Abstract

This article investigates the influence of temperature, concentration, and size of nanoparticles, and addition of surfactants on dynamic viscosity of water-based nanofluids containing alumina (Al2O3) and titania (TiO2) nanoparticles. Two viscometers, a capillary and a falling ball, were used for the measurements in the temperature range of 20–50 °C and the particle concentration of 3–14.3 wt.%. The results indicate that the viscosity of nanofluids is reduced by increasing the temperature, similar to their base fluids. Moreover, surfactants, which are used to improve the shelf stability of nanofluids, most likely increase their viscosity. The correlations derived from the linear fluid theory such as Einstein and Batchelor, especially for solid concentration above 1.5 wt.% are not accurate to predict viscosity of nanofluids, while the modified Krieger-Dougherty equation estimates viscosity of nanofluids with acceptable accuracy in a specific range of solid particle size to aggregate size.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A nanofluid is a colloidal suspension of nanoparticles in a base fluid. The presence of nanoparticles usually alters thermophysical and transport properties of its base fluid. Nanofluids have been attracting attention during the last decade due to their claimed different-than-expected characteristics and potential applications (Das et al. 2008). For example, Choi et al. (2001) reported that dispersing of 1 vol.% multi-walled carbon nanotubes increased thermal conductivity of oil by a factor of 2.5. In fact, some of the literature reported unexpected behavior of nanofluids such as high thermal conductivity, homogeneity, long-term stability, and minimal clogging in channels, which can be related to the characteristics of nanoparticles such as nanoscale size and high specific surface area (Chandrasekar et al. 2010).

Rapid development of technology demands a high performing coolant in many thermal management tasks. In current electronic systems, the device performance is often limited by the possibility of maintaining the temperature within certain limits, as high temperatures reduce the reliability of the systems. Enlargement of the device can expand the heat transfer surface and increase the heat diffusion, though in most of the cases, it is neither economical nor an energy-efficient approach (Kole and Dey 2011). Therefore, development of novel heat transfer fluids with desirable rheological behavior and enhanced thermal properties is highly desirable. Coolants with better thermal properties may be employed in many industrial applications such as transportation, cooling and heating processes, power generation, microelectronics, and HVAC (Hemalatha et al. 2011; Philip and Shima 2012).

Nanoparticles dispersed in a heat carrier fluid might make an efficient heat exchange fluid (Ijam and Saidur 2012). Nanoparticles such as metals, metal oxides, and carbides have much higher thermal conductivity than common base fluids (water, engine oil, and ethylene glycol). As a result, nanofluid may be expected to have higher thermal conductivity than its base fluid. However, addition of nanoparticles elevates viscosity and density of the base fluids. Viscosity is one of the most important characteristics of cooling systems, as pumping power and pressure drop are directly related to the viscosity of the working fluids (Kole and Dey 2010; Haghighi et al. 2013; Nabeel and Hemalatha 2013). Despite the large number of available data on thermal conductivity of nanofluids, only few studies discussed about viscosity of nanofluids (Eastman et al. 2004; Mahbubul et al. 2012; Maïga et al. 2006; Bahiraei et al. 2012; Das et al. 2006).

Pak and Cho (1998) explored the viscosity of water-based γ-Al2O3 and TiO2 nanofluids with 10 vol.% in the temperature range of 20–70 °C. The obtained data illustrated that the viscosity of water-based γ-Al2O3 and TiO2 nanofluids were about 200 and 3 times greater than the viscosity of water, respectively.

He et al. (2007) measured the viscosity of a water-based nanofluid with TiO2 nanoparticles at three different particle concentrations (0.25, 0.60, and 1.18 vol.%) and sizes (95, 145, and 210 nm). The viscosity of the nanofluids was reported to increase with particle concentration and particle size. The viscosity of the nanofluid with particle size of 95 nm increased 4, 5.5, and 11 %, respectively, for particle concentrations of 0.25, 0.60, and 1.18 vol.% at 25 °C. Furthermore, the viscosity of the nanofluid with 6 vol.% increased 5.3 and 7.2 %, respectively, for particle sizes of 95 and 210 nm.

Duangthongsuk and Wongwises (2009) investigated the viscosity of a water-based TiO2 nanofluid in the temperature range of 15–35 °C and the particle volume fraction of 0.2–2 vol.%. It was observed that the viscosity of TiO2–water nanofluid was 4–15 % higher than water at particle volume fraction 1.5 vol.% and temperature ranging from 15 to 35 °C. Also, the viscosity decreased with temperature rise and increased 4–13 % with increasing particle concentration from 0.2 to 2 vol.% at 25 °C. Similar results were reported by Silambarasan et al. (2012) for a dispersion of sub-micron TiO2 particles with particle concentration of 0.27–1.39 vol.% and temperature range of 27–55 °C. They reported the relative viscosity of TiO2–water changed from 1.03 to 1.14 while the particle concentration was increased from 0.27 to 1.39 vol.%.

