Abstract

CaF2:Ln3+ (Ln = Ce, Tb, Eu) phosphors with highly uniform shapes have been successfully synthesized by a simple hydrothermal method directly. The as-prepared samples were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), photoluminescence (PL) and lifetime. The results indicated that the pH values, organic additive and reaction time have a significant effect on the morphology and dimensions of CaF2 microcrystals and the possible formation mechanism was also proposed. Furthermore, the energy transfer from Ce3+ to Tb3+ and from Tb3+ to Eu3+ and from Ce3+ to Tb3+ to Eu3+ was observed and the corresponding mechanisms were discussed in detail. The CaF2:Ln3+ phosphors may have potential optical applications in near-UV and violet LEDs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In general, the chemical composition, size, phase, surface chemistry, shape and dimensionality of inorganic micro-/nanostructure of phosphors have great influence on their chemical and physical properties [1]. Therefore, more and more chemists pay attention to the reasonable control of these factors, which allowed us not only to own peculiar properties of the materials, but also to modify their chemical and physical properties as needed [2]. The phosphors with perfect luminescent performance require the dimensions of phosphors that should be in the range 1–3 µm with ideal spherical particles [3, 4] because of their unique properties (e.g., high packing densities, high surface-to-volume ratio and low scattering of light) and widespread applications in white light-emitting diodes (WLEDs), field emission displays (FEDs) and cathode ray tubes (CRTs) [5,6,7]. So far, the spherical phosphors can be obtained by many synthetic methods including spray pyrolysis, sol–gel process, urea homogeneous precipitation [8, 9]. However, these methods have many disadvantages such as low yield, large crystallites long reaction time and high environment loads [5, 10]. Compared with the methods mentioned above, the hydrothermal method provides a relatively green chemical alternative to preparation of various nano-/micromaterials. Meanwhile, the method has a number of other merits such as simplicity, safety, convenience and controllable size/phase/morphology of the products [11].

Inorganic fluoride materials have attracted a great deal of interest for their potential applications in labels, optics, components of gate dielectrics and insulators [12, 13] owing to their merits such as high resistivity, low-energy phonons, electron-acceptor behavior, high iconicity and anionic conductivity, compared with other oxide or sulfide materials [14,15,16,17]. Among the various fluorides, calcium fluoride (CaF2) has attracted more and more attention because of its wide band gap (Eg = 12.1 eV), low refractive index and optically transparent over a wide wavelength range from mid-infrared to vacuum ultraviolet [18, 19]. So, it is widely used in UV-transparent optical lenses, UV lithography, biocompatible luminescent markers and surface conditioning of glass [13, 19, 20]. Moreover, CaF2 is an attractive host for phosphors activated with rare-earth ions (RE3+), which display unique up-/down-conversion luminescence properties arising from their 4f electron configuration [21]. Various CaF2 with different structures including films, nanocrystals, nanowires, nanocubes, nanoparticles and 3D flower-like nanostructures have been successfully fabricated by multiple methods [12, 14, 21,22,23,24,25].

In present, the shortage of line-emitting red phosphors (above 600 nm) [26] which can improve rendering index in white light package [27] in LEDs is still a big problem. Owing to Eu3+-activated phosphors with excellent red color purity of 5D0 → 7F J transitions, they are supposed to red-emitting phosphors with high efficiency. However, the low oscillator strength and narrow line width of Eu3+ 4f → 4f absorption transitions lead to a weak absorption in the near-UV and blue region [28]. Thus, it is necessary to find sensitizers with strong and broad excitation bands in the typical emission wavelength of GaN-based LEDs (350–450 nm) for Eu3+ luminescence. Taking into account of metal–metal charge transfer (MMCT) quenching [29], direct sensitization of Eu3+ luminescence with Ce3+ is unlikely. As mentioned in the previous literature [30], the Ce3+→Tb3+→Eu3+ energy-transfer (ET) scheme can produce Eu3+ red phosphors, which are regarded as potential candidates for down-converting phosphors in the field of near-UV and violet LEDs because of their strong absorption bands in the near-UV and violet spectral regions. The luminescent properties of Er3+/Tm3+/Yb3+-doped CaF2 [25], Ce3+/Tb3+-codoped CaF2 [31, 32] and Tb3+/Eu3+-codoped CaF2 [33] have also been studied. Energy transfer between the doped luminescent ions in the solid materials has great influence on enhancing luminescent emission and excitation efficiency [34]. To the best of our knowledge, the energy transfer of Ce3+→Tb3+→Eu3+ in CaF2 materials by hydrothermal method has little been reported in the previous literature [12, 14, 21,22,23,24,25, 31,32,33,34].

