Abstract

Type R and Type S platinum/platinum–rhodium thermocouples are amongst the most widely used high-temperature thermocouples, both for process measurement and as reference thermocouples. To achieve the lowest practical uncertainties, below \(1\, ^{\circ }\hbox {C}\), the thermocouples must be in a well-defined thermoelectric state. There are two annealing procedures in common use that leave the thermocouples in different states, leading to a potential ambiguity and uncertainty. This paper reports on experiments with Type S thermocouples clearly exposing the different drift characteristics for the two different annealed states. Thermocouples used above \(800\, ^{\circ }\hbox {C}\) show the least drift when annealed at \(1100\, ^{\circ }\hbox {C}\) and then passively quenched to room temperature. If used at lower temperatures, they exhibit drift, at temperatures as low as \(170\, ^{\circ }\hbox {C}\), with the drift peaking at \(0.3\, ^{\circ }\hbox {C}\) to \(0.4\, ^{\circ }\hbox {C}\) around \(300\, ^{\circ }\hbox {C}\) to \(600 \, ^{\circ }\hbox {C}\). Thermocouples used below \(800\, ^{\circ }\hbox {C}\) are best annealed at \(1100\, ^{\circ }\hbox {C}\), and then again at \(450\, ^{\circ }\hbox {C}\). In this state, they exhibit practically zero drift for temperatures up to about \(600 \, ^{\circ }\hbox {C}\). Advice on calibration procedures to minimise the effects of drift is given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because of their good stability, ease of use, and durability, Type R and Type S thermocouples are used as secondary reference thermometers in many laboratories for measurements in the range from \(200\, ^{\circ }\hbox {C}\) to over \(1500\, ^{\circ }\hbox {C}\). They are also used in many high-temperature applications, where accuracy and longevity are important characteristics. Type R and Type S thermocouples both suffer from a number of mechanical, metallurgical, and chemical changes as a result of use and exposure to different temperatures, which can lead to measurement errors that are not always easily identified. Amongst these effects are a number of reversible effects: temperature-dependent oxide formation, thermally generated vacancies, and changes in crystal-lattice structure due to cold-work and ordering. To a large degree, the thermocouples can be restored to a known thermoelectric state simply by isothermal annealing: exposing the thermocouples to a fixed high-temperature for several hours.

There is a great deal of historical data on the use of noble-metal thermocouples in various fixed-point furnaces and the effects of several anneal and quench preconditioning sequences, and arguably the monographs of McLaren and Murdock [1–3] provide the most definitive advice to date. Although no quantitative homogeneity scanning was performed in their experiments, they were able to measure drift caused by exposure to higher-temperature fixed-points when a second immersion scan was performed at the Sn fixed-point. They also noted the drift stopped at the Zn fixed-point.

McLaren and Murdock’s work demonstrated two preconditioning annealing procedures that enable the greatest measurement accuracy: the \(1100\, ^{\circ }\hbox {C}\) quench anneal (QA) and the \(450\, ^{\circ }\hbox {C}\) vacancy anneal (VA). In this paper, the descriptor \(1100\, ^{\circ }\hbox {C}\) QA will refer specifically to an isothermal anneal for 2 h at \(1100\, ^{\circ }\hbox {C}\) followed by a passive quench to room temperature, for which the cooling rate is determined only by natural convection in air and the ceramic insulator supporting the thermocouple. The \(450\, ^{\circ }\hbox {C}\) VA refers to the process where a thermocouple is given an \(1100\, ^{\circ }\hbox {C}\) QA followed by an isothermal anneal at \(450\, ^{\circ }\hbox {C}\) for 24 h and then the passive quench to room temperature. The second lower-temperature anneal allows equilibration of vacancies to the low-temperature concentration [4]. Without the \(450\, ^{\circ }\hbox {C}\) VA, some of the vacancies generated at high temperatures would otherwise be ‘quenched in’ yielding a different thermoelectric state. For thermocouples required to measure a range of temperatures, McLaren and Murdock advocated the \(450\, ^{\circ }\hbox {C}\) VA state as being the most stable. This position was endorsed by Bentley and Jones in [5]. But, sometime later, in a reversal of his position, Bentley [6] advocated the \(1100\, ^{\circ }\hbox {C}\) QA state as being the most suitable.

A later study by Jahan and Ballico [7] provided homogeneity scans revealing some of the performance differences in Type R and S thermocouples that depend on the annealing procedures described by McLaren and Murdock [8, 9]. A more recent study by Edler and Ederer [10], which investigated numerous platinum–rhodium thermoelements with varying rhodium concentrations and annealing cycles, demonstrated that all alloyed thermoelements given a \(450\, ^{\circ }\hbox {C}\) VA were generally the most stable, with the benefits becoming more pronounced with higher rhodium concentrations in the alloyed thermoelements. They also showed that thermocouples given anneals in the intermediate temperature range from \(600 \, ^{\circ }\hbox {C}\) to \(800\, ^{\circ }\hbox {C}\) were the least stable. Stability tests were made by changing the immersion depths of the thermocouples in an oil-bath; the larger the drift, the less stable the thermocouple appeared when moved through the temperature gradient. Despite the extensive work and recommendations of these authors, there still remains no definitive guidance on which annealing and conditioning process is best. A possible reason is a lack of data on the drift of noble-metal thermocouples over a continuous range of temperatures.

