Abstract

Unsaturated soils are the major component of both natural and artificial earth structures, and they exhibit less predictable behavior than saturated soils. Presently, the world is experiencing pronounced impacts from climate change. Sudden heavy rainfalls and droughts both result in fluctuating soil moisture levels, meaning that soil responds differently to infrastructure loads. Accordingly, a better understanding is needed of failure causes in unsaturated soils. This research was conducted to investigate the coupled behavior of unsaturated soil with varying degrees of compaction and moisture change. Samples were prepared at 81% and 88% degrees of compaction with moisture content ranging from 10 to 25% on both sides of optimum moisture content for silty soil. Different parameters such as suction, porewater pressure, and deformation were carefully measured at every stage of the triaxial test, from sample placing to the shearing phase. The results show that there is more compressive soil behavior when there is a lower degree of compaction, i.e., 81%, along with moisture content of 15–25%. Where there is a higher degree of compaction at 88%, dilative behavior is more evident, which changes to compressive behavior as the moisture content increases. Any change in moisture content (increase or decrease) during the lifecycle of any earthen structure necessitates a long time to stabilize its suction value (decrease or increase) if it compacted to a degree that still exhibits a compressive response. This slow recovery of suction, specifically from the wetting to the drying cycle, is not favorable for soil stability upon loading.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Unsaturated or partially saturated soils play an important role in geotechnical engineering construction projects. Since both air and water fill pores in unsaturated soils, a three-phase system is formed (air, water, and solid soil particles), making it difficult to explain soil behavior. A full understanding of unsaturated soil behavior is essential for successful stress analysis and design of embankments, slopes, foundations, and retaining structures. The shear strength of soil is a key parameter in assessment of the bearing capacity of foundations (Rahardjo et al. 2019; Dianchun et al. 2021; Ghasemzadeh and Akbari 2020), stability of retaining earth structures, and slope stability problems (Li and Yang 2019; Rong et al. 2019). The triaxial test is most commonly used to ascertain shear strength and evaluate the mechanical characteristics of the given soil (Xiao et al. 2018; Pande et al. 2020). Unsaturated soils have become a significant area of study in recent years. Many researchers have conducted systematic experimental studies in order to assess the impact of various factors on the shear strength of unsaturated soils by varying test conditions and methods. The focus has been on the effects of dry density (Cokca et al. 2004; Shen et al. 2009; Mirzaii et al. 2018; Kang et al. 2022; Ahmad et al. 2023a, b, c, d), compaction (Zhang et al. 2017), constant void ratio (Chali and Maleki 2020; Ahmad et al. 2023a, b, 2024), cyclic wetting and drying (Chen et al. 2018, 2020; Xu et al. 2021; Liu et al. 2023), temperature (Ng et al. 2016; Jing et al. 2021), freeze–thaw cycle (Hongde et al. 2022), and soil salinity (Motalleb et al. 2017; Hongde et al. 2021).

Soil response during the construction phase is significantly influenced by variables including moisture content at compaction, method and energy involved for compaction and achieved density. It is necessary to understand soil fabric as it is more important in unsaturated soil behavior than in that of saturated soil (Alonso et al. 2013). Soil fabric is a regulator of the soil's suction potential, which helps in the prediction of pore water pressure variations which happen during different phases of construction (Melinda et al. 2004; Chowdhury and Azam 2016). Differences in compaction procedures produce different soil fabrics, which are attributed to different mechanical behavior patterns (Sun et al. 2016). Comprehending the interaction of the liquid, air, and soil phases is crucial for understanding soil slope instability during rainfall infiltration (Dhanai et al. 2022; Ravichandran and Vickneswaran 2022; Yang and Huang 2023). Soil mass under consideration becomes unstable when significant plastic stresses are produced to maintain a particular stress condition under isotropic compression and shearing (Yerro et al. 2016; Ahmad and Uchimura 2023).

