Abstract

A closed-form analytical solution for transient solidification of multicomponent alloys is proposed by analytically solving the microscale solidification to feed the local conditions, such as surface energy, surface tension, nucleation radius, interface temperature, and solute concentration, necessary to the evolution of macroscopic solidus, liquidus, and eutectic interfaces. Expressions for the critical radius, total free energy, and nucleation rate are derived for homogeneous and heterogeneous nucleation based on recent propositions for nucleation and surface energy. A general solution for interface evolution is proposed, encompassing local temperature and concentration conditions to provide the proper integration of the macroscopic temperature necessary for latent heat release in the solid–liquid phase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Solidification plays a vital role in obtaining homogeneous materials and in controlling the structure of castings and ingots in some industrial processes such as continuous casting, surface remelting, casting and laser welding. Therefore, the study of the solidification of metals has assumed considerable proportions in recent decades since essentially all metals undergo liquid–solid transformation at some stage. In many cases, peculiarities of grain structure, composition and phase distribution result from solidification and these seriously influence subsequent treatments and properties. In this sense, interest in solidification has gone beyond the field of materials and metallurgical engineering, advancing to other applied sciences, in which the knowledge of solidification theory aggregated to the fundamentals of electronics, mechanics, chemistry, physics, applied mathematics, etc., has been used to solve concrete technological problems [1]. Thus, it is essential to understand the underlying mechanisms involved in solidification to control the composition and structure of the solidified metal. Nevertheless, it must be noted that in many cases complete details of the physical mechanisms related to the formation of various types of micro- and macrostructures in the obtained solids are not yet known.

On the other hand, it has been reported that the phenomenon of heat conduction with phase change due to melting–freezing occurs in many areas of current practical interest; however, as the space domain where the heat conduction equation is to be solved changes with time, these are known as moving boundary or Stefan problems [2,3,4]. Consequently, the mathematical treatment of this problem is complicated since it leads to differential equations presenting nonlinear boundary conditions at the moving interface. Nevertheless, numerous mathematical approaches have been developed to provide an adequate theoretical background for modeling the solidification of metals over the years. In this sense, many mathematical studies aimed to find exact solutions for simple geometries (slabs, cylinders and spheres) or simplified quasi-stationary assumptions that are not realistic in many situations. The analytical methods [1, 2, 5,6,7,8,9,10,11,12,13,14,15,16,17,18], proposed to investigate the solidification process, mainly consider systems with plane geometry due to the greater simplicity of the mathematical treatment as a function of their geometric characteristics. Thus, they present considerable limitations from the point of view of their practical application. It is worth remembering that exact analytical solutions for cylindrical and spherical geometries have not yet been obtained since these geometries present greater mathematical complexity arising from both the mathematical equations and the assumed boundary conditions. The accuracy of numerical solutions [19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41,42] is often extremely high; however, the use of such solutions requires either programming knowledge and/or special software since these methods demonstrate a certain complexity. They generally lead to a greater proximity of practical cases in industry allowing more real boundary conditions to be assumed for which it would not be possible to obtain analytical solutions. Finally, a number of experimental methods [43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62] have also been used to investigate solidification. Although the several variables and transient conditions involved in the liquid–solid phase change make these methods very specific, they assume an important characteristic because in many cases they are employed to validate analytical and numerical methods.

The main purpose of the present study is to derive an analytical solution for the transient solidification of multicomponent alloys in a slab and deduce a general form for moving solidus, liquidus, and eutectic interfaces according to the heat flux direction. To achieve this goal, a solution for transient solidification of multicomponent alloys is proposed analytically for microscale solidification to furnish the local conditions necessary for the evolution and proper integration of heat at macroscopic interfaces. New formulations are derived for homogeneous and heterogeneous nucleation based on recent propositions for nucleation and surface energy [17]. A solution for transformation interface evolution is proposed to provide the proper integration of macroscopic latent heat release during the fusion/solidification of multicomponent alloys. Liquidus and eutectic macroscopic interface equations were proposed, and a new derivation was carried out of a well-known analytical transient solution for the solidification of binary alloys [1]. Simulations were performed for different Cu contents and levels of superheat.

2 Mathematical Simplifying Hypotheses

The mathematical simplifying hypotheses assumed in this work can be found in the literature [1, 2]. The purpose of the solution to be obtained is to investigate the solidification of a semi-infinite slab [3, 4]. Thus, the following assumptions are taken into account in this study:

-

a.

The microscopic and macroscopic domains are three-dimensional;

-

b.

The macroscopic domain consists of a solid mould and three metal subdomains: solid, solid and liquid, and liquid;

-

c.

Solidification occurs in a temperature range between solidus and liquidus isotherms, where the latent heat is released;

-

d.

The macroscopic solidification is unidirectional along the \(x\)-axis, and all limiting wall boundary conditions in both the \(y\) and \(z\) axes are assumed to be adiabatic;

-

e.

The microscopic solidification is three-dimensional and the boundary conditions are periodic;

-

f.

The investigated systems are isotropic;

-

g.

The thermal contact resistance at the metal/mould interface is considered;

-

h.

The convection in the melt is neglected;

-

i.

The thermophysical properties are constant within each phase but different among phases.

2.1 Binary Alloy Solidification

Alloys solidify in a temperature range, i.e., an example is between the liquidus and solidus isotherms, in such a way that these boundary conditions can be seen in Fig. 1, demonstrating the temperature profile during unidirectional solidification of a volume element.

where \({S}_{S}\) and \({S}_{L}\) are the positions of the solidus and liquidus interfaces, respectively, \({q}_{L}\) is the heat flux in the liquid phase, \({q}_{SL}\) is the heat flux in the solid–liquid mixture phase, \({q}_{S}\) is the heat flux in the solid phase, \({q}_{i}\) is the metal/mould heat flux, \({q}_{m}\) is the heat flux in the mould, \({T}_{0}\) is the environmental temperature far from the mould external surface, \({T}_{im}\) is the mould temperature at the metal/mould interface, \({T}_{is}\) is the solid temperature at the metal/mould interface, \({T}_{S}\) is the temperature of the solid phase, \({T}_{SL}\) is the temperature of the solid–liquid (mushy zone) phase, \({T}_{L}\) is the temperature of the liquid phase and, finally, \({T}_{P}\) is the pouring temperature.

Before diving into the problem of the solidification of an alloy, a physical formulation of the solidus and liquidus moving phase-change interfaces must be derived, as far as alloys solidify according to a solidification range, i.e., the latent heat \(\mathrm{\Delta H}\) from a primary \(\alpha \)-phase will be released in the temperature range between the liquidus and solidus isotherms, which move at different speeds. Let us consider the heat balance according to Fig. 2.

