Abstract

Surfactants with a wide range of uses are often preferred to reduce particle aggregation in nanofluid and provide stability. However, added surfactants affect the properties of not only nanofluids but also base fluids. In this study, binary mixtures were prepared by using water and three different surfactants, namely, SDS, Tween 80, and NP 10, in four different concentrations of 0.2 % to 0.8 % by weight, separately. Density, thermal conductivity, and viscosity values of these prepared mixtures were measured experimentally at atmospheric pressure and the temperature of 298 to 338 K. Then, correlations were derived with respect to the data obtained for the studied parameter ranges. According to the result, a quadratic polynomial with coefficients was fitted for the density equation and two models for viscosity behavior were derived. Moreover, Thermal conductivity correlations were developed as second-order polynomials of temperature and concentration function. The proposed correlations showed good agreement with our experimental results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Surfactants are among the versatile products of the chemical industry used in many different fields. In recent years, surfactant applications have expanded to high technology fields, such as electronic printing, magnetic recording, biotechnology, microelectronics, and viral research [1, 2]. Surfactants are generally long organic molecules consisting of hydrophilic and lipophilic groups and divided into four groups: nonionic surfactants, anionic surfactants, cationic surfactants, and amphoteric surfactants according to the charge of their water-loving groups. Surfactants form self-occurring molecules known as micelles in the solution and help reduce surface tension between two phases. There has been many studies on the critical micelle concentration (CMC), molar volume expansion, and thermodynamic properties of surfactants [3,4,5,6]. The behavior and micellization processes of surfactants occupy an important place in colloid chemistry and surface chemistry. One of them is to use in the preparation of colloidal suspensions. Colloid mixtures formed by particles smaller than 100 nm in fluids are called nanofluids [7]. Nanoparticles must remain suspended in the liquid, but they tend to form clusters due to having high surface areas and energies. These particle clusters change the properties of fluids, like hydrodynamic properties, volume ratio, thermal conductivity, density, and the viscosity of fluids [8,9,10]. Therefore, one of the biggest problems in nanofluids and the most important factor that restricts the use of nanofluids is the inability to ensure stability. The usage of surfactants is an economic activity to increase the stability of nanofluids. When nanoparticles are added to the solution, the polar groups of surfactants can form strong hydrogen bonds with the surface of the nanoparticles, and the effects of electrostatic repulsion and steric barrier prevent the aggregation of nanoparticles [11]. Singh et al. prepared nanofluid using CNT and SDS with the ratio of 1–3 nanoparticles/surfactants and examined the particle distributions [12]. Tam et al. provided stability of the nanofluid containing ethylene glycol and MWCNT-OH particles by adding Tween 80 surfactant as a dispersant [13]. Peng et al. used NP 10 surfactant in different concentrations to examine the effect of surfactant on nanofluid prepared with TiO2 nanoparticle [14]. The added surfactant also affects the properties of the base fluid. Hydrogen bonds formation occur between water and hydrophilic moieties of surfactants. Therefore, aware of how the properties of water change depending on different surfactant amounts and temperatures is significant in heat transfer calculations. Mingzheng et al. investigated the effects of several concentrations, temperatures, and pH values of surfactant solutions of PVP, SDS, SDSB, and CTAB on thermal conductivity and viscosity properties. They observed that compared to nonionic surfactants, ionic surfactants are more sensitive to temperature. The thermal conductivities of the three ionic surfactants gradually approach the value of pure water by increasing temperature and ionic surfactants do not significantly affect viscosity at low concentrations [11].

