Abstract

Shear modulus and damping are of the most important dynamic characteristics of soil in seismic geotechnical engineering. Improving the dynamic properties of soils by adding cement content, and then replacing a part of cement, which its production is one of the most important sources of carbon dioxide emissions in the world, with natural materials such as nanoclay is of particular importance. In the present study, the cyclic behavior of silty sand was compared with the cyclic behavior of cemented sand containing cement and nanoclay additives. The soil used in this research was Firuzkooh mountain sand and silt, classified as ML type based on the unified classification system. All the samples were made by wet complaction method and cyclic triaxial tests were performed with three different confining pressures of 50, 100 and 150 kPa in the medium shear strain range. The results showed that the values of the shear modulus of cemented sand samples with a water to cement ratio of 1 are greater than the values of the shear modulus of the silty sand samples in all ranges of shear strains. The values of shear modulus increased by substituting nanoclay instead of cement in the cemented samples, and vice versa, the damping of the samples decreased with the addition of cement. By substituting part of the cement with nanoclay, the damping decreased with a lower rate. On the other hand, with the increase of confining pressure, the shear modulus values of all the considered soils increased and their damping decreased.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Soil dynamic parameters, including shear modulus and damping ratio, are widely used in the analysis and design of geotechnical structures. These parameters are very important in linear and nonlinear analysis of geotechnical structures subjected to dynamic loads such as earthquake and wind. One of the phenomena in granular soils that causes significant changes in soil properties, such as shear strength parameters and deformation modules, is the soil cementation. Natural cementation of granular soils is a phenomenon occurring over time due to the compaction and deposition of natural chemicals among soil particles. As with many other countries, Iran has experienced many earthquakes due to its high seismicity. In order for human beings to be able to coexist with this phenomenon, engineering knowledge and basic study in the field of earthquake engineering as well as soil dynamics should be developed, so understanding the dynamic parameter is of special importance.

In a large part of the coastal areas of north and south of Iran, which are located in a zone with relatively high earthquake risk, according to Iranian code No. 2800 regulations, the dominant soil materials are silty sand and low-density silt, where there is a high probability of resistance reduction of these saturated soils during earthquakes and undrained cyclic loading condition. Since it is not always possible to implement the dynamic compaction method for soil improvement in urban areas, one of the substitute methods of soil improvement in these areas is adding cement to the poorly saturated silty granular soils, which includes deep mixing and pre-mixing methods.

In recent years, many studies have been performed on the sand stabilization methods using cement injection (Fernandez and Santamarina 2011; Mollamahmutoglu and Yilmaz 2011; Pantazopoulos and Atmatzidis 2012; Markou and Droudakis 2013; Yildiz and Soganci 2015), sand stabilization with crumb rubber grains (Nakhaei 2012), and sand stabilization with nanomaterials (Choobbasti 2015) in order to enhance the soil properties. Abbasi et al. (2018) showed that it was found that the addition of nanoclay to dispersive clayey soils could decrease their dispersivity potential considerably. Changizi and Haddad (2016) showed that Add nano-SiO2 resulted in increase in the angle of internal friction, the cohesion, the unconfined compression strength and maximum dry unit weight of the clayey soils.

Pantazopoulos and Atmatzidis (2012) investigated the dynamic properties of injected sands by ordinary cements and very fine particles through the Resonant column and flexural element experiments. They evaluated the effect of confining pressure, shear strain, water to cement ratio and type and grade of the cement on the soil dynamic properties. In their research, three types of Portland cement, Portland composite, and Pozzolanic cement were used. They also presented the dynamic properties within the small strain range of 0.0001–0.01%. Their results showed that the shear and Young's modulus increased with augmenting the confining pressure and decreasing shear strain, while the damping ratio varied differently. Smitha and Rangaswamy (2020) investigated the dynamic properties of silty sand improved with agar biopolymer using a cycle triaxial strain test. They reported that in the specimen improved with 2% biopolymer during 7 days of curing time, up to 317% increase in shear modulus was observed compared to the unmodified specimen. Using a simple cyclic shear test, Madhusudhan et al. (2020) found that 10% of tire crumbs improved the dynamic sand properties well. Also, Jijo and Pandian (2018) studied the effect of lime admixture on soil stabilization and indicated that the ultimate strength of the soil was more enhanced in compare to the early age strength.

