In this aspect, a great deal of porous Co3O4 nanoflowers which are assembled with nanorods [15], smooth nanosheets [16] and so forth with remarkable properties have been prepared and investigated [31, 33]. In this study, Co3O4 microflower assembled by ultrathin porous nanosheets was synthesized. The obtained hierarchical Co3O4 structure offered higher specific surface area and larger pore volume, which had access to extra interfacial reaction sites of Li+ insertion on cycling. As a result, the Co3O4 anode material exhibited excellent electrochemical performances in Li-ion battery. Presumably, porous structures on these ultrathin nanosheets are the key in enhancing the LIB’s performance.

Experimental

Preparation and characterization

3 mmol of C4H6CoO4·4H2O was dissolved in the mixed solvent (1, 2-propanediol/water = 20:20, volume ratio) to form a transparent pink solution after stirring for 30 min at room temperature. Ammonium Hydroxide (NH3·H2O) was used to keep the pH value at 10. This homogeneous solution was transferred into a Teflon-lined stainless steel auto clave and kept in an oven at 220 °C for 24 h. After being cooled down to ambient temperature, the red hydroxide precipitate was collected by centrifugation and washed with deionized water and ethanol for several times, then dried in a vacuum oven at 70 °C for 10 h. By annealing the precursor at 400 °C for 2 h in air, black Co3O4 powder was successfully obtained.

An X-ray diffractometer (XRD, D8/ADVANCE diffractometer) was used to characterize phase of these samples with Cu Kα(λ = 1.5418 Å) radiation. The morphology and microstructure were observed by the field emission scanning electron microscope (SEM, Oberkochen, Germany, LEO-1530) and transmission electron microscope (TEM, JEM-2100F). Thermogravimetric (TG) analysis of thermal decomposition of precursors was performed on Thermogravimetric analyzer (N33-TG 209 F3).

Electrochemical measurements

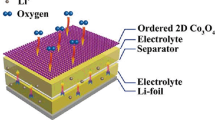

The electrochemical performance of as-prepared Co3O4 sample was evaluated using the CR2032-type coin cells. As-prepared Co3O4 as active material was mixed with acetylene black (as conductive agent) and Poly (vinylidene fluoride) (as binder) at a weight ratio of 7:2:1. N-methyl-2-pyrrolidone was used as the solvent to make the dry mixed powder into mixture paste. Then the paste was coated uniformly on the copper foil to fabricate electrode. And the electrode was dried in a vacuum drying oven at 80 °C for 24 h to remove the absorbed water. The as-prepared copper foil was punched into round sheets with a diameter of 14 mm. The mass loading of the active materials is about 0.95–1.18 mg cm−2.A metal lithium foil was utilized as the counter and reference electrodes and a polypropylene microporous film as the separator. The Co3O4/Li half-cells were made in a dry Ar-filled glovebox using 1 mol/L LiPF6 (EC: DMC, 1: 1, in volume) as the electrolyte. Cyclic voltammetry and electrochemical impedance measurements (AC voltage of 5 mV amplitude, 10 kHz–10 mHz) were performed using an electrochemical workstation (CHI 660B, Shanghai Chenhua instrument Co., Ltd).The electrochemical performance of two-electrode coin-type cell was charged and discharged over a voltage range of 0–3 V versus Li/Li+ electrode at room temperature on LAND batteries test system (Wuhan, China).

Results and discussion

The SEM images in Fig. 1 exhibited the showed morphologies of synthesized β-Co(OH)2 pink powder. As showed in Fig. 1a, it could be easily figured out that the microparticles were mainly made up of flower-like microspheres with the diameter in of 20–60 μm. The SEM images and the inserted image clearly revealed the details of the ultrathin sheets in Fig. 1b. Their surfaces and edges were pretty smooth and the thickness was about 50 nm. All the features mentioned above illustrated great surface properties of the as-synthesized β-Co(OH)2 precursor.

