Abstract

A K2-mNb2O6-m/2 single crystal with a pyrochlore phase formed when the Nb2O5 + x mol% KOH specimens with 0.6 ≤ x ≤ 1.2 were solvothermally heated at 230 °C for 24 h. They have an octahedral shape with a size of 100 μm, and the composition of this single crystal is close to K1.3Nb2O5.65. The single-crystal KNbO3 formed when the single-crystal K2-mNb2O6-m/2 was annealed at a temperature between 600 °C and 800 °C with K2CO3 powders. When annealing was conducted at 600 °C (or with a small amount of K2CO3), the KNbO3 single crystal has a rhombohedral structure that is stable at low temperatures (< − 10 °C). The formation of the rhombohedral KNbO3 structure can be explained by the presence of the K+ vacancies in the specimen. The KNbO3 single crystal with an orthorhombic structure formed when the K2-mNb2O6-m/2 single crystal was annealed at 800 °C with 20 wt% of K2CO3.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The KNbO3 crystal has attracted a considerable amount of interest due to its excellent nonlinear optical, ferroelectric, photocatalytic, and piezoelectric properties [1,2,3,4,5,6,7]. KNbO3 has a cubic structure at a temperature higher than 435 °C, and the tetragonal KNbO3 phase is stable at a temperature between 435 °C and 225 °C. KNbO3 has an orthorhombic structure at temperatures between 225 °C and -10 °C [6,7,8]. Finally, the KNbO3 phase has a rhombohedral structure at a temperature lower than -10 °C [6,7,8]. Orthorhombic KNbO3 has been extensively investigated, and it exhibits excellent physical properties. Various classical methods have been used to synthesize the good quality KNbO3 single crystal [3,4,5]. However, the process temperature of such methods is generally very high, and it is difficult to grow the good quality KNbO3 single crystal using such methods due to nonstoichiometric nature, inhomogeneity and cracking [3,4,5].

Recently, the hydrothermal method was used to synthesize a KNbO3 single crystal to overcome such problems [2, 5,6,7,8,9,10,11]. In general, the process temperature of the hydrothermal method is low, ranging between 120 °C and 250 °C. Moreover, the final product of the hydrothermal method has a homogeneous composition [2, 5,6,7,8,9,10,11]. In general, the Nb2O5 particles and KOH solution are used as starting materials to synthesize the KNbO3 using a hydrothermal method. However, the concentration of KOH is high (6 ~ 10 M), and it is thus possible to cause serious corrosion of the reaction vessel, which can be an obstacle for industrial applications [5,6,7,8,9,10,11]. Furthermore, only nano-sized KNbO3 single crystals have been produced using a general hydrothermal method, indicating that they are difficult for practical applications [6,7,8,9,10,11]. Micro-sized rhombohedral and orthorhombic KNbO3 crystals were hydrothermally synthesized in supercritical water with very low alkaline concentrations at 400 °C [2]. Moreover, several millimeter-sized KNbO3 single crystals were synthesized using a hydrothermal method, but they were produced in high KOH concentrations of 14 M at 490 °C, indicating that this method needs to be improved for practical application [5].

In this work, a K2-mNb2O6-m/2 single crystal, which has a pyrochlore structure with a size of 100 μm, was solvothermally synthesized at a low temperature of 230 °C with a low concentration of KOH. The orthorhombic and rhombohedral KNbO3 single crystals were produced when this K2-mNb2O6-m/2 single crystal was annealed at 500 ~ 800 °C with a varying amount of K2CO3 powders, indicating that relatively large KNbO3 single crystals can be easily produced. Moreover, the structural variation of the KNbO3 single crystal has also been investigated in this work.

2 Experimental procedures

Analytical-grade solid potassium hydroxide and niobium oxide (> 99.9%, High Purity Chemicals, Osaka, Japan) were used as starting materials to synthesize the K2-mNb2O6-m/2 single crystal. At first, Nb2O5 (0.05 mol) was added to the solution of KOH (0.5–2.0 mol), water, and ethanol (35 mL). The volume ratio of water and ethanol is 1:1, and this mixture solution was stirred for 1 h, poured into a Teflon vessel (100 mL) and placed in an autoclave. The autoclave was heated at 230 °C for 24 h and filtered, washed with distilled water and dried at 80 °C for 12 h. Finally, the K2-mNb2O6-m/2 single crystals were annealed at 500 - 800 °C for 6 h with a varying amount of K2CO3 (0–30 wt%) to synthesize the KNbO3 single crystals. The structural properties of the specimens were examined via X-ray diffraction (XRD; Rigaku D/max-RC, Tokyo, Japan) using Cu-Kα radiation, and scanning electron microscopy (SEM; Hitachi S-4300, Osaka, Japan) was used to investigate the morphology of the specimens. The composition of the specimens was investigated using an energy-dispersive X-ray spectroscope (EDS: EMAX, Horiba, Kyoto, Japan) attached to a SEM. Fourier transform infrared spectrometry (FT-IR; Thermo Fisher Scientific Nicolet iS50, USA) was used to identify defects in the KNbO3 single crystal. FTIR spectra were obtained at a resolution of 4 cm−1 and with 32 scans per specimen. The electron mapping images of the K2-mNb2O6-m/2 and KNbO3 single crystals were obtained using electron probe X-ray microanalysis (EPMA: JXA-8500F, Miami, U.S.A) to analyze the crystallinity and compositional homogeneity of the specimens.