Recently, Ferreira [17] derived an equation for nucleation based on the thermal field gradient normal to the forming nucleus surface area. This equation is a general form of the Gibbs–Thomson equation, and it is the so-called Gibbs–Thomson-Ferreira equation—GTF [63, 64], which considers the surface stress tensor, the surface energy, and the transformation entropy associated with the normal thermal gradient to a given nucleating phase surface area. The application of the GTF equation to phase growth implies in the derivation of a general formulation to deal with the evolution of microscopic transformation interfaces and its application to bridge microscopic to macroscopic phase-change interfaces during transient alloy solidification, which straightaway implies in a multiscale formulation. As an example of multiscale calculation, Karma et al. coupled an atomistic model and Phase-Field for micro and mesoscale solidification simulation [65]. Multiscale formulations can be found in the literature applied to numerical and analytical solidification models [66, 67]. Let us assume a stable nucleus of radius \(r\le {r}_{Eq}\) for given temperature, volume, pressure and composition gradients, assuming the equilibrium radius \({r}_{Eq}\) corresponding to the level of surface energy associated only with creating a surface area \({A}_{0}\). The equation expressing the Gibbs–Thomson coefficient for any thermal field gradient for nucleation can be expressed as,

where \(\Gamma \) is the Gibbs–Thomson coefficient, \(\overrightarrow{r}\) is the vector radius, \(\nabla \mathbf{T}\) is the thermal field gradient normal to the surface area \(A\left(\overrightarrow{r}\right)\), which can be dependent on temperature, volume, pressure and composition gradients, and \(\widehat{n}\) is the unit normal vector. Gibbs–Thomson coefficient \(\Gamma \left(\overrightarrow{r}\right)\) is defined by Ferreira [17] as the thermal field gradient \(\nabla \mathbf{T}\) normal to a surface area created in equilibrium \({A}_{0}\), and created and deformed \(A\left(\overrightarrow{r}\right)\) in nonequilibrium.

2.2 Application of GTF to the Energy Balances of Liquidus and Solidus Isothermal Surfaces in a Microscopic Domain

To analyze the correct dimensional form for the proposed moving transformation interface formulation, first a heat balance for each transformation interface evolution must be derived, and the relationship between heat flux and latent heat release due to interface coalescence must be established by introducing both properties in Eq. 1. A simple relationship between thermal conductivity \(\kappa \) \(\left[{\text{W}}\cdot{\text{m}}^{-1}\cdot{\text{K}}^{-1}\right]\) and molar specific heat capacity \({c}_{vm}\) \(\left[\mathrm{J}\cdot{\mathrm{mol }}^{-1}\cdot{\mathrm{K}}^{-1}\right]\) at a given temperature \(T\), demands \({c}_{vm}/\nu \), where \(\nu \) is the phase molar volume \(\left[{\mathrm{m}}^{3}\cdot{\mathrm{mol }}^{-1}\right]\).

Now, considering the solid/liquid transformation, latent heat of solidification, by considering the heat flux of the moving liquidus isotherm at both sides, for\(\overrightarrow{r}={\overrightarrow{S}}_{L}\), \({\overrightarrow{q}}_{SL}=-{\overrightarrow{k}}_{SL}\cdot{\left.\nabla \mathbf{T}\right|}_{\overrightarrow{r}={\overrightarrow{S}}_{L}^{-}}\) and, \({\overrightarrow{q}}_{L}=-{\overrightarrow{k}}_{L}\cdot{\left.\nabla \mathbf{T}\right|}_{\overrightarrow{r}={\overrightarrow{S}}_{L}^{+}}\), the latent heat of the primary phase, \(\Delta H\) at \(T={T}_{L}\), and Gibbs–Thomson coefficient \({\Gamma }_{L}\left({\overrightarrow{S}}_{L}\right)\), and a heat source \({q}_{L}\) similar to what is found in Crank [68],

where \(\delta \) is the piecewise Heaviside function, which depends on the heat flux signal, \(\delta \left( {\vec{q}} \right) = \left\{ {\begin{array}{*{20}c} 1 & {{\text{for}}\,\vec{q} > 0} \\ 0 & {{\text{for}}\,\,\vec{q} < 0} \\ \end{array} } \right.\)

If no heat source is present, \(\overrightarrow{q}=0\),

for \(\overrightarrow{r}={\overrightarrow{S}}_{S}\), \({\overrightarrow{q}}_{S}=-{\overrightarrow{k}}_{S}\cdot{\left.\nabla \mathbf{T}\right|}_{\overrightarrow{r}={\overrightarrow{S}}_{S}^{-}}\) and \({\overrightarrow{q}}_{SL}=-{\overrightarrow{k}}_{SL}\cdot{\left.\nabla \mathbf{T}\right|}_{\overrightarrow{r}={\overrightarrow{S}}_{S}^{+}}\), the latent heat of the primary phase, \(\Delta H\) at \(T={T}_{S}\), and the Gibbs–Thomson coefficient \({\Gamma }_{S}\left({\overrightarrow{S}}_{S}\right)\),

By considering no heat source \(\overrightarrow{q}=0\), it gives

By substituting the thermal gradients and the proper heat fluxes into Eqs. 1–5 allows the determination of the time evolution of the liquidus, Eq. 6 and solidus fronts, Eq. 7. For the liquidus isotherm,

and, for the solidus isotherm,

The relationship between the Gibbs–Thomson coefficient, \({\Gamma }_{L}\left({\overrightarrow{S}}_{L}\left(\overrightarrow{r}\right)\right),\) and the vector radius, \(\overrightarrow{r}\), is defined in terms of the surface energy, \(\gamma ,\) and the surface stress tensor, \({s}_{\alpha \beta }\), to consider surface area creation and deformation [17, 69,70,71,72], volume \(\nabla V\), pressure \(\nabla \mathbf{P}\), species \({\nabla C}_{i}\) and temperature \(\nabla T\) gradients. It is important to mention, that in the case of non-diffusional solid-state phase change, as the martensitic transformation, the term \(\frac{d{A}_{S}}{dt}\) can be as higher as the Debye speed of sound in the solid [17]. Ferreira proposed a solution for the dependence of the surface energy of the vector radius \(\overrightarrow{r}\left(\theta ,\phi \right)\) [17, 73],

where \(\overrightarrow{r}\left(\theta ,\phi \right)\) is the radius vector of a variable radius sphere [73], \({r}_{Eq}\) is the nucleation radius when the surface energy \({\gamma }_{0}\) is only due to surface area creation \({A}_{0}\), and \(s\) is the surface stress tensor, which is written for anisotropic materials [69,70,71,72] as

For isotropic materials, assuming isothermal volumetric work [71] and isotropic surface stress tensor [70],

where \(\varepsilon \) is the strain, \(\gamma \left(\varepsilon \right)\) is the surface energy due to surface area deformation \(A\left(\varepsilon \right)\) and \(s\) is the isotropic surface stress tensor [69, 71].

The absence of a term to account for the decreasing crystal ordering by increasing crystal defects as a function of the level of undercooling, can culminate, for a given thermal field gradient \(\nabla \mathbf{T}=\frac{\partial T}{\partial V}\cdot \nabla V+\frac{\partial T}{\partial \mathbf{P}}\cdot \nabla \mathbf{P}+\sum_{i=1}^{n-1}\frac{\partial T}{\partial {\mathrm{C}}_{i}}\cdot {\nabla C}_{i}+\nabla T\), in a noncrystalline (glassy) material. This dependence of latent heat and transformation entropy on undercooling is well-known and it is based on experimental observations. A suitable equation for the expression of the Gibbs–Thomson first term, Eq. 8, can be derived from homogeneous and heterogeneous nucleation considering the surface energy dependence on surface area creation and deformation [17, 69,70,71,72], and both nucleation conditions will provide the same relationship for the critical radius. In the case of homogeneous and heterogeneous nucleation,

By deriving Eqs. 11 and 12 with respect to \(r\) at \(r={r}_{C}\) gives,

The critical radii for nonequilibrium homogeneous and heterogeneous nucleation are the same and given by,

On the other hand, a more suitable form to express the Gibbs–Thomson coefficient for nonequilibrium nucleation to be applied to Eqs. 1, and 7 can be deduced from Eq. 15 as follows

and, the latent heat release is defined as \({\Delta \mathrm{H{^*} }} = {\Delta \mathrm{H }} - \frac{\partial {\upgamma }_{\mathrm{SL}}}{\partial r} \). By comparing it to equilibrium nucleation, in which the surface energy \({\gamma }_{0}\) considers only the surface area creation \({A}_{0}\),

