Abstract

Fluke Calibration (formerly Hart Scientific) in American Fork, Utah, USA is a manufacturer of temperature calibration instruments. The company manufactured reference standard gold versus platinum (Au–Pt) thermocouples from 1992 to about 2002. Manufacturing was halted in 2002 because a trend of poor curve-fit results was observed in new batches of wire. After reviewing the possible sources of the problem, it was decided to sample wire from multiple manufacturers and investigate ways to make the curve-fit work better. This paper presents the results from the study of the wire and a characterization technique to help improve characterization of thermocouples made with lower purity wire. Calibration results from NIST SRM material and older Fluke thermocouples are included as well to provide a means of comparison of contemporary wire to NIST SRM era wire.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Au–Pt thermocouple has been shown to be a very useful temperature measurement device through several decades of use and research. All indications suggest that Au–Pt thermocouples are superior in accuracy to other thermocouple types in the range \(0 \,^{\circ }\hbox {C}\) to \(1000\,^{\circ }\hbox {C}\) [2]. Furthermore, in the range \(660\,^{\circ }\hbox {C}\) to \(1000 \,^{\circ }\hbox {C}\), Au–Pt thermocouples can have accuracies similar to high-temperature SPRTS. However, manufacturing Au–Pt thermocouples, and digital thermometry readouts used to measure them, has proven to be a bit problematic. First, the reference function and deviation function approaches are not defined as formally as those of other types of temperature sensors such as platinum resistance thermometers (PRTs) with the ITS-90. Ideally the mathematics would be clearly defined, accepted world-wide, and not prone to change. Also, concise guidelines and limits for application of the mathematics, such as the \(W_{\mathrm{T90}}\) limits for ITS-90, would help users know when to accept or reject calibration results. If the mathematics are not firmly established, and globally accepted, it can be difficult, costly, and frustrating to manufacture, calibrate, and use Au–Pt thermocouples as well as the equipment designed to work them. Au–Pt thermocouples users expect consistent results backed by internationally accepted standards. One of the purposes of this paper is to show that more work needs to be done to solidify the Au–Pt thermocouple as a reference-level temperature sensor.

In the 1990s, Hart Scientific adopted the reference function developed by NIST in the 1992 publication “Gold versus platinum thermocouples: performance data and an ITS-90 based reference function,” by G. W. Burns, G. F. Strouse, B. M. Liu, and B. W. Mangum [1] and the quadratic deviation function characterization approach described by NIST in SP 260-134 [2] (see Eq. 1) for the calibration of Au–Pt thermocouples and the design of EMF-to-temperature conversion algorithms in thermocouple readouts.

The Au–Pt reference function developed by NIST where E is the thermocouple voltage in \(\upmu \hbox {V}\), \(t_{90}\) is the temperature in \(\,^{\circ }\hbox {C}\), \(a_{1}\) through \(a_{9}\) are the coefficients as defined in the 1992 Burns et al. paper [1], and \(\Delta a_{1}\) and \(\Delta a_{2}\) are the deviation coefficients.

Eventually, as wire was depleted and new wire was purchased, we started to see Au–Pt thermocouples that could not be adequately characterized with the quadratic deviation function approach. We decided to stop manufacturing Au–Pt thermocouples until the problem could be resolved. The quadratic deviation function worked well for several years, over multiple batches of wire, so we were hesitant to quickly move to a different characterization approach and we thought that it was just a matter of finding better wire. Additionally, readouts would require firmware changes to work with any new characterization approaches.

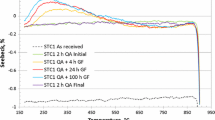

Our observation is that as time passed since the NIST work reported in 1992 [1], 99.999 % pure gold wire has become difficult to obtain. As wire purity has declined, larger deviations from the reference function and larger curve-fit errors have been observed. For example, NIST SRM 1749 thermocouples indicated deviations in EMF from the NIST reference function on the order of 16 mK [2], while we have found some contemporary Au–Pt thermocouples have been found to deviate as much as \(1.6\,^{\circ }\hbox {C}\) from the NIST reference function (see Fig. 1). Hart Scientific Au–Pt thermocouples made in the 1990s had EMF deviations similar to the NIST SRM 1749 thermocouples (see 5629-1046 in Table 2).