Fedele et al. (2012) studied the viscosity of TiO2–water nanofluid at four different nanoparticle concentrations (1, 10, 20, and 35 wt.%) in the temperature range of 10–70 °C. The results showed that the relative viscosity of nanofluids were temperature independent. The nanofluid at 1 wt.% behaved similar to the base fluid, i.e., viscosity increase was small (up to 1 %) between 10 and 50 °C; however, viscosity increase was unexpectedly high at higher concentrations (e.g., 243 % for 35 wt.% at 70 °C). Similar results were reported by Bobbo et al. (2012) and Tenga et al. (2011) for the effect of temperature and particle concentration on the viscosity of TiO2–water-based nanofluids.

Al2O3–water-based nanofluids (average particle sizes of 36 and 47 nm) were investigated by Nguyen et al. (temperature range 20 to 75 °C) (2007). The viscosities of the samples with 47-nm sizes were clearly higher than 36 nm for volume concentrations greater than 4 %. Although for lower particle loading than 4 %, the viscosities of both particle sizes were reported to be approximately the same.

Yu et al. (2012) investigated the rheological and heat transfer properties of Al2O3 nanoparticles dispersed in a mixture of ethylene glycol and water (45 and 55 vol.%, respectively). Strong dependency of viscosity on both temperature (10–60 °C) and particle loading (1–2 vol.%) was observed. They showed that the nanofluids at higher particle concentration had higher viscosity. For example, the viscosity of the nanofluid with 2 vol.% Al2O3 was about 46 % higher than the one with 1 vol.% at T = 10 °C.

Hosseini and Ghader (2010) measured the viscosity of Al2O3–water nanofluids in the temperature range 20–70 °C and particle concentrations ranging from 1 to 9.4 vol.%. Experimental data illustrated that viscosity increased with decreasing temperature and increasing particle concentration.

Temperature, volume concentration, nanoparticle shape, and size along with the properties of base fluid such as its viscosity, polarity, and density are some of the main parameters which may influence the apparent viscosity of nanofluids in practical applications (Meyer et al. 2012). However, comparing some studies in the literature, the reported values for viscosity of nanofluids containing similar nanoparticles (type, size, and concentration) in similar experimental conditions (i.e., the same temperature) disagree significantly from each other (Nguyen et al. 2007; Murshed et al 2008). These discrepancies in the results might be related to differences in the dispersion techniques, type of surfactants, and cluster size of nanoparticles. Nevertheless, this increase in viscosity may weaken the potential benefits of nanofluids as heat transfer fluids. Hence, it is required to study the effective parameters on the viscosity of nanofluids with more details.

In this study, the viscosity of water-based Al2O3 and TiO2 nanofluids was studied in the temperature range 20–50 °C using both a capillary and a Höppler (falling ball) viscometer in order to ensure the accuracy of the measurements. Moreover, the impacts of particle size and concentration, temperature, and surfactant on nanofluid viscosity were investigated. Finally, the experiments were compared with correlations from the literature.

Materials, synthesis, and characterization

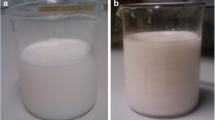

Nanofluids used in this study were provided by ENEA (Italy), Dispersia Ltd (UK), and ItN Nanovation AG (Germany). Table 1 presents the details and materials characterizations of each nanofluid system. All the nanofluids were water based and contain, besides the nanoparticles, additives to adjust pH and surfactant to increase stability. However, details of the additives for Al2O3 III were not revealed by the supplier due to their IPR. According to ItN Nanovation AG, Al2O3 nanofluids had pH around 9 and octylsilane was used as surfactant. However, TiO2 nanoparticles were stabilized with polycarboxylate and trioxadecane acid. The concentrations of these surface modifiers were unknown. All these nanofluids were fabricated via two-step method such as dispersing nanoparticles in a base fluid by high-energy tip sonication. The pH values were adjusted depending upon the surface chemistry of the particles at the stable region of the zeta potential values.

Characterizations

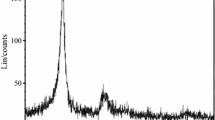

Morphology and size of Al2O3 and TiO2 nanoparticles have been studied by both scanning electron microscopy (SEM) analysis (Zeiss Gemini Ultra 55) and dynamic light scattering (DLS) analysis (Beckman Coulter Delsa Nano C system). For SEM analysis, the samples were prepared by drop casting a drop of the respective nanofluid on the sample holder and drying in a vacuum oven for 6 h to evaporate the solvent. All the samples were diluted with base fluid (water) to 1 wt.% for the DSL analysis. Figure 1 shows the SEM micrographs of all the nanoparticles used in this study and Fig. 2 presents the DLS results for all Al2O3 and TiO2 nanofluids. Dry size of nanoparticles was estimated from micrographs by counting about 300 nanoparticles.