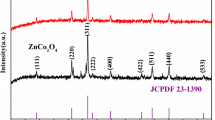

For investigating the transformation from the as-synthesized β-Co(OH)2 precursor to Co3O4, the Thermogravimetric analyzer (TG) and X-ray diffractometer (XRD) were employed to analyze the thermal decomposition behavior of precursor and the corresponding transformation of phase structure. Figure 2a depicted the TG curve of the precursor, which was identified as β-Co(OH)2 by XRD pattern in Fig. 2c. According to the thermal decomposition process in Fig. 2a, three stages could be figured out. The weight loss before 160 °C in the first stage was about 3.3%, which was corresponding to the physical dehydration of the sample. The second stage came with the initial step of thermal decomposition from β-Co(OH)2 to Co2O3, with about 86.3% weight left from 160 °C to 270 °C. As the temperature went higher toward 400 °C, the third stage which was the final thermal decomposition came with only 83.5% weight left, resulting in the final product Co3O4. And the XRD pattern in Fig. 2b of the sample after annealed at 400 °C for 2 h, well matched the standard spectrum of spinel Co3O4 (JCPDS Card No. 42-1467). Figure 2d showed FT-IR spectra of the precursor and Co3O4. Two strong absorptions at 659 and 562 cm−1 are ascribed to the decomposition of the hydroxide to Co3O4 [17] . The broad band at 495 cm−1 is assigned to Co–O. The peaks at 3421 and 1057 cm−1 are attributed to O–H stretching and C-O stretching vibrations of epoxy groups, respectively.

The morphology and microstructure of the obtained Co3O4 after annealing process were further characterized with SEM and TEM. Judging from SEM images with low magnification in Fig. 3a, b, it was found that the annealed products well preserved the flower-like framework of these precursors. However, some interesting changes about the nanosheets happened, which could be figured out in the inserted images in Fig. 3b. Some mesoporous could be found clearly on these nanosheets. The porous nanosheets were further investigated via TEM, shown in Fig. 3c, d. The TEM image indicated that the mesoporous with different sizes uniformly distributed on nanosheets and the size of the mesoporous was far less than 50 nm. The SAED pattern inserted in Fig. 3c demonstrated the polycrystalline phase of spinel Co3O4. Besides, the d value with 0.29 nm of lattice plane in HRTEM image (Fig. 3d) matched well with (220) of spinel Co3O4.

a and b LRSEM images of flower-like Co3O4 samples and the inserted HRSEM image of petal, c LRTEM image and SAED pattern of the obtained Co3O4 sample, d HRTEM image selected in red area in Fig. 3c

To study the pore structure and the specific surface areas of the as-obtained Co3O4 nanostructures, nitrogen adsorption–desorption isotherms were carried out, and the corresponding results are showed in Fig. 4. The surface area and the average pore diameter are measured to be around 39.728 m2/g and 23.74 nm, respectively. And the pore size distribution of Co3O4 is mainly located at 2–3 nm.

We investigated the electrochemical Li-ion charge and discharge behaviors of the Co3O4 powders by cyclic voltammetry (CV) in the voltage range of 0–3 V versus Li/Li+. The CV curves of Co3O4 electrode for the first five cycles at a scan rate of 2.0 mV s−1 were shown in Fig. 5a. In the first cycle, the sharp cathodic peak at around 0.4 V was ascribed to the conversion reaction between Co3O4 and Li+, relative to the formation of metallic Co and Li2O [18]. The broad anodic peak at around 2.1 V was attributed to the delithiation reaction of Co3O4. In the subsequent cycles, the intensities of the cathodic peaks decreased, due to the irreversible reaction and the formation of a solid electrolyte interface (SEI) film at the interface between the electrolyte and nanostructured electrode [19].

In Fig. 5b, the synthesized Co3O4 maintained the similar CV profiles when the scan rate increased from 0.2 to 1.0 mVs−1. It proved that the flower-like Co3O4 had a fast CV response to the rapid potential scanning [20]. According to the CV profiles of different scanning speeds, we could find out the relationship of peak current and scan rate. The relationship of peak current and scan rate could be expressed by a power law: i = av b, where i is the current (A), a and b are arbitrary coefficients and v is the potential scan rate (V s−1) [21, 22]. The coefficient b varies in the range 0.5 to 1, with a value of 0.5 being characteristic of a diffusion-limited process and a value of 1 for a capacitive process [23]. The relationship of peak current and scan rate in logarithmic algorithm was shown in Fig. 5c.The slope of the log (scan rate)-log (peak current) plots in cathodic and anodic processes are 0.863 and 0.885, respectively, indicating that the current is predominantly non-diffusion limited.