As mentioned above, the addition of surfactants is a potential solution to ensure stability in studies related to nanofluids. On the other hand, the theoretical or empirical models proposed for the physical properties of nanofluids, such as density, viscosity, and thermal conductivity, are generally given as the base fluid property ratio [15,16,17]. Therefore, to use these model equations, the property of the base fluid must be known. Water is widely used as the base fluid in preparation of nanofluids. In cases where pure water is used as the base fluid, its physical properties can be easily reached in the literature. However, when surfactants are used in the preparation of nanofluids, the physical properties of the water-surfactants mixture are needed. SDS, Tween 80 and NP10 are also widely used surfactants in nanofluids preparation. In literature, studies on the surfactants mostly focus on solvent media, the effect of temperature on the critical micelle concentration (CMC), number of aggregation, micelle volume, etc. [18,19,20]. This study aims to determine the density, viscosity, and thermal conductivity of the binary mixtures of SDS, Tween 80, and NP 10 with water individually. Measurements are conducted in the range of 0.2 % to 0.8 % by weight surfactant and 298 to 338 K temperature range. Correlations with a function of temperature and concentration are obtained for binary mixtures. Since the surfactant ratios used in the preparation of nanofluids are generally low, the maximum concentration was limited to 0.8 %. This approach was also applied to the determination of the temperature range.

2 Materials and Methods

2.1 Materials

Sodium dodecyl sulfate (SDS), Polyoxyethylene glycol sorbitan monooleate (Tween 80), and NP 10 were used as surfactants in the experiment. SDS is an anionic surfactant and Tween 80 and NP 10 are nonionic surfactants. The properties of the chemicals used are given in Table 1. Chemicals are not received any further purification but are used as received. Solutions were prepared by taking the required surfactant and distilled water and mixing them by a magnetic stirrer for 1 h. Schematic diagram of the experimental setup is shown in Fig. 1.

2.2 Density Measurements

Calibrated pycnometer with a volume of 25 ml and 0.001 ml precision and high precision electronic balance with the precision of 0.0001 g (Mettler Toledo) were used for density measurements. The temperature adjustments of the solutions were achieved by circulated water bath with 0.1 °C. An uncertainty analysis was performed using the method described by Holman [21] and the experimental uncertainty in density was calculated to be 0.04 %. First of all, the density of pure water was determined to check the uncertainty of the measurement results. The experimental and literature [22] values of pure water plotted at different temperatures are given in Fig. 2. It was found that the deviation between experimental and literature values was in the range 0.04 % to 0.3 %.

2.3 Viscosity Measurement

Rheometer (Anton Paar) was used for viscosity measurements. The temperature was controlled within ± 0.1 °C. The experimental uncertainty in viscosity is 2.5 %. The viscosities of experimental and literature data [23, 24] for distilled water are graphed in Fig. 3. The deviation between results was calculated at 2.1 %.

2.4 Thermal Conductivity Measurements

The thermal conductivity of the mixtures was measured by the transient hot-wire method with a low cost and easy application. This method is commonly preferred and can be used for different fluids, such as nanofluids, ionic liquids, and lubricants [17, 25, 26]. The transient hot-wire method works according to the principle of measuring the temperature/time response of the metallic wire given to the instantaneous electrical signal. The wire acts as both heater and thermometer. Firstly, the wire is immersed in the liquid to be tested and heated by passing the current. The temperature rise of the metallic wire is affected by the thermal conductivity of the fluid. If the thermal conductivity of the liquid is high, the temperature rise of the wire is low. The duration of the measurements made with this method is about 1 min [27]. The measurements of the thermal conductivity values were made with the Thermtest THW-L2 device. The THW sensor consists of a wire 60 mm in length and is completely immersed in the sample to be tested. The device calculates the thermal conductivity coefficient of the sample by using Fourier heat conduction equation.

The measurement uncertainty given by the manufacturer is stated to be ± 5 % at thermal conductivity values in the range, 0.01 W·m−1·K to 2 W·m−1·K. A circulating water bath was used to set temperature and remain constant during the measurement within ± 0.1 °C. Before measuring the thermal conductivity values of the prepared surfactant-water solutions, that of pure water used in this experimental study were measured. In Fig. 4, the thermal conductivity coefficients measured experimentally for pure water are plotted based on temperature. Also, the literature data [28, 29] for comparison are shown on the same graph. It was found that the maximum deviation between these results is about 1.2 %.