Figure 1a presents the SEM micrographs for Al2O3 (I) and the observed dry primary particle size is about 130 nm. Al2O3 (II) showed slightly larger particle size than Al2O3 (I) (Fig. 1b). DLS results in Fig. 2a show that the hydrodynamic particle size distribution spread between 100 and 500 nm, though the most common DLS size is 220 nm. Al2O3 (II) showed larger particle size (both SEM and DLS) than Al2O3 (I) (Figs. 1b and 2b). Al2O3 (III) nanoparticles were prepared in three distinctive sizes in order to investigate the effect of particle size (different products of the same manufacturer = 200, 250, and 300 nm) and dry particles are displayed in the micrographs Fig. 1c–e. Particles seem to have a flake-like structure, and their dry size is estimated by measuring the largest dimension. Analysis of the SEM micrographs resulted in particle sizes for these nanoparticles as 180, 250, and 290 nm, respectively. In this case, the average hydrodynamic sizes are slightly larger (Table 1) than for the dry particles due to the cluster formations that adsorbed molecular species on the surface of these nanoparticles. TiO2 nanoparticles, displayed in Fig. 1f–h, for nanofluids TiO2 (I), TiO2 (II), and TiO2 (III) were estimated to have dry particle size of about 30 nm. However, DLS analysis showed that for the TiO2 (I), TiO2 (II), and TiO2 (III) nanofluids, the most common hydrodynamic particle sizes were 140, 200, and 90 nm, respectively (Table 1), three to seven times larger values than the dry particle size. This also reveals that these nanoparticles are aggregated in the nanofluid, which has taken place most likely during the formation/fabrication of these particles.

Viscosity measurements

Viscosities were measured with both capillary and Höppler (falling ball) viscometers in the temperature range of 20–50 °C. The capillary viscometer was Ubbelohde type produced by the German company Schott Instruments (No. 52501 01). The Höppler or falling ball viscometer was produced by the German company VEB Prüfgeräte-Werk, Medingen (D.R.P.Nr.644312). The capillary and Höppler viscometers were designed and calibrated based on DIN 51562 and DIN 53015 standards, respectively. According to the standard operating procedures (SOPs), the uncertainties of these viscometers typically were 0.5–1 % (Capillary as named from now) and 0.5–2 % (Höppler as named from now (SOP for Ubbelohde viscometer 2010; SOP for Falling Ball viscometer by Höppler Royal Institute of Technology KTH Stockholm KTH 2010).

A thermostat bath (Lauda RP 200, Germany) was connected to the viscometers in order to provide constant temperature for measurements. The experimental setups were validated by measuring the viscosity of water as base fluid before and after each set of experiments. All of the measurements were carried out at atmospheric pressure. To ensure uniformity of dispersion, prior to viscosity measurement, each nanofluid was put in an ultrasonic bath (VWR, USC2100D, Malaysia) for 15 min.

Result and discussion

Validation of the instruments

The viscosity of distilled water was measured with both viscometers in the temperature range of 10–80 °C. Each measurement was repeated ten times and averaged in order to achieve reliable results. The standard deviation was 2 % for Höppler and 1 % for Capillary. The experimental data are compared with the reference data from the International Association for the Property of Water and Steam, (IAPWS 2008). Figure 3 presents the results for three sets of measurements for both viscometers. The differences between the experimental values and the reference line are below 2 % for both viscometers. Moreover, the differences between the measured values of these two viscometers are less than 1 %.

Measurements for nanofluids

The effects of temperature, nanoparticle concentration, and size of nanoparticles and surfactants on viscosity of water-based Al2O3 and TiO2 nanofluids were presented in terms of the absolute and the relative viscosity, defined as the ratio of viscosity of the nanofluid to that of its base fluid. The accuracy of instruments was validated by measuring the viscosity of distilled water at 20 °C before each set of measurements with nanofluids. Furthermore, all the measurements were repeated three times by each viscometer (with a maximum standard deviation of 2 %) and averaged to increase the accuracy. Measured values by the Capillary and Höppler viscometers showed negligible differences (below 1.1 %) and therefore averaged and considered as the final values for nanofluids.

The effect of temperature and particle concentration on viscosity

The viscosity of Al2O3 (I to III) and TiO2 (I to III) nanofluids was measured at different temperatures and solid particle concentrations. The results for relative viscosity and absolute viscosity of Al2O3 and TiO2 nanofluids at different temperatures are shown in Figs. 4 and 5, respectively.

The viscosity of Al2O3 (I) with 7.5 and 14.3 wt.% and Al2O3 (II) with 3, 6, and 9 wt.% were measured in the temperature range of 20–50 °C. As expected, adding Al2O3 nanoparticles increased the viscosity of water considerably (Fig. 4). All Al2O3–water nanofluids showed a similar trend as the base fluid, e.g., viscosity of nanofluids decreased with increasing temperature.