The results of Eqs. 13 and 14 confirms that crystallinity is dependent on the degree of undercooling \(\Delta T\) and on the variation in surface energy with respect to the nucleation radius \({\left.\frac{\partial {\upgamma }_{\mathrm{SL}}}{\partial r}\right|}_{r={r}_{C}}\), which defines the surface entropy, \({\Delta S}_{surf}=\frac{1}{\Delta T}{\left.\frac{\partial {\gamma }_{SL}}{\partial r}\right|}_{r={r}_{C}}\). Once the surface energy is a function of temperature, concentration, volume and pressure gradients according to Eq. 1 [17], the condition for liquid–solid or solid–solid transformation for nonregular crystals, Eq. 16, considering an undercooled liquid can be expressed as

Similar to a superheated phase nucleation,

By expressing in terms of entropy, for an undercooled phase,

For a superheated phase nucleation,

For a regular monocrystal,

By combining Eqs. 1 and 16 gives

By substituting the critical radius from Eqs. 15 into 11 and Eq. 12, nonequilibrium critical free energy equations are obtained for homogeneous \({\mathrm{\Delta G}}_{\mathrm{C},\mathrm{ Hom}}\), and heterogeneous \({\mathrm{\Delta G}}_{\mathrm{C},\mathrm{ Het}}\) nucleation, given by,

and,

The nucleation rate for homogeneous and heterogeneous nucleation can be expressed as

and, for heterogeneous nucleation

Equation 8 can be rewritten in terms of Eq. 23 to incorporate the surface entropy \(\Delta {S}_{Surf}=\frac{1}{\Delta T}{\left.\frac{\partial {\upgamma }_{\mathrm{SL}}}{\partial \overrightarrow{r}}\right|}_{\overrightarrow{r}={\overrightarrow{r}}_{C}}\) by considering a solution for surface energy in terms of a variable radius sphere,

A stable nucleus shape is not assumed to be a regular sphere, because it is only a special case, \(\left|\overrightarrow{r}\right|={r}_{0}\) [17], but its shape depends on the thermal field gradient pattern normal to its surface, a function of the azimuth \(\theta \) and zenith \(\phi \) angles, \(\overrightarrow{r}\left(\theta ,\phi \right)\) in \({x}_{0,i}\), which is better defined in terms of a vector radius \(\overrightarrow{r}\) that describes a variable radius sphere. Now, the shape of the nucleus can be engineered through the knowledge of the thermal field gradient \(\nabla \mathbf{T}=\left[\frac{\partial T}{\partial V}\cdot\nabla V+\frac{\partial T}{\partial \mathbf{P}}\cdot\nabla \mathbf{P}+\sum_{i=1}^{n-1}\frac{\partial T}{\partial {C}_{i}}\cdot{\nabla C}_{i}+\nabla T\right]\), expressed as a function of volume \(\nabla V\), pressure \(\nabla \mathbf{P}\), species \({\nabla C}_{i}\) and temperature \(\nabla T\) gradients. A set of points in \({\mathbb{R}}^{3}\) defines a sphere in Euclidean coordinates in 3-space, with a variable distance \(r\left(\theta ,\phi \right)\), as a function of any property \(p\in {\mathbb{R}}^{3}\), defined as a vector radius \(\overrightarrow{r}\) from a set of fixed center points \({x}_{0,i}\), \({r}^{2}\left(p\right)=\sum_{i=1}^{3}{\left({x}_{i}-{x}_{0,i}\right)}^{2}\). There are several algorithms applied to sphere decoding—SD. One situation can be posed as a known surface area, and a set of unknown vector radii must be found as described in Di et al. [73]. In the present formulation, the property \(p=\nabla \mathbf{T}\).

Figure 3 shows a schematic domain representation for nucleation and solidification evolution interfaces of an alloy in the microscopic domain \(r\in {\mathbb{R}}^{3}\), consisting of three distinct subdomains: a solid for \(0<r<{S}_{S}\), solid and liquid for \({S}_{S}\le r\le {S}_{L}\), and liquid for \(r>{S}_{L}\) phases. For the microscopic domain, Eqs. 3, 4, 6, and 7 can be applied directly.

2.3 Application of Energy Balances of Liquidus and Solidus Isothermal Surfaces in the Macroscopic Domain inside a Slab for Unidirectional Solidification

In the present model proposition for the unidirectional transient solidification of multicomponent alloys, the microscopic and macroscopic domains are defined in \({\mathbb{R}}^{3}\). Nevertheless, solidification occurs macroscopically only along the \(x\) coordinate. The mathematical formulation of transient solidification of a binary alloy inside a slab, consisting of a cross-section \({A}_{0}={Y}_{0} {Z}_{0}\) and height \(h={X}_{o}\) along with \(x\) coordinates, is derived in terms of macroscopic phase subdomains for the temperature fields inside the solid \({T}_{S}\left(x,t\right)\), solid and liquid \({T}_{SL}\left(x,t\right)\), and liquid \({T}_{L}\left(x,t\right)\) phases.

The thermal gradients at each transformation interface are written in terms of the \(x\) coordinate for the liquidus and solidus (indeed eutectic) moving interfaces and are given in terms of the heat flow direction \(\delta \) as the follows:

and,

where \(A\) is surface area normal to the heat flux, which is independent of the moving surface position, and \({q}_{L}\) and \({q}_{S}\) are source terms. In the case of \({\Gamma }_{L}\left(\overrightarrow{r}\right)\) and \({\Gamma }_{S}\left(\overrightarrow{r}\right)\) formulations, such as the Representative Elementary Volume [66] and the Volume Averaged Technique [67], it is necessary to capture the mean radius from the microscopic domain.

2.4 Mathematical Model Physical Assumptions

As proposed by Garcia and Prates for solidification of metals in cooled moulds [6] and by Garcia, Clyne and Prates in massive moulds [7], a virtual system can be introduced in which heat flow is treated in two regimes, as shown in Fig. 4 for a binary alloy in a massive mould [11]. In the virtual system, the metal/mould heat transfer coefficient is represented by two parcels of pre-existing adjuncts of material: a solid layer of metal (S0), a layer of metal due to the solid and mushy zone (L0), and, finally, an existing layer of mould (E0).

In the virtual system, Eq. 1 is exactly applicable and heat flow in the metal and mould are connected by a hypothetical plane of invariant temperature Ti. The transposition of variables between real and virtual systems is given by the following expressions:

By considering \({t}_{0}\) as the solidification time of a virtual thickness \({S}_{0}\) as found in [11], the time is assumed to be

where \(x\) and \({x}^{^{\prime}}\) represent the distances from the metal/mould interface, \({S}_{S}\) and \({S}_{S}^{^{\prime}}\) are the solidus isotherm interface in real and virtual systems, \({S}_{L}\) and \({S}_{L}^{^{\prime}}\) are the liquidus interface isotherm interface in real and virtual systems, and t/t′ are the time from zero point in the real and virtual systems, respectively, \({E}_{0}\) is the thickness of mould pre-existing adjunct in the virtual system, \({\mathrm{S}}_{0}\) is the thickness of solid pre-existing adjunct in the virtual system, and \({L}_{0}\) is the thickness of mushy and solid pre-existing adjuncts in the virtual system.