Previous studies suggested that soil behavior varies because of the effect of compaction moisture content on matric suction (Ma et al. 2023). Researchers investigated the effect of moisture content (Abbas et al. 2023) when the samples were prepared on the wet and then the dry side of the optimum moisture range. The collapse happens under steady loading due to a change in soil volume produced by decreasing suction. When the sample is compacted on the lower side of the optimum moisture content due to a decrease in the matric suction, it experiences collapsing deformation, whereas the opposite behavior occurs once it is on the upper side of the optimum value (Zhai et al. 2019). Several researchers have focused on the association between soil water characteristic curve and shear strength; findings were that the stress conditions do affect the soil water characteristic curve (SWCC) measurements in low matric suction ranges. Isotropic confined soil has a denser void structure, ultimately hindering the soil moisture flow in the soil matrix (Zhou et al 2012; Yoshikawa and Noda 2020; Han and Vanapalli 2016; Rui et al. 2018; Habasimbi and Nishimura 2018, 2019; Yoshikawa and Noda 2020).

Studies have been undertaken on the effect of moisture change on famous red clay specimens in regard to its cohesiveness and angle of internal friction with uniform and uneven moisture distribution under fluctuated water loss degrees (Ahmed et al. 2021; Xie et al. 2022), and results suggested moisture impacts the internal friction angle. A landslide hyperbolic stress model was developed on the basis of large-scale direct shear experiments investigating the effect of moisture content on the landslide zone soil of the Lock's Head landslide. It was determined that the stress-deformation mechanism of the landslide zone soil along the landslide direction changed during different periods of drastic fluctuation in the landslide's moisture content (Chae et al. 2010; Riaz et al. 2021).

Matric suction (ua − uw) has a considerable impact on the mechanical characteristics of unsaturated soils (Garakani et al. 2015). Previous studies tested the soil water characteristics curve (SWCC) of silty soil under unidimensional stress and isotropic confining stress conditions (Ahmad et al. 2023a, b, c, d). The findings were that altering stress conditions influences the soil water characteristic curve, and unsaturated soil behavior is impacted by suction due to variations in compaction moisture content.

Considering the aforementioned, the current study was formulated with the objective of examining the coupling effect of the degree of compaction and variable moisture content on the strength and volume change characteristics of unsaturated soil using triaxial testing. Soil vulnerability was analyzed under conditions of constant deviatoric stress, volumetric strain, pore water pressure, and different degrees of saturation. While past studies focused mostly on the shear phase alone, the primary focus of the current study is evaluation of the behavior of especially unsaturated soils throughout different test phases including sample placing, consolidation and shear. Finally, the different stress variables were plotted to illustrate this linked behavior of unsaturated soil throughout its evolution during testing.

2 Materials and Methodology

2.1 Materials

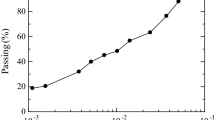

This research study used fine soil without plasticity, commercially named “DL Clay” in Japan. Kaolinite and silica, which are utilized as agricultural compounds, are components of powdered DL clay. The particle size distribution of DL clay is reasonably uniform, with a maximum particle size dmax of about 0.039 mm. According to Unified Soil Classification System (USCS) (ASTM D2487-11 2011), it has medium–low compressibility with 90% Silt and 10% Clay content. Table 1 and Fig. 1a, b show the physical properties, compaction curve, and particle size distribution of the studied soil. The optimum moisture content for DL clay is 21%, having a maximum dry unit weight value of 14.81 kN/m3. The suction value of DL clay stabilizes in a shorter time, allowing the test to be concluded within time constraints.

2.2 Experimental Setup

Strain-controlled triaxial apparatus, which is suitable for unsaturated soils, was used in this study. The apparatus consists of a double cell with a range of transducers to measure pore air pressure (ua), pore water pressure (uw), and cell pressure. The volume change behavior was measured using a low-capacity Differential Pressure Transducer (LCDPT) having a measuring range of 0.1 kPa. To monitor axial deformation, an LVDT (Linear Variable Differential Transducer) with maximum measuring span of 50 mm was employed. Pore-air and pore-water connections were kept independent at the bottom and top caps to allow for simultaneous measurement. Pore water pressure sensors installed at the bottom pedestal with maximum measuring capacity of 1 MPa were able to record the uw value. An amplifier was used to reduce noise and increase signal voltage from the data obtained from all the sensors attached. For getting physical values, Digit Basic software was employed to convert analog signals into digital ones through an A/D board. PTFE membrane (poly-tetra-flouro-ethylene), often known as Teflon film, having an air entry value of 250 kPa, pore size of 0.45 µm and membrane thickness of 140 µm, was used to separate the paths of uw and ua monitoring. Figure 2 depicts a schematic description of the triaxial system employed in this study. For controlling drained or undrained ua, a dedicated transducer with maximum capacity of 200 kPa and a solenoid valve were installed in the top cap.