3 Results and discussion

Figure 1(a)‑(e) show the XRD patterns of the Nb2O5 + x mol% KOH specimens with 0.5 ≤ x ≤ 2.0 solvothermally heated at 230 °C for 24 h. The K2-mNb2O6-m/2 (JCPDS #35–1464) pyrochlore phase was formed in the specimen with x = 0.5, but the K4Nb6O17 (JCPDS #76–0977) secondary phase was also developed in this specimen (see Fig. 1(a)). A pure K2-mNb2O6-m/2 pyrochlore phase was obtained in the specimen with x = 0.6, and this phase was maintained for a specimen with x = 1.2, as shown in Fig. 1(b) and (c). The K2-mNb2O6-m/2 pyrochlore phase show a high intensity (l l l) reflections (l = 1, 2, 3), indicating that it has a large (111) plane. However, the K2Nb2O6·H2O phase formed for specimens with 1.3 ≤ x ≤ 1.5 (see Fig. 1(d)), and it changed to a KNbO3 phase for the specimen with x = 2.0, as shown in Fig. 1(e) [12]. The Nb2O5 + x mol% KOH specimens with 0.5 ≤ x ≤ 2.0, which were solvothermally heated at 230 °C for 24 h, were investigated using SEM, as shown in Fig. 2(a)‑(d). Specimens with x ≤ 1.2, which have a K2-mNb2O6-m/2 pyrochlore phase, have an octahedral shape with a large (111) plane, as shown in Fig. 2(a) and (b). On the other hand, the K2Nb2O6·H2O (x = 1.5) and KNbO3 (x = 2.0) specimens show nanorods and nanoparticles shapes, respectively, as shown in Fig. 2(c) and (d). The K2-mNb2O6-m/2 specimens are considered to be a single crystal because grain boundaries were not observed in the EPMA image of the specimen with x = 1.0 (see Fig. 2(e)). Moreover, K+ and Nb5+ ions are homogeneously distributed in this specimen. The size of the K2-mNb2O6-m/2 single crystal with x = 0.5 is approximately 30 μm, and it increased with an increase of x to 100 μm for the specimen with x = 1.2, indicating that the size of the K2-mNb2O6-m/2 single crystal can be further increased by controlling the process conditions. The ratio of K+ and Nb5+ ions in the K2-mNb2O6-m/2 single crystal is approximately 2: 3, as shown in Fig. S1 a in supplemental material 1, indicating that the K1.3Nb2O5.65 pyrochlore phase was developed in specimens with 0.6 ≤ x ≤ 1.2. Furthermore, the ratios of K+ and Nb5+ ions in the K2Nb2O6·H2O nanorods (x = 1.5) and KNbO3 nanoparticles (x = 2.0) are approximately 1: 1 and 1.1: 1, respectively, as shown in Figs. S1(b) and (c) in supplemental material 1. Therefore, the morphology of the specimen is considered to be influenced by the ratio of K+ and Nb5+ ions.

The K2-mNb2O6-m/2 specimen was annealed at various temperatures with varying amounts of K2CO3 powders to synthesize the KNbO3 single crystal by supplying K2O to the K2-mNb2O6-m/2 phase. Figure 3(a)‑(d) show the XRD patterns of the K2-mNb2O6-m/2 specimen annealed at various temperatures for 6 h with 30 wt% K2CO3 powders. The K2-mNb2O6-m/2 phase was maintained in the specimen annealed at 500 °C (see Fig. 3(a)), but a small amount of K4Nb6O17 phase also formed in this specimen. Therefore, the reaction between the K2-mNb2O6-m/2 specimen and K2CO3 powders is not considered to be significant at 500 °C, but a small amount of K2O evaporated from the K2-mNb2O6-m/2 specimen resulting in the formation of a K4Nb6O17 secondary phase. The KNbO3 phase was formed in specimens annealed at temperatures higher than 500 °C, as shown in Fig. 3(b)‑(d). In general, the KNbO3 ceramic has an orthorhombic structure at room temperature, but the KNbO3 single crystal synthesized at 600 °C has a rhombohedral structure that can be identified by a peak at 45.5o in Fig. 3(b). The orthorhombic KNbO3 phase was formed in the specimen annealed at 800 °C, as shown in Fig. 3(d) [13,14,15,16]. Moreover, both rhombohedral and orthorhombic structures are considered to coexist in the KNbO3 specimen annealed at 700 °C.