3 Results and Discussion

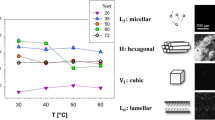

Density, viscosity, and thermal conductivity values of the solutions with 0.2 %, 0.4 %, 0.6 %, and 0.8 % by weight were measured experimentally for 298 K, 308 K, 318 K, 328 K, and 338 K. Concentration ranges examined in this study are between 0.0069 and 0.0277, 0.0015 and 0.0061, and 0.0029 and 0.0117 for SDS, Tween 80, and NP 10, respectively, in terms of molality. CMC are reported in the range of 1.8–2.8 × 10–5 M at 295 K for Tween 80 [4], 8 × 10–3 M for SDS [30], and 7.8 × 10–5 M for NP 10 [31] surfactants at 298 K. The studied concentrations of solution for Tween 80 and NP 10 are above CMC. The concentration of the solution prepared with 0.2 SDS by weight is below CMC value. On the other hand, the other concentrations are above the CMC, and it is also known that temperature affects the CMC point [32].

3.1 Density

In Fig. 5, the density values for each surfactant solution at different temperatures are plotted against the weight percentage of surfactants. As expected, the density decreases with the increasing temperature for all concentrations of water-surfactant solutions used in this study. The increase in temperature results in volume expansion. It causes a greater gap between surfactant molecules and a less regular structure due to the decrease in the interaction force between the molecules of the samples [3, 33]. As shown in Fig. 5, the change of densities with the weight percentage of all three surfactant solutions shows a monolithic increase except for local deviations at high temperatures for SDS and NP 10. The reason can be interpreted as the penetration of molecules into the spaces in the hydrogen-bonded frame of the molecules in the water structure and having a positive interaction with the water [34]. In a study conducted by Khatun and Islam in 2012, the density values of solutions prepared with different concentrations of SDS have been evaluated. They found that while the density of the solutions increases with concentration, it decreases as the temperature increases. These values are compared with the values obtained in this experimental study. Accordingly, the values are close to each other, and the maximum difference between them is around 0.2 % [35]. Since the concentrations used in this study are low, the slope of the curve is not substantially high. Density data were correlated as a second-order polynomial with a function of the amount of surfactant and temperature as given in Eq. 1. The density gradient of the mixtures is similar to that of pure water based on the temperature in the studied temperature range.

where ρ, T, and m indicate the density of solutions, temperature, and molality, respectively. Also, a, b, c, and d are constants. The constants and regression parameters given in Eq. 1 are presented in Table 2. In Fig. 5, the symbols and the lines show the experimental data and the data calculated from Eq. 1, respectively. As can be seen, the compatibility between experimental and calculated values, and the height of R2 values given in Table 2 are well.

3.2 Viscosity

The effect of the molality of the surfactant solutions on viscosity values is presented graphically in Fig. 6. As can be seen, viscosity decreases with the increasing temperature and slightly increase with the increasing molarity for SDS and Tween 80 surfactant solutions (Fig. 6a, b). For NP 10 solutions (Fig. 6c), the change of viscosity with molarity is similar, but the change with temperature is different. It has been stated that the rheological behavior of surfactant solutions is directly related to microstructures, such as micelle or liquid crystal structures [36]. Mingzheng et al. reported that viscosity values for some surfactant solutions prepared at low concentrations do not change regularly with concentration [11]. They also demonstrated that viscosity decreases with the increasing temperature, but different types of surfactant solutions have different characteristics, and viscosity variation should be caused by micelle form. The viscosities of the Tween 80 surfactant solution prepared with different concentrations at temperature 293 to 318 K were investigated by Szymczyk and Taraba [33]. They reported viscosity values about 0.89 and 0.72 mPa s for 10–3 M at 298 K and 308 K. In this study, the viscosity values obtained at 298 K and 308 K for 1.5 × 10–3 M solutions are 0.9153 and 0.6936 mPa s, respectively. The experimental and reported values were found to be so close to each other.