Herein, it is very useful for practical applications that self-assembled CaF2:Ce3+/Tb3+/Eu3+ microspheres composed of nanoparticles not only possess the desirable properties of nanocrystals but also have the quite stable form of microspheres and solve the problem of nanomaterial agglomeration. Various morphologies of CaF2 phosphors can be achieved by simple tuning several critical parameters including pH, organic additive and reaction time. Meanwhile, the growth mechanism for the microspheres has been proposed. Moreover, we also investigate the energy-transfer process of Ce3+→Tb3+, Tb3+→Eu3+ and Ce3+→Tb3+→Eu3+ in CaF2 phosphors in detail. The transfer efficiency is 90.5% (Ce3+→Tb3+) and 89.5% (Ce3+→Tb3+→Eu3+), respectively. In addition, the ET process is systematically discussed based on the decay times of Ce3+ and Tb3+. The results indicate that the energy transfer of Ce3+→Tb3+→Eu3+ in CaF2 successfully makes it as potential down-converting phosphor candidates for near-UV and violet LEDs [35].

Experimental section

Preparation

All chemicals were purchased from Aladdin and used directly without further purification. The Eu2O3 (99.99%), Tb4O7 (99.99%), CeO2 (99.99%) were dissolved in hot diluted HNO3 solution under constant stirring followed by evaporation of excessive HNO3 to form Ln(NO3)3 (Ln = Ce, Tb, Eu) solutions (0.1 mol/L); however, in the process of dissolving CeO2 in hot diluted HNO3 solution, the H2O2 solution was continuously added to the above solution. A typical procedure was described as follows: Firstly, 2 mmol of Ca(NO3)2·4H2O was added to 25 mL distilled water at room temperature, followed by the addition of 4 mmol of sodium citrate to form an optically transparent solution. Then, 15 mL of aqueous solution containing 4 mmol of NaBF4 was added to the mixture under vigorous stirring. After that, HNO3 was dropwise introduced to the vigorous stirred solution to keep pH = 6.5. Sequentially, the mixture was agitated for another 30 min and transferred into a 50-mL autoclave, heated at 180 °C for 24 h and cooled naturally to room temperature. Finally, the precipitates were washed, centrifuged for several times with distilled water and absolute ethanol in turn, then dried at 60 °C for 8 h and crushed in an agate mortar to obtain samples which was denoted as S 1. Additionally, rare-earth nitrate solutions of 0.1 mol/L (Ce, Tb, Eu) were added into the solution to form CaF2:Ln3+ (Ln = Ce, Tb, Eu). The typical synthetic samples with experimental parameters are listed in Table S1 (Supporting Information).

Characterizations

All measurements were taken at room temperature. X-ray power diffraction (XRD) measurements were taken on a Purkinje General Instrument MSALXD3 using Cu Kα radiation (λ = 0.15406 nm). The morphology analysis was carried out on a field emission scanning electron microscopy (FESEM, Hitachi, S-4800). The PL excitation and emission spectra were detected by an F-7000 spectrophotometer (Hitachi, Japan) equipped with a 150-W xenon lamp as excitation source. The luminescence decays were measured on a FLSP920 fluorescence spectrophotometer.

Results and discussion

Phase and morphology

Effects of pH values

The composition and phase purity of the products which were prepared using Cit3− as organic additive and synthesized with hydrothermal treatment at 180 °C for 24 h under various pH conditions were first investigated by XRD. The XRD patterns of the samples and the standard data of CaF2 (JCPDS No. 35-0816) are shown in Fig. 1. We can see that all the diffraction peaks of the obtained products coincide well with the standard data of CaF2 (JCPDS 35-0816), which can be attributable to pure cubic phase. The sharp diffraction peaks indicate that these four samples are well crystallized at a relatively low hydrothermal treatment temperature (180 °C). It can be seen that the XRD peaks of the four samples show slight shift with respect to those of CaF2 in the JCPDS card. This may be caused by the minor alteration of the cell parameters of CaF2 crystals grown under different conditions or the instrument errors.

The representative low-magnification SEM images of CaF2 prepared by using Cit3− as organic additive at different pH values are exhibited in Fig. 2. The size of CaF2 microcrystals is critically dependent on the pH value during the hydrothermal process. It is clear that all the CaF2 microcrystals prepared at different pH values are spherical in shape. At pH = 5, the uneven CaF2 microspheres (S 2) with size of 410 nm–1.7 µm in diameter are observed from Fig. 2a. When the pH value of the initial solution is 8, the general image of CaF2 microspheres (S 3) is shown in Fig. 2c. The diameter of the particles is from 330 nm to 1.4 µm. Upon a further increase of the pH value up to 9, the CaF2 microspheres (S 4) have a mean diameter from 380 nm to 1.9 µm (Fig. 2d). When the experiment is performed at pH = 6.5 adjusted with HNO3 solution and other experimental conditions remain unchanged, it clearly indicates that the products (S 1) are composed of remarkable uniformity and monodisperse microspheres (Fig. 2b) with uniform size of 1 µm in diameter. The surface of microspheres is not smooth and contains many dense nanoparticles. From the above analysis, it can be concluded that the size of microspheres decreases generally with the increase of pH value. The reason for that can be ascribed to the different interactions of Cit3− with CaF2-specific crystal planes under different pH [36] which leads to different crystal growth rates during the complicated hydrothermal process [37]. It was reported that the pH value of the precursor solution could effectively affect the balance between the chemical potential and the rate of ionic migration in the precursor solution, and affect the morphology and size of the products [38]. For CaF2 microspheres, a low pH value results in a fast crystal growth and leads to a large crystal size (Fig. 2a). On the contrary, a high pH value is beneficial to a fast nucleation and thus the generation of a large number of crystal nuclei, resulting in crystals with a small size (Fig. 2d).