The aim of this paper is to provide definitive guidance on the annealing procedures for Type S thermocouples, by measuring the drift for the two anneal states over the range of temperatures from \(150\, ^{\circ }\hbox {C}\) to \(900\, ^{\circ }\hbox {C}\). Descriptions of the experiments and the results are provided in Sects. 2 and 3. Section 4 then considers the results in more detail and links the observations to known effects within the thermocouples. Section 4 also provides guidance on procedures for use and calibration that minimise uncertainty due to drift. The final section summarises the recommendations and conclusions.

2 The Experiments

2.1 Thermocouples

For this study, three Type S thermocouples were assembled in 4 mm diameter twin-bore high-purity alumina insulators, 1.06 m in length. Prior to assembly, the alumina insulators were heated to \(1100\, ^{\circ }\hbox {C}\) for 6 h to ensure any potential contaminants were baked out. The platinum thermoelements were chosen from two suppliers, Franco Corradi (FC) and Johnson Matthey (JM). The purity of the platinum wire from both manufacturers was nominally 99.99+ % and the wires were claimed to be in an annealed state ready for use. For all three thermocouples, the platinum–rhodium 10 % thermoelement was supplied by Johnson Matthey, so was not a variable in comparing performance of the three thermocouples. Table 1 identifies the thermocouples and the origin of the thermoelements. Note that STC1 and STC3 are nominally identical.

All wires were cleaned with alcohol before assembly to remove any grease, oil, or other foreign material from the surface. Likewise, all tools used to assemble the thermocouples were also cleaned with alcohol before use, and rubber gloves were worn when handling bare wires. The thermoelements were then threaded into the insulators using a draw-through technique [4, 11]. PTFE insulation was threaded over the bare wires exiting the alumina, and the wires were then terminated to custom-made connectors and extension wires of platinum and platinum/rhodium 10 %, which in turn were terminated in the multiplexer described by Webster et al. [12]. Two of the three thermocouples, STC1 and STC2, were given homogeneity scans (described below) to assess the thermocouples in the as-received state. Next, all three thermocouples were given a \(1100\, ^{\circ }\hbox {C}\) QA to remove any cold-work defects in wire that have been present from the manufacturing process and/or assembly. The performance of each thermocouple was again assessed by homogeneity scanning.

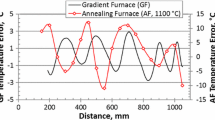

2.2 Gradient and Annealing Furnaces

The use of a gradient furnace to apply a wide temperature gradient along the length of the thermocouple, to investigate ageing of thermocouples over a range of temperatures, was first described by Bentley [13]. Both the temperature range and linearity of the gradient furnace developed at MSL (Measurement Standards Laboratory NZ) exceed that described by Bentley. The maximum achievable linear range is \(100\, ^{\circ }\hbox {C}\) to \(1080\, ^{\circ }\hbox {C}\) with a standard deviation from linearity of only \({\sim }1.5\, ^{\circ }\hbox {C}\). In this study, only the range \(170\, ^{\circ }\hbox {C}\) to \(900\, ^{\circ }\hbox {C}\) was accessible for investigation due to the limited length of the thermocouple alumina insulators and physical restrictions of the homogeneity scanner. Full details on the gradient furnace can be found in [12].

Additionally, a six-zone isothermal annealing furnace was constructed to operate over the range \(100\, ^{\circ }\hbox {C}\) to \(1100\, ^{\circ }\hbox {C}\) and be stable over a 1.2 m length to within 1 % of its set temperature. This high level of uniformity ensures there is a minimum of temperature-induced variations in the chosen annealing state.

2.3 Homogeneity Scanner

The homogeneity scanner used in this study was the open water heat-pipe using direct immersion into steam, described by White [14] in 2010. Since then, a number of improvements have been made: an acetone heat-pipe and air coupling system was added to cool the thermocouple immediately outside the water heat-pipe and narrow the gradient region, and a fully automated control system was implemented. The two heat-pipes of the scanner operate in close proximity to create the narrowest practicable temperature gradient. The scans of this study have a temperature gradient region limited mainly by radial and axial conduction in the alumina insulator of the thermocouple. To prevent steam entering the bores and disturbing the homogeneity scan, a thin silicon-rubber sheath was placed over the tip of the thermocouples. The scanning kernel can be acquired by differentiating the temperature gradient \((\hbox {d}T/\hbox {d}x)\), and is found to have a (spatial) standard deviation of 5.6 mm [15]. The uncertainty in the temperature for the presented scans is related to the linearity of the gradient furnace and the standard deviation of the kernel. When these two components are combined, the total uncertainty for the gradient furnace and scanner is approximately \(\pm 5\, ^{\circ }\hbox {C}\).

2.4 Experimental Procedure

The experimental design used in this study was similar to that described in a study conducted earlier on base metal thermocouples [12]. A linear gradient-furnace spanning \(100\, ^{\circ }\hbox {C}\) to \(900\, ^{\circ }\hbox {C}\) was used to age thermocouples over a continuous range of temperatures and over a range of time periods. To investigate drift as a function of temperature in the \(1100\, ^{\circ }\hbox {C}\) QA state, the thermocouples were aged in the gradient furnace [12] for periods of 4 h, 24 h, and 100 h. The thermocouples were scanned between each ageing cycle. Lastly, the thermocouples were given an \(1100\, ^{\circ }\hbox {C}\) QA and scanned again to ascertain the repeatability of the \(1100\, ^{\circ }\hbox {C}\) QA state.