Mola Abasi et al. (2021) investigated the Use of a GMDH-type neural network to model the mechanical behavior of cement-treated sand. And they concluded that the two-hidden layer model can accurately predict the q–ε and u–ε behavior for the testing data, compared to other machine learning methods. By and large, GMDH modeling is suggested as a potent method to estimate the soil mechanical properties like brittle index (IB), maximum strength (qmax), failure strain (εf) and stiffness (E50). Mola Abasi et al. (2022) conducted an experimental and environmental study on the stabilization of low-plasticity clay with cement and zeolite. Unconfined (UCS) compressive strength results indicated that up to 15% cement content replacement with zeolite, strength increased. Ahmadi et al. (2020) stated that in clay, unconfined compression tests show that nano-MgO can significantly increase the stiffness of the soil and the undrained cohesion of the clay. Adding 0.2% nano-MgO raises the undrained cohesion by approximately 45%. Fattahi Masrour et al. (2021) showed that adding the optimum amount of 1% nanosilica to the dispersive clay altered the soil characteristic into non-dispersive. The liquid limit (LL), plastic limit (PL), and optimum moisture content (OMC) of the treated soil specimens increased.

Lang et al. (2020) used the Resonant column experiments to investigate the dynamic shear modulus of small strain (G) and the damping ratio (D) for silty clay specimens reinforced by cement and cement-fly ash compositions. The results indicated that the performance of 5% cement along with 30% fly ash as a stabilizer was more effective in improving G and D than using 15% cement alone. Subramaniam and Banerjee (2020) inspected the shear modulus and damping ratio of the cement improved sea-clay using Resonant column and cyclic triaxial experiments. The results showed that at confining pressure of 100 kP, the shear modulus for improved specimens with 5, 7.5, and 10% cement increased by 88, 131, and 282%, respectively. In addition, the increase in shear modulus was more prominent at small strains and longer curing time.

With the increasing growth of economic and industrial development in the world, especially in the developing countries, there will be a need to optimize the materials and components of additives in the soil stabilization methods. On the other hand, considering this growth and the progressive demands, the crisis of limited energy and natural resources is too obvious nowadays and the importance of the environmental protection cannot be ignored. Extensive energy has been consumed to produce cement products and this yet produces 7% of the CO2 contents in the world (Gjorv and Sakai 2000). In addition, cement-stabilized soils have shown brittle behavior (Lothenbach et al. 2011; Scrivener and Nonat 2011; Ramezanianpour et al. 2012; Mola-Abasi et al. 2016a Mola-Abasi et al. 2016b). Thus, there will be a need to optimize the materials and components of additives in soil stabilization approaches.

The use of nanomaterials as a substitute for cement can be a significant option to reduce cement consumption. Today, nanotechnology is widely used in various branches of science and industry. Soil nanoparticles, typically between 1 and 100 nanometers in size, are the smallest particles in soil environments. Due to their significantly small size, they have a very high specific surface area, so they effectively react with the other soil particles. Given their high specific surface area and surface loads, even in the case of small amounts of these particles in the soil environment, they can affect the physiochemical behavior and engineering properties of the soil in a very special and significant way.

The useful effects of this technology in various environmental, energy, and national security areas have led to the increasing production of nanomaterials and large amounts of investment. For this, research in this regard can help the purposeful production of nanomaterial products. Nanotechnology is an advanced technology in recent years, which goes back to half a century ago across the world. In this connection, one of the problems caused by using soil additives is environmental pollution, while nano clays, while being compatible with the environment, could leave highly desirable impacts on environmentally destructive processes and absorbing environmental pollutants. (Majeed and Taha 2012; Majeed and Taha 2013; Majeed and Taha and Jawad 2014; Ouhadi and Amiri. 2011)