The electrochemical impedance spectroscopy (EIS) was used to evaluate the charge transfer and Li+ diffusion kinetics of the synthesized Co3O4. Figure 5d showed there were two regions of an arc followed by an inclined line of the Nyquist plot. The inclined line at low frequency represented the Warburg impedance, which was inversely proportional to the diffusion. The intercept at Z’-axis in high frequency represented the resistance of the electrolyte, which was relevant to the ohmic resistance [9]. And the diameter of the semicircle in the high-frequency region, which represented the interparticle contact resistance, was about 70 O, much smaller than the pristine Co3O4 electrode. It suggested that the contact and charge-transfer resistance of the synthesized Co3O4 electrode was lower [24].

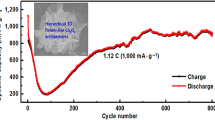

Figure 6a displayed the cycling performance of the Co3O4 electrode at a current density of 296 mA g−1. For comparison, we have listed the electrochemical performances of various Co3O4 nanostructures in Table 1. From Table 1, the hierarchical Co3O4 nanoflowers in this work exhibit the highest initial capacity. It was found that the initial discharge and charge capacities were 1685 and 1224 mA h g−1, respectively, rendering an initial coulombic efficiency of 74.2%. The corresponding irreversible capacity loss might be mainly attributed to the formation of solid electrolyte interface (SEI) [25] and irreversible phase conversion of Co3O4 [26] during the first lithiation–delithiation cycle. Then the coulombic efficiency still maintained about 95% efficiency within 50 cycles. The charge and discharge capacities still kept above 1100 mA h g−1 within 50 cycles, higher than the theoretic capacity of bulk Co3O4 (about 890 mA h g−1).This might be the reason of flower-like Co3O4 with mesoporous structure, which had more interfacial bonding for extra active sites of Li+ insertion. It has been reported that the comparatively appropriate pore size was more convenient for the intercalation of Li+ ions into the active materials, benefiting for its charge–discharge performance consequently [7]. Figure 6b revealed the representative discharge–charge curves of 1st, 2nd, 3rd, 10th and 50th of the electrode, which was in accordance with the cycling performance in Fig. 6a. The potential window was 0–3 V at a current density of 296 mA g−1.

a Cycling performance of Co3O4 electrode at current densities of 296 mA g−1, b the charge–discharge curves of the Co3O4 electrode in the voltage range of 0–3 V versus Li+/Li at a current density of 296 mA g−1, c the cycling performance of the Co3O4 electrode at current densities of 445 and 890 mA g−1, d the charge–discharge curves of the Co3O4 electrode at a current density of 296,445 and 890 mA g−1

The rate capability of the Co3O4 electrode at higher current densities (445 and 890 mA g−1) was shown in Fig. 6c. The initial capacity loss at a current density of 445 and 890 mA g−1 might have the same reasons with that of 296 mA h g−1. The discharge specific capacity at 445 mA g−1 began with 937 mA h g−1 at the second cycle, coming with a decay to about 690 mA h g−1 at the 50th cycle. While the current density was up to 890 mA g−1, it began with about 831 mA h g−1 at the second cycle followed by a rapid decline to about 350 mA h g−1 after 30 cycles This might be attributed to the microstructure changes of Co3O4 active material. However, rate capability kept steady at the capacity of around 350 mA h g−1 and the coulombic efficiency could remain 98.5% after 30 cycles. It suggested that the electrode/electrolyte interface might approach to a more stable state gradually [7]. Figure 6d showed that the charge and discharge process with higher current density caused great reduction in rate capacity. The reason why the capacity reduced in the charge and discharge processes is that some of the extra sites were irreversible for Li+. More inactive Li+ were amassed in the anode material to form SEI layer when the current density got higher. Also, the pulverization of the structure got worse.

Conclusions

In summary, the Co3O4 microflower has been prepared by the hydrothermal method followed with annealing process. These hierarchical Co3O4 porous structures provide space for the large volume variation of Co3O4 structure during the lithium uptake/release process, preventing it from structure collapsing too quickly. The mesoporous structures provided the passageway for transport of Li+ and more interfacial bonding for extra active sites of Li+ insertion. The reversible capacity at 296 mA g−1 still kept above 1100 mA h g−1 after 50 cycles, suggesting Co3O4 with microflower structure is a promising anode material for LIBs.