For alloy solidification [6, 7, 11], the temperature-distance system is given in Fig. 2. At \(x={\mathrm{S}}_{L}\) and \(t>0\), the temperature of the moving boundary is \(T={T}_{L}\) after a time \(\delta \), and the solidus isotherm moving boundary at \(x={\mathrm{S}}_{S}\) is \(T={T}_{S}\). The boundary conditions are written in terms of the virtual system,

for \({t}^{^{\prime}}=0\),

for \({t}^{^{\prime}}>0\),

where \({A}_{L}^{^{\prime}}={r}^{2}{\int }_{\phi =0}^{2\pi }{\int }_{\theta =0}^{\frac{\pi }{2}}\mathrm{cos}\theta \mathrm{sin}\theta d\theta d\phi \) and \({A}_{S}^{^{\prime}}={r}^{2}{\int }_{\phi =0}^{2\pi }{\int }_{\theta =0}^{\frac{\pi }{2}}\mathrm{cos}\theta \mathrm{sin}\theta d\theta d\phi \) are normal to the surface area independent of the moving surface position. By considering the heat flux direction, \({A}_{L}^{^{\prime}}=\delta 8\pi r+\left(1-\delta \right)8 {\left(\pi r\right)}^{2}\), and \(d{A}_{L}^{^{\prime}}= 8\pi r dr\). In the case of \({A}_{S}^{^{\prime}}=\left(1-\delta \right) 8\pi r+\delta 8 {\left(\pi r\right)}^{2}\) and, \(d{A}_{S}^{^{\prime}}= 8\pi r dr\). \({k}_{S}\) is the solid phase, \({k}_{SL}\) is the mushy zone and \({k}_{L}\) is the liquid phase thermal conductivities. \({T}_{0}\) is the initial temperature of the liquid phase, and \({\Gamma }_{S}\) and \({\Gamma }_{L}\) are the Gibbs–Thomson at the eutectic and liquidus isotherms, respectively.

2.4.1 Solid Region

Applying the performed change of variables to the exact solution based on the error function, which represents the solidification of a semi-infinite slab, gives

Then, applying the boundary conditions of Eqs. 43 into 51, provides

and introducing the similarity variable \({\phi }_{1}\),

Substituting the boundary conditions of Eqs. 44, 52 and the function argument Eqs. 53 into 51, the integration constant \({B}_{S}\) can be derived as

Substituting the obtained integration constants Eqs. 52, 54 and the error function argument Eqs. 53 into 51, an expression for the temperature profile in the solid phase is obtained as follows:

2.4.2 Liquid Region

The solution for Eq. 40 for the liquid phase, considering the transformed radial variable, can be expressed as

Then, applying the boundary conditions given by Eqs. 4) and Eq. 48 into Eq. 56, provides

and,

Then, \({A}_{L}\) and \({B}_{L}\) are provided as

and,

and the similarity variable \({\phi }_{2}\),

where \(n\) is the relation between the solid–liquid (mushy zone) and liquid phase heat diffusivities, given by

By solving the mean integral at the neighborhood of \({S}_{L}^{{^{\prime}}-}\) for thermal conductivity \({\left.{k}_{SL}\right|}_{{S}_{L}^{{^{\prime}}-}}\) and density \({\left.{d}_{SL}\right|}_{{S}_{L}^{{^{\prime}}-}}\),

and,

Finally,

Then, the thermal diffusivity in the neighborhood of \({S}_{L}^{{^{\prime}}-}\) can be expressed as

For comparison purposes with Garcia’s model [1],

Substituting the obtained integration constants, Eqs. 59–62 into Eq. 56 provides an expression for the liquid temperature profile,

2.4.3 Mold Region

The solution of Eq. 37 for the mould region can be expressed as

Then, applying the boundary conditions of Eqs. 42 into 64, provides

By applying boundary conditions Eqs. 43 into 64, gives

where

and, introducing the geometric correlation \(\Theta \) into the similarity variable \(\Lambda \),

where \(n\) is the relationship between the heat diffusivities of the solid and liquid phases, given by

Substituting the boundary conditions of Eqs. 66, 67 and 58 into Eq. 64, provides an expression for the temperature profile in the mould:

2.4.4 Determination of the Equilibrium Temperature at the Metal/Mould Interface (\({T}_{i}\))

The equilibrium temperature at the metal/mould interface can be derived by determining the heat balance at this interface,

which provides

The derivatives of Eqs. 55 and 70, with respect to \({x}^{^{\prime}}\) give, respectively

and,

By substituting Eqs. 73 and 74 into Eq. 72

where \(M\) is defined as

and, Eq. 55 for the solid region

Substituting \({T}_{i}\) from Eq. 75 into Eq. 70 mould temperature profile,

2.4.5 Solid + Liquid Region

The solution of Eq. (39) for the mushy region can be written as follows:

By applying the boundary conditions Eqs. 45 and 46,

and,

A possible relationship between Eqs. 80 and 81 arguments can be made by rearranging in terms of similarity variables \({\phi }_{1}\) and \({\phi }_{2}\), and by combining them with Eq. 61

By solving the mean integral at the neighborhood of \({S}_{S}^{{^{\prime}}+}\) for thermal conductivity \({\left.{k}_{SL}\right|}_{{S}_{S}^{{^{\prime}}+}}\) and density \({\left.{d}_{SL}\right|}_{{S}_{S}^{{^{\prime}}+}}\),

and

Finally,

Then, the thermal diffusivity in the neighborhood of \({S}_{L}^{{^{\prime}}-}\) can be expressed as

where

The present model equivalent to Garcia’s model demands \({c}_{PSL}\) defined as given by Eq. 62f.

Now, integration constants \({A}_{SL}\) and \({B}_{SL}\) can be determined as follows:

and,

By combining Eq. 82 with Eqs. 53, 83 provides

The temperature profile for the mushy zone can be written by substituting Eqs. 84, 85 and Eqs. 86 into 79

2.4.6 Determination of Similarity Variables (\({\phi }_{1}, {\phi }_{2}\))

Regarding the heat balance equation at the moving solid/liquid interface, Eqs. 49 and 50, the derivatives with respect to \({x}^{^{\prime}}\) at the interface position \({S}_{S}^{^{\prime}}\) and \({S}_{L}^{^{\prime}}\) of Eqs. 63, 77, and Eq. 87) for liquid, solid and solid–liquid phases, respectively, provide the following equations:

and,

and,

The time derivatives of the expression for the similarity variables for \({\phi }_{1}\) and \({\phi }_{2}\) and their derivatives with respect to with \({x}^{^{\prime}}\) for \({S}_{L}^{^{\prime}}\) are

and,

and, for \({S}_{S}^{^{\prime}}\) provides,

and,

Combined with Eq. 83,

By substituting Eqs. 88–95 into Eq. 49) and Eq. (50), expressions for \({\phi }_{1}\) and \({\phi }_{2}\) are obtained:

and,

In the case of solidification, \(\delta =0\), and the interface is a function of \(r\), then the liquidus interface is a nucleation and growth site and the latent heat integration occurs at the eutectic interface. For fusion, \(\delta =1\), the eutectic is a nucleation and growth site and liquidus is a latent heat integration isotherm.

and,

The Gibbs–Thomson coefficient, surface energy, surface tension, and nucleation radius for the liquidus and solidus isotherm positions are calculated from the microscopic scale and will be discussed in detail in the coming sections.