As mentioned above, dynamic parameters including shear modulus and damping ratio are widely used in the analysis and design of geotechnical structures. Variations of these parameters with shear strain are one of the most considerable properties required for the response of soil layers under dynamic loads. Proper evaluation of these parameters is of great importance both for the basic understanding of soil behavior as well as for its application in practical seismic geotechnical problems. By performing various laboratory experiments on different types of soils, the dynamic parameters can be calculated; one of these experiments used to calculate the shear modulus and damping ratio is the cyclic triaxial test. As noted, many studies have been conducted on the dynamic properties of different common and improved soils. One of the most important additives in of the soil improvement process is the cement whose optimum consumption seems necessary due to environmental and economic considerations. On the other hand, although studies on sands have been very extensive so far, fine-grained soils have received less attention. Accordingly, in this study, we intend to investigate the specifications of the dynamic properties of sand with 60% non-plastic silt, improved by cement and different percentages of Montmorillonite nanoclay (nanoclay will replace some parts of the cement contents) using a cyclic triaxial strain control test subjected to confining pressure and different strain ranges.

High non-plastic fine-grained sandy soils are greatly prone to liquefaction and fall under problematic soils in coastal areas. For this, it is required to eliminate the soil liquefaction to improve its dynamic parameters. One of the ways to improve problematic soils is to use additives; to understand the effects of this method, it is necessary to properly evaluate soil dynamic parameters with and without additives, investigate various additives, and also optimize these additives.

The novelty of this study comes from its type of soil (40% sand and 60% non-plastic silt), and the effects of using cement and replacing part of the cement with nano clay on the intended soil dynamic parameters.

2 Materials and Methods

2.1 Characteristics of the Considered Soil

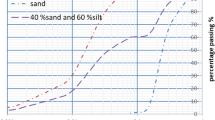

In this research, Firuzkuh #161 casting sand (Marzuni et al. 2022) and non-plastic silt have been used, whose specifications are presented in Tables 1, 2, 3 and Fig. 1, respectively.

2.2 Specifications of (Montmorillonite) Nanoclay

The physical and chemical properties of nanoclay used in this research are reported in Table 4.

2.3 Specimen Preparation Method

In order to prepare specimens with uniform density along its height, wet compaction method with reduced density was used according to the method presented by Ladd (1978). The procedure was as follows: the entire soil (with a weight of 259 gr) was divided into five equal parts (59 gr each). Considering the moisture rate of 0.1, 5.9 gr of the water weight was added to the samples of each layer. According to the height of the soil mold (109.15 mm), the first layer was so compacted that the height from the upper mold to the surface of the first sample was 87.9 mm. Also, this height reached the compaction of 68.21, 48.53, 28.84, and 9.15 mm in the second, third, fourth, and fifth layers. As a result, a homogenized sample 100 mm high was obtained from the sample. In addition, for better binding of different layers, the surface of the previous compacted layer was grooved after reaching the desired height to create a more suitable collision with the next layer at the interface.

Specimens containing cement additives were made by adding 4% cement of the weight ratio of the base soil, dry mixing of the compound by hand and finally adding the required moisture as well as re-mixing in the same layers. The required moisture was calculated as the sum of the required moisture for compaction of the silty sand at a certain energy and density (all samples w = 0.5) along with the water required for hydration of cement particles with water to cement ratio of \({\raise0.7ex\hbox{$w$} \!\mathord{\left/ {\vphantom {w c}}\right.\kern-0pt} \!\lower0.7ex\hbox{$c$}} = 1\) (Saadati et al. 2022). Meanwhile, in order to eliminate the effect of water evaporation during the mixing process, 1 mg of additional water was added to the mixture of each layer.

In the present study, the percentage of nanoclay cement replacement was equal to 20 and 40% of weight ratio of cement. All specimens containing cement and nanoclay in all tests were casted in the mold without being subjected to surcharge loads. Once placed in sealed bags (to prevent evaporation of the internal moisture), they were maintained in a humid environment (water bath) for 28 days.