Effects of additives

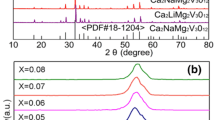

As shown in Fig. 3, the samples of CaF2 prepared under various organic additive conditions were first examined by XRD. All the diffraction peaks correspond to the JCPDS No. 35-0816 of pure cubic phase of CaF2. The strong and sharp diffraction peaks of the samples indicate that as-prepared nanocrystals are well crystallized. However, the diffraction peaks of products without organic additive (Fig. 3a) are much sharper than those of products using organic additive (Figs. 3b–d and 1a). The similarity of XRD patterns indicates the negligible influence of the used organic additive on phase of cubic CaF2.

The direct impact of organic additive on morphologies of CaF2 can be observed in their SEM images (Fig. 4). In the absence of organic additive, it is found that the morphology of the as-prepared CaF2 consists of highly dispersed cubes with edge length of 3 µm (Fig. 4a, b). When 0.8416 g CA is added, uniform spheres with average size of 2 µm in diameter are observed from Fig. 4c. The high-magnification SEM image (Fig. 4d) of the CaF2 microspheres provides detailed structural information on the spheres. The peripheral surface of individual spheres is not smooth and contains many dense nanoparticles. In order to investigate the effect of organic additives further, other organic additives, SDBS and CTAB, are used to synthesize CaF2 by an identical procedure. When SDBS is used as organic additive, the CaF2 cube with the concave in the middle of the surface is formed (Fig. 4e) and its size is 700 nm (Fig. 4f). While the other experimental conditions are identical and CTAB acts as organic additive, the crystal shapes of the samples are quite different. As shown in Fig. 4g, h the sample is of a similar shape. The truncated irregular octahedron can be observed, and a large number of heterogeneous dispersed polyhedron with the edge length about 400 nm–3.8 µm are formed. These results indicate that the morphologies of the CaF2 microstructures are sensitive to organic additives. The reasons may be as follows: On the one hand, the differences of the chelating constants of various organic additives with Ca2+ lead to the different nucleation rates of CaF2; on the other hand, various organic additives selectively adsorb on the specific crystal facets of CaF2 particles which result in the different growth rates of different facets, and then form the different morphologies and sizes.

Effects of reaction time

For the better understanding of the growth mechanism of CaF2 microspheres, time-dependent experiments were carried out (pH = 6.5) by using Cit3− as organic additive at 180 °C for 2, 4, 8 and 24 h, respectively (Fig. 5). The SEM images clearly show a typical process of the microspherical structure which is obtained by the self-assembly of the primary nanoparticles to form the final products. After hydrothermal treatment of 2 h, the sample obtained is primary particle which consists of random nanoparticles (Fig. 5a). At a reaction time of 4 h, the products consist of spherical-like particles with a mean diameter of 800 nm (Fig. 5b). It proves that the particle aggregates by the growth of crystal nucleus on different direction (random aggregation) to form spherical crystals. Figure 4c is the image of the sample with reaction time of 8 h; microspheres with an average size of 1.2 µm are formed and become bigger due to isotropic growth at the expense of nanoparticles. Finally, after hydrothermal treatment of 24 h (Fig. 5d), the spherical crystals have become more uniform after further growth and recrystallization.

The possible formation mechanism for the CaF2 microspheres

Based on the above experimental results, the probable reaction process for the formation of CaF2 microspheres using Cit3− as organic additive at pH = 6.5 may be summarized as Eqs. (1)–(3):

As is well known, the formation of a particle includes the initial production, subsequent growth and final stabilization of nuclei; the morphology and size of particles are mainly determined by the nucleation rate [33]. The detailed formation process of the CaF2 microspheres can be summarized as follows: In the early stage of the reaction, Ca2+ and Cit3− formed Ca2+–Cit3− as the intermediate which not only affect the morphology of the product but also afford a reactant source for an interfacial reaction. With the addition of NaBF4, Ca2+ could be released into the solution because the bond Ca2+–Cit3− could be destroyed by anions BO3 3− and BF4 −; then the F− ions deposited onto the surface of the intermediate and reacted with the Ca2+ to generate CaF2 nuclei under hydrothermal treatment. As a result, the CaF2 nuclei were formed by surface deposition and a subsequent crystal growth process; further, the nonuniform particles were obtained due to particles growing quickly after nucleation. As the reaction continued, the CaF2 nuclei aggregated each other to form CaF2 particles with the consumption of intermediate gradually. Finally, the CaF2 particle size was uniform and the adjacent particles could connect with each other to form the CaF2 microspheres with enough ripening time due to the higher surface energy. The formation mechanism of the CaF2 spheres depends on a series of chemical and structural transformations. During the process, Cit3− plays a key role in controlling the morphology of the final CaF2 products.

Luminescence properties and energy transfer

The self-assembled CaF2 microspheres are beneficial to obtain the ideal luminescent properties, because the narrow size distribution and good dispersivity of spherical CaF2: Ln3+ phosphors lead to high brightness, high resolution, low scattering and high packing densities of light [33].