2.4.7 Determination of the Virtual Pre-existing Adjuncts to Mold (\({\mathrm{S}}_{0}, {L}_{0} \mathrm{and} {E}_{0}\))

In the real system, the Newtonian resistance at the metal/mould interface is represented by the heat transfer coefficient \({h}_{i}\), which must be determined for each experiment. In the virtual system, a portion of the Newtonian thermal resistance is exchanged by an additional layer of solid, and it must be related to the heat transfer coefficient \({h}_{i}\). As both systems are equivalent, the same thermal behavior is expected. The real and virtual systems can be related to each other at the beginning of the solidification process. The heat fluxes at the mould for both systems must be the same. According to the real and virtual system, the following set of equations can be determined as a function of the total thermal resistance, i.e.,

where \({h}_{S}\) is the Newtonian heat transfer coefficient at the metal/mould interface. The temperature \({T}_{i}\) can be eliminated from Eq. 100 by comparing the thermal resistances, as shown in Fig. 2 as

By applying \({x}^{^{\prime}}={S}_{0}\) in \({S}_{S}^{^{\prime}}={S}_{0}\) in Eq. 89 gives

By substituting Eqs. 101 and 102 into Eq. 100), the following relation is obtained:

The pre-existing adjunct \({L}_{0}\) is related to \({S}_{0}\) from the boundary conditions Eqs. 44 and 45 and Eq. 95,

For \({t}^{^{\prime}}={t}_{0}\), and considering \({S}_{S}^{^{\prime}}={S}_{0}\) and \({S}_{L}^{^{\prime}}={L}_{0}\) and substituting into Eq. 104 provides the following relationship:

The energy balance, at the beginning of solidification ( \(t=0\)) in the real coordinate system metal/mould interface, demands the following translation to the virtual system, \({t}^{^{\prime}}={t}_{0}\) and \({x}^{^{\prime}}={-E}_{0}\). In this case,

Considering \({x}^{^{\prime}}={-E}_{0}\) in \({S}_{S}^{^{\prime}}={L}_{0}\) the thermal gradient can be evaluated

By substituting Eq. 107 into Eq. 106, the following \({E}_{0}\) correlation can be obtained:

Now, the heat transfer coefficient \({h}_{M}\) at the mould must be expressed in terms of the global heat transfer \({h}_{g}\), and by applying Eq. 75 to eliminate \({T}_{i}\). In this case,

and, by substituting Eq. 109 and the product \(N.M= \frac{{k}_{S}}{{k}_{M}}\) in Eq. 108, \({E}_{0}\) can be written as follows

and, by introducing Eqs. 105 into 110, the final equation for \({E}_{0}\) is given by

2.4.8 Expressions for the Solidification Time (\(t\)) and Velocity of the Solidification Front (\(v\))

The solidification kinetics were handled previously by the relationship between the time in the virtual and in the real systems, by considering either that the kinetics represented by the pre-existing virtual adjunct is not the same as that expected for the liquid and solid metal domains, as no latent heat release is expected from the virtual layer. No energy barrier implies faster kinetics for heat conduction in the virtual adjunct domain. The similarity variables \({\phi }_{1}\) and \({\phi }_{2}\) can be obtained employing interface equations Eqs. 49 and 50 by considering a parabolic relationship between space and time, providing

and,

By rearranging Eqs. 112 and 113 for \({t}^{^{\prime}}\) gives

and,

By setting \(t=0,\) implies \({S}_{S}={S}_{L}=0\), according to Eqs. 33–36, which assumes

By applying SS′ = S0and \({t}^{^{\prime}}\)= t0 into Eq. 114:

By substituting Eqs. 35, 36, 116 and 117, into Eqs. 114 and 115, the following relationships for the times of displacement of solidus (tS) and liquidus (tL) isotherms are obtained:

for solidus

and for liquidus

The time can be written as a function of \({S}_{0}\) and \({L}_{0}\), so that

From Eqs. 110 and 111, \({S}_{0}\) and \({L}_{0}\) can be derived as

and,

By substituting Eqs. 122 and 123 into Eqs. 120 and 121

and,

By rewriting the time of the solidus and liquidus isotherms in terms of \({\alpha }_{S}\), \({\beta }_{S}\), \({\alpha }_{L}\) and \({\beta }_{L}\), the following expressions are obtained:

and,

The deduced solidus and liquidus isotherm velocities, the reciprocal derivative of \({t}_{S}\) and \({t}_{L}\), give

and,

3 Application of GTF at Liquidus and Solidus Isothermal Surfaces in the Microscopic Domain

The macroscopic energy balance of moving solidus and liquidus macroscopic interfaces demands the values of Gibbs–Thomson at liquidus, \({\Gamma }_{L}\left(r\right)\) Eq. 98 and solidus \({\Gamma }_{S}\left(r\right)\), Eq. 99, the sides of the microscopic moving interface are known beforehand to calculate similarity roots \({\phi }_{1}\) and \({\phi }_{2}\). By applying Eq. 1 into Eqs. 6 and 7 and by assuming spherical or any suitable shape (for ice, a hexagonal prism or cylindric can be assumed depending on concentration, temperature, volume and pressure gradients) for the surface area of the nucleus \(A\left(\overrightarrow{r}\right)\), as can be observed in Eqs. 1 and Eq. 23, which depends on temperature, volume, pressure and concentration gradients, isotherm velocity and cooling rate,

In the absence of mechanical or electromagnetic vibration or agitation, the term \(\frac{\partial T}{\partial P} \frac{\partial P}{\partial r}\) and \(\frac{\partial T}{\partial V} \frac{\partial V}{\partial r}\) can be neglected, which provides

The temperature and concentration gradients will be applied for the determination of surface energy, surface stress, nucleation radius and Gibbs–Thomson coefficients, which are necessary to determine the evolution of the macroscopic solidus and liquidus interfaces. Neglecting the pressure and volume gradients, considering a spherical nucleus of radius of \(r\), and assuming \(A\left(r\right)=4\uppi { r}^{2}\), provides the following expression for the nucleation radius at the liquidus temperature:

For the solidus side of the microscopic transformation moving interface,

Recently, Jahkar et al. [74] derived a similarity solution for solidification of undercooled binary alloys, including shrinkage-induced flow, in which the thermophysical properties are assumed to be constants within a phase but discontinuous between the solid and liquid phases, and temperature and concentration fields are coupled through the Lewis number. The solution derived by the authors encompassed only the solution for the liquid phase gradient, but in the present case, solid and liquid phase gradients are necessary. Problems arise concerning the stability of analytical solutions when concentration and temperature fields are coupled, according to Voller [13] and Swaminathan and Voller [66], and the only critical change of variable is given by Eq. 133

For the solid phase, \(0<{x}^{^{\prime}}<{S}^{^{\prime}}\left({t}^{^{\prime}}\right)\)

For the liquid phase, \({s}^{^{\prime}}\left({t}^{^{\prime}}\right)<{x}^{^{\prime}}<+\infty \)

and the interface temperatures \({T}_{Li}^{*}\) and \({T}_{Si}^{*}\), and concentrations \({C}_{Li}^{*}\) and \({C}_{Si,j}^{*}\) can be derived as

By deriving Eqs. 139–142 with respect to \({x}^{^{\prime}}\) at the interface \({x}^{^{\prime}}={S}^{^{\prime}}\),

To derive the interface temperature, \({T}_{Si}^{*}\) the liquidus interface temperature is defined as a function of the temperature-concentration slope for each solute \(j\), \({m}_{S,j}=\frac{\partial {\widetilde{T}}_{S}^{*}}{\partial {C}_{o,j}^{*}}\), as follows:

since

The interface temperature \({T}_{Si}^{*}\) can be written as

and \({C}_{L,i}^{*}\)

The equilibrium equation is expressed as a function of liquidus and solidus temperatures,

Then, Eq. 152 permits the similarity root \(\phi \) to be calculated.