2.4 Test Method

In this study, normal and cemented specimens with a diameter of 50 mm and a height of 100 mm were prepared for cyclic triaxial experiments using wet compaction method. The experiments were executed in Geotechnic Laboratory of Islamic Azad University Science and Research Branch in Tehran city. As the specimens had to reach the desired density at the end of the consolidaton phase, the initial density for specimen preparation was lower than the final value. This difference depends on the confinement stress, which was already approximated by several experimental tests for the initial confinement stresses.

The experiments would be divided into two categories, improved and normal (without improvement) samples. In both categories, once the specimen was prepared for testing, the cell could be closed and the surrounding area would be filled with water. In the next step, a confining pressure of about 10 kPa was applied to the specimen. And then carbon monoxide gas was passed through the specimen and so the saturation capacity of the specimen increased. Then, the vacuum distilled water also passed through the soil specimen. Thereafter, in order to completely saturate the specimen and achieve a saturation percentage above 95% (\({B}_{value}\)= 0.95), the cell pressure (confining pressure) as well as the pressure inside the specimen (post-pressure) were elevated. This process was repeated in different steps until the specimen reached 95% saturation, so the pressure applied to the saturation of the pure sand specimen was about 150–200 kPa while for the cemented specimen was about 200–250 kPa. Finally, the specimens including silty sand, cemented silty, sand and silty sand containing cement as well as nanoclay were similarly consolidated under three confining pressures of 50, 100, and 150 kPa. Finally, they were subjected to the cyclic loading up to 50 cycles with different strain ranges. Saadati and Overton (2022)

In order to obtain the values of shear modulus, a number of cyclic triaxial experiments were performed under undrained and identical conditions on pure sand, cement, and nanoclay cement specimens with a relative density of 50%. After each experiment, a soil hysteresis diagram was plotted using the obtained data. To plot the hysteresis diagram, the shear stress must be plotted in terms of shear strain. Since only axial strain and stress can be measured in cyclic triaxial experiments, the values of shear stress and shear strain were calculated through the axial stress and strain using Eqs. 1 and 2, respectively.

where, \(\tau\) represents the shear stress, \(\sigma_{1}\) and \(\sigma_{3}\) reflect the main stresses, \(\gamma\) shows shear strain, \(\varepsilon_{a}\) denotes the axial strain, and \(\nu\) is the Poisson's ratio. In Eq. 2, since the test was conducted under the undrained conditions and the specimen was completely saturated, the Poisson's value was considered to be 0.5. After drawing the hysteresis curve, the shear modulus was calculated using the slope of the hysteresis rings. In Table 5, the abbreviations which indicate the type of the soil and additives are listed.

In the following, soil specimens and percentage of nanoclay are named by the following abbreviations:

M6S4: 60% silt, 40% sand

NC%: Percentage of nanoclay to cement

C%: Cement percentage

3 Analysis Results

3.1 Initial Results

Figures 2 and 3, respectively, depict the results of deviatoric stress and hysteric loops versus the number of loading cycles of silty sand, cemented silty sand, and cemented silty sand containing nanoclay with a relative density of 50% plus an effective confining stress of 100 kPa with uniform consolidation at strain of 1%. As observed, due to the strain-control loading process, a high amount of stress is observed in the first cycles, whose value diminishes with increasing the load, and finally reaches a constant value.

At the beginning of loading, due to the device’s noise, the value of the deviator stress was non-conventional at the beginning of the first cycle.

3.2 Shear Modulus

In order to explore the effects of cementation process on improving the dynamic properties of the soil as well as the effects of the replacing the cement component with nanoclay , cyclic triaxial tests were performed on the silty sand, cemented silty sand, and cemented nanoclay silty sand specimens with water to cement ratio of 1. In all cyclic triaxial tests, the percentage of cement used for cemented specimens was 4% of the weight ratio of the base soil and the percentages of nanoclay used for the cemented nanoclay specimen were 20% and 40% of the weight ratio of cement. The results of shear modulus for different improved and unimproved samples at confining pressures of 50, 100, and 150 kPa are shown in Tables 6, 7, and 8, respectively.