2.3 Sample Preparation and Methodology

In this research, the samples with a dry unit weight of 12.35 kN/m3 were prepared with an initial water content of 15%, 20%, and 25%, and the samples with a dry unit weight of 13.43 kN/m3 were prepared with an initial water content of 10%, 15%, and 25%. The static compaction technique was adapted as it was noticed that the material behaved poorly during the use of the standard compaction method. To check the uniform densification, the soil sample was prepared in both ways: by compacting the whole soil statically at once, and by compacting it in layers of 2 cm thickness (Fig. 3a). After cutting both specimens into 2 cm slices, the unit weight and moisture content of each layer were calculated, and this revealed that the specimen compacted in layers was more homogeneous throughout its height than the other specimen. Based on the above findings, homogeneous specimens were created in 2 cm thickness in five layers, using a compaction steel mold and a static compaction machine, as illustrated in Fig. 3b. The procedure was incorporated to avoid the variation in sample properties. For this research, two sets of tests were conducted. In order to test for a correlation between the soil behavior and moisture level and degree of compaction, samples of DL clay were prepared, each with a height of 10 cm and a diameter of 5cm, while moisture content was varied between both sides of the optimum value. Table 2 displays sample properties.

After sample preparation, the sample was shifted to the triaxial machine to measure the initial suction value through the bottom pedestal. Consolidated undrained (CU) tests were conducted, during which moisture was not allowed to drain out during the shearing phase to maintain a constant moisture content during the last stage of the test.

3 Results

3.1 Effect of Moisture Content on the Initial Suction of Unsaturated Soil

In this study, CU tests at a strain rate of 0.05%/min and up to 15% strain development were carried out in accordance with Japanese Geotechnical Society Standards (JGS 0527–2020). Tests were performed in four stages under constant moisture conditions to represent a state where additional ua swiftly dispels while uw gradually dissipates at a confining pressure of approximately 100kPa. Higher confinement was employed as the top cap completely touches the sample with no gaps, which allows clear analysis of the true behavior of the sample. In phase I, suction measurement started as soon as the sample was placed on the pedestal. Figure 4 shows that with varying moisture content, the suction value increased and subsequently stabilized. This corresponds to the intuitive presumption that suction stabilized more quickly where there is higher moisture content and less quickly where there is lower moisture content (Głuchowski et al. 2019).

3.2 Effect of Degree of Compaction and Moisture Content on Stress–Strain and Volumetric Strain Response of Unsaturated Soil

Figure 5 shows a schematic diagram of all test phases, from PI to PIV. To avoid the air trapped inside the pedestal and maintain positive pore water pressure, the axis translation technique was used in Phase II. During the application of the axis translation technique, it is important to maintain a balance between the increments of both air and cell pressure on one hand, and pore water pressure on the other. Any imbalance may cause internal stress modification in the sample.

After the initial suction measurement, and as soon as the volume change was quantified through LCDPT, stabilized isotropic consolidation was initiated in Phase III. In the consolidation process, the moisture in the pores is allowed to drain after the confining pressure is applied.

Figure 6 depicts the cumulative response of mean effective stress (p'), deviatoric stress (q), and suction with respect to time throughout the test (PI ~ IV) for series # 1, with a dry unit weight of 12.35 kN/m3 at 15% moisture content indicating that the suction value reaches 25 kPa with q reaching 272 kPa and p' 202 kPa.

3.2.1 Phase I and II

During the quantification of the initial suction and axis-translation method, no axial or radial stresses were imposed. While p' occurred due to the variation in suction and saturation values of the sample, as shown by Eqs. (1–3), there is no net stress, while stresses are due to suction and saturation.

Mean effective stress,

Effective axial stress,

Effective radial stress,

3.2.2 Phase III

During the isotropic consolidation stage, to get the net zero q value, confining and axial stresses were applied in balanced quantity, and because of this arrangement, mean effective stresses grow. Finally, during the shearing phase, confining pressure remains constant while axial stresses increase, resulting in an increase in deviatoric stress and mean effective stresses.

3.2.3 Phase IV

The strength and deformation characteristics of the soil used are addressed during compressive (Series # 1) and dilative (Series # 2) behavior tests. The shearing phase is the key phase that provides information on the mechanical characteristics of the material. It was discovered that deviatoric stress exceeded on the dry side of optimum moisture content (OMC) and reduced on the wet side of OMC (Fig. 7). Furthermore, due to a lower degree of compaction, the q is lower in Series # 1 compared to Series # 2.