Different correlations have been proposed for fluids to change the viscosity with temperature [37,38,39]. A two parameters model, as given in Eq. 2, known as Arrhenius behavior, is widely applied:

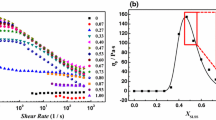

where µ and T indicate dynamic viscosity of solutions in mPa s and temperature in K, respectively; A and B are constants. The logarithm of dynamic viscosity is plotted against the reciprocal temperature in Fig. 7 at different molarity values for three surfactant solutions. The good linear fit is shown in Fig. 7a, b for SDS and Tween 80 solutions, and it indicates that the viscosities of the SDS and Tween 80 solutions exhibit an Arrhenius behavior as given in Eq. 2. On the other hand, the representative curves of ln µ versus 1/T for NP 10 solutions, except lowest molarity, 0.0029, are not linear, as shown in Fig. 7c. This behavior can be explained in detail later.

The change of logarithm of dynamic viscosity as a function of temperature at different molarity values. The symbols show experimental data, while the lines are the fitted curve from Eq. 2. (a) SDS, (b) Tween 80, and (c) NP 10

The experimental dynamic viscosity data for SDS and Tween 80 solutions were fitted to Eq. 2 with the help of commercial software, and the regression coefficients are obtained. Statistical results are collectively given in Table 3 for different molality values. The regression was similarly applied to pure water data for comparison, and the results are also given in Table 3. As can be seen from Table 3, the regression coefficients are quite high. In this study, to obtain a general correlation for the studied temperature and molality ranges, Eq. 3 is derived by adding the molality term to Eq. 2. Regression results are given in Table 3. A comparison of the experimental viscosity data for SDS and Tween 80 solutions with the viscosity values calculated from Eq. 3 is shown in Fig. 8. It is seen from Fig. 8 that the calculated values lie quite close to those of experimental. It must be noted that the obtained equation is valid for the temperature range of 298–338 K and molality range of 0.0069 ≤ m ≤ 0.0277 for SDS solutions and 0.0015 ≤ m ≤ 0.0061 for Tween 80 solutions.

Experimental viscosity data and the viscosity values calculated from Eq. 3. (a) SDS, (b) Tween 80

As seen in Fig. 7c, viscosity values for the lowest molarity (m = 0.0029) among NP 10 solutions in this study decrease with the increasing temperature and fit the model, including two coefficients given in Eq. 2. The constants and statistical data obtained at the end of the regression according to Eq. 2 for this molarity are presented in Table 3. When the temperature increases, viscosity values at the other concentrations decrease similarly, but after nearly a temperature of 318 K, viscosity changes with temperature become different and begin to increase. It has been thought that this behavior exhibits due to occurring of the dehydration with temperature. The effect of temperature on the viscosity of the surfactant solution is related to the surfactant type. The interactions of nonionic surfactants with water molecules are in the form of hydrogen bonds with the surfactant's hydrophilic part. These interactions can be weakened with an increase in temperature because dehydration and solution appear turbid with micelle aggregation effects. The temperature at which the fact occurred is known as cloud point temperature [40]. Phase separation is observed above this temperature. Therefore, the behavior may be the reason for the increase in viscosity at temperatures close to the cloud point temperature. Similar behavior was reported for pentaethylene glycol monododecyl ether and hexaethylene glycol monododecyl ether surfactants [40]. Cloud point temperature of 1 % NP 10 surfactant solution is 63 °C which is given from the supplier.