According to Fig. 4, the shear modulus values of the silty sand specimen for confining pressure of 50 kPa have lied within the range of 39.98–0.41 MPa in the shear strain range of about 0.01–1%. On the other hand, the shear modulus values of cemented silty sand and 20% nanoclay cemented silty sand specimens for confining pressure of 50 kPa were 61.63 to 10.61 MPa and 66.59–12.09 MPa respectively, within the shear strain range of 0.01–1%. In addition, the values of shear modulus of 40% nanoclay silty sand specimen were 76.64–12.39 MPa. It can be concluded that for all specimens including silty sand, cemented silty sand, and nanoclay silty sand, the values of shear modulus diminished with increasing the shear strain. Under stress-controlled harmonic loading conditions, pore pressure generation and structural change can cause the shear strain amplitude of a soil specimen to increase with increasing number of cycles. If clay or saturated sand specimens are loaded harmonically under strain-controlled undrained conditions, the shear stress amplitude would be observed to decrease with increasing number of cycles. (Kramer 1996)

The shear modulus values of the cemented sand specimens within all ranges of shear strains were greater than the shear modulus values of the silty sand specimens. The shear modulus values of the cemented silty sand specimen and the nanoclay cemented silty sand specimen increased with augmenting the strain compared to the silty sand. On the other hand, at the strain of 1%, the values of shear modulus increased from 0.52 MPa for silty sand to 6.72 MPa for cemented silty sand and 8.12 MPa for cemented silty sand with 20% nanoclay as well as silty sand with 40% nanoclay. The shear modulus has increased with raising the cement contents and then replacing cement with nanoclay 20 and 40%. Fig. 4 indicates the shear modulus has grown with increasing confining pressure. Modulus reduction behavior is also influenced by effective confining pressure perticuly for soils of low plasticity (Kramer 1996)

3.3 Damping

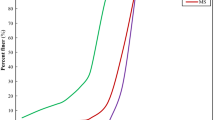

Damping ratio of the silty sand specimens and cemented specimens with 4% cement content and water to cement ratio of 1% plus nanoclay cemented silty sand were evaluated to compare and determine the improvement of dynamic properties due to the addition of nanoclay material. the damping results of silty sand and silty sand with cement, and silty sand with cement and nanoclay samples are shown in Tables 9, 10 and 11 for different strains.

Figure 5 reveals the damping ratio values of silty sand within different shear strain ranges. In contrast to the stiffness (shear modulus), the damping ratio of all specimens diminished with increasing the confining pressure. This can be attributed to bond weakness between the sand grains and cement particles by increasing the shear strain and thus higher energy dissipation by enhancing the mobility of the soil grains the stiffness was higher in the case of using nanoclay comparing to the cementitious soil and the damping is lower as well.

Figures 67, 8 and 9 shows the variations of the damping ratio of silty sand, silty sand with cement, and silty sand with nanoclay for confining pressures of 50, 100 and 150 kPa in different shear strains. As shown in Figure 8, the damping ratio decreases with the increase of confining pressure.

Damping behavior is also influenced by effective confining pressure, particularly for soils of low plasticity (Kramer 1996).

4 Conclusion

In this study, initially, the dynamic parameters (shear modulus and damping ratio) of the fine-grained silty soil were investigated by cyclic triaxial experiments. Then, the parameters of shear modulus and damping were compared by adding 4% cement and then replacing cement with nanoclay 20% and 40%. The results revealed that, in general, the shear modulus diminished, and damping increased with increasing the strain. In addition, the results showed that adding the cement and replacing a part of it with nanoclay had a positive effect on the shear modulus and a negative effect on the damping ratio of the silty soil. Further, the shear modulus rose, and the damping declined with increasing the confining pressure.

Pantazopoulos and Atmatzidis (2012) by examining the dynamic properties of sands improved with ordinary and very fine types of cement, concluded that the shear modulus was enhanced with increasing confining pressure and decreasing shear strain, while the damping ratio behaved differently, which is consistent with the results of the current study.in the present study, the cyclic behavior of fine-grained silty sand improved by nanoclay and Zanjan type 2 Portland cement between medium shear strains was investigated using a cyclic triaxial device. The main results are summarized:

-

With increasing shear strain, the stiffness imparted because of the intergranular contact surfaces diminished and caused the loosening and rupture of the cement paste joints. This event also freed the confinement caused by the stiffness and ultimately by increasing the strain levels, it rapidly reduced the shear modulus. In addition, shear modulus values decrease, and damping increases for all specimens, including silty sand, cemented silty sand and nanoclay cemented silty sand specimens, with increasing shear strain.