It can be observed in Fig. 4 that the viscosity of nanofluids with the higher Al2O3 loadings was greater than those with the lower solid particle concentrations. This reveals that the particle concentration is an influential parameter on viscosity of nanofluids. Figure 4b shows the relative viscosity of the Al2O3 nanofluids in the temperature range of 20–50 °C. The average increases for viscosity of Al2O3–nanofluid were 8, 18, 37, 47, and 80 % for particle concentrations of 3, 6, 7.5, 9, and 14.3 wt.%, respectively, at 20 °C. Figure 4b shows that the relative viscosity of alumina–water-based nanofluid is temperature independent in particle concentration varying from 3 to 9 % and temperature range of 20–50 °C. However, the relative viscosity of Al2O3 (I) with 14.3 wt.% solid particle slightly decreases (15 %) in the temperature range of 30–50 °C.

TiO2 nanofluids with 3, 6, and 9 wt.% solid concentrations were investigated similarly to the Al2O3 nanofluids in the temperature range of 20–50 °C. Generally, the nanofluids with TiO2 nanoparticles (Fig. 5) showed the same trends as the Al2O3 nanofluids (Fig. 4) as for both nanofluids the viscosity increased with higher particle loading and lower temperature. For example, the nanofluid with 9 wt.% TiO2 nanoparticles had the highest viscosity at 20 °C among all TiO2 nanofluids (Fig. 5a).

Higher viscosity for the more concentrated nanofluids can be attributed to the stronger internal shear force among nanoparticles. According to Xie et al. (2008), by increasing the number of nanoparticles, bigger agglomerates form and a larger force is required to disperse them. Furthermore, decrease in viscosity of nanofluids with increasing temperature is, as for ordinary liquids, due to the decrease of intermolecular and inter-particle adhesion forces (Nguyen et al. 2007).

The relative viscosities of the TiO2 nanofluids were more or less temperature independent (Fig. 5b), similar to the Al2O3 nanofluids (Fig. 4b). The experimental values reported by Chen et al. (2007a, b) and Prasher et al. (2006) also confirm temperature-independent behavior of relative viscosity for titania–water and alumina–propylene glycol nanofluids at temperatures between 20 and 60 °C and 30–60 °C, respectively. On the contrary, Lee et al. (2011) and Nguyen et al. (2007) found that the relative viscosity of SiC–water and alumina–water nanofluids were dependent on temperature, respectively in the temperature range of 28–72 and 20–70 °C. Apart from these, Suganthi and Rajan (2012) had the same observation as was seen in this study for Al2O3 (I) 14.3 wt.%. They reported that the relative viscosity of ZnO–water nanofluids was temperature independent in the range from 10 to 35 °C and then it decreased with temperature and became temperature dependent in the temperature range of 35–50 °C. Chen et al. (2008) suggested that this may be attributed to the lubricating effect of the nanoparticles. While a small amount of a nanofluid is sheared between two solids, nanoparticles can experience surface adsorption on the solid surface. This adsorption results in friction reduction. Also, it increases the spreading velocity of the nanofluid and alters its fluidity and leads to a decrease in viscosity (Sefiane et al. 2008). Besides, increasing temperature intensifies reduction in viscosity of the nanofluid in comparison to the base fluid. Accordingly, relative viscosity of the nanofluid decreases with temperature at higher temperature (35–50 °C) (Suganthi and Rajan 2012). Nguyen et al. (2007) admitted this phenomenon also and expressed that it is physically due to Brownian diffusion, which is negligible at temperatures near ambient temperature and becomes stronger at higher temperature.

The average increase in viscosity for TiO2–nanofluid compared to water, for concentrations of 3, 6, and 9 wt.%, were 17, 50, and 78 %, respectively at T = 20 °C. However, for Al2O3 (II) with the same temperature and particle concentrations, the increase was 8, 18, and 47 %, i.e., considerably lower. Higher viscosities of TiO2 nanofluids than of Al2O3 nanofluids were in agreement with results by Murshed et al. (2008) and Masuda et al. (1993). However, in the literature, contradictory results have been reported for Al2O3 and TiO2 nanofluids for the same particle concentrations (Haghighi et al. 2013; Mahbubul et al. 2012).

The effect of particle size on viscosity

The effect of particle size on viscosity was investigated for Al2O3 (III) water-based nanofluids at the particle concentration 9 wt.% and three different primary particle sizes (Table 1). The results in Fig. 6 show that the Al2O3 nanofluid with 200 nm had lower viscosity than Al2O3 nanofluids with 250 and 300 nm particle sizes. However, a general trend cannot be extracted from these results. The nanofluid with 250 nm particle size showed between 0.4 and 7 % higher viscosities than the nanofluid with 300 nm in temperature from 20 to 50 °C. It should be noted that these nanofluids had inhomogeneous morphology (Fig. 1, Table 1), which could affect the analysis and somewhat explain this contradictory result.