Viscosities of NP 10 solutions with the molality values of 0.0059, 0.0088, and 0.0117 fit the model, given in Eq. 4, and variables and the statistical results are presented in Table 3. It does not seem appropriate to obtain a general equation covering the studied temperature and molarity ranges for the NP 10 because, as mentioned above, the change of viscosity values with molarity for NP 10 solutions is not monolithic. Therefore, further studies with more substantial temperature and molarity ranges are required for NP 10 solutions.

where µ and T indicate dynamic viscosity of solutions and temperature, respectively.

While the maximum changes in viscosities of the SDS and Tween 80 surfactant solutions are 9.66 % and 7.77 %, respectively, for the studied concentration and temperature range, the value for NP 10 is up to 21 % at high concentrations and temperatures as seen from Figs. 6 and 7.

3.3 Thermal Conductivity

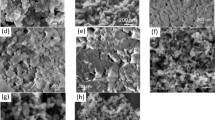

Figure 9 shows the variation of thermal conductivity with molality at various temperatures for SDS solutions. With the increasing temperature, the thermal conductivity increases for all surfactant solutions, similar to that of water in the studied temperature range. However, the change with the amount of surfactant varied according to the type of surfactant. In Fig. 9b, the thermal conductivity ratio of SDS solutions to distilled water versus concentration of surfactant at different temperatures is plotted, where k and ko represent the thermal conductivity of solutions and water, respectively. It is seen from Fig. 9b that thermal conductivity ratios change in the range of 0.983–1.015 depending on the concentration of the solutions and temperature, and decreased slightly with molarity and then increased. Nonmonolithic behavior is much more apparent at high temperatures. Mingzheng et al. [11] investigated the effects of surfactant concentration on the thermal conductivity ratio of the surfactant solutions at room temperature. They reported that the thermal conductivity ratio begins to increase with the increase of SDS concentration at the beginning, starts to decrease after surfactant concentrations of 0.03 wt%, slows down at 0.3 %, and keeps stable at 0.8 %. These results match our results at low temperatures. However, in their study, when the concentration of solution varies from 0.2 % to 0.8 %, the thermal conductivity ratio is around 0.95, while in our study, the change in thermal conductivity ratios is in the range of 1.02–0.98 at the same concentration.

Thermal conductivity and thermal conductivity ratio to concentration for Tween 80 and NP 10 surfactant solutions are presented in Figs. 10 and 11, respectively. When graphs are analyzed, it is seen that the change of thermal conductivity with the concentration of the solutions is different from SDS. Thermal conductivity coefficients decrease with molarity and increase with temperature for both Tween 80 and NP 10 solutions. The thermal conductivities of the solutions start from a higher value than that of pure water. The thermal conductivity ratio begins at approximately 1. When the concentration is changed from 0.2 % (w/w) to 0.8 %, it decreases to around 0.98 from 0.6 %. Although there is no significant amount of decrease in thermal conductivity below 0.4 % concentration for both nonionic surfactants, it is clearly seen that there is a decrease with a concave behavior after this value. Tween 80 and NP 10 solutions exhibit a more monolithic behavior than SDS. Therefore, this situation should be taken into account in the preparation of nanofluid.

The thermal conductivity correlation of the solutions is obtained as a function of temperature and molality as given in Eq. 5:

where a, b, c, d, e, and f are constants. Table 4 contains constants and statistical data for surfactant solutions in the equation. The symbols and the lines show the experimental data and the data calculated from Eq. 5, respectively, in Figs. 9, 10, 11. Figure 12 shows the experimental thermal conductivity values with the values derived from Eq. 5. As can be seen from Fig. 12, the compatibility between experimental and calculated values are satisfactory.

Experimental thermal conductivity values and predicted values derived from Eq. 5. (a) SDS, (b) Tween 80, and (c) NP 10

For the concentration and temperature range examined, it is observed that the surfactant solutions of SDS, Tween 80, and NP 10 have a maximum change in thermal conductivity coefficient according to water with the values of 1.86 %, 2.07 %, and 2.93 %, respectively. The variance in thermal conductivity coefficient with respect to the concentration is similar for Tween 80 and NP 10 solutions but different for SDS solutions. This fact is due to the different types of surfactants.