The second and complementary part of the experiment involved placing the thermocouples in a \(450\, ^{\circ }\hbox {C}\) VA state. From the \(450\, ^{\circ }\hbox {C}\) VA state, the gradient-furnace ageing procedure described above was then repeated, also with scans between each ageing period. Finally, the thermocouples were returned to the \(450\, ^{\circ }\hbox {C}\) VA state, but omitting the \(1100\, ^{\circ }\hbox {C}\) QA that would normally precede it. The omission of the \(1100\, ^{\circ }\hbox {C}\) QA ensured that any rhodium oxide developed during the ageing cycles would be retained in the final scan.

3 Results

3.1 Drift from the \(1100\, ^{\circ }\hbox {C}\) QA State

Figures 1, 2 and 3 show the homogeneity scans for the three thermocouples in a number of states, including as-received, \(1100\, ^{\circ }\hbox {C}\) QA, after a number of ageing periods in the gradient furnace, and after a final \(1100\, ^{\circ }\hbox {C}\) QA. The data are presented as the percentage error in Seebeck coefficient

where \(S_{\mathrm{meas}}\) is the average Seebeck coefficient inferred from the measured voltage and the temperatures measured either side of the scanner gradient, and \(S_{\mathrm{ref}}\) is the corresponding Seebeck coefficient inferred from the thermocouple reference tables [16]. Consequently, the results reflect the thermocouples’ adherence to the reference functions as well as their inhomogeneity and drift. Note that the Seebeck coefficient for Type S thermocouples is approximately constant over the whole temperature range so that \(\Delta S/S\) corresponds closely to \(\Delta t/t\), where \(\Delta t\) is the approximate equivalent temperature error and t is the measured temperature in degrees Celsius.

In the as-received state, the slightly lower Seebeck coefficient for STC1 (Fig. 1) compared to that for STC2 (Fig. 2) suggests there is more residual drawing cold-work in the platinum from FC, as both are paired with JM platinum/rhodium wire from the same reel. Both figures indicate about a 1 % reduction in the Seebeck coefficient for Type S thermocouples manufactured from supplier-annealed wire, where no preconditioning has been applied. The careful draw-through process used in assembling the thermocouples is not capable of introducing such large offsets.

After the \(1100\, ^{\circ }\hbox {C}\) QA, all three thermocouples show a high level of homogeneity. The standard deviations in the Seebeck coefficient over the 800 mm serviceable lengths were 0.015 % (STC1), 0.009 % (STC2), and 0.008 % (STC3). The average Seebeck coefficient offset from the Type S reference function for the three STCs were \(-\)0.073 % (STC1), \(-\)0.148 % (STC2), and \(-\)0.085 % (STC3). The equivalent temperature errors at \(100\, ^{\circ }\hbox {C}\) are of the order of 50 mK to 100 mK.

All three thermocouples show broadly similar drift patterns, with a large positive drift below \(550\, ^{\circ }\hbox {C}\) and a smaller negative drift above \(600 \, ^{\circ }\hbox {C}\). Most of the drift occurs in the first 4 h. In the thermocouples containing FC platinum, Figs. 1 and 3, the drift occurs at temperatures as low as \(170\, ^{\circ }\hbox {C}\) with a significant peak of 0.3 % at \(250\, ^{\circ }\hbox {C}\) after 100 h. Drift in the thermocouple containing JM platinum, Fig. 2, is different with little drift below \(250\, ^{\circ }\hbox {C}\) and drift of approximately +0.18 % between \(350\, ^{\circ }\hbox {C}\) and \(550\, ^{\circ }\hbox {C}\). In all thermocouples, the drift between \(600 \, ^{\circ }\hbox {C}\) and \(900\, ^{\circ }\hbox {C}\) peaks at about \(-\)0.1 % at \(750\, ^{\circ }\hbox {C}\). A final \(1100\, ^{\circ }\hbox {C}\) QA returned the thermocouples to the previous \(1100\, ^{\circ }\hbox {C}\) QA state, indicating that there was no significant contamination or other types of inhomogeneities created during the tests.

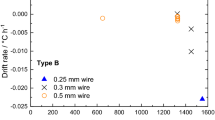

3.2 Drift from the \(450\, ^{\circ }\hbox {C}\) VA State

The results for the thermocouples in the \(450 \, ^{\circ }\hbox {C}\) state are shown in Figs. 4, 5, and 6 for STC1 to STC3, respectively. As with the \(1100\, ^{\circ }\hbox {C}\) QA state, all three thermocouples show a high level of homogeneity after the initial \(450 \, ^{\circ }\hbox {C}\) VA. The standard deviations of the Seebeck coefficients were 0.010 % (STC1), 0.013 % (STC2), and 0.015 % (STC3). The average Seebeck coefficient offset values from the Type S reference function were +0.020 % (STC1), \(-\)0.055 % (STC2) and \(-\)0.015 % (STC3). The values are consistently higher than that of the \(1100\, ^{\circ }\hbox {C}\) QA. The differences in the Seebeck coefficient values between the two annealing states are roughly 0.1 %.