In fact, contrary results for dependency of viscosity of nanofluids to particle size were reported in the literature. While He et al. (2007) reported that the viscosity of TiO2–water nanofluids increased with increasing particle size, Prasher et al. (2006) expressed that viscosity of nanofluids did not show a strong dependency on nanoparticle size. Anoop et al. (2009) reported contradictory result. According to their tests, viscosity of Al2O3–water nanofluids (1–6 wt.%) decreased with increasing particle sizes (45 and 150 nm). Chevalier et al. (2007) studied the viscosity of SiO2–ethanol nanofluid at volume fractions of 1.4–7 vol.% and three different solid particle sizes (35, 94, 190 nm). They also found that viscosity increased with the reduction of particle size. Namburu et al. (2007) measured the effect particle size on the viscosity of SiO2 nanofluids with ethylene glycol–water (60:40 by weight) as the base fluid for three different sizes (20, 50, 100 nm). Their studies also showed that viscosity decreased with the increase in particle size.

Although it seems that particle size influences the viscosity of a nanofluid, the effect of the other issues also should be taken into account. Nanoparticles can easily agglomerate and make clusters, which make it hard to investigate the pure effect of particle size on viscosity of nanofluids. In other words, hydrodynamic particle size of nanoparticles would be increased due to clustering and agglomeration of nanoparticles, which consequently leads to an increase in viscosity (Mahbubul et al. 2012). A well-dispersion method is a solution to avoid clustering and agglomeration as Ghadimi and Metselaar (2013) stated. Moreover, ultrasonic processing alters particle size distribution and break clusters into smaller sizes.

The effect of surfactant on viscosity

Addition of nanoparticles to the base fluid increases the viscosity of the nanofluids in which as a result pressure drop of the flow inside a pipeline system increases. Unfortunately, higher viscosity may inference on flow properties as well. For example, the pressure drop for 10 vol.% Al2O3 in ethylene glycol–water base fluid is 4.7 times greater than in the base fluid (Vajjha et al. 2010). Surfactants are often added to the nanofluid as a beneficial technique to reduce drag in the nanofluids because they can keep their drag reduction effect under high shear forces. For instance, augmentation of cationic surfactant to carbon nanotubes–water decreases pressure drop up to 45 % (Liu and Liao 2010).

In any practical application, it is essential to have a stable suspension. In order to stabilize the nanofluid, surfactants are often added to nanofluids. Although the use of surfactant is an important technique to enhance the stability and dispersibility of the nanofluids, it may have a detrimental effect on viscosity.

In this investigation, the viscosities of TiO2–water nanofluids with different surfactants were measured. Figure 7 illustrates the dynamic viscosity of the tested TiO2–water nanofluids (9 wt.%) with different surfactants in the temperature range of 20–50 °C.

Based on the results, TiO2 (II) nanofluid (with trioxadecane acid as surfactant) had the highest viscosities and TiO2 (III) nanofluid (without surfactant) had the lowest viscosities (Fig. 7). The viscosities of TiO2 (II) nanofluids were approximately 5.6 and 61 % higher than those for TiO2 (I) and TiO2 (III) nanofluids, respectively. Particularly, it is interesting to note that the TiO2 (III) nanofluid, without surfactant, had a very small increase in viscosity compared to water. Comparing to the results above, it is obvious that the surfactant may have a much larger influence on the viscosity than the particle size or particle shape. Ghadimi and Metselaar (2013) studied the influence of surfactant and ultrasonic processing on stability and viscosity of titania nanofluid with 0.1 wt.% loading of TiO2 nanoparticles (25 nm diameter) and sodium dodecyl sulfate as anionic surfactant. They showed that addition of surfactant increased the viscosity of the nanofluid but the nanofluid without surfactant had the higher sedimentation rate as well. They concluded that the addition of surfactant coupled with ultrasonic bath is the optimum option to improve the stability of nanofluid.

Comparison of experimental values and theoretical correlations

Various theoretical correlations have been developed to predict the viscosity of nanofluids. Some of these correlations were introduced by Enistein (1926), Batchelor (1977), Brinkman (1952), Krieger and Dougherty (1959), and Chen et al. (known as modified Krieger-Dougherty) (2007a, b) in addition to some other correlations derived specifically for Al2O3 or TiO2 nanofluids such as the ones presented by Maïga et al. (2006, 2005), Williams (2006), Rudyak (2013), and Nguyen et al. (2007, 2008). Table 2 summarizes these equations.