Figure 6 demonstrates the photoluminescence excitation (PLE) and emission (PL) spectra of Ce3+ and Tb3+ single-doped and Ce3+/Tb3+ co-doped CaF2 phosphors. As shown in Fig. 6a, when monitored at 359 nm, the CaF2:2%Ce3+ sample exhibits a broad and strong band with a maximum at 304 nm and a weaker band at 251 nm which are assigned to the electron transition from the 4f energy level to different 5d sublevels of the Ce3+. The PL spectrum has an asymmetric blue broadband ranging from 320 to 600 nm with a peak at 359 nm which is assigned to the f–d absorption of the Ce3+ ions. The broad and asymmetric emission bands of CaF2:2%Ce3+ can be attributed to the transitions of the Ce3+ ions occupying two Ca2+ ion sites in the host structure. As shown in Fig. 6b, the PLE spectrum monitored at 544 nm for CaF2:4%Tb3+ sample presents a strong band at 215 nm and a weak band at 259 nm which correspond to the spin-allowed (ΔS = 0) and spin-forbidden (ΔS = 1) components of the 4f8–4f75d transition [39], respectively. On excitation into the 4f8–4f75d transition at 215 nm, the PL spectrum consists of emission lines at 494 nm (5D4 → 7F6) in the blue region and 544 nm (5D4 → 7F5) in the green region, as well as 590 nm (5D4 → 7F4) and 626 nm (5D4 → 7F3) in the red region. The intensity of 5D4 → 7F5 transition peaks at 544 nm is much higher than that of the other emission lines on account of a magnetic dipole-allowed transition. In order to enhance the absorption intensity in the NUV region for the Tb3+ emission, Ce3+ ions can be codoped as sensitizers to transfer energy to the Tb3+ ions. As given in Fig. 6c, the PLE and PL spectra of the CaF2:2% Ce3+/4%Tb3+ phosphors are investigated. Using 544 nm (Tb3+: 5D4 → 7F5 transition) as monitoring wavelength, we can get PLE spectra which contain a weak band at 215 nm, a moderate band at 251 nm and a strong broadband with a maximum at 304 nm. We can easily know that the peak at 215 nm assigns to the 4f8–4f75d transitions of Tb3+ ions and the bands at 251 nm and 304 nm belong to 5d–4f transitions of Ce3+ ions by contrast with the PLE spectra of CaF2:2%Ce3+ and CaF2:4%Tb3+ samples (Fig. 6a, b). The presence of the excitation bands of Ce3+ in the excitation spectrum monitored with Tb3+ emission indicates that energy transfer occurs from Ce3+ to Tb3+ in CaF2:2%Ce3+/4%Tb3+. Moreover, when excited at 304-nm wavelength from the characteristic absorption peak of Ce3+, the PL spectra of CaF2:2%Ce3+/4%Tb3+ phosphor exhibit not only the weak emission peak in the blue region from the electric-dipole-allowed 4f–5d transitions of Ce3+, but also the strong emission of Tb3+ (5D4 → 7F J(J = 6, 5, 4, 3) at 494, 544, 590 and 626 nm), which also provides another evidence for the energy transfer from Ce3+ to Tb3+ in CaF2:2%Ce3+/4%Tb3+ microspheres.

The PL spectra for CaF2:2%Ce3+/y%Tb3+ (y = 0.01–6) samples are shown in Fig. 7. Under excitation at 304 nm, each of the emission spectrum for CaF2:2%Ce3+/y%Tb3+ samples consists of an emission band of Ce3+ ions and several emission peaks of Tb3+ ions. At the same time, with the increase in the Tb3+ concentration (0.01 ≤ y ≤ 4), the intensity of blue emission at 359 nm decreased monotonously, while the emission intensity of Tb3+ increased and reached the maximum at y = 4 and then generally decreases due to Tb3+ concentration quenching. The shape of corresponding PL spectra remains unchanged when y = 6, which suggests that the possible energy-transfer process can exist between Ce3+ and Tb3+. The distance between sensitizer Ce3+ and activator Tb3+ becomes closer with increase of Tb3+ ions content, which is beneficial for efficient energy transfer from Ce3+ to Tb3+ ions. When Tb3+ content is beyond the critical concentration (y = 4), the emission intensity of Tb3+ decreases because of Tb3+−Tb3+ internal concentration quenching.