Although there are many studies on nanofluids prepared using surfactants in different concentrations, studies comparing the base fluid containing the surfactant and nanofluids are limited. However, the relative thermal conductivity change of nanofluid with SDBS surfactant concentration has been stated to be very similar to that of the water with SDBS in a study [41]. Therefore, this study also can be preliminary work for predicting and optimizing of nanofluid properties.

4 Conclusion

Surfactants are widely used to increase the stability of nanofluids. In this study, the effect of surfactant concentration and temperature on density, viscosity, and thermal conductivity of aqueous surfactant solutions was investigated experimentally. Surfactant concentration was changed in the range of 0.2 % to 0.8 % by weight and temperature in the 298–338 °C range. Regression analysis was applied for the studied parameter ranges, and correlations were obtained. The significant findings obtained from the experimental results can be summarized as follows: The equation obtained for the density was correlated as a quadratic polynomial. Thermal conductivity was found as second-order polynomials of temperature and concentration. The change of viscosity of mixtures for SDS and Tween 80 was conformed with Arrhenius behavior, while different behaviors were observed for NP 10 solutions with concentrations higher than 0.2 %. It was observed that the viscosities of surfactant solutions decrease with the increasing temperature, but an increase in viscosity was observed after 318 K for the concentration of NP 10 higher than 0.2 %. The correlations proposed for density, thermal conductivity, and viscosity showed good agreement with our experimental results. Hence, these model correlations can be used for the prediction of density, thermal conductivity, and viscosity of SDS, Tween 80, and NP 10/water solutions when their weight concentrations are in the range of 0.2 % to 0.8 % and temperatures in the range of 298 to 338 K.

Availability of data and materials

Not applicable.

References

M.J. Rosen, Surfactants and Interfacial Phenomena, Third Edit (John Wiley & Sons, Inc., 2004)

L.L. Schramm, E.N. Stasiuk, D.G. Marangoni, Annu. Reports Prog. Chem. - Sect. C 99, 3 (2003)

F.M. Sannaningannavar, S.N. Patil, R.M. Melavanki, B.S. Navati, N.H. Ayachit, J. Mol. Liq. 196, 244 (2014)

A. Patist, S.S. Bhagwat, K.W. Penfield, P. Aikens, D. O. Shah 3, 53 (2000)

K.M. Glenn, S. Moroze, S.C. Bhattacharya, R.M. Palepu, 2691, (2007)

R. Khanom, A.B.H. Susan, M.Y.A. Mollah, A.N.M.S. Rahman, Am. J. Appl. Chem. 3, 105 (2015)

S.U.S. Choi, in Am. Soc. Mech. Eng. Fluids Eng. Div. FED (ASME, 1995), pp. 99–105

A. Ghadimi, R. Saidur, H.S.C. Metselaar, Int. J. Heat Mass Transf. 54, 4051 (2011)

N. Ali, J.A. Teixeira, A. Addali, J. Nanomater. 2018, 23 (2018)

F. Yu, Y. Chen, X. Liang, J. Xu, C. Lee, Q. Liang, P. Tao, T. Deng, Prog. Nat. Sci. Mater. Int. 27, 531 (2017)

Z. Mingzheng, X. Guodong, L. Jian, C. Lei, Z. Lijun, Exp. Therm. Fluid Sci. 36, 22 (2012)

K. Singh, S.K. Sharma, S.M. Gupta, Integr. Ferroelectr. 204, 11 (2020)

N.T. Tam, P. Van Trinh, N.N. Anh, N.T. Hong, P.N. Hong, P.N. Minh, B.H. Thang (2018)