References

Tarascon JM, Armand M (2001) Issues and challenges facing rechargeable lithium batteries. Nature 414(6861):359–367

Armand M, Tarascon JM (2008) Building better batteries. Nature 451(7179):652–657

Wang J, Zhang Q, Li X, Xu D, Wang Z, Guo H, Zhang K (2014) Three-dimensional hierarchical Co3O4/CuO nanowire heterostructure arrays on nickel foam for high-performance lithium ion batteries. Nano Energy 6:19–26

Ding C, Zhao Y, Yan D, Zhao Y, Zhou H, Li J, Jin H (2016) An insight into the convenience and efficiency of the freeze-drying route to construct 3D graphene-based hybrids for lithium-ion batteries. Electrochim Acta 221:124–132

Zhao Y, Yan D, Ding C, Su D, Ge Y, Zhao Y, Zhou H, Li J, Jin H (2016) Fe2O3 nanocubes exposed (012) active facets combination with graphene rendering enhanced lithium storage capability. J Power Sources 327:658–665

Ding C, Yan D, Zhao Y, Zhao Y, Zhou H, Li J, Jin H (2016) A bubble-template approach for assembling Ni–Co oxide hollow microspheres with an enhanced electrochemical performance as an anode for lithium ion batteries. Phys Chem Chem Phys 18(37):25879–25886

Wu X, Wu W, Wang K, Chen W, He D (2015) Synthesis and electrochemical performance of flower-like MnCo2O4 as an anode material for sodium ion batteries. Mater Lett 147:85–87

Xia Y, Xiong Y, Lim B, Skrabalak S (2009) Shape-controlled synthesis of metal nanocrystals: simple chemistry meets complex physics. Angew Chem Int Ed 48(1):60–103

Fang D, Li L, Xu W, Li G, Li G, Wang N, Luo Z, Xu J, Liu L, Huang CL, Liang C (2013) Self-assembled hairy ball-like Co3O4 nanostructures for lithium ion batteries. J Mater Chem A 1:13203–13208

Kong D, Luo J, Wang Y, Ren W, Yu T, Luo Y, Yang Y, Cheng C (2014) Three-dimensional Co3O4@MnO2 hierarchical nanoneedle arrays: morphology control and electrochemical energy storag. Adv Funct Mater 24(24):3815–3826

Wang D, Wang Q, Wang T (2011) Morphology-controllable synthesis of cobalt oxalates and their conversion to mesoporous Co3O4 nanostructures for application in supercapacitors. Inorg Chem 50(14):6482–6492

Yan N, Hu L, Li Y, Wang Y, Zhong H, Hu X, Kong X, Chen Q (2012) Co3O4 nanocages for high-performance anode material in lithium-ion batteries. J Phys Chem C 116(12):7227–7235

Zhuo L, Wu Y, Ming J, Wang L, Yu Y, Zhang X, Zhao F (2013) Facile synthesis of a Co3O4–carbon nanotube composite and its superior performance as an anode material for Li-ion batteries. J Mater Chem A 1(4):1141–1147

Wang Z, Zhou L (2012) Metal oxide hollow nanostructures for lithium-ion batteries. Adv Mater 24(14):1903–1911

Yan C, Chen G, Zhou X, Sun J, Lv C (2016) Template-based engineering of carbon-doped Co3O4 hollow nanofibers as anode materials for lithium-ion batteries. Adv Funct Mater 26(9):1428–1436

Liu J, Kelly SJ, Epstein ES, Pan Z, Huang X, Liu J, Braun PV (2015) Three-dimensionally scaffolded Co3O4 nanosheet anodes with high rate performance. J Power Sources 299:40–48

Wang HW, Hu ZA, Chang YQ, Chen Y, Zhang Z, Yang Y, Wu H (2011) Preparation of reduced graphene oxide/cobalt oxide composites and their enhanced capacitive behaviors by homogeneous incorporation of reduced graphene oxide sheets in cobalt oxide matrix. Mater Chem Phys 130(1):672–679

Park JS, Cho JS, Kim JH, Choi YJ, Kang YC (2016) Electrochemical properties of micron-sized Co3O4 hollow powders consisting of size controlled hollow nanospheres. J Alloys Compd 689:554–563