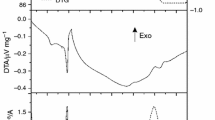

For a detailed analysis of the crystal structure of the KNbO3 specimens, the XRD reflections at 45.5o were measured via slow-speed scanning for specimens annealed at various temperatures, as shown in Fig. 4(a). Rhombohedral (020)R reflection was observed for specimen annealed at 600 °C, confirming that the rhombohedral KNbO3 structure has developed in this specimen. The intensities of the orthorhombic (220)O and (002)O reflections increased with an increase in the annealing temperature and the orthorhombic (220)O and (002)O reflections were only observed for the specimen annealed at 800 °C, confirming that an orthorhombic KNbO3 phase formed in the specimen annealed at 800 °C. Furthermore, both rhombohedral (020)R and orthorhombic (220)O and (002)O reflections were observed for the specimen annealed at 700 °C. According to a previous work, KNbO3 nanorods synthesized using a hydrothermal method have a tetragonal structure that is not stable at room temperature [6, 7]. The formation of a tetragonal KNbO3 phase was explained by the presence of OH− ions in the O2− sites that produced metal vacancies in the KNbO3 phase [6, 7, 17]. Moreover, a rhombohedral structure was observed in the hydrothermally synthesized KNbO3 particles with a small K/Nb ratio, but the presence of the unstable rhombohedral structure was not explained [2]. An FTIR analysis was conducted on the KNbO3 specimens synthesized at various temperatures, as shown in Fig. 4(b). The peaks at 509 cm−1 and 593 cm−1 can be explained by the stretching vibrations of the O-Nb-O [5, 10, 18]. Multiple peaks between 1000 cm−1 and 1650 cm−1 correspond to the K-O absorption bond [19]. The intensities of multiple peaks between 1000 cm−1 and 1650 cm−1 are small for the KNbO3 specimen synthesized at 600 °C, and they increased with an increase in annealing temperature. Therefore, the number of K-O bonds is considered to increase with an increase in temperature. Moreover, the EDS analysis shows that a K-deficient KNbO3 phase formed in the specimen synthesized at 600 °C, and a stoichiometric KNbO3 phase (or slightly K-excess KNbO3 phase) formed in specimens synthesized at 700 °C (or 800 °C), as shown in Figs. S3(a)-(c) in supplemental material 2. Therefore, the presence of a rhombohedral KNbO3 phase is suggested to be related to the presence of vacancies formed in the K-sites.

Figure 5(a)‑(d) show the XRD patterns of a K2-mNb2O6-m/2 specimen annealed at 800 °C with varying amounts of K2CO3 powders. The K4Nb6O17 phase formed in the K2-mNb2O6-m/2 specimen that was annealed at 800 °C without K2CO3 particles, owing to the evaporation of K2O during the annealing. The KNbO3 phase formed in the specimen annealed with 10 wt% K2CO3 powders, but the (220)O and (002)O reflections at 45.5o were not completely separated, indicating that both rhombohedral and orthorhombic structures could form in this KNbO3 phase. The (220)O and (002)O reflections were clearly separated for the specimens annealed with a large amount of K2CO3 powders, as shown in Fig. 5(c) and (d), indicating that they have an orthorhombic KNbO3 phase [13,14,15,16]. This result also implies that the formation of rhombohedral KNbO3 crystals could be related to the presence of K vacancies. Figure 6(a)‑(c) show SEM images of KNbO3 specimens synthesized at 800 °C with varying amounts of K2CO3 powders. For the specimens annealed without K2CO3 powders, cracks formed, probably due to the evaporation of K2O during annealing. The KNbO3 single crystal with an octahedral shape was well developed for specimens synthesized with 10 and 20 wt% K2CO3 powders, as shown in Fig. 6(b) and (c). However, the KNbO3 single crystals were agglomerated for a specimen annealed with 30 wt% K2CO3 powders (see Fig. S2(d) in supplemental material 2). Figure 6(d) shows EPMA images of the KNbO3 specimen synthesized with 20 wt% K2CO3 powders, and the homogeneous KNbO3 single crystal formed without grain boundaries. Therefore, the orthorhombic KNbO3 single crystal with an octahedral shape was considered to have formed when the K2-mNb2O6-m/2 specimen was annealed at 800 °C with 20 wt% K2CO3 powders, and the size of this KNbO3 single crystal is approximately 100 μm.