H. Peng, L. Lin, G. Ding, Energy 89, 410 (2015)

X.Q. Wang, A.S. Mujumdar, Brazilian J. Chem. Eng. 25, 613 (2008)

X.Q. Wang, A.S. Mujumdar, Int. J. Therm. Sci. 46, 1 (2007)

X.Q. Wang, A.S. Mujumdar, Brazilian J. Chem. Eng. 25, 631 (2008)

B.L. Bales, L. Messina, A. Vidal, M. Peric, O.R. Nascimento, J. Phys. Chem. B 102, 10347 (1998)

J. Bhattacharjee, G. Verma, V.K. Aswal, A.A. Date, M.S. Nagarsenker, P.A. Hassan, J. Phys. Chem. B 114, 16414 (2010)

F.A. Vicente, I.S. Cardoso, T.E. Sintra, J. Lemus, E.F. Marques, S.P.M. Ventura, J.A.P. Coutinho, J. Phys. Chem. B 121, 8742 (2017)

J. P. Holman, W. J. Gajda, Jr., Experimental Methods for Engineers, 5th edition (McGraw-Hill, 1989)

H. Rodríguez, J.F. Brennecke, J. Chem. Eng. Data 51, 2145 (2006)

L. Korson, W. Drost-Hansen, F.J. Millero, J. Phys. Chem. 73, 34 (1969)

Viscosity of Water – viscosity table and viscosity chart : Anton Paar Wiki. https://wiki.anton-paar.com/tr-tr/su/. Accessed 1 June 2020

Z.S. Baird, P.U. Kyyny, A. Dahlberg, D. Cederkrantz, V. Alopaeus, Int. J. Thermophys. 41, 12 (2020)

R.A. Perkins, M.L. Huber, Int. J. Thermophys. 41, 1 (2020)

S.K. Das, S.U.S. Choi, W. Yu, T. Pradeep, Nanofluids: Science and Technology (Wiley, 2007)

M.L.V. Ramires, J.M.N.A. Fareleira, C.A.N. De Castro, M. Dix, and W. A. W 14, 1119 (1993)

E. W. Lemmon, M. O. McLinden, and D. G. Friend, NIST Chemistry WebBook NIST Standard Reference Database, (2017)

B. Hammouda, J. Res. Natl. Inst. Stand. Technol. 118, 151 (2013)

L. Zhang, X. Guo, B. Zhang, T. Ren, Des. Monomers Polym. 22, 122 (2019)

E. Mohajeri, G.D. Noudeh, E-Journal Chem. 9, 2268 (2012)

K. Szymczyk, A. Taraba, J. Therm. Anal. Calorim. 126, 315 (2016)

M.F. Hossain, T.K. Biswas, M.N. Islam, M.E. Huque, Monatshefte Fur Chemie 141, 1297 (2010)

R. Khatun, M.N. Islam, Orient. J. Chem. 28, 165 (2012)

R. J. Farn, Chemistry and Technology of Surfactants (John Wiley and Sons, 2006)

C.J. Seeton, Tribol. Lett. 22, 67 (2006)

I. Stanciu, J. Pet. Technol. Altern. Fuels 3, 19 (2012)

Dortmund Data Bank Software & Separation Technology, Fitting Pure Compon. Equations 3 (2014)

G. Zhao, C.C. Khin, S.B. Chen, B.H. Chen, J. Phys. Chem. B 109, 14198 (2005)

X.J. Wang, D.S. Zhu, S. Yang, Chem. Phys. Lett. 470, 107 (2009)

Acknowledgement

This study is supported by Bursa Technical University Scientific Research Projects Unit with the project number of 190Y011.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Altun, A., Şara, O.N. Thermal Conductivity and Viscosity Correlations in Different Kinds of Aqueous Surfactant Solutions at Atmospheric Pressure as a Function of Temperature. Int J Thermophys 42, 8 (2021). https://doi.org/10.1007/s10765-020-02759-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10765-020-02759-9