The volumetric response of the material is presented in Fig. 8. Results showed that the soil sample compacted at 81% degree of compaction demonstrated a compressive nature while the sample was undergoing shear. In comparison, samples compacted at 88% degree of compaction showed a dilative nature at lower moisture content, whereas this behavior changes with higher moisture content. The experimental results also revealed that as moisture content increased, the sample compressed and the void ratio reduced, although the degree of saturation grew as the void ratio decreased. The degree of saturation reduced marginally due to dilative action on the dilation side. Various critical parameters such as suction, volumetric strain, void ratio, and deviatoric stress were measured during the experiment to determine their response against time and the axial strain developed in the sample.

3.3 Comparison of Compressive and Dilative Response of Unsaturated Soil Under Similar Moisture Content Throughout the Testing Phases

Figures 9, 10, 11, and 12 present variations in suction, void ratio, volumetric strain, and deviatoric stress against time through different test phases for both test series (m.c. 15%). From the test results, it is evident that when the sample enters the testing environment, the values of suction tend to stabilize after the initial phases from sample placing, axis translation, and consolidation for both the cases with higher and lower degrees of compaction (88% and 81%). The initial suction is higher for the sample with a higher degree of compaction, i.e., 88%; moreover, the suction stabilization stage was reached much faster than the sample with a lower degree of compaction 81% (Fig. 9). As both samples have the same moisture content, the reason for the higher initial suction value may be the smaller size of the pore skeleton within the sample. Both samples, i.e., 88% and 81% degrees of compaction, showed similar behavior related to volumetric strain and void ratio during Phases I to III. However, during the shear phase (PIV), the volumetric strain decreased, whereas the void ratio increased for the sample with a higher degree of compaction (88%). This trend reversed for the lower degree of compaction (81%) sample (Figs. 10, 11). The suction values did not change considerably and reached the initial stabilized value for both samples during the shearing phase, irrespective of one sample being dilated and the other compressed. Figure 12 shows the deviatoric stress for both samples throughout the phases, with the highest value for the sample having a degree of compaction of 88%. These results clearly demonstrate that the internal soil structural characteristics that change as a result of the degree of compaction are influenced by the coupled effect of compaction and moisture variation during the lifecycle of the earthen structure. Moreover, the results also demonstrate that any change in the moisture content (increase or decrease) of the silty soil (DL Clay) during the lifecycle of any earthen structure necessitates a long time to stabilize its suction value (decrease or increase) if it is compacted at a degree of compaction that still exhibits a compressive response. This slow recovery of suction, specifically from the wetting to the drying cycle, is not favorable for soil stability upon loading.

4 Conclusions

Based on consolidated undrained test results on DL Clay (silty soil), the major conclusions of the study are:

-

1.

The sample compacted at a higher degree of compaction (88%) exhibits dilation if the moisture content is 10% during the shearing phase. This dilation reduces, however, as the moisture content increases and becomes compressive close to OMC, i.e., 20%. By contrast, the sample at a lower degree of compaction (81%) exhibits a compressive response at all moisture levels, with compressibility increasing with an increase in moisture content.

-

2.

The initial suction is higher for the sample with a higher degree of compaction, i.e., 88%. Moreover, the suction stabilization stage was reached much faster than was the case with the sample with a degree of compaction of 81%. As both samples have the same moisture content, the reason for the higher initial suction value may be the smaller size of the pore skeleton within the sample.

-

3.

The suction values did not change considerably and reached the initial stabilized value for samples compacted at 88% and 81% during the shearing phase, irrespective of one sample being dilated and the other compressed. This study also highlights that any change in the moisture content (increase or decrease) of the silty soil (DL Clay) during the lifecycle of any earthen structure necessitates a long time to stabilizes its suction value (decrease or increase) if it compacted at a degree of compaction that still exhibits a compressive response. This slow recovery of suction, specifically from the wetting to the drying cycle, is not favorable for soil stability upon loading.

Data Availability

Data will be available if the request is made to the authors.