In order to study the validity of these correlations, the experimental results are compared with the calculated values from these correlations. Figure 8a presents the results for the Al2O3–water nanofluids at 20 °C and particle loading 3–14.3 wt.% (0.8–4 vol.%). Also, Fig. 8b shows similar results for the TiO2–water nanofluids (particle loading 3–9 wt.% or 0.7–2.3 vol.%). The Einstein, Brinkman, Batchelor, and Krieger-Dougherty correlations in both figures are very identical and considerably underestimate the viscosity of these nanofluids. The Nguyen (for Al2O3 with 36 and 47 nm sizes) and Williams correlations respectively undervalue and overvalue noticeably the experimental values of most of Al2O3 nanofluids. The correlation by Maïga et al. only can predict viscosity of Al2O3 nanofluids at concentrations lower than 6 wt.%. Most of these equations only take into account the effect of volume fraction. Based on the results in Fig. 8, correlations which consider the influence of solid particle and aggregate diameters as well as concentration can be used to evaluate the viscosity of most of Al2O3 and TiO2 nanofluids. For example, Rudyak correlation can predict the viscosity of Al2O3–water-based nanofluid with ±6 % error. Moreover, modified Krieger-Dougherty correlation estimates viscosity of TiO2–water nanofluids better than the other correlations. However, the success of good prediction by modified Krieger-Dougherty correlation is highly dependent on the ratio of the aggregated to the primary nanoparticles size (ξ). Chen et al. (2007a, b) suggested that the ratio of aggregated to primary nanoparticles size (ξ) is in the range 2–4 in order to fit the experimental results to modified Krieger-Dougherty correlation for spherical nanoparticles. However, in this study, this value was evaluated based on SEM and DLS analysis (Table 1). As the results in Fig. 9 show, modified Krieger-Dougherty is only applicable while the values for ξ are in the range of 4–5 for Al2O3 and 4–6 for TiO2. However, for Al2O3 (I) and (II), the ξ values are 1.7 and 1.82, respectively, which are beyond the above range; as a result, modified Krieger-Dougherty estimates the viscosity of these nanofluid samples with larger error (22–32 %). D f (fractional index) is an experimental parameter, and it was assumed 1.8 for Al2O3 and 1.6 for TiO2 nanofluids. The modified Krieger-Dougherty correlation, however, can predict the viscosity of TiO2 nanofluids in which the ξ value for these samples is around 4.67.

Conclusions

The viscosity of water-based Al2O3 (3–14.3 wt.%) and TiO2 (3–9 wt.%) nanofluids were measured in the temperature range of 20–50 °C by means of two viscometers (Capillary and Höppler) to achieve reliable results. The viscosity in both nanofluids increased by adding more solid particles and by decreasing temperature. However, the relative viscosity of these nanofluids was nearly temperature independent (in the range 20–50 °C). The nanofluids comprising TiO2 nanoparticles showed roughly higher viscosity than the ones with Al2O3 nanoparticles in the same loading. Surfactants are normally added to a base fluid in order to improve shelf-stability of nanofluids; however, they most likely increase their viscosity. Furthermore, the increment in the viscosity might be dependent on the type of surfactant; for example, TiO2 nanofluids with polycarboxylate surfactant showed higher viscosity than the ones with trioxadecane acid. Some correlations have been suggested to predict the viscosity of nanofluids. Nevertheless, most of these correlations underestimate or overestimate the experimental data of the present study except those which have considered the effect of aggregate size of nanoparticle in nanofluid. Modified Krieger-Dougherty correlation can predict the viscosity of nanofluids with ±5 % error provided the correct fractional index and the ratio of aggregated to primary nanoparticles size are experimentally determined. However, the modified Krieger-Dougherty correlation cannot be used for nanofluid with inhomogeneous morphology and with various ratios of aggregated to primary nanoparticles size.

Abbreviations

- a.u.:

-

Arbitrary unit

- Df:

-

Fractal dimension

- DW:

-

Distilled water

- HVAC:

-

Heating ventilation and air conditioning

- K-D:

-

Krieger-Dougherty

- Ra:

-

Aggregated particles radius

- T :

-

Temperature (°C)

- vol:

-

Volume percentage

- wt:

-

Weight percentage

- ρ :

-

Density (kg/m3)

- μ :

-

Dynamic viscosity (cP)

- φ :

-

Particle volume fraction

- φ m :

-

Maximum particle packaging fraction

- φ agg :

-

Volume fraction of aggregates

- φ p :

-

Volumetric concentration of nanoparticles

- bf:

-

Base fluid

- d p :

-

Nanoparticle diameter

- p:

-

Particle

- nf:

-

Nanofluid

- r:

-

Nanofluid to base-fluid ratio

References

(2010) SOP for Falling Ball viscometer by Höppler. Royal Institute of Technology (KTH). Stockholm: KTH

Anoop KB, Sundararajan T, Das Sarit K (2009) Effect of particle size on the convective heat transfer in nanofluid in the developing region. Int J Heat Mass Transf 52(9–10):2189–2195

Bahiraei M, Hosseinalipour SM, Zabihi K, Taheran E. (2012). Using neural network for determination of viscosity in water–TiO2 nanofluid. Adv Mech Eng, 2012 (dx.doi.org/10.1155/2012/742680), 10

Batchelor GK (1977) The effect of Brownian motion on the bulk stress in a suspension of spherical particle. J Fluid Mech 83:97–117

Bobbo S, Fedele L, Benetti A, Colla L, Fabrizio M, Pagura C, Barison S (2012) Viscosity of water based SWCNH and TiO2 nanofluids. Exp Therm Fluid Sci 36:65–71