4 Conclusions

The Nb2O5 + x mol% KOH specimens with 0.5 ≤ x ≤ 2.0 were solvothermally heated at 230 °C for 6 h. The single crystal with a K2-mNb2O6-m/2 pyrochlore structure formed for the specimens with 0.6 ≤ x ≤ 1.2. The K2Nb2O6 ·H2O nanorods and KNbO3 nanocrystals formed for specimens with 1.3 ≤ x ≤ 1.9 and x = 2.0, respectively. The K2-mNb2O6-m/2 single crystal has an octahedral shape with a size of 100 μm, and the composition of this single crystal is approximately K1.3Nb2O5.65. The K2-mNb2O6-m/2 single crystals annealed at high temperatures (≥ 600 °C) with K2CO3 powders were transformed into KNbO3 single crystals. The rhombohedral KNbO3 single crystal was formed when the K2-mNb2O6-m/2 single crystal was annealed at 600 °C, probably due to the presence of K+ vacancies in the specimen. On the other hand, the KNbO3 single crystal with an orthorhombic structure was obtained when the K2-mNb2O6-m/2 single crystal was annealed at 800 °C. However, the agglomeration of KNbO3 single crystals occurred when they were annealed with a large amount of K2CO3 (≥ 30 wt%).

References

Y. Nakayama, P.J. Pauzauskie, A. Radenovic, R.M. Onorato, R.J. Saykally, J. Liphardt, P. Yang, Nature 447(7148), 1098–1101 (2007)

B. Li, Y. Hakuta, H. Hayashi, J. Supercrit. Fluids 35(3), 254–259 (2005)

V.I. Chani, K. Shimamura, T. Fukuda, Cryst. Res. Technol. 34(4), 519–525 (1999)

H. Kimura, A. Miyazaki, K. Maiwa, Z.X. Cheng, C.V. Kannan, Opt. Mater. 30(1), 198–200 (2007)

M. Mann, S. Jackson, J. Kolis, J. Solid State Chem. 183(11), 2675–2680 (2010)

M.R. Joung, H. Xu, J.S. Kim, I.T. Seo, S. Nahm, J.Y. Kang, S.J. Yoon, J. Appl. Phys. 111(11), 114314 (2012)

M.R. Joung, H. Xu, I.T. Seo, D.H. Kim, J. Hur, S. Nahm, H.M. Park, J. Mater. Chem. A 2(43), 18547–18553 (2014)

S. Chakraborty, S.K. Ghosh, G.C. Das, S. Mukherjee, Int. J. Appl. Ceram. Technol. 13(4), 743–752 (2016)

C. Huiqun, Y. Cheng, Y. Jie, C. Bo, X. Hong, Y. Bin, Rare Metal Mat. Eng. 45(6), 1391–1395 (2016)

Y. Wang, X. Kong, W. Tian, D. Lei, X. Lei, RSC Adv. 6(63), 58401–58408 (2016)

G. Shi, J. Wang, H. Wang, Z. Wu, H. Wu, Ceram. Int. 43(9), 7222–7230 (2017)

X. Kong, D. Hu, P. Wen, T. Ishii, Y. Tanaka, Q. Feng, Dalton Trans. 42(21), 7699–7709 (2013)

H. Tian, X. Meng, C. Hu, P. Tan, X. Cao, G. Shi, Z. Zhou, R. Zhang, Sci. Rep. 6(1), 25637 (2016)

Y. Purusothaman, N.R. Alluri, A. Chandrasekhar, S.J. Kim, J. Mater. Chem. C 5(22), 5501–5508 (2017)

F. Madaro, J.R. Tolchard, Y. Yu, M.A. Einarsrud, T. Grande, CrystEngComm. 13(5), 1350–1359 (2011)

D.H. Kim, M.R. Joung, I.T. Seo, J. Hur, J.H. Kim, B.Y. Kim, H.J. Lee, S. Nahm, J. Eur. Ceram. Soc. 34(16), 4193–4200 (2014)

N. Kumada, T. Kyoda, Y. Yonesaki, T. Takei, N. Kinomura, Mater. Res. Bull. 42(10), 1856–1862 (2007)

G. Pecchi, B. Cabrera, A. Buljan, E.J. Delgado, A.L. Gordon, R. Jimenez, J. Alloys Compd. 551, 255–261 (2013)

S. Kumar, L.K. Sahay, A.K. Jha, K. Prasad, Adv. Mater. Lett. 5, 67 (2013)

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy(MOTIE) of the Republic of Korea(No. 20152020104960). The authors also thank the Ku-Kist graduate school program of Korea University.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

ESM 1

(DOCX 1811 kb)

Rights and permissions

About this article

Cite this article

Lee, WH., Ko, YJ., Im, M. et al. Formation of a KNbO3 single crystal using solvothermally synthesized K2-mNb2O6-m/2 pyrochlore phase. J Electroceram 41, 37–42 (2018). https://doi.org/10.1007/s10832-018-0149-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10832-018-0149-7