The most significant feature of the three figures is the almost complete absence of drift for temperatures below \(500\, ^{\circ }\hbox {C}\). This provides evidence that the \(450\, ^{\circ }\hbox {C}\) VA is the best procedure for thermocouples to be used at low temperatures. Above \(550\, ^{\circ }\hbox {C}\), all three thermocouples exhibit negative drift that peaks at about \(-\)0.18 % between \(650\, ^{\circ }\hbox {C}\) and \(800\, ^{\circ }\hbox {C}\). Above \(850\, ^{\circ }\hbox {C}\), there are indications in all three figures that the drift is lessening with increasing temperature.

At the end of the gradient-furnace ageing period, a second \(450\, ^{\circ }\hbox {C}\) VA was applied without the preceding \(1100\, ^{\circ }\hbox {C}\) QA. The omission of the \(1100\, ^{\circ }\hbox {C}\) QA step prevents the rhodium oxide, which is developed in the temperature range between \(550\, ^{\circ }\hbox {C}\) and \(900\, ^{\circ }\hbox {C}\), from being dissociated, but allows the vacancy annealing of any point defects generated at these temperatures. Therefore, the remaining drift signature in the final scan is the result of residual rhodium oxide only.

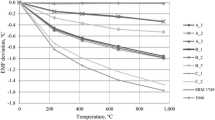

3.3 Equivalent Temperature Drift from Anneal State

In order to investigate the effect of drift in the Seebeck coefficient on measured temperatures, the data for thermocouples scans were re-evaluated in terms of the drift only, as shown in Figs. 7, 8, and 9. The left-hand graph in each figure plots the drift contribution to the change in Seebeck coefficient for 100 h exposure:

where \(S_{\mathrm{100h}}\) is the measured Seebeck coefficient after 100 h in the gradient furnace, and \(S_{\mathrm{initial}}\) is the measured Seebeck coefficient after the corresponding initial anneal (\(1100\, ^{\circ }\hbox {C}\) QA or \(450\, ^{\circ }\hbox {C}\) VA). The starting values (at \(170\, ^{\circ }\hbox {C}\)) in each figure have been offset to zero. The right-hand graph of each figure plots the integral, with respect to temperature, of the curves in the left-hand plot. The resulting curves are indicative of the temperature error due to drift after 100 h versus operating temperature for the thermocouples. The inhomogeneity caused by ordering and oxides is assumed to scale linearly with temperature.

Figures 7, 8, and 9 clearly show the benefit of using a \(450 \, ^{\circ }\hbox {C}\) VA for thermocouples used at temperatures below approximately \(800\, ^{\circ }\hbox {C}\). For measured temperatures above \(800\, ^{\circ }\hbox {C}\), the error is less for thermocouples in the \(1100\, ^{\circ }\hbox {C}\) VA state, and this trend is expected to continue to higher temperatures.

4 Discussion

4.1 Drift Mechanisms in the Platinum and Platinum–Rhodium Thermoelements

4.1.1 Oxidation

Oxidation of rhodium in the platinum–rhodium thermoelement is responsible for reducing the Seebeck coefficient at temperatures between approximately \(500\, ^{\circ }\hbox {C}\) and \(900\, ^{\circ }\hbox {C}\). The effect is thought to be due to the high vapour pressure of the rhodium oxide, which leads to the depletion of rhodium in the surface of the thermoelement [9, 11, 17, 18]; thereby lowering the rhodium concentration in the bulk. Similar changes in palladium thermocouples have been attributed to surface strain caused by oxide growth [19]. The effect of oxidation can be seen to some extent in all of Figs. 1, 2, 3, 4, 5, and 6, but is the dominant feature in Figs. 4, 5, and 6. Bentley [6] provides a hand-drawn curve for drift of Type R and S thermocouples in the \(1100\, ^{\circ }\hbox {C}\) QA state that is similar to that for STC2 (Fig. 2) of this study.

In the bore of a typical alumina insulator and at temperatures in excess of \(900\, ^{\circ }\hbox {C}\), the maximum rhodium-oxide vapour concentration is rapidly reached, existing as a thin viscous layer, which limits further loss [6, 17, 20, 21]. At these temperatures, a complex disassociation process occurs where rhodium oxide transitions back into solid rhodium. However, vapor saturation does not take place when the thermoelements are in a moving air stream so that rhodium loss continues and can cause significant rhodium attrition [10, 17]. This attrition probably also occurs to some degree during a high-temperature electrical anneal [22]. At temperatures between approximately \(500\, ^{\circ }\hbox {C}\) and \(900\, ^{\circ }\hbox {C}\), the bulk of the rhodium oxide exists in solid form and is often identifiable as a dark tarnish on the surface of the Pt/Rh wire.

When insulated thermoelements are cooled from temperatures less than \(900\, ^{\circ }\hbox {C}\), any gaseous oxides are condensed on the wire surface and persist as oxide, adding to any solid oxides already present. Hence, the change in the Seebeck coefficient due to oxide is maintained at temperatures below \(500\, ^{\circ }\hbox {C}\) (see the final \(450\, ^{\circ }\hbox {C}\) VA curves in Figs. 4, 5, 6). However, if the temperature is increased above \({\sim }900\, ^{\circ }\hbox {C}\), the oxides again start to disassociate and metallic rhodium is deposited on to the surface of thermoelement. The slight rise in the Seebeck coefficient above \(850\, ^{\circ }\hbox {C}\) in all of the thermocouple curves in Figs. 1, 2, 3, 4, 5, and 6 is indicative of this process. In Figs. 4, 5, and 6, the final \(450\, ^{\circ }\hbox {C}\) VA curve, which is affected by the oxide only, shows that the oxide has fully dissociated in STC1 and STC3 (Figs. 4, 5, 6) by \(900\, ^{\circ }\hbox {C}\), but less so in STC2 (Fig. 5). Probably, exposure at \(950\, ^{\circ }\hbox {C}\) is sufficient to dissociate all of the oxide, but the exact temperature needs to be confirmed.