Brinkman HC (1952) The viscosity of concentrated suspensions and solution. J Chem Phys 20:571–581

Chandrasekar M, Suresh S, Bose AC (2010) Experimental investigations and theoretical determination of thermal conductivity of Al2O3/water nanofluid. Exp Therm Fluid Sci 34(2):210–216

Chen H, Ding Y, He Y, Tan C (2007a) Rheological behaviour of ethylene glycol based titania nanofluids. Chem Phys Lett 444(4–6):333–337

Chen H, Ding Y, Tan C (2007) Rheological behaviour of nanofluids. New J. Phys., 9

Chen L, Xie H, Li Y, Yu W (2008) Nanofluids containing carbon nanotubes treated by mechanochemical reaction. Thermochim Acta 477(1–2):21–24

Chevalier J, Tillement O, Ayela F (2007) Rheological properties of nanofluids flowing through microchannels. Appl. Phys. Lett., 91

Choi SUS, Zhang ZG, Yu W, Lockwood FE, Grulke EA (2001) Anomalous thermal conductivity enhancement in nanotube suspensions. Appl Phys Lett 79(14):2252–2254

Das SK, Choi SUS, Patel HE (2006) Heat transfer in nanofluids—a review. Heat Transf Eng 27(10):3–19

Das SK, Choi SU, Yu W, Pradeep T (2008) Nanofluids: science and technology. Wiley, New York

Duangthongsuk W, Wongwises S (2009) Measurement of temperature dependent thermal conductivity and viscosity of TiO2–water nanofluids. Exp Therm Fluid Sci 33(4):706–714

Eastman JA, Phillpot S, Choi S, Keblinski P (2004) Thermal transport in nanofluids. Annu Rev Mater Res 34:219–246

Enistein A (1926) Investigations on the theory of the Brownian movement. Dover, New York

Fedele L, Colla L, Bobbo S (2012) Viscosity and thermal conductivity measurements of water-based nanofluids containing titanium oxide nanoparticles. Int J Refrig 35(5):1359–1366

Ghadimi A, Metselaar IH (2013) The influence of surfactant and ultrasonic processing on improvement of stability, thermal conductivity and viscosity of titania nanofluid. Exp Therm Fluid Sci 51:1–9

Haghighi E. B., Saleemi M., Nikkam N., Ghadamgahi M., M Beh, Mirmohammadi S.A, Khodabandeh R., Palm B., Topark M. S., Muhammad M. (2013). Measured of temperature-dependent viscosity of nanofluids and its effect on pumping power in cooling systems. ICAE 2013—International Conference on Applied Energy. Pretoria, South Africa

He Y, Jin Y, Chen H, Ding Y, Cang D, Lu H (2007) Heat transfer and flow behaviour of aqueous suspension of TiO2 nanoparticles (nanofluids) flowing upward through a vertical pipe. Int J Heat Mass Transfer 50(11–12):2272–2281

Hemalatha J, Prabhakaran T, Pratibha Nalini R (2011) A comparative study on particle-fluid interactions in micro and nanofluids of aluminum oxide. Microfluid Nanofluid 10(2):263–270

Hosseini M, Ghader S (2010) A model for temperature and particle volume fraction effect on nanofluid viscosity. J Mol Liq 153(2–3):139–145

IAPWS Release on the IAPWS Formulation 2008 for the Viscosity of Ordinary Water Substance. (2008)

Ijam A, Saidur R (2012) Nanofluid as a coolant for electronic devices (cooling of electronic devices). Appl Therm Eng 32:76–82

Kole M, Dey TK (2010) Viscosity of alumina nanoparticles dispersed in car engine coolant. Exp Therm Fluid Sci 34(6):677–683

Kole M, Dey TK (2011) Effect of aggregation on the viscosity of copper oxide-gear oil nanofluids. Int J Therm Sci 50(9):1741–1747

Krieger IM, Dougherty JM (1959) A mechanism for non‐Newtonian flow in suspensions of rigid spheres. Trans Soc Rheol 3(1):137–152

Lee SW, Park SD, Kang S, Bang IC, Kim JH (2011) Investigation of viscosity and thermal conductivity of SiC nanofluids for heat transfer applications. Int J Heat Mass Transf 54(1–3):433–438

Liu ZH, Liao L (2010) Forced convective flow and heat transfer characteristics of aqueous drag-reducing fluid with carbon nanotubes added. Int J Therm Sci 49:2331–2338

Mahbubul IM, Saidur R, Amalina MA (2012) Latest developments on the viscosity of nanofluids. Int J Heat Mass Transf 55(4):874–885

Maïga SEB, Palm SJ, Nguyen CT, Roy G, Galanis N (2005) Heat transfer enhancement by using nanofluids in forced convection flows. Int J Heat Fluid Flow 26(4):530–546