The temperature and concentration gradients of a semi-infinite slab will be applied to provide the nucleation radius at the liquidus and solidus sides of the microscopic moving transformation interface, Eqs. 144–147, by substituting them into Eqs. 132 and 133 at any position \({S}^{^{\prime}}=S+{S}_{0}\), and \({S}_{0}=\frac{\beta }{2\alpha }\) based on the solidus and liquidus sides at the moving microscopic interface.

The surface stress tensor \(s\), considering an isotropic mean, can be determined by the Gurtin and Murdoch [70] approach for spheres,

and,

where the \({\sigma }_{0}\) is the surface tension and \(\lambda \), \({\lambda }_{0}\), \(\mu \) and \({\mu }_{0}\) are the Lamé moduli. Equations 157 and 158 will be used for local integration to provide an analytical solution for the surface stress tensor \(s\) at the nucleating surface \(A\left(r\right)\).

4 Results and Discussion

The analytical model derived to calculate local temperature/concentration gradients is a closed-form solution, and it is used to reckon analytically by Eqs. 154–157 the critical radius, surface energy, surface tension, surface stress, local Gibbs–Thomson, critical nucleation energy, and rate. Based on numerical simulations, both the macroscopic present proposition and Garcia’s model are dependent on the Biot and Fourier numbers, where only the Biot number was considered in the pre-existing virtual adjunct \({h}_{g}=f\left({S}_{0},{L}_{0}\right)=f(Biot, Fo, {Biot}^{2}Fo)\). There is a relationship with the virtual adjunct for which the macroscopic solidification model is a closed-form solution.

The results and discussion section will be divided into microscopic and macroscopic solidification, since the temperature and species gradients must be provided for liquidus and solidus macroscopic interfaces, as both are dependent on the local nucleation conditions associated with the temperature, solute, volume, and pressure gradients captured by the Gibbs–Thomson coefficients, which are calculated at the microscopic transformation moving interface from the liquid and solid phase sides.

In Fig. 5 the temperature gradients are calculated at the solidus and liquidus sides of the microscopic interface for the very first solidified layer plotted against the global heat transfer coefficient \({h}_{g}\). As can be observed, according to Eq. 142 for higher values of \({h}_{g}\), the temperature gradient of the solid will increase faster than that of the liquid and the interface velocity will be controlled by the solid phase gradient.

In Fig. 6 the solute concentration is plotted against interface position \(S\) = 4 mm, considering the global heat transfer coefficient varying from 1 \(\mathrm{W}\cdot {\mathrm{m}}^{-2}\cdot {\mathrm{K}}^{-1}\) to \(200 \mathrm{W}\cdot {\mathrm{m}}^{-2}\cdot {\mathrm{K}}^{-1}\). Assuming Lewis number for the solid, \({Le}_{S}={10}^{3}\), and for the liquid, \({Le}_{L}={10}^{2}\), a similar test was performed in Jakhar et al. [74]. As can be observed, for lower \({h}_{g}\) the composition remains unchanged in the liquid region. For higher \({h}_{g}\) a continuous decrease in the concentration profile causes a decrease in the diffusion layer in the liquid, reaching the nominal alloy concentration closer to the interface.

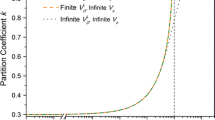

Recently, Ferreira and Moreira [64] presented the transformation interfaces occurring during the solidification of Al-Xwt%Cu alloys for the composition range of Cu varying from pure Al to 33wt%Cu. The addition of Cu causes the single solidification interface to split into two, a liquidus and a solidus, until the solid phase Al-rich \({\alpha }_{Al}\) reaches its solubility limit at \({C}_{S}\sim 5.65\) wt% Cu, where a eutectic reaction takes place. The eutectic solid interface remains until the liquidus isotherm reaches the eutectic concentration \({C}_{L}={C}_{Eut}\), where a single eutectic interface governs the final instants of solidification. Considering only the liquidus and solidus isotherms, here for example, Fig. 7 shows the nucleation critical radius determined at both sides of the microscopic moving transformation interface, as the Gibbs–Thomson coefficient \(\Gamma \) at both the macroscopic liquidus and solidus fronts needs to be calculated to determine the similarity roots \({\phi }_{1}\) and \({\phi }_{2}\) by Eqs. 29 and 30. For the first solidified layer, considering the Al-4.5wt%Cu alloy as a function of the global heat transfer coefficient \({h}_{g}\), the nucleation critical radius will decrease at the solidus and liquidus fronts compared with the equilibrium critical nucleation radius. At positions close to the solidus isotherm the lowest values of critical radius are found due to the higher thermal gradients.

Figures 8 and 9 present the surface tension and surface energy, respectively, for the first solidified layer of the Al-4.5wt%Cu alloy as a function of the global heat transfer coefficient, \({h}_{G}\). At both sides of the microscopic transformation interface, at liquidus and solidus temperatures, both surface tension and surface energy increase with the increase in \({h}_{G}\). In the case of the liquidus isotherm, for \({h}_{g}>2000 \mathrm{W}{\mathrm{ m}}^{-2}{\mathrm{K}}^{-1}\) both surface tension and surface energy are higher than those of equilibrium. The same behavior occurred for the critical radius. The surface energy is more sensitive to the kinetics than the surface tension. That is why Ferreira et al. [75] have noticed that the surface energy reaches similar values when the kinetics are considered (120 to 1540 \(\mathrm{K}.{\mathrm{min}}^{-1}\)) due to the surface area deformation [17].

Figure 10 shows the Gibbs–Thomson coefficients calculated at both sides of the microscopic moving transformation interface relative to the liquidus \({\Gamma }_{L}\) and solidus \({\Gamma }_{S}\) isotherms for the first solidified layer as a function of the global heat transfer coefficient. These coefficients are related to the nucleation resistance of liquidus \(\frac{{h}_{L}}{{T}_{L}}\frac{{\Gamma }_{L}\left(\overrightarrow{r}\right)}{{\nu }_{L}}\) and eutectic \(-\frac{{h}_{S}}{{T}_{S}}\frac{{\Gamma }_{S}\left(\overrightarrow{r}\right)}{{\nu }_{S}}\) on the moving interfaces depending on the heat flow direction under nucleation, which is related to the heat flux direction of the integration of latent heat, i.e., fusion or solidification as shown in Fig. 11.

The evaluation of the proposed multiscale model assumes that the Lamé moduli are the same for Cu compositions varying in the range from 4.5 wt% to 8.1 wt%. A microscopic multicomponent model was derived to calculate the liquidus and solidus thermal gradients necessary to compute the surface energy, surface tension, Gibbs–Thomson coefficient, local nucleation critical radius, energy and nucleation rate as a function of thermal gradients. The multiscale model is validated against the model proposed by Garcia [1] for the transient solidification of binary alloys. The macroscopic model developed is a multicomponent model, as it is coupled to the multicomponent microsegregation model. In the case of the proposed macroscopic model, velocities were considered from both interfaces, i.e., the proposed eutectic and liquidus. The alloy compositions chosen are Al-4.5 wt% Cu, Al-6.2 wt% Cu, and Al-8.1 wt% Cu, in Figs. 12, 13, and 14, respectively. In Fig. 12 good agreement is found for the liquidus position, velocity and cooling rate. In the case of eutectic times and velocities, a similar trend can be noticed for higher positions. In Fig. 13 a similar behavior can be observed. However, for low superheats, the agreement is improved. In the case of Fig. 14, again, excellent agreement can be noticed for the liquidus isotherm times, velocities and cooling rates for both low and high superheats. Considering the eutectic isotherm for the highest superheat \(\Delta T=113\mathrm{K}\), the proposed model occurred for higher times when compared with Garcia’s model [1]. On the other hand, for the isotherm growth rates, both models have a similar behavior.