Figure 8a shows the PLE and PL spectrum of CaF2:4%Tb3+. In the excitation spectrum under monitoring of Tb3+ at 544 nm, the PLE spectrum is composed of a strong band at 215 nm and a weak band at 259 nm attributed to the Tb3+ of 4f8–4f75d transition. The PL spectrum obtained under the excitation at 215 nm shows characteristic sharp emission lines of Tb3+ f → f transitions at 494, 544, 590 and 626 nm which are corresponding to the 5D4 → 7F J(J = 6, 5, 4, 3) transitions. The PLE and PL spectra of CaF2:10%Eu3+ are shown in Fig. 8b. By monitoring the dominant emission of Eu3+ at 593 nm (5D0 → 7F1 transition), the sharp peaks in the range of 200−450 nm are ascribed to the typical intraconfigurational f–f transitions of Eu3+ ions. They are the 7F0 → 5H6 transition at 318 nm, the 7F0 → 5D4 transition at 361 nm, the 7F0 → 5L6 transition at 393 nm, respectively. Under 393-nm excitation, the sharp emission peaks at 593 and 617 nm are observed in PL spectrum, which attributed to Eu3+ 5D0 → 7F J(J = 1, 2) transitions. It is observed that the magnetic dipole 5D0 → 7F1 transition at 593 nm is stronger than the electric dipole 5D0 → 7F2 transition at 617 nm, which indicate the Eu3+ localized in symmetric environment. When doping 10%Eu3+ in CaF2:4%Tb3+, the sample shows a red–orange emission under UV excitation. The doped Eu3+ affects the matrix’s luminescent properties significantly in the present case. The PLE and PL spectra of the sample are shown in Fig. 8c. In the excitation spectrum of CaF2:4%Tb3+/10%Eu3+ under monitoring of Eu3+ at 619 nm, the main appearance is similar to that in Fig. 8a except from a few weak transition lines of Eu3+ appearing at 318 nm (7F0 → 5H6), 361 nm (7F0 → 5D4) and 393 nm (7F0 → 5L6), respectively. Under 215-nm excitation (4f8 → 4f7 5d transition of Tb3+), the PL spectrum is consisted of not only the emission of Tb3+ (5D4 → 7F6 at 494 nm, 5D4 → 7F5 at 544 nm), but also the emission of Eu3+ (5D0 → 7F1 at 593 nm, 5D0 → 7F2 at 617 nm). The existence of Tb3+ f → d transition lines in the excitation spectrum by monitoring the emission of Eu3+ (5D0 → 7F1, 593 nm) and the presence of the intense emission lines of Eu3+ by exciting into Tb3+ (215 nm) both clearly suggest efficient energy transfer from Tb3+ to Eu3+ in CaF2:4%Tb3+/10%Eu3+.

As discussed by Blasse [35, 40], Tb3+ can act as an energy-transfer chain to bridge Ce3+→Eu3+ energy transfer and block the corresponding metal–metal charge transfer (MMCT) process. Figure 9c demonstrates the PLE and PL spectra of CaF2:2%Ce3+/4%Tb3+/10%Eu3+. Under Ce3+ excitation band at 304 nm, the synthesized samples exhibit the Eu3+ 5D0 → 7F2 red emission peaks at 593 nm together with the emission of Tb3+ (5D4 → 7F6 at 494 nm, 5D4 → 7F5 at 544 nm), while the Ce3+ emission suffers obvious quenching. As shown in Fig. 9c, the CaF2:2%Ce3+/4%Tb3+/10%Eu3+ possesses an excitation spectrum which is similar to that of CaF2:2%Ce3+/4%Tb3+. By monitoring the dominant emission at 593 nm (Eu3+: 5D0 → 7F2), the PLE spectrum consists of Ce3+ f → d and Tb3+ f → d excitation bands. These results give a direct evidence of Eu3+ sensitized by Ce3+→Tb3+→Eu3+ energy transfer.

To better understand the energy-transfer process, the energy-transfer efficiency (η ET) from sensitizer ions to activator ions can be calculated by the following formula [41]:

where η ET is the energy-transfer efficiency and I and I0 are the emission intensities of the sensitizer in the presence and the absence of an activator, respectively. As shown in Fig. 10, by monitored at 304 nm of CaF2: 2% Ce3+/y%Tb3+ phosphor and CaF2: 2% Ce3+/4%Tb3+/z% Eu3+ phosphor, we can obtain the peak value of corresponding emission band at 359 nm (Ce3+ emission) and 544 nm (Tb3+ emission) which can be regarded as “I” for calculating Ce3+→Tb3+ energy-transfer efficiency and Tb3+→Eu3+ energy-transfer efficiency, respectively. As shown in Fig. 10a, the energy-transfer efficiencies from Ce3+ to Tb3+ in CaF2: 2% Ce3+/y% Tb3+ can be found to increase gradually with concentration of Tb3+ from 0 to 6 and the corresponding value of ηET is calculated to be 0, 4.6, 27, 61.4, 73.3, 84.2, 90.5%, which provide additional evidence of the energy transfer between Ce3+ and Tb3+ [3]. Figure 10b shows the η ET for further Tb3+→Eu3+ energy transfer which is a relative function of the Eu3+ concentration. It was found that the η ET increases from 0 to 89.5% with the increase of Eu3+ content in CaF2:2% Ce3+/4%Tb3+/z% Eu3+ phosphors. When z = 15, the maximum value of η ET is calculated to be 89.5%. The obtained results prove that the energy-transfer process from Tb3+ to Eu3+ is very efficient. From above, we can draw a conclusion that Tb3+-doped content is an critical factor for blocking the MMCT process between Ce3+ and Eu3+ and realizing an efficient Tb3+→Eu3+ energy transfer [42].