Maïga SEB, Nguyen CT, Galanis N, Roy G, Maré T, Coqueux M (2006) Heat transfer enhancement in turbulent tube flow using Al2O3 nanoparticle suspension. Int J Numer Methods Heat Fluid Flow 16:275–292

Masuda H, Ebata A, Teramae K, Hishinuma N (1993) Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles (dispersion of Al2O3, SiO2 and TiO2 ultra-fine particles). 227–233 (4)

Meyer JP, Nwosu PN, Sharifpur M, Ntumba T (2012) Parametric analysis of effective viscosity models for nanofluids. ASME 2012 International Mechanical Engineering Congress & Exposition (IMECE2012), (pp. 1149-1157). Houston, USA

Murshed SMS, Leong KC, Yang C (2008) Investigations of thermal conductivity and viscosity of nanofluids. Int J Therm Sci 47(5):560–568

Nabeel Rahin M, Hemalatha J (2013) Viscosity studies on novel copper oxide–coconut oil nanofluid. Exp Therm Fluid Sci 48:67–72

Namburu PK, Kulkarni DP, Dandekar A, Das DK (2007) Experimental investigation of viscosity and specific heat of silicon dioxide nanofluids. Microbiol Nano Lett 2(3):61–67

Nguyen CT, Desgranges F, Roy G, Galanis N, Maré T, Boucher S, Mintsa HA (2007) Temperature and particle-size dependent viscosity data for water-based nanofluids–hysteresis phenomenon. Int J Heat Fluid Flow 28(6):1492–1506

Nguyen CT, Desgranges F, Galanis N, Roy G, Maré T, Boucher C, Angue Mintsa H (2008) Viscosity data for Al2O3–water nanofluid–hysteresis: is heat transfer enhancement using nanofluids reliable? Int J Therm Sci 47(2):103–111

Pak BC, Cho YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transfer 11(2):151–170

Philip J, Shima PD (2012) Thermal properties of nanofluids. Adv. Colloid Interface Sci., 183-184, 30-45

Prasher R, Song D, Wang J, Phelan P (2006) Measurement of nanofluid viscosity and its implications for thermal applications. Appl. Phys. Lett., 89 (13)

Rudyak VY (2013) Viscosity of nanofluids—why it is not described by the classical theories. Adv Nanoparticle 2:266–279

Sefiane K, Skilling J, MacGillivray J (2008) Contact line motion and dynamic wetting of nanofluid solutions. Adv Colloid Interface Sci 138(2):101–120

Silambarasan M, Manikandan S, Rajan KS (2012) Viscosity and thermal conductivity of dispersions of sub-micron TiO2 particles. Int J Heat Mass Transf 55(25–26):7991–8002

SOP for Ubbelohde viscometer (2010) 7. Stockholm: KTH

Suganthi KS, Rajan KS (2012) Temperature induced changes in ZnO–water nanofluid: zeta potential, size distribution and viscosity profiles. Int J Heat Mass Transf 55(25–26):7969–7980

Teng T, Hung YH, Jwo CS, Chen CC, Jeng LY (2011) Pressure drop of TiO2 nanofluid in circular pipes. Particuology 9(5):486–491

Utomo AT, Poth H, Robbins PT, Pacek AW (2012) Experimental and theoretical studies of thermal conductivity, viscosity and heat transfer coefficient of titania and alumina nanofluids. Int J Heat Mass Transf 55:7772–7781

Vajjha RS, Das DK, Kulkarni DP (2010) Development of new correlations for convective heat transfer and friction factor in turbulent regime for nanofluids. Int J Heat Mass Transf 53:4607–4618

Williams WC (2006) Experimental and theoretical investigation of transport phenomena in nanoparticle colloids (nanofluids). Massachusetts Institute of Technology

Xie H, Chen L, Wu Q (2008) Measurements of the viscosity of suspensions (nanofluids) containing nanosized Al2O3 particles. High Temp High Press 37(2):127–135

Yu W, Xie H, Li Y, Chen L, Wang Q (2012) Experimental investigation on the heat transfer properties of Al2O3 nanofluids using the mixture of ethylene glycol and water as base fluid. Powder Technol 230:14–19

Acknowledgments

The financial support of the EU project NanoHex (Enhanced Nano-fluid Heat Exchange), Ref: 228882, for this study is highly appreciated.

The authors would like to thank ItN Nanovation AG, Germany and Dispersia Ltd, England for the effort in the preparation of the nanofluids. The authors also gratefully acknowledge ENEA (Italian National Agency for New Technologies, Energy and Sustainable Economic Development) for producing TiO2 (III) nanoparticles. The authors would like to express their gratitude to Thibault Brändle and Shohreh Moshtarikhah for performing parts of the experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jarahnejad, M., Haghighi, E.B., Saleemi, M. et al. Experimental investigation on viscosity of water-based Al2O3 and TiO2 nanofluids. Rheol Acta 54, 411–422 (2015). https://doi.org/10.1007/s00397-015-0838-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-015-0838-y