Abbreviations

- ε a :

-

Axial strain (%)

- u a :

-

Pore air pressure (kPa)

- u w :

-

Pore water pressure (kPa)

- σ 3 :

-

Confining pressure (kPa)

- σ d :

-

Deviatoric stress (kPa)

- ε v :

-

Volumetric strain (%)

- m.c. :

-

Moisture content (%)

- e :

-

Void ratio

- \({\gamma }_{d}\) :

-

Dry unit weight (kN/m3)

References

Abbas MF, Shaker AA, Al-Shamrani MA (2023) Hydraulic and volume change behaviors of compacted highly expansive soil under cyclic wetting and drying. J Rock Mech Geotech Eng 15(2):486–499. https://doi.org/10.1016/j.jrmge.2022.05.015

Ahmad T, Kato R, Kuwano J (2023a) Experimental study on state boundary surface of compacted silty soil. Int J GEOMATE 24(102):26–33. https://doi.org/10.21660/2023.102.g12148

Ahmad T, Kato R, Kuwano J (2023b) Constant volume shear tests on compacted silty soil. Int J GEOMATE 24(103):104–111. https://doi.org/10.21660/2023.103.s8536

Ahmad W, Uchimura T, Umar M (2023c) Comparison of the shear strength of unsaturated sandy soils at optimal and residual moisture contents. Int J GEOMATE 24(101):43–51. https://doi.org/10.21660/2023.101.3645

Ahmad T, Kato R, Shrestha DR, Kuwano J (2023d) Constant void ratio vs. constant confining pressure tests on partially saturated silty soil. E3S Web Conf 382:04006. https://doi.org/10.1051/e3sconf/202338204006

Ahmad T, Kato R, Kuwano J (2024) Experimental investigation on shear behavior of partially saturated silty soil under constant water content and constant void ratio conditions. ASTM Geotech Test J. https://doi.org/10.1520/GTJ20230322

Ahmad W, Uchimura T (2023) The effect of moisture content at compaction and grain size distribution on the shear strength of unsaturated soils. Sustainability 15:5123. https://doi.org/10.3390/su15065123

Ahmed I, Kuwano J, Malik AA, Shrestha DR (2021) Behavior of unsaturated silty soil due to change in water content and suction. In: Hazarika H et al (eds) Advances in sustainable construction and resource management. Lecture notes in civil engineering, vol 144. Springer, Singapore. https://doi.org/10.1007/978-981-16-0077-7_35

Alonso EE, Pinyol NM, Gens A (2013) Compacted soil behavior: initial state, structure, and constitutive modelling. Géotechnique 63(6):463–478. https://doi.org/10.1680/geot.11.P.134

ASTM D2487-11 (2011) Standard practice for classification of soils for engineering purposes (unified soil classification system—USCS)

Chae J, Kim B, Park SW, Kato S (2010) Effect of suction on unconfined compressive strength in partly saturated soils. KSCE J Civ Eng 14:281–290. https://doi.org/10.1007/s12205-010-0281-7

Chali E, Maleki M (2020) Experimental study on mechanical behavior of unsaturated silty sand in constant equivalent granular void ratio. Geotech Geol Eng 39:735–750. https://doi.org/10.1007/s10706-020-01518-9

Chen T, Zhou C, Wang G, Liu E, Dai F (2018) Centrifuge model test on unsaturated expansive soil slopes with cyclic wetting–drying and inundation at the slope toe. Int J Civ Eng 16:1341–1360. https://doi.org/10.1007/s40999-017-0228-1

Chen H, Guo H, Yuan X, Chen Y, Sun C (2020) Effect of temperature on the strength characteristics of unsaturated silty clay in seasonal frozen region. KSCE J Civ Eng 24:2610–2620. https://doi.org/10.1007/s12205-020-1974-1

Chowdhury RH, Azam S (2016) Unsaturated shear strength properties of a compacted expansive soil from Regina, Canada. Innov Infrastruct Solut. https://doi.org/10.1007/s41062-016-0047-2

Cokca E, Erol O, Armangil F (2004) Effects of compaction moisture content on the shear strength of an unsaturated clay. Geotech Geol Eng 22:285–297. https://doi.org/10.1023/B:GEGE.0000018349.40866.3e

Dhanai P, Singh VP, Soni P (2022) Rainfall triggered slope instability analysis with changing climate. Indian Geotech J 52:477–492. https://doi.org/10.1007/s40098-021-00581-0