In order to further study the tunable PL properties and energy-transfer process, the decay time of CaF2:2%Ce3+/y%Tb3+/z%Eu3+ phosphors was also investigated to obtain information on the Ce3+→Tb3+ and Tb3+→Eu3+ energy transfer. The decay curves of Ce3+ in CaF2:2% Ce3+, y%Tb3+(y = 0 and 4), Tb3+ in CaF2:4%Tb3+, z%Eu3+(z = 0 and 10) and Tb3+ in CaF2:2%Ce3+, 4%Tb3+, z%Eu3+ (z = 0 and 10) phosphors are demonstrated in Fig. 11. As is known to all, when the radiative energy-transfer processes play a major role in specific materials, the acceptor makes no difference on the decay time of a donor. Nevertheless, when the nonradiative energy-transfer processes have a principal position, the concentration of acceptor has a great impact on the decay time of a donor. The decay time of the donor decreases gradually with the increasing concentration of acceptor [40, 41].

The decay curves and lifetime of Ce3+ in CaF2:2% Ce3+, y%Tb3+ (y = 0, 4) are exhibited in Fig. 11a. It can be seen that the decay curves are well fitted with the following double exponential equation:

Here I is the luminescence intensity; A 1 and A 2 are two constants which are related with the initial intensity; t is time; τ 1 and τ 2 are the lifetimes for the exponential components. The average lifetime (τ*) can be calculated using the following equation:

When only Ce3+ ions doped in CaF2 phosphor, the lifetime of the Ce3+ is 1600 ns. However, the lifetime of Ce3+ decreases (1300 ns) with the introduction of Tb3+ which proves the energy transfer from Ce3+ to Tb3+ through nonradiative process.

The decay curves of Tb3+ in the CaF2:4%Tb3+, z%Eu3+ (Fig. 11b) and CaF2:2%Ce3+,4%Tb3+, z%Eu3+(Fig. 11c) well fit a typical single exponential function as:

The lifetime of Tb3+ in CaF2: 4%Tb3+ was compared with that in CaF2:4%Tb3+, 10%Eu3+, as shown in Fig. 11b. The lifetime of Tb3+ was shortened from 6.37 μs to 1.69 μs. This result indicates that the shortened decay time of Tb3+ emission with increasing Eu3+ ions is attributed to the energy transfer from Tb3+ to Eu3+ in CaF2:4%Tb3+, z%Eu3+ phosphor. The energy transfer of Ce3+→Tb3+→Eu3+ through nonradiative process can be further proved from the fact that the lifetime of Tb3+ (5.68 μs) declines with the introduction of Eu3+ (1.78 μs). With higher Eu3+ concentration, it is hard to get the lifetime of Ce3+ because of too weak signal of Ce3+ emission.

The proposed energy level model for the ET processes of Ce3+ → Tb3+ → Eu3+ in the CaF2 host is demonstrated in Fig. 12. Firstly, Ce3+ ions can be effectively excited from the ground state (2F5/2) to the excited states (5d energy levels) by UV irradiation. Later on, Ce3+ ions either get back to the lowest vibrational level of the excited state giving out the excess energy to their surroundings or return to the ground states (2F7/2 and 2F5/2) spontaneously by a radiative process. The phosphor emits blue light or transfer their excitation energy to 5D3 level of Tb3+ ions, followed by nonradiative relaxation to 5D4 level (5D3 + 7F6 = 5D4 + 7F0) due to the same energy difference between 5D3 → 5D4 and 7F0 → 7F6 in Tb3+ ions [41]. Then, as a result of the electrons moving from the 5D4 excited state to the 7F J(J = 3, 4, 5, 6) ground state, green light is obtained. Meanwhile, the excitation energy on 5D4 level of Tb3+ transfers to higher excited energy level of Eu3+ (4f6) through cross-relaxation and then relaxes to the 5D0 level of Eu3+ and gives out red emission due to 5D0 → 7F J(J = 0, 1, 2) transitions [42].

Conclusion

The CaF2:Ce3+, Tb3+, Eu3+ phosphors with homogeneous, monodispersed and well-defined morphology were synthesized by a simple hydrothermal method. The pH, organic additive and reaction time have significant influences on the phase and shape of the obtained products. The energy transfer of Ce3+→Tb3+→Eu3+ through nonradiative process has been investigated in CaF2, which exhibits strong and broad excitation band in NUV region. The Ce3+ ions act as a good sensitizer and transfer most part of their energy to the activator ions. The efficient color-tunable emission can be generated from blue to green to red with increase of Tb3+ and Eu3+ in the CaF2:Ce3+ phosphors. The results also indicate that CaF2:Ce3+, Tb3+, Eu3+ phosphors will have promising applications in field of near-UV and violet LEDs.