Oxidation is also known to occur in the platinum thermoelements and the platinum oxide exhibits similar physical and chemical behaviour to the rhodium oxide, but corresponding changes in the Seebeck coefficient have not been demonstrated. Berry [23] discusses at length the complex interaction of two- and three-dimensional oxides and the temperature of their formation and dissociation. Beyond \(500\, ^{\circ }\hbox {C}\) a complex process of oxide disassociation and gasification start, much as with the rhodium oxide. Bentley [24, 25] reported no differences in drift between dissimilarly treated platinum thermoelements when measured for periods up to 20 h in his gradient furnace operated between \({\sim }180 ^{\circ }\hbox {C}\) and \(450\, ^{\circ }\hbox {C}\), with one platinum thermoelement given an \(1100\, ^{\circ }\hbox {C}\) QA and the other a \(450\, ^{\circ }\hbox {C}\) VA. Subsidiary experiments conducted here also failed to detect any change in the Seebeck coefficient with different treatments of the platinum wire. Further investigation on the role of platinum and its oxides, in both solid and volatile form, is required to conclusively determine the effects on drift for Types R and S thermocouples.

4.1.2 Vacancies and Defects

Vacancies and defects are known to have a major effect on the Seebeck coefficient. The initial \(1100\, ^{\circ }\hbox {C}\) QA plots in Figs. 1 and 2 clearly show the substantial (\({\sim }1\,\%\)) effects arising from defects, presumably introduced during the drawing of the wire, and are consistent with results reported in other studies [6, 7, 11]. The dislocations and defects start annealing out in most thermocouples between \(600 \, ^{\circ }\hbox {C}\) and \(800\, ^{\circ }\hbox {C}\) and are almost completely removed at temperatures over \(1050\, ^{\circ }\hbox {C}\) with exposures times longer than 1/2 h in noble-metal thermocouples [6]. Once the wire has been properly annealed, typically using an electrical anneal and/or an extended \(1100\, ^{\circ }\hbox {C}\) QA, the concentration of defects is much reduced and the Seebeck coefficient returns close to the value cited in the reference tables. There remains, however, a small difference of the order of 0.1 %, between wire subjected to the \(1100\, ^{\circ }\hbox {C}\) QA and that subjected to the \(450\, ^{\circ }\hbox {C}\) VA (e.g., compare the initial anneal states in Figs. 1 and 4). This is due to the thermally generated vacancies, for which the equilibrium concentration increases exponentially with temperature according to an Arrhenius relationship [26, 27], and the difference is therefore largely absent in the \(450\, ^{\circ }\hbox {C}\) VA state. The optimum equilibration temperature and time for vacancy movement have been both experimentally and theoretically found to be \(450\, ^{\circ }\hbox {C}\) to \(500\, ^{\circ }\hbox {C}\) and 16 h to 24 h, respectively [2, 4]. McLaren and Murdock [8] concluded that the relatively rapid quench from \(1100\, ^{\circ }\hbox {C}\) causes thermally generated mono-vacancies and to a lesser extent, more complex vacancy clusters, to remain ‘quenched in’ [8]. Their measurements showed these defects were able to cause a small, but measureable, change of \(0.1\, {\upmu }\hbox {V}\) at the Sn point, which is consistent with the shifts observed here (see the right-hand plots in Figs. 7, 8 and 9).

4.1.3 Ordering

It is now known that short-range ordering (non-random distribution of the rhodium in the crystal lattice), similar to the ordering effects occurring in the positive leg in Type K thermocouples [28], can occur in platinum–rhodium alloys, and is probably responsible for the drift in platinum–rhodium thermoelements below \(600 \, ^{\circ }\hbox {C}\) [29, 30]. In Figs. 1, 2, and 3, the progressive positive drift between \(170\, ^{\circ }\hbox {C}\) and \(550\, ^{\circ }\hbox {C}\) is suggestive of this process. Recent theoretical modelling of the platinum–rhodium system [30] has confirmed that ordering effects occur in all platinum–rhodium alloys at temperatures below \(600 \, ^{\circ }\hbox {C}\). Because the ordered regions within the wire occur over atomic scales, direct observation has been difficult, with most attempts to observe ordering processes being made on NiCr alloys, via X-ray diffraction and electron microscopy [31–33]. The ordering effects are thought to cause highly localised strain, which affects not only the Seebeck coefficient, but also the electrical resistance and tensile strength [34, 35]. The results here demonstrate that these crystallographic changes are certainly reversed when thermocouples are exposed to the \(1100\, ^{\circ }\hbox {C}\) QA. The possibility of reversing these changes at lower temperatures has not yet been fully explored. Historical references [11, 27] argue that at temperatures below \(250\, ^{\circ }\hbox {C}\), there is insufficient energy available for vacancy mobility; hence drift in this range has been attributed to ordering processes.