-

For all specimens, including silty sand, cemented silty sand, and nanoclay cemented silty sand specimens, the shear modulus values increased, and damping diminished by elevating the confining pressure.

-

Adding cement at 4% by weight of soil enhanced the shear modulus and reduced the damping.

-

By replacing 20% of cement with nanoclay in the cement specimen, the shear and damping modulus increased. However, by replacing 40% of cement with nanoclay compared to 20% of nanoclay, no significant change was observed in the shear and damping modulus. This indicates that the replacement of 20% of cement with nanoclay is optimal for improving the dynamic parameters of the considered soil.

-

damping ratio decreases with the increase of confining pressure.

Data Availability

The datasets generated during the current study are available in the Mohammad Mollaei repository, Mollaei.s@gmail.com.

References

Abbasi N, Farjad A, Sepehri S (2018) The use of nanoclay particles for stabilization of dispersive clayey soils. Geotech Geol Eng 36:327–335. https://doi.org/10.1007/s10706-017-0330-9

Ahmadi H, Janati S, Jamshidi Chenari R (2020) Strength parameters of stabilized clay using polypropylene fibers and Nano-MgO: an experimental study. Geotech Geol Eng 38(3):2845–2858. https://doi.org/10.1007/s10706-020-01191-y

Changizi F, Haddad A (2016) Effect of Nano-SiO2 on the geotechnical properties of cohesive soil. Geotech Geol Eng 34:725–733. https://doi.org/10.1007/s10706-015-9962-9

Choobbasti AJ, Vafaei A, Soleimani Kutanaei S (2015) Mechanical properties of sandy soil improvedwith cement and nanosilica. Open Eng 5(1):111–1116. https://doi.org/10.1515/ENG-2015-0011

Fattahi Masrour F, Naghdipour Mirsadeghi M, MolaAbasi H, Jamshidi Chenari R (2021) Effect of nanosilica on the macro-and microbehavior of dispersive clays. J Mater Civ Eng 33(12):04021349. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003975

Fernandez AL, Santamarina JC (2011) Effect of cementation on the small-strain parameters of sands. Can Geotech J 38(1):191–199. https://doi.org/10.1139/T00-081

Gjorv OE, Sakai K (2000) Concrete technology for a sustainable development in the 21st century - google books. CRC Press. https://doi.org/10.1016/j.jclepro.2015.08.057

Jijo J, Kasinatha Pandian P (2018) Resistencia y Microestructura Del Polvo Micro Cerámica Mezclado Suelo Cal Estabilizado. Rev de la Construccio 17(1):5–22. https://doi.org/10.7764/RDLC.17.1.5

Kramer SL (1996) Geotechnical earthquake engineering. Pearson Educ India 6:216–245

Ladd RS (1978) Preparing test specimens using undercompaction. Geotech Test J 1(1):16. https://doi.org/10.1520/GTJ10364J

Lang L, Li F, Chen B (2020) Small-strain dynamic properties of silty clay stabilized by cement and fly ash. Constr Build Mater 237:117646. https://doi.org/10.1016/J.CONBUILDMAT.2019.117646

Lothenbach B, Scrivener K, Hooton RD (2011) Supplementary cementitious materials. Cem Concr Res 41(12):1244–1256. https://doi.org/10.1016/J.CEMCONRES.2010.12.001

Madhusudhan BR, Boominathan A, Banerjee S (2020) Cyclic simple shear response of sand-rubber tire chip mixtures. Int J Geomech 20(9):04020136. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001761

Majeed ZH, Taha MR (2012) Effect of nanomaterial treatment on geotechnical properties of a penang soft soil. J Asian Sci Res 2(11):587–592

Majeed ZH, Taha MR (2013) A review of stabilization of soils by using Nanomaterial. Australian J Basic Appl Sci 7(2):576–581