To investigate the suspected causes of the poor calibration results, we obtained wire samples from three leading suppliers of precious metal wire with the goal to identify how much variability may be occurring with contemporary wire and if any wire exists in the market that would work well with our accepted reference function and deviation characterization approach. Enough wire was purchased to build multiple thermocouples from each manufacturer. The identity of the suppliers are identified as A, B, and C to maintain anonymity.

2 Assembly and Measurement

Each wire supplier was asked to provide the best available gold and platinum wire. Suppliers A and C provided wire with a reported purity of 99.99 % for both elements. Supplier B provided 99.99 % pure gold wire and 99.999 % pure platinum wire. No additional studies of the wire purity were performed. Samples of each piece of wire were saved to allow purity analysis at a future date.

Eight thermocouples were built following guidelines described in NIST SP260-134-3 [2], the same method used to build Hart Scientific thermocouples since the 1990s. Three units were built with wire from suppliers A and B, while only two were built from supplier C wire due to a section of wire that was damaged. The wires were annealed separately then drawn through twin-bore alumina tubing and joined in the measuring junction using a coil of platinum wire. The assembly was then inserted in a sandblasted quartz sheath with sufficient room left in the tip for thermal expansion. A reference junction was attached using matched copper wires. After assembly, the thermocouples were annealed in a horizontal furnace at \(1000\,^{\circ }\hbox {C}\) for one hour then cooled to \(450\,^{\circ }\hbox {C}\) over a three-hour period. Then they were held at \(450\,^{\circ }\hbox {C}\) for 20 h before being removed to ambient.

Measurements were made in 20.5 cm deep fixed-point cells in descending temperature fixed points from silver, to the triple point of water. A ramp-down furnace was used to slowly cool the thermocouples from silver to aluminum and again from aluminum to \(480\,^{\circ }\hbox {C}\) to prevent quenching the wire. The thermocouples were measured using a long-scale DMM calibrated to 180 nV (\(k = 2\)) uncertainty. A low-thermal manual switch was used to connect the thermocouples to the DMM to facilitate zeroing the DMM before each measurement. The reference junctions were maintained in an ice bath with a reference thermistor probe measuring the actual bath temperature. Measured EMF values were corrected for any ice bath deviations from \(0\,^{\circ }\hbox {C}\). See Table 1 for the measurement uncertainties of the calibration system.

3 Measurement Results

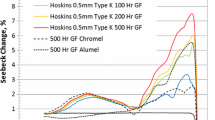

The measured EMF values are shown in Table 2 and EMF deviations from the reference function are shown in Fig. 1. For a point of reference, measurements from a NIST SRM Au–Pt thermocouple and a Fluke model 5629 Au–Pt thermocouple, built in the 1990s, are included. Figure 2 shows the values for SRM-1749 and the 5629-1046 separately since the EMF deviations for these thermocouples are difficult to see in Fig. 1.

The measured EMF deviations from the reference function were fitted with a quadratic deviation function and then with a 3rd-order fit in order to see if a curve-fit improvement could be realized. The curve-fit residuals for each thermocouple are shown in Table 3. Residuals were as high as 25 mK with the 2nd-order fit and as high as 4.2 mK with the 3rd-order fit.

We use a chi-squared analysis (see Eq. 2) to compare curve-fit residuals with measurement uncertainty. Chi-squared analysis is a statistical tool used to determine the appropriateness of curve-fit residual size by considering the ratio of curve-fit residual to standard uncertainty at each measured data point. For the measurement results in this study, curve-fit residuals that failed chi-squared analysis are italicized in Table 3. Multiple thermocouples failed chi-squared analysis with 2nd-order fits but none fail with 3rd-order fits. Also, residuals for all the thermocouples were reduced with the 3rd-order fit. It is noted that the 3rd-order fit yields only one degree of freedom which is not ideal.

Chi-squared analysis where d.f. (degrees of freedom) is calculated as number of measured points minus the number of deviation function coefficients, n = number of data points, \(R_{n}\) is the curve-fit residual at each data point (mK), and \(U_{n}\) is standard uncertainty (\(k = 1\)) at each data point (mK).

A homogeneity measurement was taken at zinc after measurement at silver and aluminum. The homogeneity measurement was performed by first measuring at full immersion in the zinc cell followed by a measurement with the thermocouple withdrawn 9 cm. The inhomogeneity value is the difference between the two measurements. Results are shown in Table 4.