Perhaps the most interesting feature of Figs. 1, 2, 3, 4, 5, and 6 is that the drift occurs only when the thermocouples have been subjected to the \(1100\, ^{\circ }\hbox {C}\) QA (Figs. 1, 2, 3). The effect is absent in the same thermocouples following the \(450 \, ^{\circ }\hbox {C}\) VA (Figs. 4, 5, 6). This suppression of the drift has also been seen in other heavily-used Type S thermocouples employed in our laboratory, and there is some evidence for similar drift-halting behaviour from other studies [11, 36]. We speculate that the ordering cannot take place, or takes place extremely slowly (\({\gg }100 \hbox { h}\)), in the absence of vacancies.

4.1.4 Variations in Composition

When Figs. 1, 2, and 3 are compared to Figs. 4, 5, and 6, for the initial \(1100\, ^{\circ }\hbox {C}\) QA and \(450 \, ^{\circ }\hbox {C}\) VA scans, a difference in the Seebeck coefficient of approximately 0.1 % is evident. This difference was originally thought to be caused by the combined effect of vacancy annealing in both thermoelements, and partial ordering within the platinum–rhodium thermoelement [5, 11]. Subsidiary experiments (data not presented here) suggest that this difference is not caused by the platinum thermoelement, but further investigation is required to establish the attributes of each thermoelement and identify the drift mechanism in each. However, these results are consistent with the apparent measurement scatter reported for fixed-point measurements using similar thermocouples, and for different laboratories using thermocouples of the same nominal purity of platinum wire (see, for example [37]).

4.2 Drift, Hysteresis, and Anneal State

Drift caused by rhodium oxide, vacancy annealing, and ordering processes are shown to be completely reversible, in good agreement with the results of other studies [5, 11]. The slow reaction rates and strong temperature dependencies for these effects lead to Seebeck coefficients that are modified by the time and temperature of exposure, leading to drift and hysteresis in any sequence of temperature measurements. The right-hand plots of Figs. 7, 8, and 9, which are similar to measurements reported elsewhere [7], are strongly dependent on the initial thermoelectric state of the thermocouple. For measurement of temperatures below about \(800\, ^{\circ }\hbox {C}\), the \(450\, ^{\circ }\hbox {C}\) VA state is better than the \(1100\, ^{\circ }\hbox {C}\) QA state, and for measurement of temperatures above \(800~^{\circ }\hbox {C}\), the \(1100~^{\circ }\hbox {C}\) QA state is best. These conclusions are similar to those reported previously. Both Bentley [6] and Jahan and Ballico [7] have reported that for temperature measurements over \(1000\, ^{\circ }\hbox {C}\), the \(1100\, ^{\circ }\hbox {C}\) QA is the better choice and suffers the lowest drift.

Although the measurements only directly considered the \(1100\, ^{\circ }\hbox {C}\) QA and \(450\, ^{\circ }\hbox {C}\) VA anneal states, the results also demonstrate that the choice of temperatures for these states is critical. Ideally, any anneal state should be highly reproducible to ensure that the thermocouples can be returned to this state and be used in a manner that minimises the measurement uncertainty. In this respect, it is necessary to manage both the oxidation and ordering effects. The oxidation effect can be managed by dissociating the oxide at \(1100\, ^{\circ }\hbox {C}\), and then cooling rapidly through the \(500\, ^{\circ }\hbox {C}\) to \(900\, ^{\circ }\hbox {C}\) region where the oxide grows. The poor performance for platinum–rhodium thermocouples annealed at intermediate temperatures between \(600 \, ^{\circ }\hbox {C}\) and \(1100\, ^{\circ }\hbox {C}\) has been reported in another study [10]. If a slow cool from \(1100\, ^{\circ }\hbox {C}\) is used, as is sometimes reported [38], the wire will be in some intermediate oxidation state, determined by the cooling rate of the furnace, and the Seebeck coefficient may not be uniform along the length of the thermocouple. To date, only McLaren and Murdock [2] have investigated the effect of cooling rates on drift, but their work was for electrically annealed bare-wire thermoelements. The influence of an alumina sheath in determining the atmosphere surrounding the thermoelements within a furnace may make significant differences to the drift processes (see Sect. 4.1).

Exposure above \({\sim }600 \, ^{\circ }\hbox {C}\) probably also ensures recrystallization (dissolution of the ordered platinum–rhodium lattice state) and elimination of the ordering effects. The quench from \(1100\, ^{\circ }\hbox {C}\) does, however, leave a small and relatively uncontrolled concentration of vacancies in the wire. Note that all thermocouples used above \(950\, ^{\circ }\hbox {C}\) have parts of the thermocouples exhibiting both the oxidation effects and ordering effects, and because they have opposing signs, these effects partially compensate each other.

4.3 Recommendations, Maintenance

It is essential to anneal newly assembled noble-metal thermocouples at high temperatures \(({>}1100\, ^{\circ }\hbox {C})\) to remove localised wire strains and residual manufacturing cold-work [6]. If following an \(1100\, ^{\circ }\hbox {C}\) QA the thermocouple is shown to contain irreversible inhomogeneities, the thermocouple may need acid washes and further annealing treatments at higher temperatures, i.e., electrical annealing at \(1200\, ^{\circ }\hbox {C}\) to \(1400\, ^{\circ }\hbox {C}\) [6, 8, 11]. In particular, some researchers recommend a preliminary electrical anneal at \(1400\, ^{\circ }\hbox {C}\) for approximately 1 h to 2 h to remove high-energy defects in the platinum–rhodium thermoelement [2]. Previously unused wire from the reel will generally contain a uniform level of cold-work and may appear homogeneous when scanned, but will have a reduced Seebeck coefficient due to residual cold-work and strain introduced during the drawing of the wire. In used thermocouples, localised cold-work from point strains will result in an inhomogeneous thermocouple very sensitive to the location of temperature gradients.