Majeed ZH, Taha MR, Jawad T (2014) Stabilization of soft soil using nanomaterials. Australian J Basic Appl Sci 8(4):503–509

Markou IN, Droudakis AI (2013) Factors affecting engineering properties of microfine cement grouted sands. Geotech Geol Eng. https://doi.org/10.1007/s10706-013-9631-9

Marzuni SS, Fadaee M, Bahmanpour A, Derakhshandi M (2022) Effect of cyclic stress ratio and non-plastic fines content on the liquefaction potential of sandy and silty soil in cyclic triaxial testing. Soil Mech Found Eng 58(6):467–473

Mola-Abasi H, Kordtabar B, Kordnaeij A (2016) Effect of natural zeolite and cement additive on the strength of sand. Geotech Geol Eng 34(5):1539–1551. https://doi.org/10.1007/S10706-016-0060-4

Mola-Abasi H, Kordtabar B, Kordnaeij A (2016) Parameters controlling strength of zeolite–cement–sand mixture. Int J Geotech Eng 11(1):72–79. https://doi.org/10.1080/19386362.2016.1186412

MolaAbasi H, Khajeh A, Jamshidi Chenari R (2021) Use of GMDH-type neural network to model the mechanical behavior of a cement-treated sand. Neural Comput Appl 33(22):15305–15318. https://doi.org/10.1007/s00521-021-06562-x

MolaAbasi H, Kharazmi P, Khajeh A, Saberian M, Chenari RJ, Harandi M, Li J (2022) Low plasticity clay stabilized with cement and zeolite: an experimental and environmental impact study. Resour Conserv Recycl 184:106408. https://doi.org/10.1016/j.resconrec.2022.106408

Mollamahmutoglu M, Yilmaz Y (2011) Engineering properties of medium-to-fine sands injected with microfine cement grout. Mar Georesour Geotechnol 29(2):95–109. https://doi.org/10.1080/1064119X.2010.517715

Nakhaei A, Marandi SM, Sani Kermani S, Bagheripour MH (2012) Dynamic properties of granular soils mixed with granulated rubber. Soil Dyn Earthq Eng 43:124–132. https://doi.org/10.1016/J.SOILDYN.2012.07.026

Ouhadi VR, Amiri M (2011) Geo-environmental behavior of nanoclays in interaction with heavy metal contaminants. J Civ Environ Eng 42(3):29–36

Pantazopoulos IA, Atmatzidis DK (2012) Dynamic properties of microfine cement grouted sands. Soil Dyn Earthq Eng 42:17–31. https://doi.org/10.1016/J.SOILDYN.2012.05.017

Ramezanianpour AA, Kazemian A, Sarvari M, Ahmadi B (2012) Use of natural zeolite to produce self-consolidating concrete with low portland cement content and high durability. J Mater Civ Eng 25(5):589–596. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000621

Saadati M, Derakhshandi M, Bahmanpour A, Ganjian N (2022) Experimental investigation of cyclic behavior of zeolite cemented sand. Amirkabir J Civ Eng 53(12):17–17

Scrivener KL, Nonat A (2011) Hydration of cementitious materials present future. Cem Concr Res 41(7):651–665. https://doi.org/10.1016/J.CEMCONRES.2011.03.026

Smitha S, Rangaswamy K (2020) Effect of biopolymer treatment on pore pressure response and dynamic properties of silty sand. J Mater Civ Eng. https://doi.org/10.1061/(ASCE)MT.1943-5533.0003285

Subramaniam P, Banerjee S (2020) Dynamic properties of cement-treated marine clay. Int J Geomech 20(6):04020065. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001673

Yildiz M, Soganci AS (2015) Improvement of the strength of soils which comprises granular pumice by injection of cement under low pressure. Scientia Iranica A 22(1):81–91

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by MM. The first draft of the manuscript was written by HJ and MA. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mollaei, M., Jahanian, H. & Azadi, M. Laboratory Study of the Cyclic Behavior of Cement Sand with Nanoclay. Geotech Geol Eng 41, 3375–3387 (2023). https://doi.org/10.1007/s10706-023-02463-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02463-z