4 Experimental Reference Function

In order to test if the contemporary thermocouples would benefit from a new reference function, we decided to use the measured data to make a new 9th-order reference function representing the average of all the thermocouples listed in Table 2. However, since the measured points alone were insufficient in number for a 9th-order polynomial, more data points were calculated by adjusting the NIST reference function for each thermocouple, then using it to calculate EMF values at multiple temperature points for each thermocouple. Average EMF values were then calculated at each temperature point, for a total of 20 temperature points, and the temperature and EMF data pairs were fit to a 9th-order polynomial.

The new reference function is shown as the origin in Fig. 3. The EMF deltas show how the thermocouples deviate from the new reference function.

Table 5 shows the curve-fit residuals resulting from the experimental reference function, using the same quadratic deviation function approach used in the previous fits. Only the 2nd-order results are shown since the purpose of this portion of the study is to find out if contemporary thermocouples could still be satisfactorily characterized with a 2nd-order deviation function with a new reference function. The results indicate that residuals do decrease for all of the measured thermocouples, when compared with the NIST reference function based fits, but two of the thermocouples still fail chi-squared analysis.

5 Conclusions

Contemporary “best available” Au–Pt thermocouple wire varies tremendously and some wire may simply be too different from the NIST SRM wire to be relied upon for use in reference grade thermocouples. However, virtually no guidelines exist for specifying appropriate wire for manufacturing reference-grad Au–Pt thermocouples. Curve-fit errors and inhomogeneity errors associated with lower purity wire drive the uncertainties well above those reported by NIST in SP 260-134. Limits similar in concept to those used for \(W_{\mathrm{T90}}\) requirements for SPRTs on the ITS-90 would help guide manufacturers and users of Au–Pt thermocouples to achieve reliable results. Help from the international community to push wire manufacturers to build high-purity wire again would be very beneficial.

A direct effect of wire inconsistency is variation in curve-fit error. The results in this study indicate that a new reference function is not necessary to deal with this issue. Using a 3rd-order deviation function with the NIST reference function appears to provide satisfactory results, although it is noted that one degree of freedom poses some risk that must be more thoroughly investigated. Even the NIST SRM thermocouple curve-fit residuals can be improved by using the 3rd-order deviation function.

6 Suggestions for Future Studies

To further establish the Au–Pt thermocouple as a reference thermometer in the 0\(\,^{\circ }\hbox {C}\) to 1000\(\,^{\circ }\hbox {C}\) range, and to bolster it as a possible alternative to high-temperature SPRTs in the 660\(\,^{\circ }\hbox {C}\) to 1000\(\,^{\circ }\hbox {C}\) range, more work needs to be done to further define the thermometer. We suggest that limits be created to ensure adequate adherence to the reference function. Some suggestions are to create EMF limits at particular fixed points or limits for EMF ratios between two fixed points. Inhomogeneity limits may also be useful but standardized homogeneity testing would need to be developed first.

The Fluke laboratory intends to continue this study and experiment with wire that promises to be comparable with the NIST SRM wire. The thermocouples in this study will continue to be measured to study other characteristics such as EMF repeatability and inhomogeneity repeatability. The Fluke laboratory has recommended to Fluke design engineering that future thermocouple readout devices should employ EMF deviation function options with higher-order coefficients or to provide the ability to edit reference function coefficients stored in the device firmware.

References

G.W. Burns, G.F. Strouse, B.M. Liu, B.W. Mangum, Gold versus platinum thermocouples: performance data and an ITS-90 based reference function, in Temperature: Its Measurement and Control in Science and Industry, vol. 6, ed. by J.F. Schooley (AIP, New York, 1992), pp. 531–536

D.C. Ripple, G.W. Burns, NIST Special Publication 260–134: Standard Reference Material 1749: Au/Pt Thermocouple Thermometer (National Institute of Standards and Technology, Gaithersburg, MD, 2002)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Coleman, M.J., Wiandt, T.J. & Harper, T. A Comparison of Contemporary Gold Versus Platinum Thermocouples with NIST SRM 1749-Based Thermocouples and Reference Function. Int J Thermophys 36, 3384–3392 (2015). https://doi.org/10.1007/s10765-015-2001-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-015-2001-5