Prior to use and calibration, and for best accuracy, the thermocouples should be restored to a stable and well-defined thermoelectric state. This study confirms that Type R and S thermocouples to be used between \(100\, ^{\circ }\hbox {C}\) and \(800\, ^{\circ }\hbox {C}\) should be in the \(450\, ^{\circ }\hbox {C}\) VA state. After every use above \(600 \, ^{\circ }\hbox {C}\), Type R and S thermocouples should be given an \(1100\, ^{\circ }\hbox {C}\) QA, to remove rhodium oxide, followed by a \(450\, ^{\circ }\hbox {C}\) VA to inhibit drift between \(200\, ^{\circ }\hbox {C}\) and \(500\, ^{\circ }\hbox {C}\). For thermocouples to be used above \(800\, ^{\circ }\hbox {C}\), the most stable thermoelectric state is achieved using the \(1100\, ^{\circ }\hbox {C}\) QA, and for maximum accuracy, a \(1100\, ^{\circ }\hbox {C}\) QA should be applied after every use above \(200\, ^{\circ }\hbox {C}\). For the best accuracy, these procedures apply for both use and calibration. This study shows that repeat anneals, although laborious, are necessary when the thermocouple is moved to a different temperature gradient with a different immersion depth, as might occur when switching between fixed-points or from a salt-bath to fixed-points. If the recommendations of this study are followed, then the claim of Jahan and Ballico [7, 36], that Type S and R measurements can be made within 30 mK to 60 mK, appears reasonable.

Because contamination is a major cause of inhomogeneity in noble-metal thermocouples, a high-resolution homogeneity scan should be undertaken on a regular basis to ensure the thermocouple remains fit-for-purpose [7, 15]. An initial scan before annealing indicates the magnitude of drift effects and, by comparison with the post anneal scan, allows differentiation of reversible and irreversible effects. To correctly quantify the magnitude of inhomogeneities, a single gradient scanner with moderately high-resolution is required [12].

5 Conclusion

This study has investigated the changes in Seebeck coefficient that occur in Type S thermocouples as a function of the initial annealing state for temperatures between \(170\, ^{\circ }\hbox {C}\) and \(900\, ^{\circ }\hbox {C}\). For the thermocouples annealed at \(1100\, ^{\circ }\hbox {C}\), it was found that changes in Seebeck coefficient occurred in thermoelements exposed over the full temperature range of \(170\, ^{\circ }\hbox {C}\) to \(900\, ^{\circ }\hbox {C}\), with peak changes of about 0.2 % at \(250\, ^{\circ }\hbox {C}\) to \(350\, ^{\circ }\hbox {C}\) after 100 h exposure. If these thermocouples were calibrated in this state, these drifts would lead to deviations from calibration of up to \(0.4\, ^{\circ }\hbox {C}\), with the peak errors occurring at measurements made between \(500 \, ^{\circ }\hbox {C}\) and \(600 \, ^{\circ }\hbox {C}\).

For the thermocouples initially annealed at \(1100\, ^{\circ }\hbox {C}\), followed by a second anneal at \(450 \, ^{\circ }\hbox {C}\), it was found that that there was very little drift in the Seebeck coefficient for temperatures below \(600 \, ^{\circ }\hbox {C}\), and drifts of up to 0.2 % occurred above \(500 \, ^{\circ }\hbox {C}\), peaking at about \(750\, ^{\circ }\hbox {C}\). If thermocouples are calibrated in this state, then they exhibit practically zero drift for temperatures below \(600 \, ^{\circ }\hbox {C}\), and a slowly increasing negative drift at higher temperatures. For all temperatures below about \(800\, ^{\circ }\hbox {C}\), the drifts and errors occurring in the thermocouple given the \(450 \, ^{\circ }\hbox {C}\) anneal are less than those for the \(1100\, ^{\circ }\hbox {C}\) anneal. This implies that thermocouples used routinely at temperatures below \(800\, ^{\circ }\hbox {C}\), calibrated after a \(450\, ^{\circ }\hbox {C}\) anneal, will have lower errors due to reduced drifts in the Seebeck coefficient. This work supports the conclusions of Bentley, Jahan and Ballico, and McLaren and Murdock, whose work also demonstrated lower drift after a \(450 \, ^{\circ }\hbox {C}\) anneal. For temperature measurement above \(800\, ^{\circ }\hbox {C}\), the thermocouples should be annealed at \(1100\, ^{\circ }\hbox {C}\) and quenched passively to room temperature.

To achieve the highest accuracy in measurements using standard thermocouples, it is recommended that annealing be undertaken after each calibration point in excess of \(600 \, ^{\circ }\hbox {C}\) when in the \(450\, ^{\circ }\hbox {C}\) anneal state and annealed after each measurement above \(200\, ^{\circ }\hbox {C}\) when in the \(1100\, ^{\circ }\hbox {C}\) anneal state. By following this process, the effects of Seebeck coefficient changes induced in the temperature gradients can be effectively eliminated. This conclusion is in accordance with McLaren and Murdock’s recommendations for standard thermocouples.