Zhang XX, Xie QS, Yue GH, Zhang Y, Zhang XQ, Lu AL, Peng DL (2013) A novel hierarchical network-like Co3O4 anode material for lithium batteries. Electrochim Acta 111:746–754

Zhao Y, Li Y, Ma C, Shao Z (2016) Micro-/nano-structured hybrid of exfoliated graphite and Co3O4 nanoparticles as high-performance anode material for Li-ion batteries. Electrochim Acta 213:98–106

Lindström H, Södergren S, Solbrand A, Rensmo H, Hjelm J, Hagfeldt A, Lindquist S-T (1997) Li+ ion insertion in TiO2 (anatase). 2. Voltammetry on nanoporous films. J Phys Chem B 101(39):7717–7722

Lübke M, Shin J, Marchand P, Brett D, Shearing P, Liu Z, Darr JA (2015) Highly pseudocapacitive Nb-doped TiO2 high power anodes for lithium-ion batteries. J Mater Chem A 3:22908–22914

Lübke M, Sumboja A, Johnson ID, Brett D, Shearing P, Liu Z, Darr JA (2016) High power nano-Nb2O5 negative electrodes for lithium-ion batteries. Electrochim Acta 192:363–369

Pan L, Zhao H, Shen W, Dong X, Xu J (2013) Surfactant-assisted synthesis of a Co3O4/reduced graphene oxide composite as a superior anode material for Li-ion batteries. J Mater Chem A 1(24):7159–7166

Zhu X, Ning G, Ma X, Fan Z, Xu C, Gao J, Xu C, Wei F (2013) High density Co3O4 nanoparticles confined in a porous graphene nanomesh network driven by an electrochemical process: ultra-high capacity and rate performance for lithium ion batteries. J Mater Chem A 1(44):14023–14030

Wang Y, Yan F, Liu SW, Tan AYS, Song H, Sun XW, Yang HY (2013) Onion-like carbon matrix supported Co3O4 nanocomposites: a highly reversible anode material for lithium ion batteries with excellent cycling stability. J Mater Chem A 1(17):5212–5216

Wang J, Yang N, Tang H, Dong Z, Jin Q, Yang M, Kisailus D, Zhao H, Tang Z, Wang D (2013) Accurate control of multishelled Co3O4 hollow microspheres as high-performance anode materials in lithium-ion batteries. Angew Chem 125(25):6545–6548

Li H, Ma H, Yang M, Wang B, Shao H, Wang L, Yu R, Wang D (2017) Highly controlled synthesis of multi-shelled NiO hollow microspheres for enhanced lithium storage properties. Mater Res Bull 87:224–229

Zhang J, Ren H, Wang J, Qi J, Yu R, Wang D, Liu Y (2016) Engineering of multi-shelled SnO2 hollow microspheres for highly stable lithium-ion batteries. J Mater Chem A 4(45):17673–17677

Fan Y, Shao H, Wang J, Liu L, Zhang J, Cao C (2011) Synthesis of foam-like freestanding Co3O4 nanosheets with enhanced electrochemical activities. Chem Commun 47(12):3469–3471

Zhao Y, Xu X, Zhao Y, Zhou H, Li J, Jin H (2016) Synthesis and their physicochemical behaviors of flower-like Co3O4 microspheres. J Alloys Compd 654:523–528

Ding C, Su D, Ma W, Zhao Y, Yan D, Li J, Jin H (2017) Design of hierarchical CuS/graphene architectures with enhanced lithium storage capability. Appl Surf Sci 403:1–8

Xu X, Zhao Y, Li J, Jin H, Zhao Y, Zhou H (2015) Hydrothermal synthesis of cobalt particles with hierarchy structure and physicochemical properties. Mater Res Bull 72:7–12

Zhao Y, Zhang X, Wang C, Zhao Y, Zhou H, Li J, Jin H (2017) The synthesis of hierarchical nanostructured MoS2/Graphene composites with enhanced visible-light photo-degradation property. Appl Surf Sci 412:207–213

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (Grant No. 51602023) and Beijing Institute of Technology Research Fund Program for Young Scholars.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhai, X., Xu, X., Zhu, X. et al. Porous layer assembled hierarchical Co3O4 as anode materials for lithium-ion batteries. J Mater Sci 53, 1356–1364 (2018). https://doi.org/10.1007/s10853-017-1579-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1579-3