References

Quan ZW, Xu HW, Wang CY, Wen XD, Wang YX, Zhu JL, Li RP, Sheehan CJ, Wang ZW, Smilgies DM, Luo ZP, Fang JY (2014) Solvent-mediated self-assembly of nanocube superlattices. J Am Chem Soc 136:1352–1359

Dong H, Li XJ, Peng Q, Wang X, Chen JP, Li YD (2005) Monodisperse magnetic single-crystal ferrite microspheres. Angew Chem Int Ed 44:2782–2785

Li G, Hou Z, Peng C, Wang W, Cheng Z, Li C, Lian H, Lin J (2010) Electrospinning derived one-dimensional LaOCl: Ln3+ (Ln = Eu/Sm, Tb, Tm) nanofibers, nanotubes and microbelts with multicolor-tunable emission. Adv Funct Mater 20:3446–3456

Huang CH, Chan TS, Liu WR, Wang D, Chiu YC, Ye H, Yeh YT, Chen TM (2012) Crystal structure of blue–white–yellow color-tunable Ca4Si2O7F2:Eu2+, Mn2+ phosphor and investigation of color tunability through energy transfer for single-phase white-light near-ultraviolet LEDs. J Mater Chem 22:20210–20216

Zhang Y, Geng DL, Kang XJ, Shang MM, Wu Y, Li XJ, Lian HZ, Cheng ZY, Lin J (2013) Rapid, large-scale, morphology-controllable synthesis of YOF:Ln3+(Ln = Tb, Eu, Tm, Dy, Ho, Sm) nano-/microstructures with multicolor tunable emission properties. Inorg Chem 52:12986–12994

Wang LS, Zhou YH, Quan ZW, Lin J (2005) Formation mechanisms and morphology dependent luminescence properties of Y2O3:Eu phosphors prepared by spray pyrolysis process. Mater Lett 59:1130–1133

Li JG, Li X, Sun X, Ishigaki TJ (2008) Monodispersed colloidal spheres for uniform Y2O3:Eu3+ red-phosphor particles and greatly enhanced luminescence by simultaneous Gd3+ doping. Phys Chem C 112:11707–11716

Wang H, Lin CK, Liu XM, Lin J (2005) Monodisperse spherical core-shell-structured phosphors obtained by functionalization of silica spheres with Y2O3:Eu3+ layers for field emission displays. Appl Phys Lett 87:181907

Song KC, Kang Y (2000) Preparation of high surface area tin oxide powders by a homogeneous precipitation method. Mater Lett 42:283–289

Feng W, Sun LD, Zhang YW, Yan CH (2010) Synthesis and assembly of rare earth nanostructures directed by the principle of coordination chemistry in solution-based process. Coord Chem Rev 254:1038–1053

Zhou L, Hu SS, Zhou XJ, Tang JF, Yang J (2016) One-step surfactant-free synthesis of Eu3+ activated NaTb(MoO4)2 microcrystals with controllable shape and their multicolor luminous properties. CrystEngComm 8:7590–7600

Mao YB, Zhang F, Wong SS (2006) Ambient template-directed synthesis of single-crystalline alkaline-earth metal fluoride nanowires. Adv Mater 18:1895–1899

Wang WS, Zhen L, Xu CY, Chen JZ, Shao WZ (2009) Aqueous solution synthesis of CaF2 hollow microspheres via the Ostwald ripening process at room temperature. ACS Appl Mater Interfac 1:780–788

Feldmann C, Roming M, Trampert K (2006) Polyol-mediated synthesis of nanoscale CaF2 and CaF2:Ce, Tb. Small 2:1248–1250

Liu YS, Tu DT, Zhu HM, Ma E, Chen XY (2013) Lanthanide-doped luminescent nano-bioprobes: from fundamentals to biodetection. Nanoscale 5:1369–1384

Gao P, Xie Y, Li Z (2006) Controlling the size of BaF2 nanocubes from 1000 to 10 nm. Eur J Inorg Chem 2006:3261–3265

Quan ZW, Yang PP, Li CX, Yang J, Yang DM, Jin Y, Lian HZ, Li HY, Lin J (2009) Shape and phase-controlled synthesis of KMgF3 colloidal nanocrystals via microwave irradiation. J Phys Chem C 113:4018–4025

Sokolov NS, Suturin SM (2000) MBE-growth peculiarities of fluoride (CdF2–CaF2) thin film structures. Thin Solid Films 367:112–119

Pilvi T, Arstila K, Leskel M, Ritala M (2007) Novel ALD process for depositing CaF2 thin films. Chem Mater 19:3387–3392

Sun XM, Li YD (2003) Size-controllable luminescent single crystal CaF2 nanocubes. Chem Commun 17:1768–1769

Quan ZW, Yang DM, Yang PP, Zhang XM, Lian HZ, Liu XM, Lin J (2008) Uniform colloidal alkaline earth metal fluoride nanocrystals: nonhydrolytic synthesis and luminescence properties. Inorg Chem 47:9509–9517

Blednov AV, Gorbenko OY, Samoilenkov SV, Amelichev VA, Lebedev VA, Napolskii KS, Kaul AR (2010) Epitaxial calcium and strontium fluoride films on highly mismatched oxide and metal substrates by MOCVD: texture and morphology. Chem Mater 22:175–185

Zhang XM, Quan ZW, Yang J, Yang PP, Lian HZ, Lin J (2008) Solvothermal synthesis of well-dispersed MF2 (M = Ca, Sr, Ba) nanocrystals and their optical properties. Nanotechnology 19:075603

Pandurangappa C, Lakshminarasappa BN, Nagabhushana BM (2010) Synthesis and characterization of CaF2 nanocrystals. J Alloys Compd 489:592–595