References

E.H. McLaren, E.G. Murdock, The Properties of Pt/PtRh Thermocouples for Thermometry in the Range 0–1100\(\, ^{\circ }{C}\), Part 3, 17409th edn. (National Research Council Canada, 1983)

E.H. McLaren, E.G. Murdock, The Properties of Pt/PtRh Thermocouples for Thermometry in the Range 0–1100\(\, ^{\circ }C\), Part 2, 17408th edn. (National Research Council Canada, 1979)

E.H. McLaren, E.G. Murdock, The Properties of Pt/PtRh Thermocouples for Thermometry in the Range 0–1100\(\, ^{\circ }\text{ C }\), Part 1, 17407th edn. (National Research Council Canada, 1979)

R.E. Bentley, Measurement 23, 35–46 (1998)

R.E. Bentley, T.P. Jones, High Temp. High Press. 12, 33–45 (1980)

R.E. Bentley, Theory and Practice of Thermoelectric Thermometry, 1st edn. (Springer, Berlin, 1998)

F. Jahan, M. Ballico, Int. J. Thermophys. 31, 1544–1553 (2010)

E.H. McLaren, E.G. Murdock, in Temperature, Its Measurement and Control in Science and Industry (Part 2), vol. 5, ed. by J.F. Schooley (Instrument Society of America, Pittsburgh, 1982), pp. 959–975

E.H. McLaren, E.G. Murdock, C.G. Kirby, Rev. Sci. Instrum. 43, 827–828 (1972)

F. Edler, P. Ederer, qq, in Temperature, Its Measurement and Control in Science and Industry. Part 1, ed. by C.W. Meyer (AIP, Melville, NY, 2013), pp. 532–537

E.H. McLaren, E.G. Murdock, in Temperature, Its Measurement and Control in Science and Industry. Part 3, vol. 4, ed. by H.H. Plumb, H.H. Plumb (Instrument Society of America, Pittsburgh, 1972), pp. 1543–1560

E.S. Webster, D.R. White, H. Edgar, Int. J. Thermophys. 36, 444–466 (2014)

R.E. Bentley, J. Phys. E 20, 1368–1373 (1987)

D.R. White, R.S. Mason, Int. J. Thermophys. 31, 1654–1662 (2010)

E.S. Webster, D.R. White, Metrologia 52, 130–144 (2015)

G.W. Burns, M.G. Scroger, G.F. Strouse, M.C. Croarkin, W.F. Guthrie, Temperature-Electromotive Force Reference Functions and Tables for the Letter-Designated Thermocouple Types Based on the ITS-90 (NIST, Washington, DC, 1993)

J.C. Chaston, Platin. Met. Rev. 19, 135–140 (1975)

T. Li, E.A. Marquis, P.A.J. Bagot, S.C. Tsang, G.D.W. Smith, Catal. Today 175, 552–557 (2011)

W.S. Ohm, K.D. Hill, Int. J. Thermophys. 31, 1402–1416 (2010)

C.A. Krier, R.I. Jaffee, J. Less Common Met. 5, 411–431 (1963)

J.C. Chaston, Platin. Met. Rev. 10, 91–93 (1966)

H. Jehn, J. Less Common Met. 100, 321–339 (1984)

R.J. Berry, Metrologia 16, 117–126 (1980)

R.E. Bentley, Meas. Sci. Technol. 11, 538–546 (2000)

R.E. Bentley, Meas. Sci. Technol. 12, 627–634 (2001)

A. Seeger, G. Schottky, D. Schumacher, Phys. Status Solidi 11, 363–370 (1965)

D. Schumacher, A. Seeger, O. Harlin, Phys. Status Solidi 25, 359–371 (1968)

T.G. Kollie, J.L. Horton, K.R. Carr, M.B. Herskovitz, C.A. Mossman, Rev. Sci. Instrum. 46, 1447–1461 (1975)

Z.W. Lu, S.H. Wei, A. Zunger, Phys. Rev. Lett. 66, 1753 (1991)

K. Yuge, A. Seko, A. Kuwabara, F. Oba, I. Tanaka, Phys. Rev. B 74, 174202 (2006)

A. Marucco, B. Nath, J. Mater. Sci. 23, 2107–2114 (1988)

E. Lang, V. Lupinc, A. Marucco, Mater. Sci. Eng. 114, 147–157 (1989)

A. Marucco, Mater. Sci. Eng. 189, 267–276 (1994)

R. Norhein, N.J. Grant, J. Inst. Met. 82, 440–444 (1953)

W.E. Clayton, C.R. Brooks, Metall. Mater. Trans. A 2, 531–535 (1971)

F. Jahan, M. Ballico, Int. J. Thermophys. 28, 1832–1842 (2007)

R.E. Bentley, Metrologia 35, 41–47 (1998)

J.P. Evans, S.D. Wood, Metrologia 7, 108–130 (1971)

Acknowledgments

The author wishes to acknowledge the work of Hamish Edgar (MSL) in the construction of the furnaces used in this study and the insightful discussions with Rod White (MSL).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Webster, E.S. Effect of Annealing on Drift in Type S Thermocouples Below \(900\, ^{\circ }\hbox {C}\) . Int J Thermophys 36, 1909–1924 (2015). https://doi.org/10.1007/s10765-015-1910-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-015-1910-7