5 Conclusions

In this paper, a multi-scalar analytical solution was proposed for the unsteady solidification of multicomponent alloys by solving the microscopic local temperature field and compositional fields and coupling the nucleation with local kinetics based on the Gibbs–Thomson-Ferreira-GTF equation [64], which was recently proposed [17]. Surface energy based on area creation and deformation formulation was solved for homogeneous and heterogeneous nucleation, critical radius, critical nucleation energy, and nucleation rate.

The derived model can predict the decrease in crystal regularity and the crystalline-glassy transition by considering the volumetric and surface entropy relationship in the present formulation of nucleation. An analytical solution for nucleation was proposed by considering the surface stress tensor, solidification shrinkage, and temperature and concentration coupled fields assuming that the analytical solution of a slab can be applied for the one-dimensional solidification/fusion problem, depending on \(\delta \). The microscopic and macroscopic models were applied to Al-Cu alloys, and the macroscopic model was plotted against a well-known analytical solution for transient solidification of binary alloys. A macroscopic multicomponent solidification model was derived and found to provide a similar solution to a well-known analytical model [1]. Numerical analysis has shown that the present macroscopic model provides an exact solution, and a set of dependencies of \({S}_{0}\) and \({L}_{0}\) virtual adjuncts on Fourier and Biot numbers need to be determined. The results of the model with the addition of interfaces were very similar to those calculated without the equations for the interfaces, which reiterates the robustness of the model previously deduced [1] and, at the same time, confirms the validity of the interface formulation.

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

A. Garcia, Solidificação: Fundamentos e Aplicações, 2nd edn. (University of Campinas Publishing House, Campinas, 2007), pp.117–199

H.S. Carslaw, J.C. Jaeger, Conduction of Heat in Solids, 2nd edn. (Clarendon Press, Oxford, 1959), pp.282–296

A. Mori, K. Akari, Methods of analysis of the moving boundary-surface problem. Int. J. Chem. Eng. 16, 734 (1976)

M.N. Ozisik, Finite Difference Methods in Heat Transfer, 1st edn. (CRC Press, Boca Raton, 1994), p.417

R.M. Furzeland, A survey of the formulation and solution of free and moving boundary (Stefan) problems, Brunel University Math. Report (1977)

A. Garcia, M. Prates, Metall. Trans. B (1978). https://doi.org/10.1007/BF02654420

A. Garcia, T.W. Clyne, M. Prates, Metall. Trans. B (1979). https://doi.org/10.1007/BF02653977

J. Lipton, A. Garcia, W. Heinemann, Arch. Eisenhüttenw. (1982). https://doi.org/10.1002/srin.198205182

D. Bouchard, J.S. Kirkaldy, Metall. Mater. Trans. A (1997). https://doi.org/10.1007/s11663-997-0039-x

M. Rappaz, W.J. Boettinger, Acta Mater. (1999). https://doi.org/10.1016/S1359-6454(99)00188-3

J.M.V. Quaresma, C.A. Santos, A. Garcia, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. (2000). https://doi.org/10.1007/s11661-000-0096-0

M. Rappaz, A. Jacot, W.J. Boettinger, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. (2003). https://doi.org/10.1007/s11661-003-0083-3

V.R. Voller, Trans. Indian Inst. Met. (2009). https://doi.org/10.1007/s12666-009-0042-9

A. Hamasaiid, M.S. Dargusch, T. Loulou, G. Dour, Int. J. Therm. Sci. (2011). https://doi.org/10.1016/j.ijthermalsci.2011.02.016

D.V. Alexandrov, A.A. Ivanov, I.V. Alexandrova, Philos. Trans. R. Soc. A (2018). https://doi.org/10.1098/rsta.2017.0217

I.L. Ferreira, A. Garcia, A.L.S. Moreira, Int. J. Math. Math. (2021). https://doi.org/10.1155/2021/6624287

I.L. Ferreira, Int. J. Thermophys. (2022). https://doi.org/10.1007/s10765-021-02956-0

I.L. Ferreira, A. Garcia, A.L.S. Moreira, J. Therm. Anal. Calorim. (2022). https://doi.org/10.1007/s10973-021-11153-y

J. Crank, in Numerical Methods in Heat Transfer. ed. by R.W. Lewis, K. Morgan, O.C. Zienkiewicsz (Wiley, New York, 1981), p.177

M. El-Bealy, Metall. Mater. Trans. B (2000). https://doi.org/10.1007/s11663-000-0052-9

L. Tan, N. Zabaras, J. Comput. Phys. (2007). https://doi.org/10.1016/j.jcp.2006.06.003

H. Hou, Y. Zhao, X. Niu, Trans. Nonferrous Met. Soc. China (2008). https://doi.org/10.1016/S1003-6326(10)60207-5

M.F. Zhu, T. Dai, S.Y. Lee, C. Hong, Comput. Math. Appl. (2008). https://doi.org/10.1016/j.camwa.2007.08.023

A.A. Ranjbar, A. Ghaderi, P. Dousti, M. Famouri, Int. J. Eng. 23, 273 (2010)

A. Choudhury, K. Reuther, E. Wesner, A. August, B. Nestler, M. Rettenmayr, Comput. Mater. Sci. (2012). https://doi.org/10.1016/j.commatsci.2011.12.019

J. Li, Z. Wang, Y. Wang, J. Wang, Acta Mater. (2012). https://doi.org/10.1016/j.actamat.2011.11.037

M. Eshraghi, S.D. Felicelli, B. Jelinek, J. Cryst. Growth (2012). https://doi.org/10.1016/j.jcrysgro.2012.06.002

X. Zhang, J. Zhao, H. Jiang, M. Zhu, Acta Mater. (2012). https://doi.org/10.1016/j.actamat.2011.12.045

Y. Shi, Q. Xu, B. Liu, Trans. Nonferrous Met. Soc. China (2012). https://doi.org/10.1016/S1003-6326(11)61529-X

Z. Guo, J. Mi, P.S. Grant, IOP Conf. Ser.: Mater. Sci. Eng. (2012). https://doi.org/10.1088/1757-899X/33/1/012101

B. Jelinek, M. Eshraghi, S. Felicelli, J.F. Peters, Comput. Phys. Commun. (2014). https://doi.org/10.1016/j.cpc.2013.09.013

M. Paliwal, I.H. Jung, J. Cryst. Growth (2014). https://doi.org/10.1016/j.jcrysgro.2014.02.010

M. Zhu, D. Sun, S. Pan, Q. Zhang, D. Raabe, Model. Simul. Mater. Sci. Eng. (2014). https://doi.org/10.1088/0965-0393/22/3/034006

A. Viardin, M. Založnik, Y. Souhar, M. Apel, H. Combeau, Acta Mater. (2017). https://doi.org/10.1016/j.actamat.2016.10.004

A.M. Jokisaaria, P.W. Voorheesa, J.E. Guyerd, J.A. Warrend, O.G. Heinonen, Comput. Mater. Sci. (2018). https://doi.org/10.1016/j.commatsci.2018.03.015

B. Wu, A.L. Jiang, H. Lu, H.L. Zheng, X.L. Tian, Mater. Sci. Forum. (2018). https://doi.org/10.4028/www.scientific.net/MSF.913.212