Dianchun D, Zhuang Y, Qiangqiang S, Xiaoli Y, Dias D (2021) Bearing capacity evaluation for shallow foundations on unsaturated soils using discretization technique. Comput Geotech. https://doi.org/10.1016/j.compgeo.2021.104309

Garakani AA, Haeri SM, Khosravi A, Habibagahi G (2015) Hydro-mechanical behavior of undisturbed collapsible loessial soils under different stress state conditions. Eng Geol 195:28–41. https://doi.org/10.1016/j.enggeo.2015.05.026

Ghasemzadeh H, Akbari F (2020) Investigation of soil active wedge angle with linear matric suction distribution below the footing. Int J Civ Eng 18:161–168. https://doi.org/10.1007/s40999-019-00426-1

Głuchowski A, Soból E, Szymański A, Sas W (2019) Undrained pore pressure development on cohesive soil in triaxial cyclic loading. Appl Sci. https://doi.org/10.3390/app9183821

Habasimbi P, Nishimura T (2018) Comparison of soil–water characteristic curves in one-dimensional and isotropic stress conditions. Soil Syst 2(43):1–15. https://doi.org/10.3390/soilsystems2030043

Habasimbi P, Nishimura T (2019) Soil water characteristic curve of an unsaturated soil under low matric suction ranges and different stress conditions. Int J Geosci 10:39–56. https://doi.org/10.4236/ijg.2019.101004

Han Z, Vanapalli SK (2016) Stiffness and shear strength of unsaturated soils in relation to soil-water characteristic curve. Géotechnique 66(8):627–647. https://doi.org/10.1680/jgeot.15.P.104

Hongde W, Dongli S, Xiaoqin S, Donghao M (2022) Investigation of the mechanical behavior of salinized agricultural soils using unsaturated triaxial tests and a constitutive framework. Eng Geol 299:106567. https://doi.org/10.1016/j.enggeo.2022.106567

Hongde W, Dongli S, Xiaoqin S, Shengqiang T, Yipeng Z (2021) Analysis of unsaturated shear strength and slope stability considering soil desalinization in a reclamation area in China. CATENA. https://doi.org/10.1016/j.catena.2020.104949

Japanese Geotechnical Society JGS 0527-2020 (2020) Method for triaxial compression test on unsaturated soils

Jing X, Cui Z, Doh S, Ma L, Wei L, Liu D (2021) Effect of freeze-thaw cycles on shear strength of unsaturated bentonite modified clay. Phys Chem Earth Parts a/b/c 121:102955. https://doi.org/10.1016/j.pce.2020.102955

Kang Q, Xia Y, Li X, Zhang W, Feng C (2022) Study on the effect of moisture content and dry density on shear strength of silty clay based on direct shear test. Adv Civ Eng. https://doi.org/10.1155/2022/2213363

Li ZW, Yang XL (2019) Active earth pressure from unsaturated soils with different water levels. Int J Geomech 19:7. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001471

Liu D, Sun W, Kong Y, Zhang S (2023) Effect of dry and wet cycles on the strength characteristics of biochar–clay mixture. Processes 11:970. https://doi.org/10.3390/pr11030970

Ma X, Yu Q, Xuan M, Ren H, Ye X, Liu B (2023) Study on the influence mechanism of sample preparation method on the shear strength of silty soil. Sustainability 15:2635. https://doi.org/10.3390/su15032635

Melinda F, Rahardjo H, Han KK, Leong E (2004) Shear strength of compacted soil under infiltration conditions. J Geotech Geo-Environ Eng 130(8):807–817

Mirzaii A, Yasrobi SS, Hefzi E (2018) Critical state behavior of an unsaturated clayey sand along constant moisture content direct shear and triaxial loading conditions. Int J Geotech Eng 14(3):286–294. https://doi.org/10.1080/19386362.2018.1438151

Motalleb M, Nejad SM, Kalehiwot NM (2017) Investigating the role of soil fabric in unsaturated soils. Geotechnical Frontiers, 595–605 Orlando, Geo-Institute of ASCE Florida, March 12–15. https://doi.org/10.1061/9780784480472

Ng CWW, Mu QY, Zhou C (2016) Effects of soil structure on the shear behavior of an unsaturated loess at different suctions and temperatures. Can Geotech J 54(2):270–279. https://doi.org/10.1139/cgj-2016-0272