Cao CY, Qin WP, Zhang JS, Wang Y, Wang GF, Wei GD, Zhu PF, Wang LL, Jin LZ (2008) Up-conversion white light of Tm3+/Er3+/Yb3+ tri-doped CaF2 phosphors. Opt Commun 281:1716–1719

Setlur AA, Heward WJ, Gao Y, Srivastava AM (2006) Crystal chemistry and luminescence of Ce3+-doped Lu2CaMg2(Si, Ge)3O12 and its use in LED based lighting. Chem Mater 18:3314–3322

Ye S, Xiao F, Pan Y, Ma Y, Zhang Q (2010) Phosphors in phosphorconverted white light-emitting diodes: recent advances in materials, techniques and properties. Mater Sci Eng R 71:1–34

Xia ZG, Liu RS (2012) Tunable blue–green color emission and energy transfer of Ca2Al3O6F:Ce3+, Tb3+ phosphors for near-UV white LEDs. J Phys Chem C 116:15604–15609

Blasse G (1991) Optical electron transfer between metal ions and its consequences. Struct Bonding 76:153–187

Setlur AA (2012) Sensitizing Eu3+ with Ce3+ and Tb3+ to make narrow-line red phosphors for light emitting diodes. Electrochem Solid State Lett 15:J25–J27

Zhang CM, Li CX, Peng C, Chai RT, Huang SS, Yang DM, Cheng ZY, Lin J (2010) Facile and controllable synthesis of monodisperse CaF2 and CaF2:Ce3+/Tb3+ hollow spheres as efficient luminescent materials and smart drug carriers. Chem Eur J 16:5672–5680

Zheng W, Zhou SY, Chen Z, Hu P, Liu YS, Tu DT, Zhu HM, Li RF, Huang MD, Chen XY (2013) Sub-10 nm lanthanide-doped CaF2 nanoprobes for time-resolved luminescent biodetection. Angew Chem 125:6803–6808

Ritter BJ, Thoralf KK, Rurackand EK (2014) Nanoscale CaF2 doped with Eu3+ and Tb3+ through fluorolytic sol–gel-synthesis. J Mater Chem C 2:8607

Chen LM, Hong ZR, Li G, Yang Y (2009) Recent progress in polymer solar cells: manipulation of polymer: fullerene morphology and the formation of efficient inverted polymer solar cells. Adv Mater 21:1434–1449

Zhang XG, Zhou LY, Pang Q, Shi JX, Gong MG (2014) Tunable luminescence and Ce3+ → Tb3+ → Eu3+ energy transfer of broadband-excited and narrow line red emitting Y2SiO5:Ce3+, Tb3+, Eu3+ Phosphor. J Phys Chem C 118:7591–7598

Li CX, Quan ZW, Yang PP, Huang SS, Lian HZ, Lin J (2008) Shape-controllable synthesis and upconversion properties of lutetium fluoride (doped with Yb3+/Er3+) microcrystals by hydrothermal process. J Phys Chem C 112:13395–13404

Xu L, Yang XY, Zhai Z, Chao X, Zhang ZH, Hou WH (2011) EDTA-mediated hydrothermal synthesis of NaEu(MoO4)2 microrugbies with tunable size and enhanced luminescence properties. CrystEngComm 13:4921–4929

Luo Y, Yang RH, Zhang XL, Hu B, Hu SS, Zhou L, Yang J (2015) Shape-controllable hydrothermal synthesis of NaTbF4:Eu3+ microcrystals with energy transfer from Tb to Eu and multicolor luminescence properties. CrystEngComm 17:7762–7771

Zhao B, Yuan L, Hu SS, Zhang XM, Zhou XJ, Tang JF, Yang J (2016) One-step hydrothermal synthesis of Sc2Mo3O12:Ln3+ (Ln = Eu, Tb, Dy, Tb/Eu, Dy/Eu) nanosheets and their multicolor tunable luminescence. New J Chem 40:9211–9222

Zhang XG, Gong ML (2015) Photoluminescence and energy transfer of Ce3+, Tb3+, and Eu3+ doped KBaY(BO3)2 as near ultraviolet-excited color-tunable phosphors. Ind Eng Chem Res 54:7632–7639

Wen DW, Shi JX (2013) A novel narrow-line red emitting Na2Y2B2O7:Ce33+, Tb3+, Eu3+ phosphor with high efficiency activated by terbium chain for near-UV white LEDs. Dalton Trans 42:16621–16629

Zhou J, Xia Z (2015) Luminescence color tuning of Ce3+, Tb3+ and Eu3+ codoped and tri-doped BaY2Si3O10 phosphors via energy transfer. J Phys Chem C 3:7552–7560

Acknowledgements

This project is financially supported by the National Natural Science Foundation of China (51302229 and 51302228), the Fundamental Research Funds for the Central Universities (XDJK2016C147 and XDJK2015B019) and the Scientific Research Foundation for Returned Scholars, Ministry of Education of China (46th).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhao, B., Shen, D., Tan, Q. et al. Morphology-controllable synthesis, energy transfer and luminescence properties of Ce3+/Tb3+/Eu3+-doped CaF2 microcrystals. J Mater Sci 52, 5857–5870 (2017). https://doi.org/10.1007/s10853-017-0822-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0822-2