C. Gu, C.D. Ridgeway, A.A. Luo, Metall. Mater. Trans. B (2019). https://doi.org/10.1007/s11663-018-1480-8

D. Montes de Oca Zapiain, J.A. Stewart, R. Dingreville, Comput. Mater. Sci. (2021). https://doi.org/10.1038/s41524-020-00471-8

D. Tourret, H. Liu, J. Lorca, Prog. Mater. Sci. (2022). https://doi.org/10.1016/j.pmatsci.2021.100810

K.D. Noubary, M. Kellner, B. Nestler, Materials (2022). https://doi.org/10.3390/ma15031160

V.P. Laxmipathy, F. Wang, M. Selzer, B. Nestler, Metals (2022). https://doi.org/10.3390/met12030376

Y. Le Bouar, A. Finel, B. Appolaire, M. Cottura, Phase field models for modeling microstructures evolution in single crystal Ni-base super alloy, in Nickel Base Single Crystals Across Length Scales. ed. by G. Cailletaud, J. Cormier, G. Eggeler, V. Maurel, L. Nazé (Elsevier, Amsterdam, 2022), pp.379–399

L. Ceschini, I. Boromei, A. Morri, S. Seifeddine, I.L. Svensson, J. Mater. Process. Technol. (2009). https://doi.org/10.1016/j.jmatprotec.2009.05.030

M. Easton, C. Davidson, D. John, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. (2010). https://doi.org/10.1007/s11661-010-0183-9

D.B. Carvalho, E.C. Guimarães, A.L.S. Moreira, D.J. Moutinho, J.M. Dias-Filho, O.L. Rocha, Mater. Res. (2013). https://doi.org/10.1590/S1516-14392013005000072

V.A. Hosseini, S.G. Shabestari, R. Gholizadeh, Mater. Des. (2013). https://doi.org/10.1016/j.matdes.2013.02.088

A.L.S. Moreira, O.F.L. Rocha, J.E. Spinelli, D.L.B. Carvalho, D.J.C. Moutinho, J.M.S. Dias Filho, Mater. Res. (2014). https://doi.org/10.1590/S1516-14392014005000015

J.D. Miller, T.M. Pollock, Acta Mater. (2014). https://doi.org/10.1016/j.actamat.2014.05.040

K.G. Prashanth, S. Scudino, H.J. Klauss, K.B. Surreddi, L. Löber, Z. Wang, A.K. Chaubey, U. Kühn, J. Eckert, Mater. Sci. Eng. A (2014). https://doi.org/10.1016/j.msea.2013.10.023

A.L.S. Moreira, A.S. Barros, I.A.B. Magno, F.A. Souza, C.A.M. Mota, M.A.P.S. Silva, O.F.L. Rocha, Met. Mater. Int. (2015). https://doi.org/10.1007/s12540-015-4499-2

E. Acer, E. Çadirli, H. Erol, M. Gündüz, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci. (2016). https://doi.org/10.1007/s11661-016-3484-9

E. Karaköse, M. Yildiz, M. Keskin, Metall. Mater. Trans. B (2016). https://doi.org/10.1007/s11663-016-0678-x

E. Çadırlı, U. Büyük, S. Engin, H. Kaya, J. Alloys Compd. (2017). https://doi.org/10.1016/j.jallcom.2016.10.010

M. Riestra, E. Ghassemali, T. Bogdanoff, S. Seifeddine, Mater. Sci. Eng. A (2017). https://doi.org/10.1016/j.msea.2017.07.074

A. Medjahed, A. Henniche, M. Derradji, T. Yu, Y. Wang, R. Wu, L. Hou, J. Zhang, X. Li, M. Zhang, Mater. Sci. Eng. A (2018). https://doi.org/10.1016/j.msea.2018.01.118

Ü. Bayram, N. Maraşlı, Metall. Mater. Trans. B (2018). https://doi.org/10.1007/s11663-018-1404-7

X. Dong, S. Ji, J. Mater. Sci. (2018). https://doi.org/10.1007/s10853-018-2022-0

A. Barros, C. Cruz, A. Silva, N. Cheung, A. Garcia, O. Rocha, A. Moreira, Acta Metall. Sin-Engl. (2019). https://doi.org/10.1007/s40195-018-0852-z

A.P. Hekimoglu, M. Çalıs, G. Ayata, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00429-6

T. Gu, B. Chen, C. Tan, J. Feng, Optics (2019). https://doi.org/10.1016/j.optlastec.2018.11.008

Y.Z. Li, N. Mangelinck-Noël, G. Zimmermann, L. Sturz, H. Nguyen-Thi, J. Alloys Compd. (2020). https://doi.org/10.1016/j.jallcom.2020.155458

S. Birinci, S. Basit, N. Marasli, J. Mater. Eng. Perform. (2022). https://doi.org/10.1007/s11665-021-06564-9

H. Li, G. Wang, Z. Qui, Z. Zheng, D. Zeng, Adv. Eng. Mater. (2022). https://doi.org/10.1002/adem.202200142

I.L. Ferreira, A.L.S. Moreira, Designing Shape of Nucleus and Grain Coalescence during Alloy Solidification in 3d-ICOMAS Conference. Verona (2022)

A. Karma, D. Tourret, Curr. Opin. Solid State (2016). https://doi.org/10.1016/j.cossms.2015.09.001

C.R. Swaminathan, V.R. Voller, Int. J. Mass Transf. (1997). https://doi.org/10.1016/S0017-9310(96)00329-8

J. Ni, C. Beckermann, Metall. Trans. B (1991). https://doi.org/10.1007/BF02651234

J. Crank, Free and Moving Boundary Problems, 1st edn. (Oxford University Press Inc., New York, 1996), pp.16–17

R. Shuttleworth, Proc. Phys. Soc. A (1950). https://doi.org/10.1088/0370-1298/63/5/302

M.E. Gurtin, A.I. Murdoch, Int. J. Solids Struct. (1978). https://doi.org/10.1016/0020-7683(78)90008-2

P. Müller, A. Saul, F. Leroy, Nanosci. Nanotechnol. (2014). https://doi.org/10.1088/2043-6262/5/1/013002

I.L. Ferreira, Int. J. Thermophys. (2021). https://doi.org/10.1007/s10765-021-02903-z

W. Di, L. Dezhi, W. Zhenyong, Comp. Sci. Info. Technol. (2015). https://doi.org/10.5121/csit.2015.51104

A. Jakhar, P. Rath, S.K. Mahapatra, Eng. Sci. Technol. (2016). https://doi.org/10.1016/j.jestch.2016.04.002

I.L. Ferreira, A.L.S. Moreira, J. Aviz, T.A. Costa, O.F.L. Rocha, A.S. Barros, A. Garcia, J. Manuf. Proc. (2018). https://doi.org/10.1016/j.jmapro.2018.08.010

Funding

The authors acknowledge the financial support provided by FAPERJ (The Scientific Research Foundation of the State of Rio de Janeiro—Brazil) and CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil—Finance Code 001) and CNPq—Brazil (National Council for Scientific and Technological Development).

Author information

Authors and Affiliations

Contributions

ILF developed the formalism, derived equations proposed, performed computations, and wrote the text. ALSM wrote the Introduction section, performed the literature review, and improved the text. AG helped with the comparison with his model and proposed improvements in the English text and the figures layouts.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ferreira, I.L., Garcia, A. & Moreira, A.L.S. On the Multiscale Formulation and the Derivation of Phase-Change Moving Interfaces. Int J Thermophys 44, 2 (2023). https://doi.org/10.1007/s10765-022-03099-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-022-03099-6