Pande PB, Khandeshwar SR, Bajad SP (2020) Review of experimental techniques for evaluating unsaturated shear strength of soil. In: Advances in civil engineering and infrastructural development. Lecture notes in civil engineering, vol 87, pp 579–590. https://doi.org/10.1007/978-981-15-6463-5_57

Rahardjo H, Kim Y, Satyanaga A (2019) Role of unsaturated soil mechanics in geotechnical engineering. Geo-Engineering 10:8. https://doi.org/10.1186/s40703-019-0104-8

Ravichandran N, Vickneswaran T (2022) Coupled large deformation finite element formulations for the dynamics of unsaturated soil and their application. Geosciences 12:320. https://doi.org/10.3390/geosciences12090320

Riaz S, Kikumoto M, Basharat M, Putra AD (2021) Wetting indued deformation of soils triggering landslides in Pakistan. Geotech Geol Eng 39:5633–5649. https://doi.org/10.1007/s10706-021-01851-7

Rong Y, Peiwei X, Shunchao Q (2019) Analysis of slope stability in unsaturated expansive soil: a case study. Frontiers Earth Sci. https://doi.org/10.3389/feart.2019.00292

Rui M, Guo J, Huang Z, Pu S, Chen J, Liu Y (2018) Study on the influence of uneven moisture content on the shear strength of red clay. People’s Pearl River 39(6):63–66 ((in Chinese))

Shen C, Wang F, Wang H (2009) Effect of suction, moisture content and dry density on shear strength of remolded soil. Rock Soil Mech 30(5):1347–1351

Sun D, Li X, Feng P, Zang Y (2016) Stability analysis of unsaturated soil slope during rainfall infiltration using coupled liquid-gas-solid three-phase model. Water Sci Eng 9(3):183–194. https://doi.org/10.1016/j.wse.2016.06.008

Xiao J, Yang H, Zhang J, Tang X (2018) Properties of drained shear strength of expansive soil considering low stresses and its influencing factors. Int J Civ Eng 16(10):1389–1398. https://doi.org/10.1007/s40999-017-0268-6

Xie X, Qi L, Li X (2022) Deformation, strength, and water variation characteristics of unsaturated compacted loess. Case Stud Constr Mater 16:e01129. https://doi.org/10.1016/j.cscm.2022.e01129

Xu X, Shao L, Huang J, Xu X, Liu D, Xian Z, Jian W (2021) Effect of wet-dry cycles on shear strength of residual soil. Soils Found 61(3):782–797. https://doi.org/10.1016/j.sandf.2021.03.001

Yang SR, Huang LJ (2023) Infiltration and failure behavior of an unsaturated soil slope under artificial rainfall model experiments. Water 15:1599. https://doi.org/10.3390/w15081599

Yerro A, Alonso E, Pinyol N (2016) Modelling large deformation problems in unsaturated soils. E3S Web Conf 9:08019. https://doi.org/10.1051/e3sconf/20160908019

Yoshikawa T, Noda T (2020) Triaxial test on water absorption compression of unsaturated soil and its soil-water-air-coupled elastoplastic finite deformation analysis. Soils Found 60(5):1151–1170. https://doi.org/10.1016/j.sandf.2020.06.010

Zhai Q, Rahardjo H, Satyanaga A, Dai G (2019) Estimation of unsaturated shear strength from soil–water characteristic curve. Acta Geotech 14:1977–1990. https://doi.org/10.1007/s11440-019-00785-y

Zhang H, Hanbing L, Jing W, Weizhi D (2017) Investigation of the effect of water and degree of compaction on the shear strength of clay soil material. Funct Mater 24(2):290–297. https://doi.org/10.15407/fm24.02.290

Zhou A, Sheng D, Sloan SW, Gens A (2012) Interpretation of unsaturated soil behavior in the stress—saturation space, I: volume change and water retention behavior. Comput Geotech 43:178–187. https://doi.org/10.1016/j.compgeo.2012.04.010

Acknowledgements

The authors duly acknowledge the Geotechnical Engineering Laboratory at Saitama University for providing its research facilities for conducting this research.

Funding

The authors declare that they have no funding issues involved.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests or conflicts of interest that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ahmed, I., Shah, S.K.H., Ahmad, T. et al. Coupled Influence of Compaction and Moisture on Unsaturated Soil Response in Triaxial Tests. Geotech Geol Eng 42, 4693–4705 (2024). https://doi.org/10.1007/s10706-024-02807-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-024-02807-3